11111

Perforated metal sheets play an important role in modern architectural styles with suspended ceiling systems.

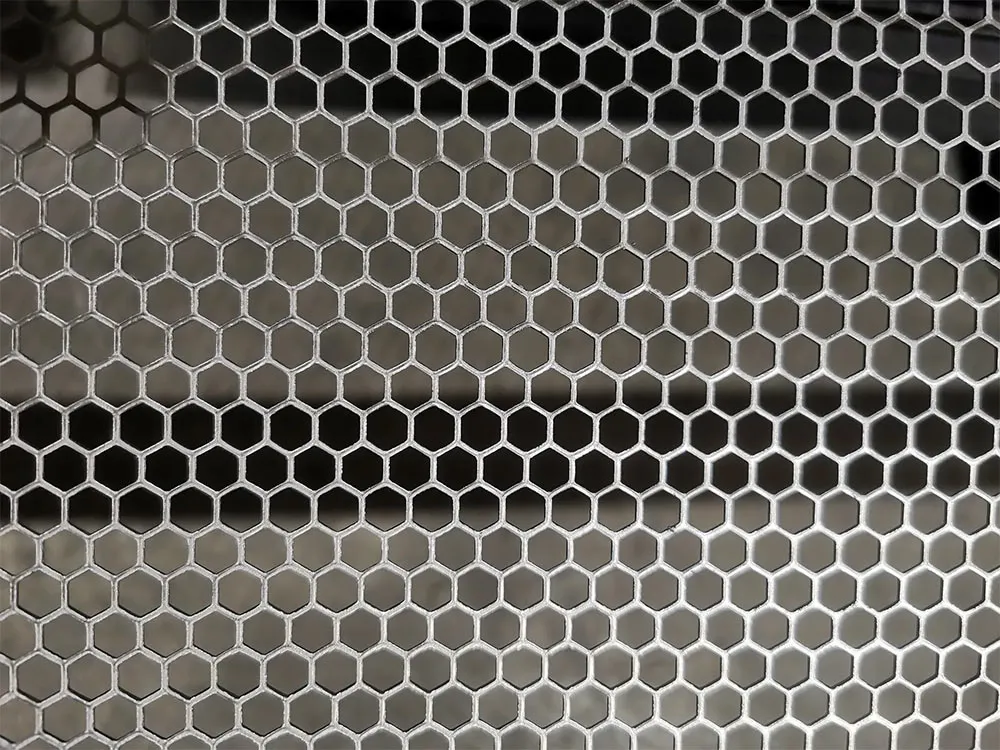

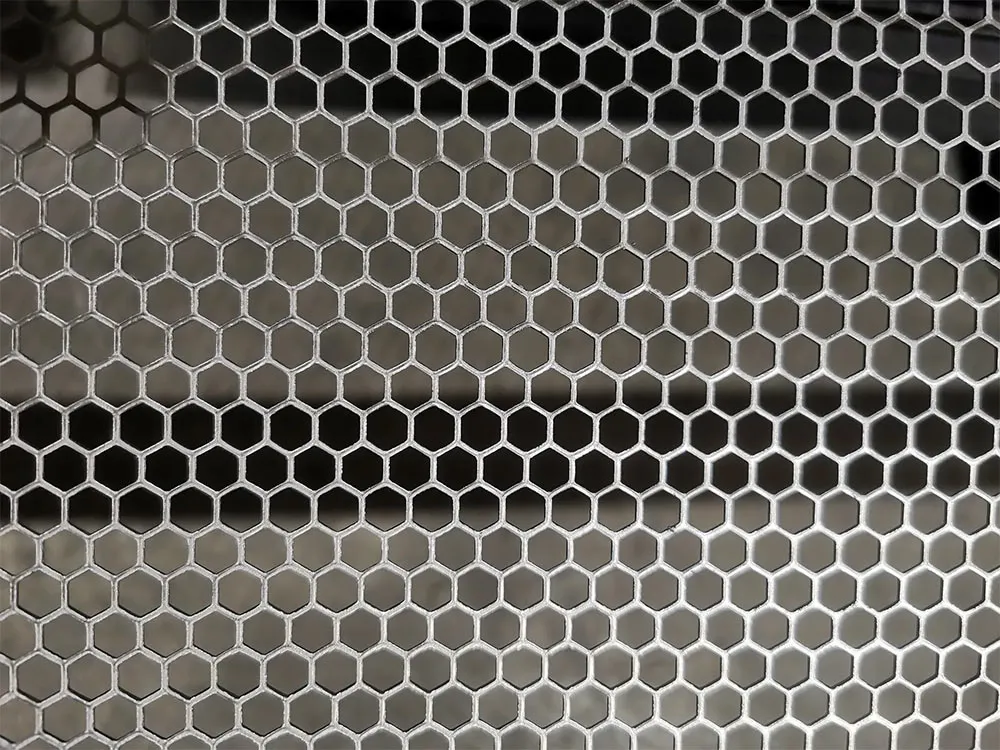

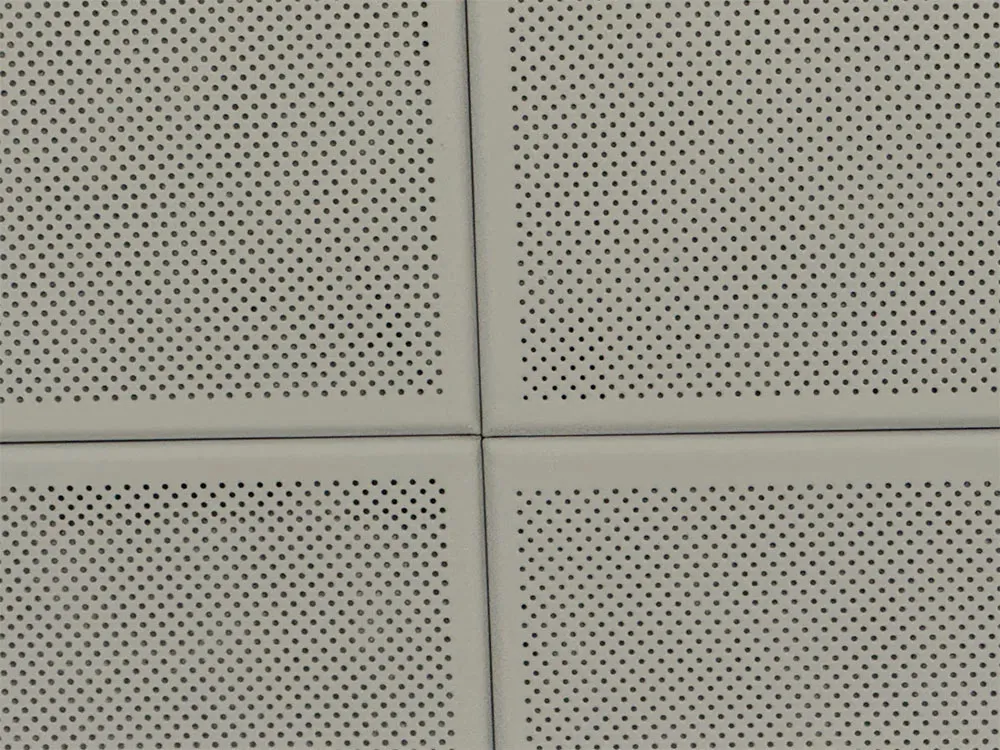

Perforated metal not only provides beautiful hole shaped decorative effects, but also has functional advantages such as ventilation, sound absorption, and heat insulation. Perforated panels should match aesthetics and practicality in ceiling design systems, and perforated sheets have characteristics such as lightweight, durability, and high performance, which are used in commercial buildings, offices, airports, stations, and other places.

What manufacturing processes does Perfoated Metal have?

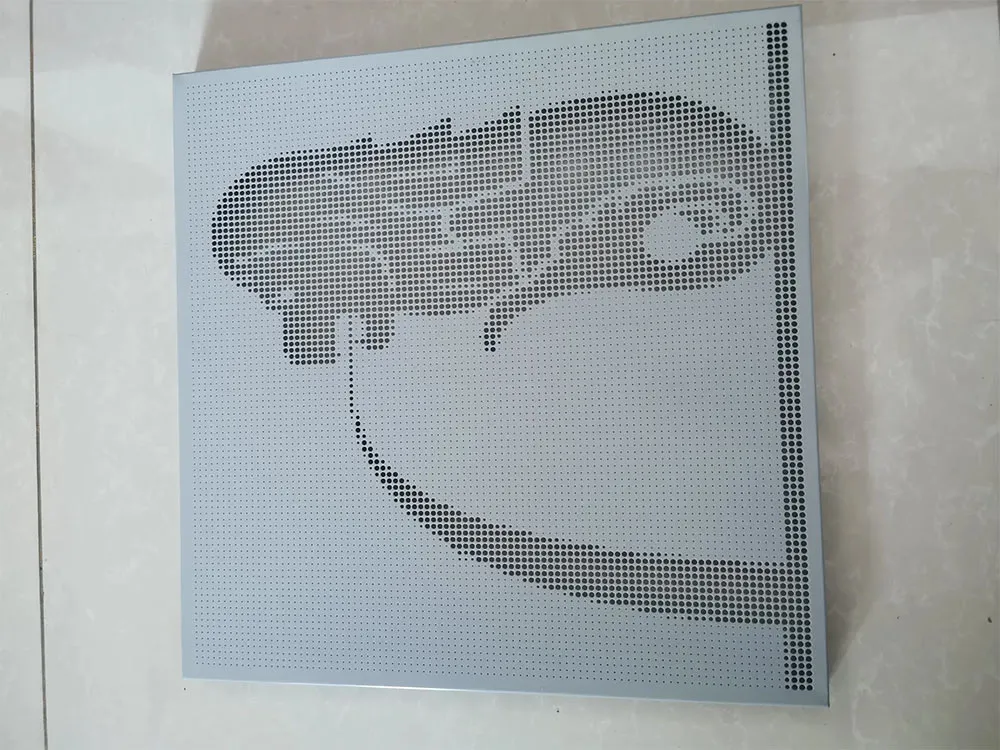

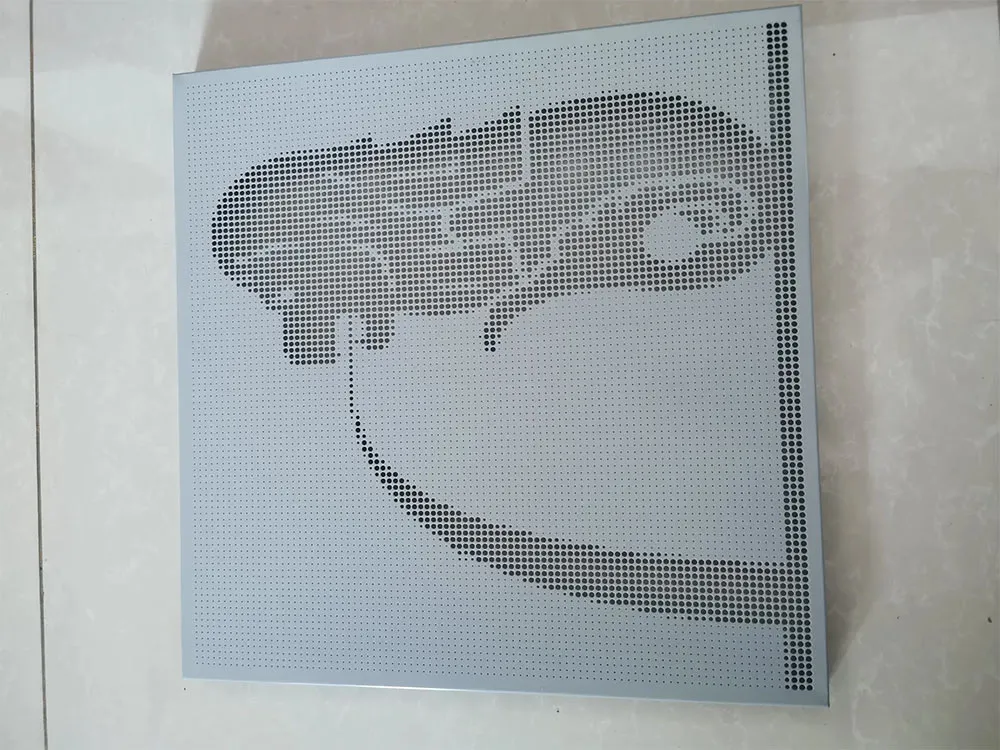

The manufacturing process of punched metal plates determines the quality and service life in the application field. So far, common processing methods include CNC punching, aiming to achieve efficient and precise production, suitable for large-scale production. The purpose of using laser cutting equipment is to achieve the design of complex patterns, making the edges smooth and burr free. By using CNC bending molding, the three-dimensional sense and overall aesthetics of the ceiling system are improved.

Perforated metal sheet how to make effect performance of ceiling?

The hole arrangement design of punched metal plates will affect the overall performance of the ceiling system. By designing a reasonable hole diameter and hole arrangement, ventilation performance can be achieved, air circulation can be enhanced, and indoor air quality can be optimized. Moreover, micro perforated metal can achieve sound absorption effect, reduce echo rate, and improve the overall quietness and comfort of the space. It can also achieve lighting adjustment, and perforated metal can create a soft light and shadow effect, greatly enhancing the overall spatial atmosphere.

How to choose different materials and structures based on their overall characteristics:

Different metals can affect the overall performance of the ceiling system. The most common raw material used is aluminum alloy, which is corrosion-resistant, lightweight, and suitable for large-scale ceiling use. If a cost-effective material is chosen, galvanized steel material is suitable for projects with limited costs.

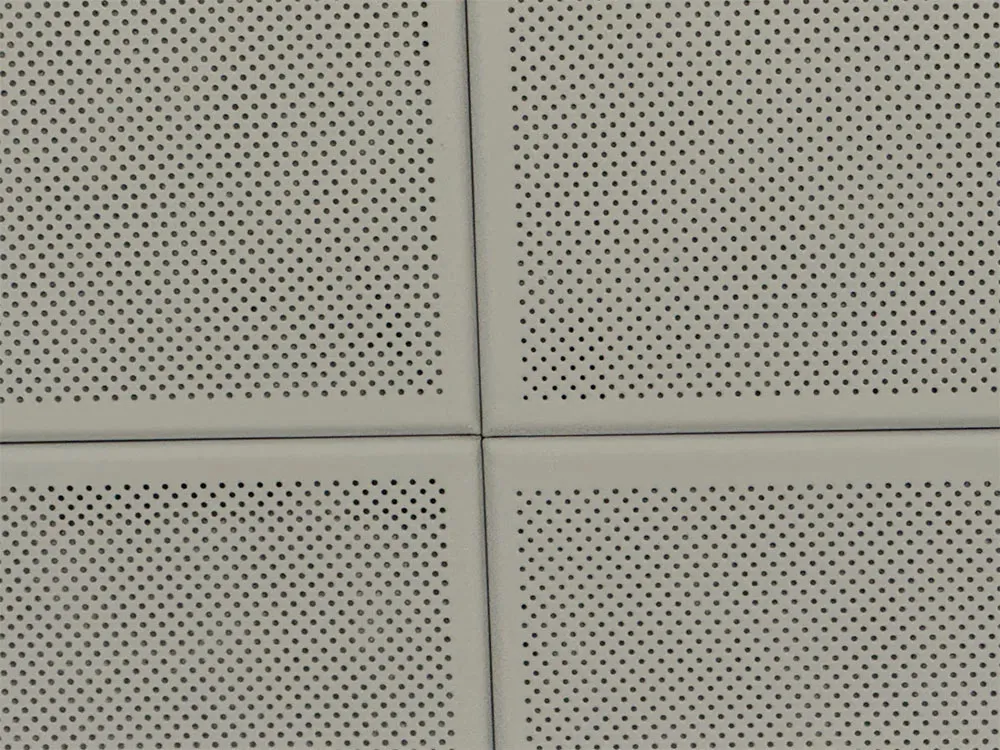

Ceiling system installation method

The installation method of Perforated metal in the ceiling system includes modular installation and prefabricated panels for quick installation. The method of fixing the keel adopts aluminum alloy keel or steel structure keel to enhance the overall stability. Adopting a suspended ceiling system, it is suitable for large-span spaces in large areas, improving the overall visual hierarchy. Reasonable installation of the ceiling not only affects the overall aesthetics, but also achieves low-cost maintenance.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)