11111

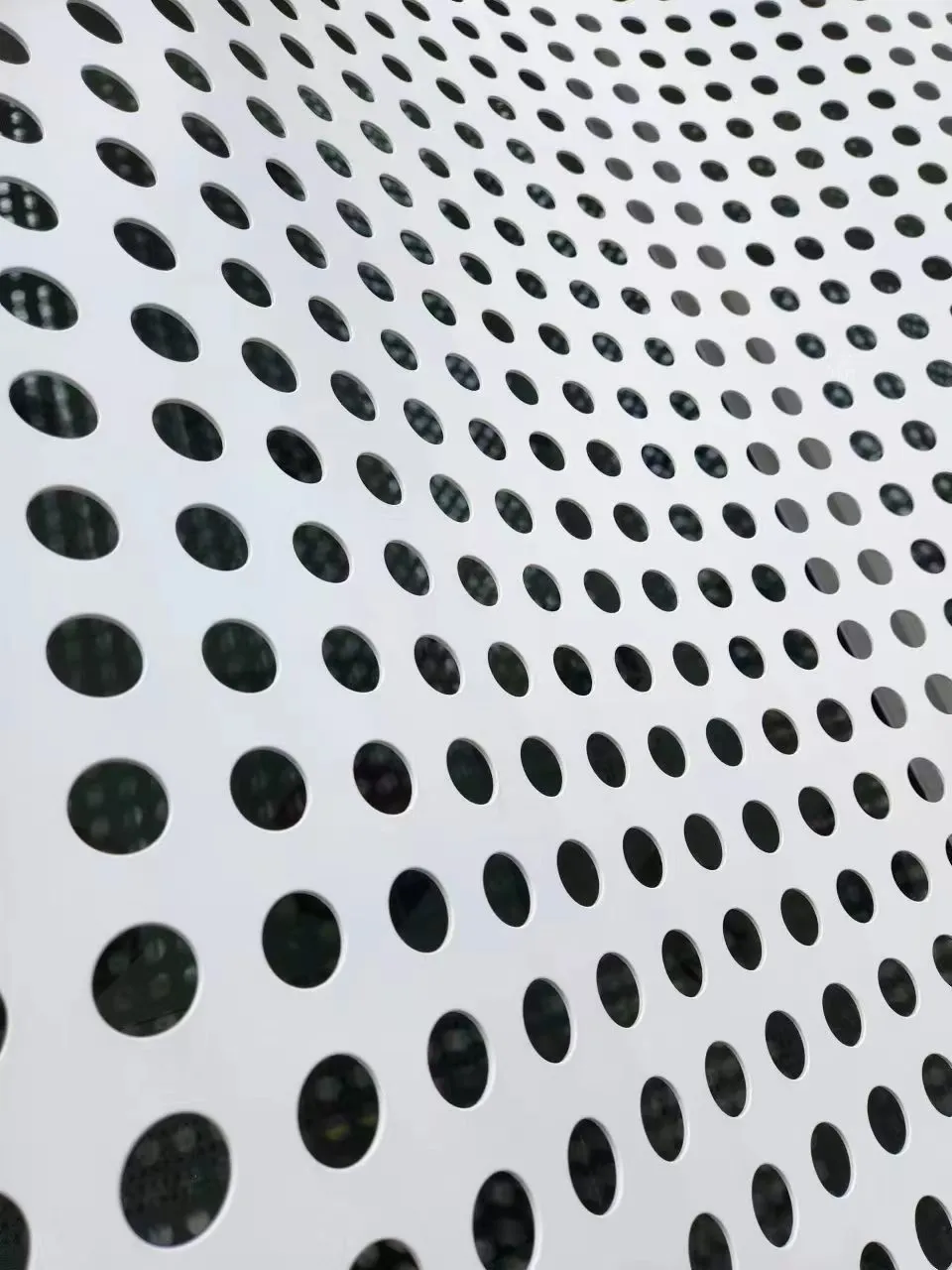

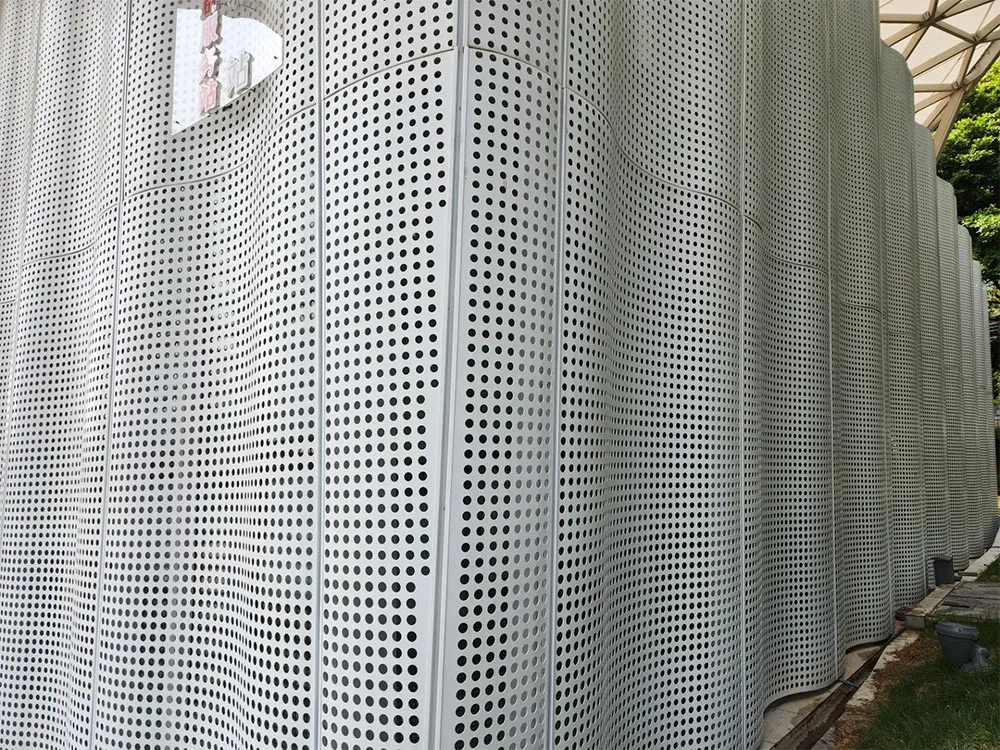

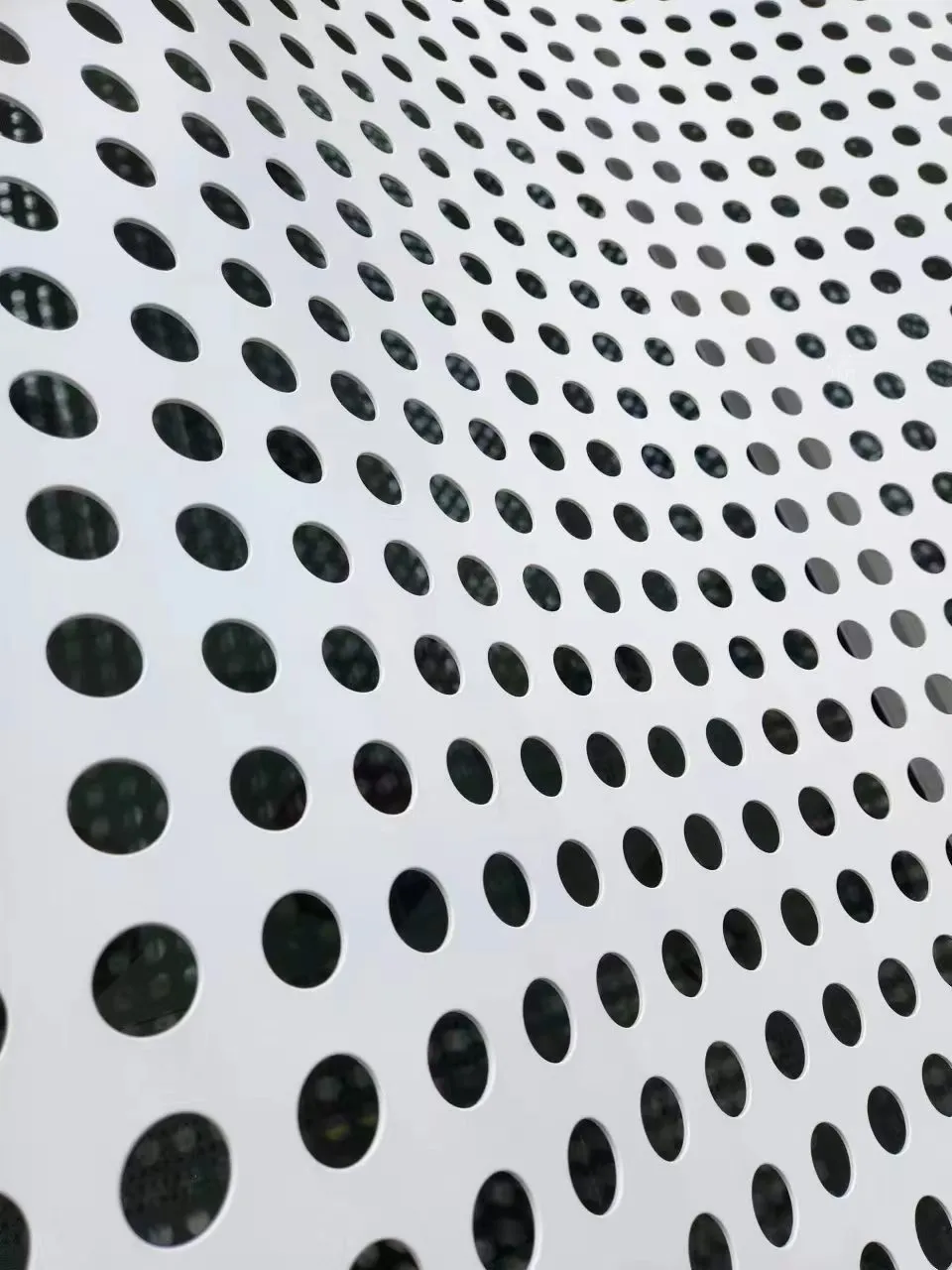

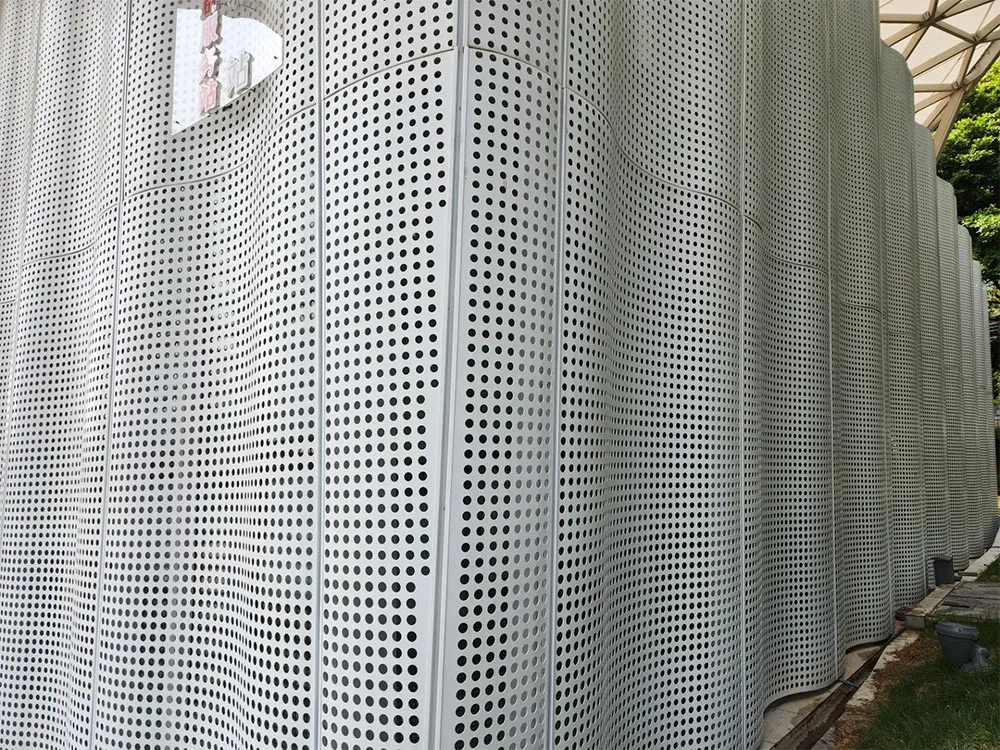

The performance of perforated panel in curtain wall system: Perforated metal panel is the main component of modern building façade, which not only shows the decorative aesthetic value, but also provides important functions such as ventilation, light transmission, sunshade, sound insulation and sound absorption. Curtain wall system now requires light weight, durability and structural stability, so perforated metal panel has become one of the ideal curtain wall materials.

Manufacturing Technique of Perforated Metal Sheet

The manufacturing process of Perforated Metal Panel involves precise punching technology, the purpose is to ensure uniform hole diameter and accurate size. The most common manufacturing processes include CNC punching, laser cutting with smooth edges and no burrs, CNC shearing and bending machines, which can be customized according to customer requirements to enhance the overall three-dimensional sense of the curtain wall.

The hole design of perforated metal panel affects the performance of curtain wall:

The hole design of perforated metal panel affects the light transmittance of curtain wall. If round holes and square holes are used, the proportion of light entering the whole building can be adjusted to improve energy efficiency. The use of larger aperture diamond holes and hexagonal holes will help air circulation, while reducing heat temperature and achieving ventilation. The use of micro hole structure can help the whole building reduce external noise, achieve sound absorption effect, and improve indoor quietness and comfort. Different customized patterns can create unique facade architectural design and achieve aesthetic visual effects.

Raw material selection of Perforated metal panel

Different metal materials will affect the overall performance of the curtain wall. Aluminum alloy is commonly used as raw material because it is lightweight, corrosion-resistant and suitable for high-rise buildings. Stainless steel has high structural strength and strong wind resistance, and is suitable for harsh outdoor environments. Galvanized steel is economical and low cost.

Technique and endurance of Surface Treatment

Today's architectural design uses powder coating technology to improve the weather resistance and aesthetics of curtain walls, so as to achieve color selection and enhance the corrosion resistance of the surface.

Façade/ Curtain wall Installation and optimized Structure of Perforated Metal Panel

There are three ways to install the curtain wall of Perforated metal panel:

Suspension system: by using aluminum alloy keel for support, the main reason is easy installation, suitable for large-area curtain wall installation.

Aluminum frame fixing: by using the frame structure to improve the overall stability, suitable for complex curtain wall shape.

Modular form assembly: the purpose is to improve construction efficiency, in order to quickly realize the installation of commercial projects.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)