11111

What is perforated metal sheet?

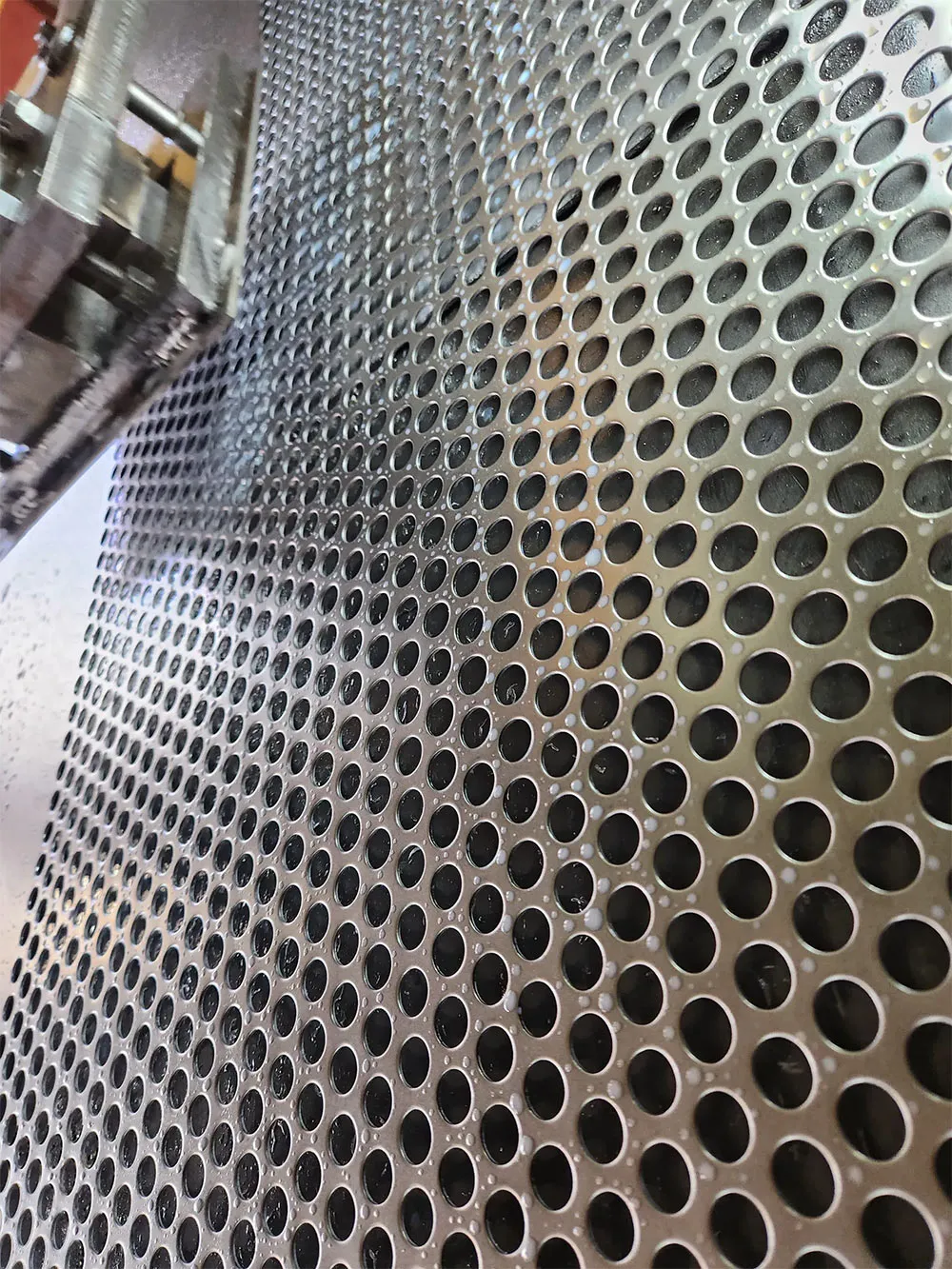

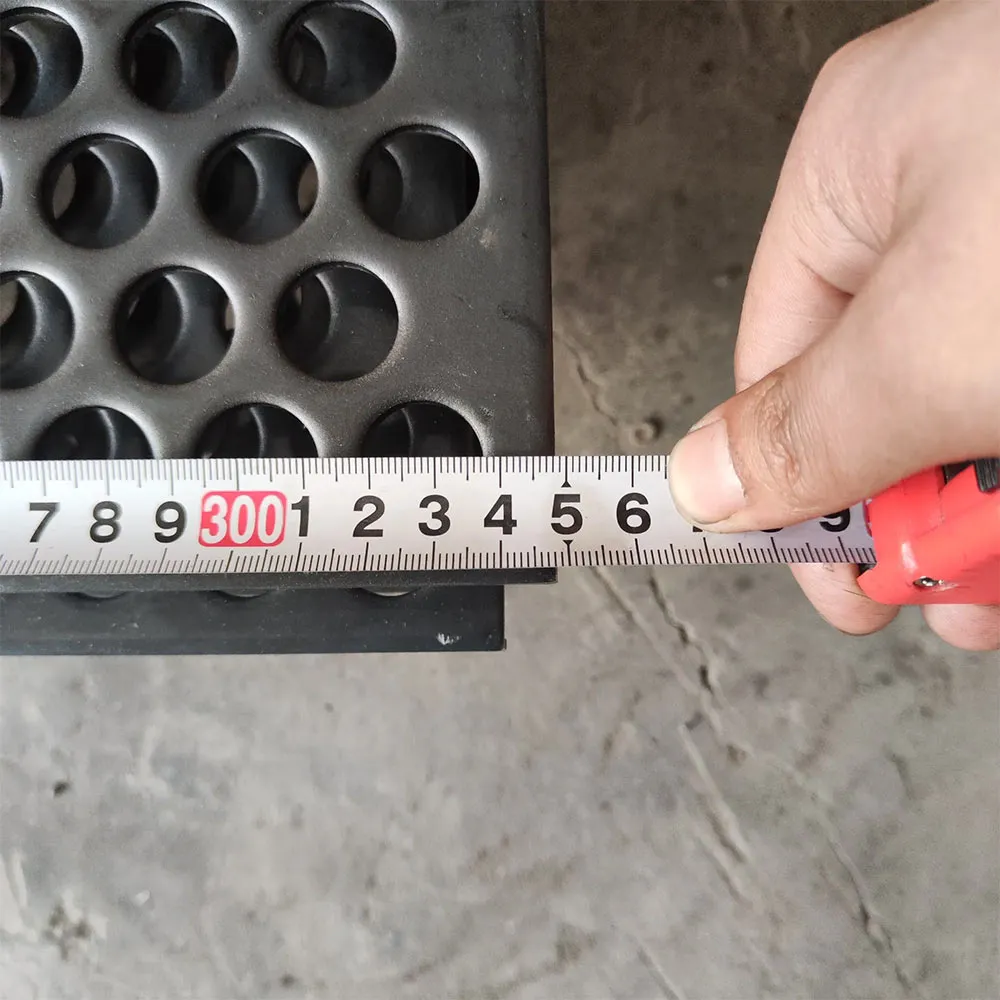

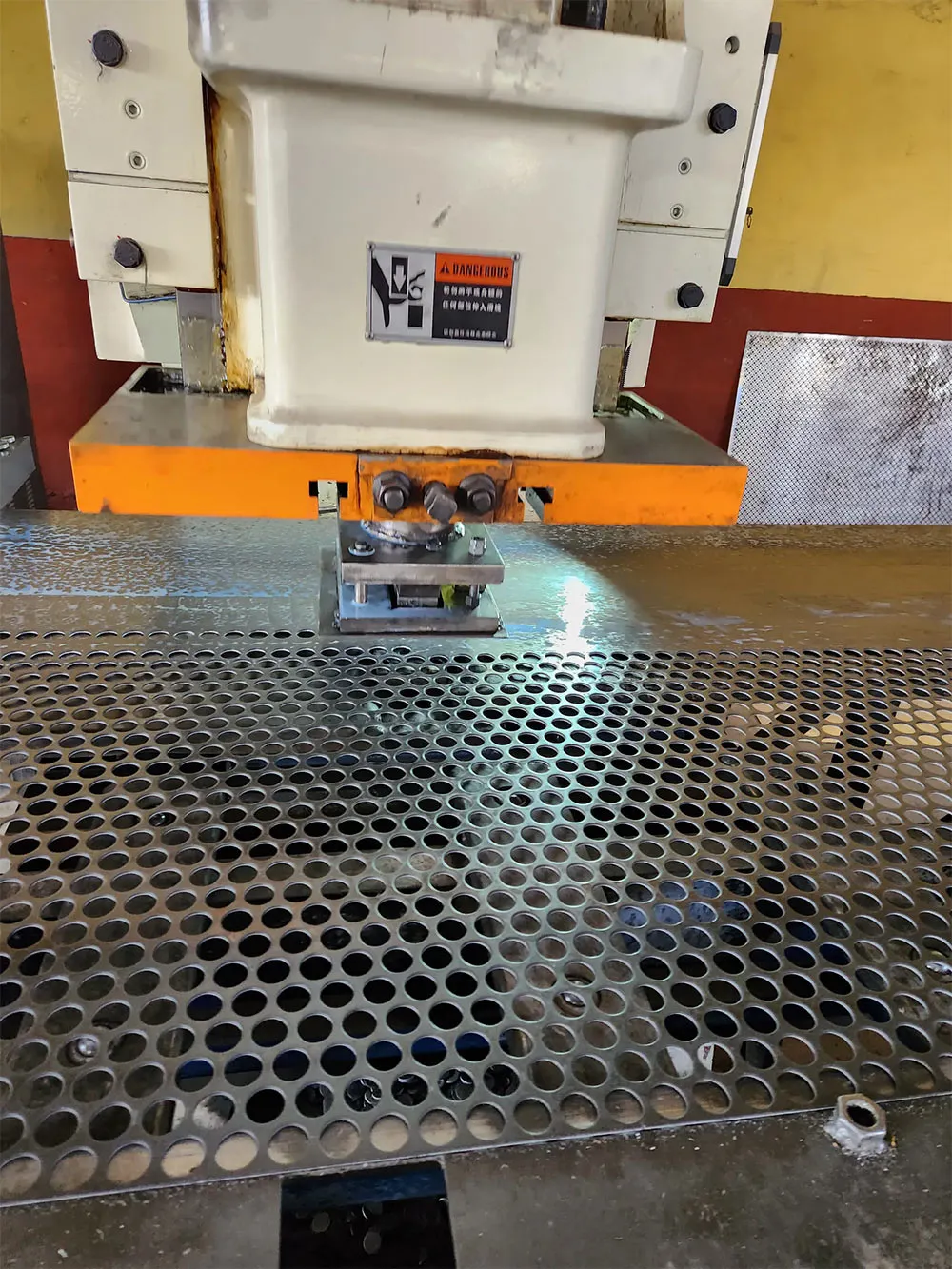

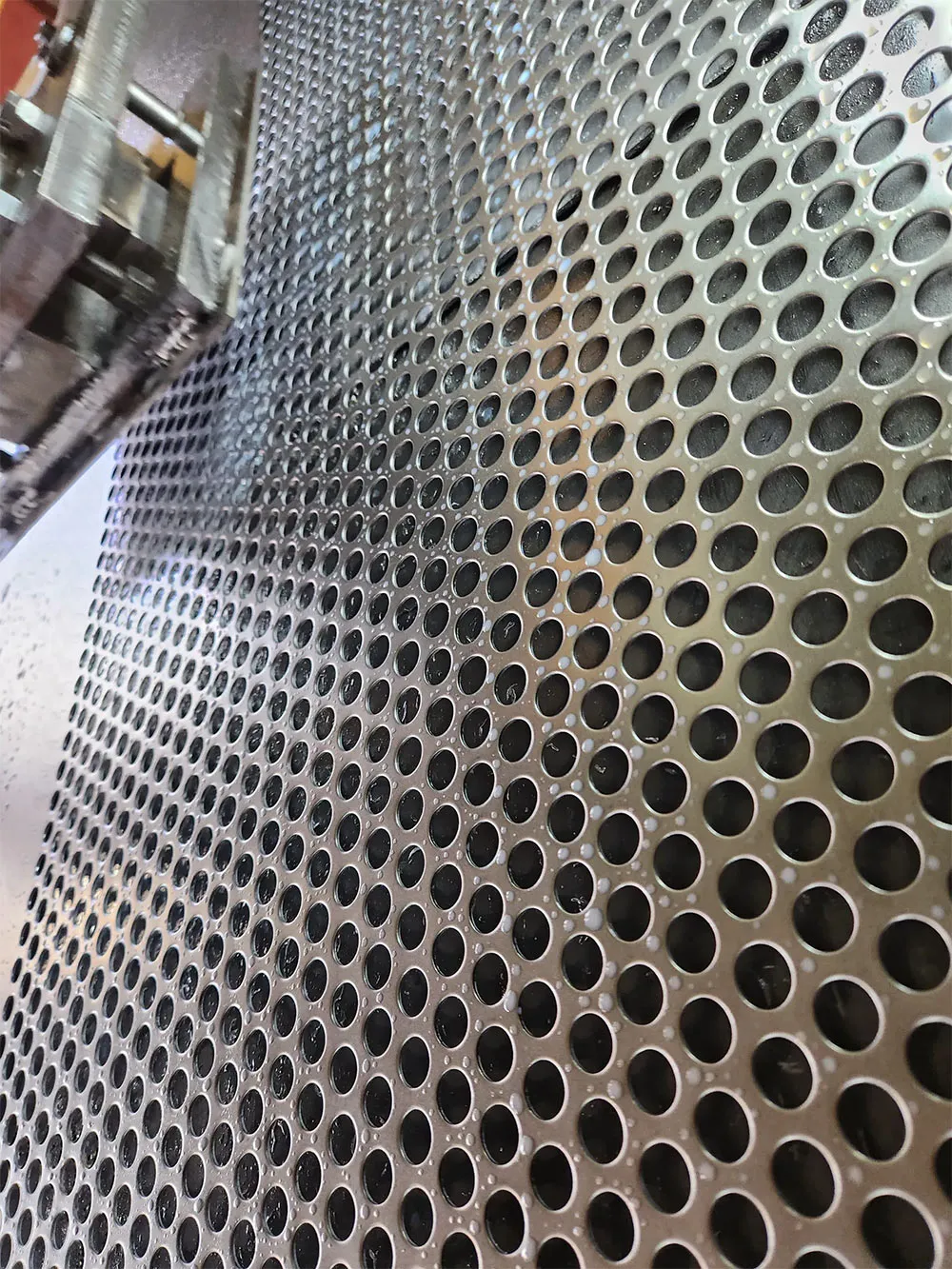

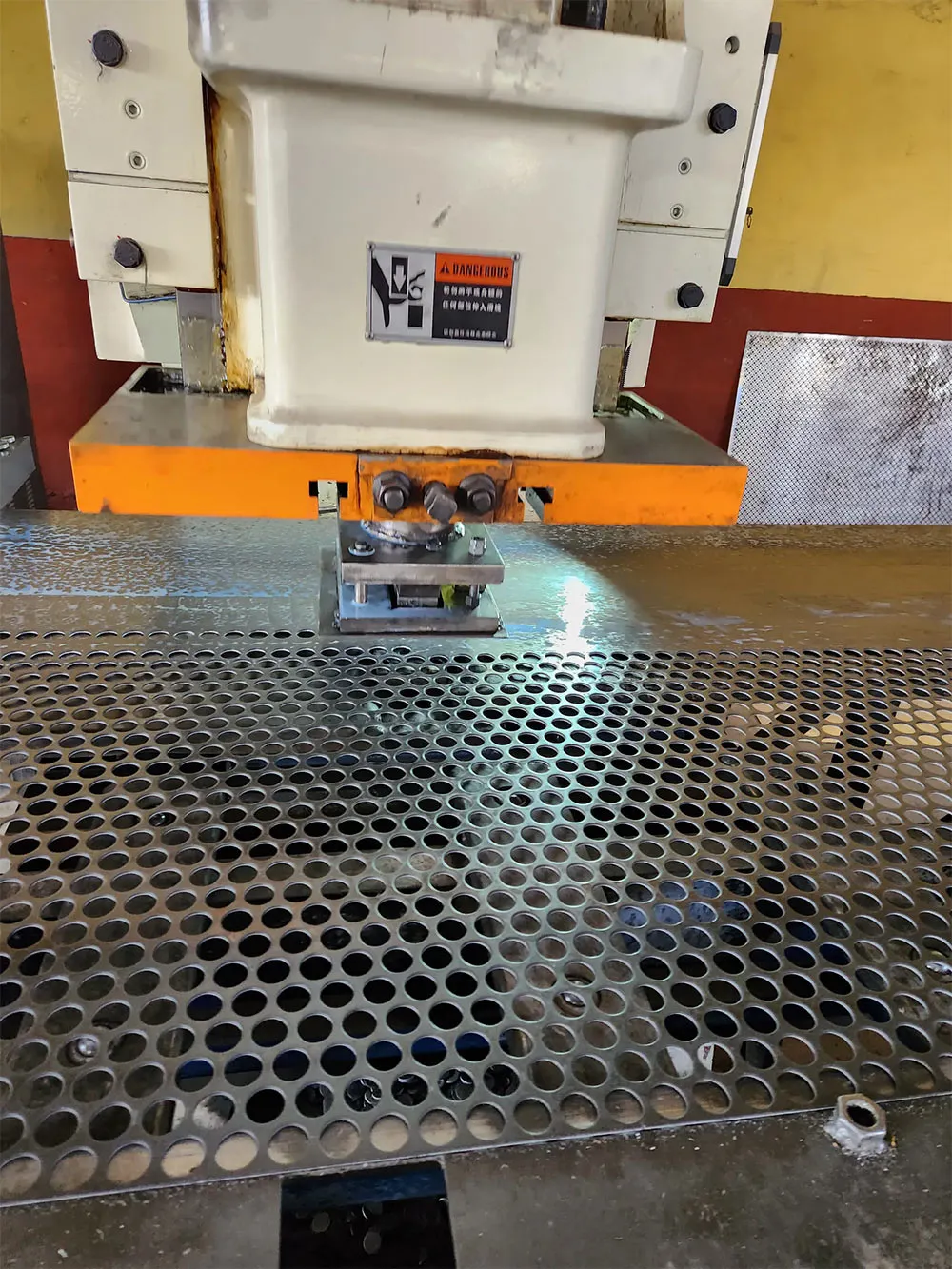

Perforated metal sheet is a metal material that is precision-processed by CNC machine. It is mainly used in construction, industry and decoration industries. The raw materials usually used are stainless steel, aluminum, galvanized steel or carbon steel. It uses advanced stamping machinery and equipment to produce products with different shapes of holes and sizes. The porous structure of this product shows unique air permeability, light weight and aesthetics, making perforated metal sheet one of the important materials in today's modern manufacturing and design industries.

Unique advantages of Perforated Metal

Perforated metal sheets have many advantages over other materials:

- Light transmission and air circulation: In the surface structure of perforated metal, the uniform mesh structure allows air and light to flow freely, which is suitable for scenes such as curtain walls and ceilings, which require uniform ventilation and lighting.

- Sound reduction: This product is widely used in sound insulation panels and sound-absorbing structural devices, effectively achieving noise reduction and sound absorption.

- Strong corrosion resistance: Perforated metal is made of stainless steel raw materials, which is very suitable for humid and harsh environments.

- Decorative beauty: Perforated metal uses CNC equipment to make different patterns and shapes, providing unique design elements for modern design buildings and interior decoration.

- Light weight and high strength: Compared with solid metal sheets, perforated sheets reduce the overall material weight while maintaining overall strength.

Main applications of Perforated metal sheet

The application fields of perforated metal sheets are diverse:

Architecture and decoration industry: used for ceiling decoration, exterior curtain walls, partition walls, handrail decoration, etc., creating new designs for modern style buildings.

Industrial filtration: In the industrial industry, perforated metal is used as a filter for impurities in air filters, sewage treatment, petroleum and natural gas and other chemical fields.

Safety protection: perforated metal shows safety in guardrail protection and anti-skid plates.

Agricultural industry and food processing: mainly used for grain screening, food processing equipment, etc., to achieve strong production efficiency.

Automobile manufacturing: perforated metal sheet is used as a car cooling system, engine hood, etc. to improve the performance and safety of the car.

Industry Trends and Development of Perforated Metal Sheets

- Green and Environmental Protection Demand: With the requirements of global environmental protection regulations, perforated metal sheets have become the preferred materials for sustainable construction materials and environmental protection projects due to the recyclability and energy-saving of raw materials.

- Processing upgrade of intelligent manufacturing technology: Through the technological development of CNC processing equipment, perforated metal has higher precision and better design, thus achieving a gradual expansion of its application range.

- Innovative development of decorative design: According to the increasing demand for personalized customization from customers, the aesthetic value of perforated metal sheets is becoming more and more popular from architectural designers.

How to choose the right perforated metal sheet?

When choosing perforated metal sheet, the following factors should be considered:

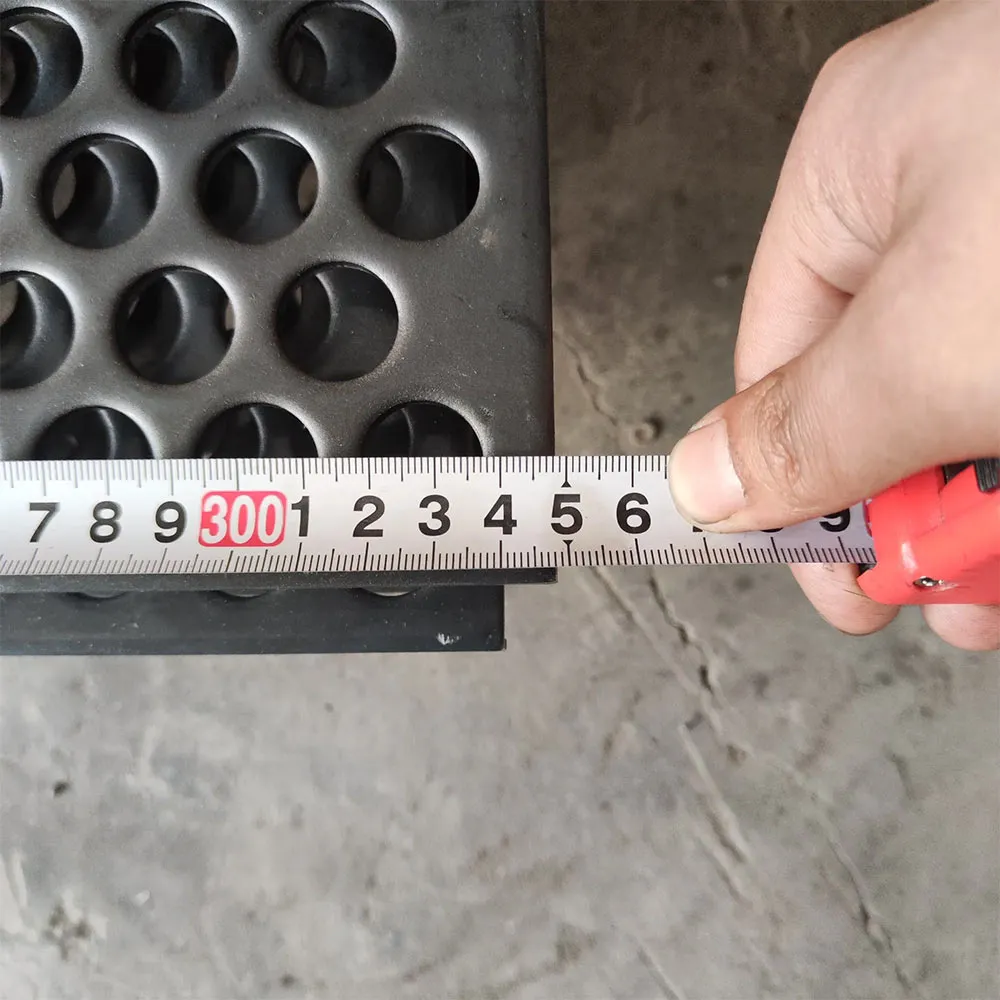

In terms of hole type and hole diameter, the shape suitable for the application scenario should be considered, such as round, square, hexagonal, etc. The decision of raw materials is determined by the usage scenario. Aluminum alloy is lighter and more corrosion-resistant, stainless steel has higher hardness and strength, and carbon steel is economical and practical.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)