|

Ihe

|

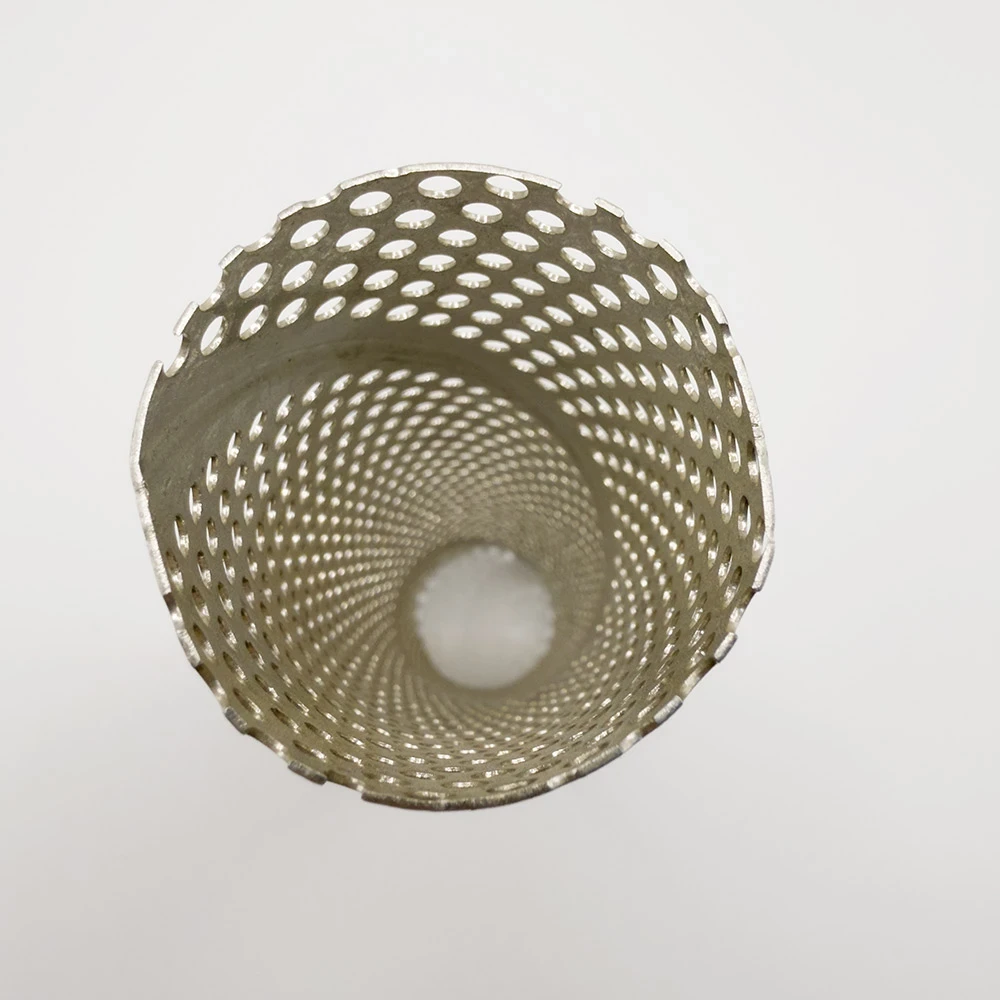

Nkọwa

|

|

Aha ngwaahịa

|

Ọkụ gbadoro agbadoro agbadoro

|

|

Raw Ihe onwunwe

|

1. Igwe anaghị agba nchara (304, 316L)

2. Carbon ígwè

3. Nickel Alloys (Monel, Hastelloy)

4. Titanium Alloy, wdg.

|

|

Ogologo Tube dayameta

|

0.5mm - 1000mm (nwere ike ịhazi ya)

|

|

Ọkpụrụkpụ mgbidi

|

0.3mm - 5mm (nwere ike ịhazi ya)

|

|

Nha oghere

|

0.5mm - 20mm (dị na oghere gburugburu, square na oghere nwere oghere)

|

|

Mepee Oke Mpaghara

|

10% - 60% (nwere ike ịhazi dabere na nzacha chọrọ)

|

|

Ọgwụgwọ elu

|

1. Pickling (igwe anaghị agba nchara (304, 316L), carbon ígwè, nickel dabeere alloy (Monel, Hastelloy)

2. Electrolytic Polishing (igwe anaghị agba nchara (304, 316L), nickel dabeere alloy (Monel, Hastelloy))

3. Sandblasting (Iron, carbon ígwè, igwe anaghị agba nchara (304, 316L), titanium alloy, nickel dabeere alloy (Monel, Hastelloy))

4. Galvanizing (Iron, carbon ígwè)

5. Nickel plating (Iron, carbon ígwè, igwe anaghị agba nchara (304, 316L), nickel dabeere alloys (Monel, Hastelloy))

wdg.

|

|

Usoro ịgbado ọkụ

|

Mgbado ọkụ gburugburu (ịgbado ọkụ na-akpaghị aka nke ọma maka ike na akara)

|

|

Nguzogide nrụgide

|

Ruo 30MPa (dị iche dabere na ihe na ọkpụrụkpụ)

|

|

Nguzogide corrosion

|

Na-eguzogide acid, alkalis, okpomọkụ dị elu, na oxidation

|

|

Ụdị njikọ

|

Njikọ Flange, Njikọ eriri, Njikọ Welded, Mkpọgide

|

|

Mmiri mmiri ọdabara

|

Kwesịrị ekwesị maka mmiri mmiri, gas, mmanụ, uzuoku, wdg.

|

|

Ụzọ nhicha

|

Ịsacha azụ, ihicha kemịkalụ, ihicha nke Ultrasonic, achịcha dị oke ọkụ

|

|

Mpaghara ngwa

|

Petroleum, Chemical Industry, Environmental Water Treatment, Food & Pharmaceuticals, Metallurgy, Power Industry, Automotive Industry, wdg.

|

|

Njirimara ngwaahịa

|

1. Ọdịdị dị elu nke nwere nrụgide dị mma na nguzogide corrosion

2. Perforation Uniform maka ikuku kacha mma na nzacha

3. Ịgbado ọkụ gburugburu nkenke na-eme ka ọ dị ogologo na ntụkwasị obi

4. Ihe ndị a na-emezigharị, nha oghere, na oghere oghere maka mkpa nzacha dị iche iche

|

![$ihe[aha] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)