|

Ihe

|

Nkọwa

|

|

Aha ngwaahịa

|

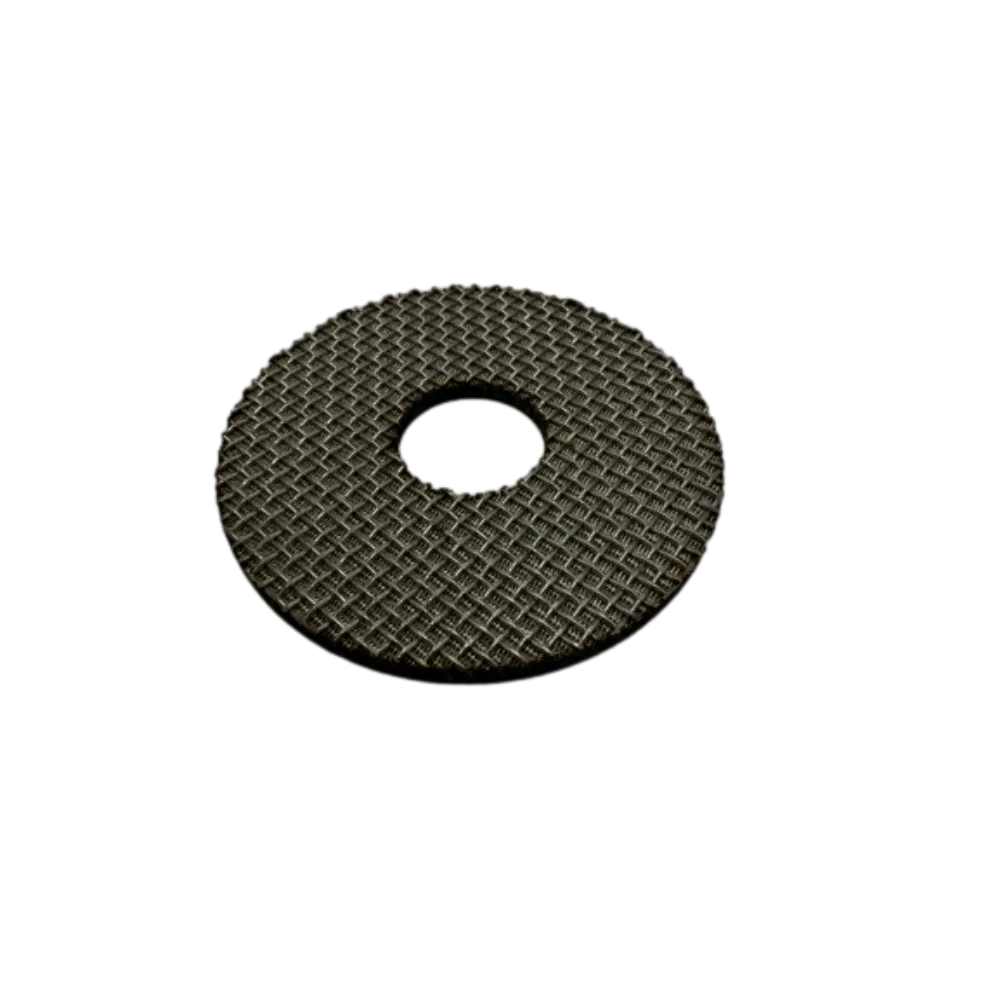

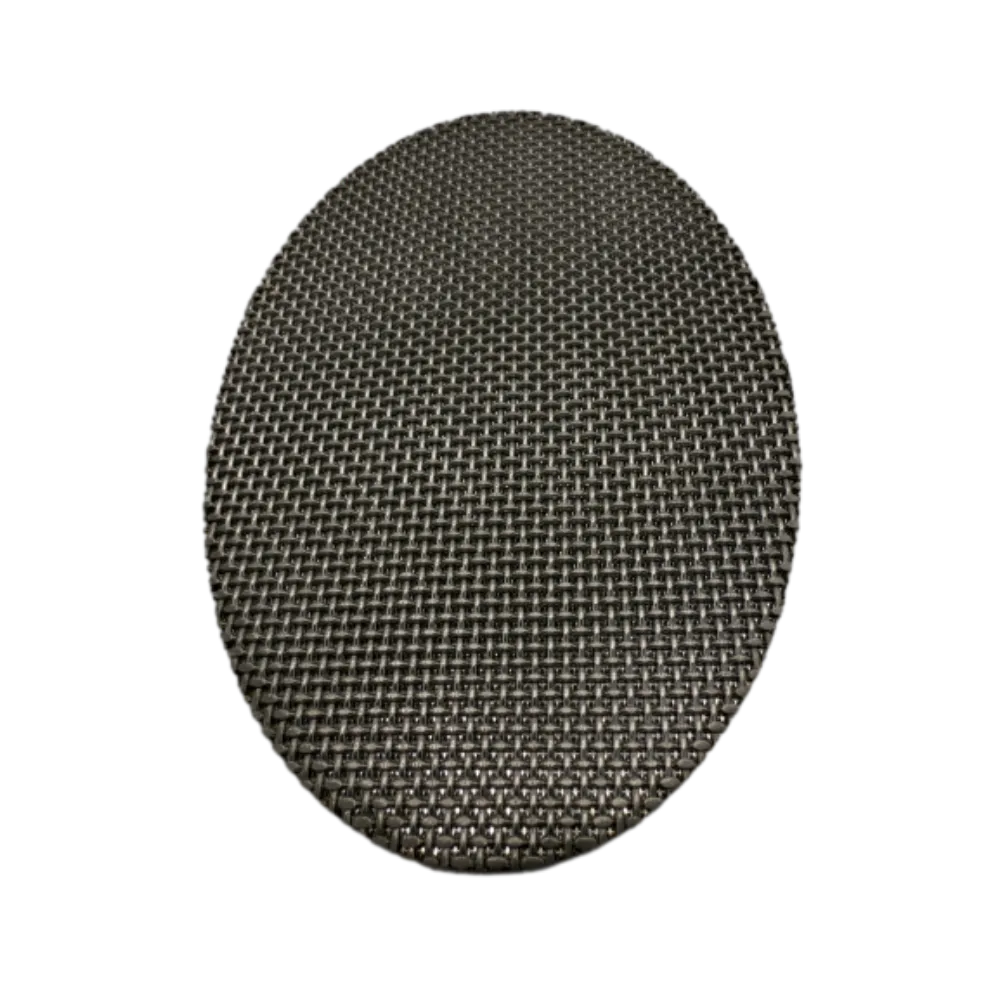

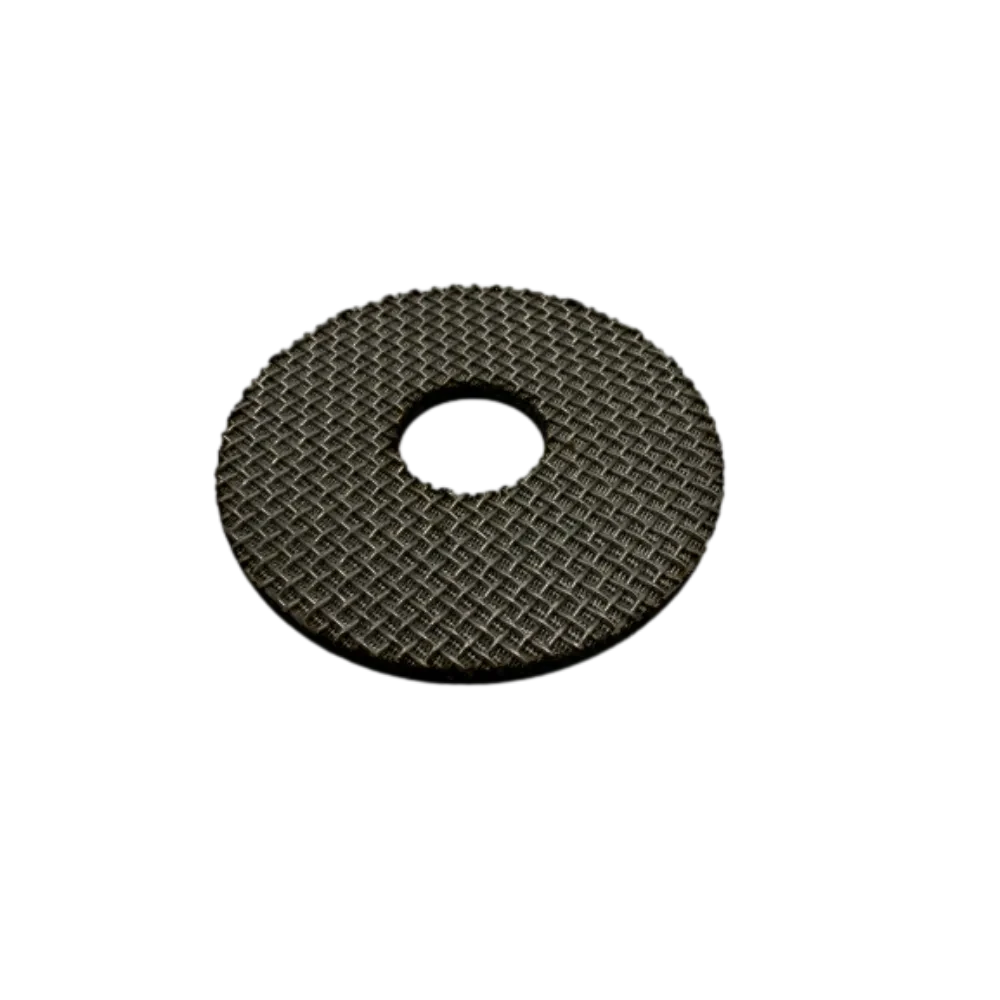

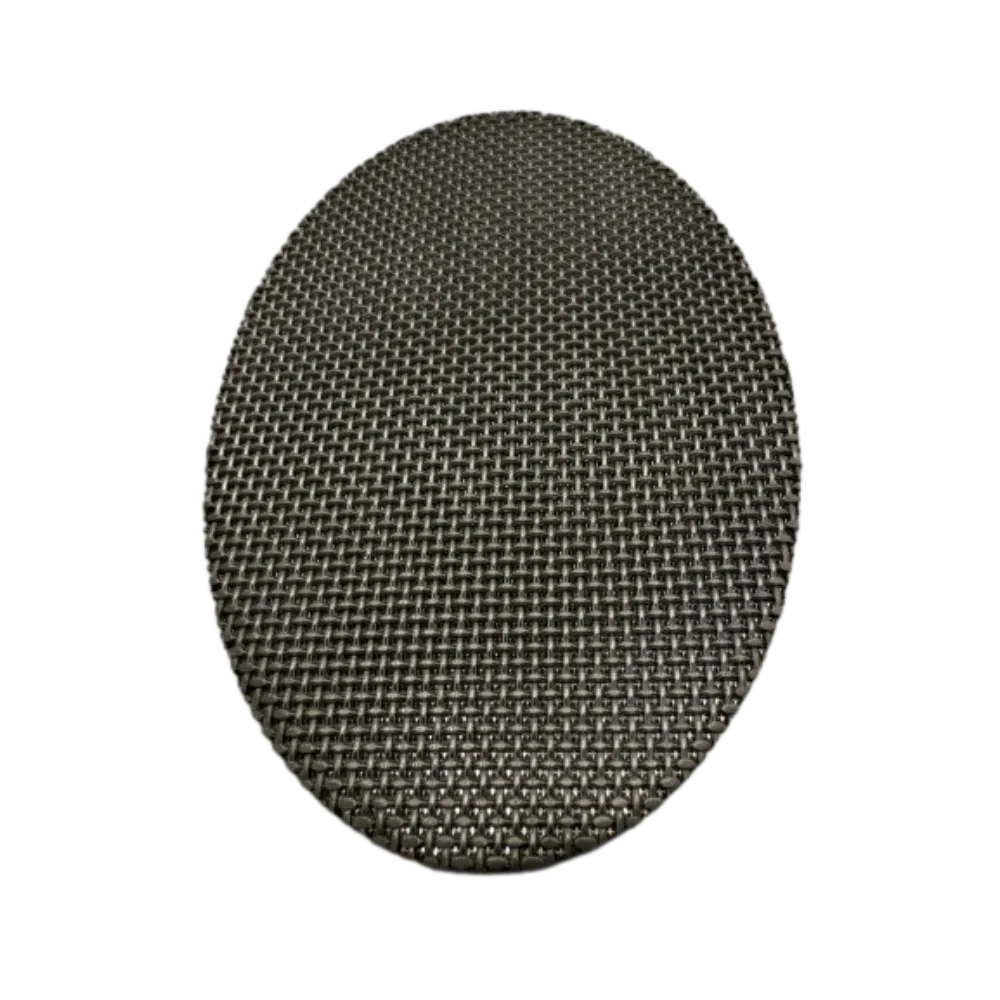

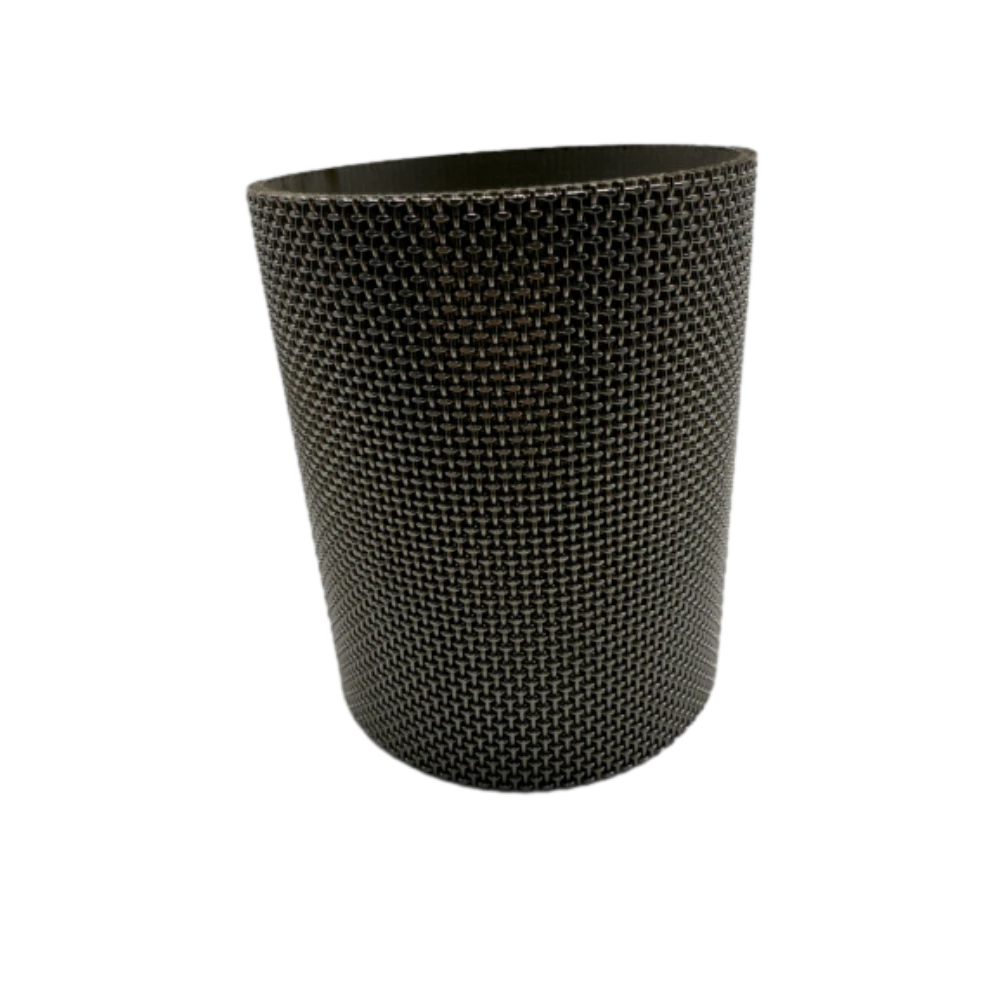

Igwe ntupu eriri nke Sintered

|

|

Usoro nrụpụta

|

1. Sintering: Na elu okpomọkụ, mgbasa nke metal ahụ na-ejikọta metal ntupu ọnụ na-etolite a cohesive Ọdịdị

2. Na-agbagharị: Site na nfegharị elu dị elu, a na-ejikọta oyi akwa ntupu ọ bụla iji hụ na ịdị n'otu ya.

3. Laser Cutting / Plasma Cutting: Beechapụ eriri waya nke Sintered iji hụ na nha na ọdịdị ziri ezi.

|

|

kpara ụzọ nke kpara waya ntupu

|

1. Plain Weave (Ụdị akpa akwa a na-ahụkarị nwere oghere ntupu edo ma dabara adaba maka nzacha izugbe)

2. Twill Weave(Higher nzacha izi ezi, tighter Ọdịdị, adabara elu-nkenke nzacha)

3. Dutch Weave (A na-emepụta ihe nzacha njupụta dị elu site na ịwe akwa eriri ogologo na eriri akwa dị mma, nke a na-ejikarị maka ultrafine filtration)

4. Reverse Dutch Weave (nwere ike dị elu na ikike ibu ibu, dabara maka nzacha nrụgide dị elu)

|

|

Nhọrọ ihe onwunwe

|

1. Igwe anaghị agba nchara (304, 316, 316L)

2. Nickel Alloy (Monel, Hastelloy, Inconel)

3. Titanium ntupu

ETC

|

|

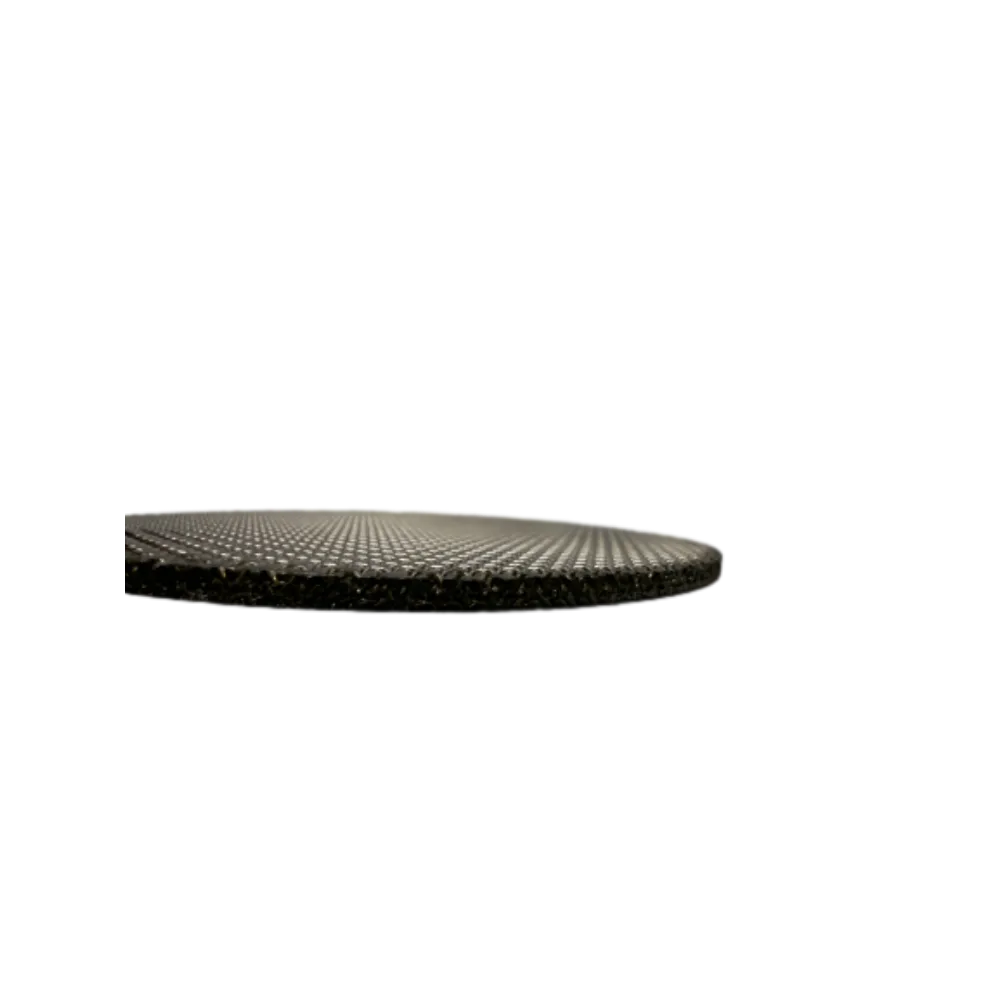

Ọnụọgụ nke oyi akwa

|

3, 5, 7 n'ígwé (ma ọ bụ ahaziri multi-layer Ọdịdị)

|

|

Ịdị mma nzacha

|

1μm - 200μm (nwere ike ịhazi ya)

|

|

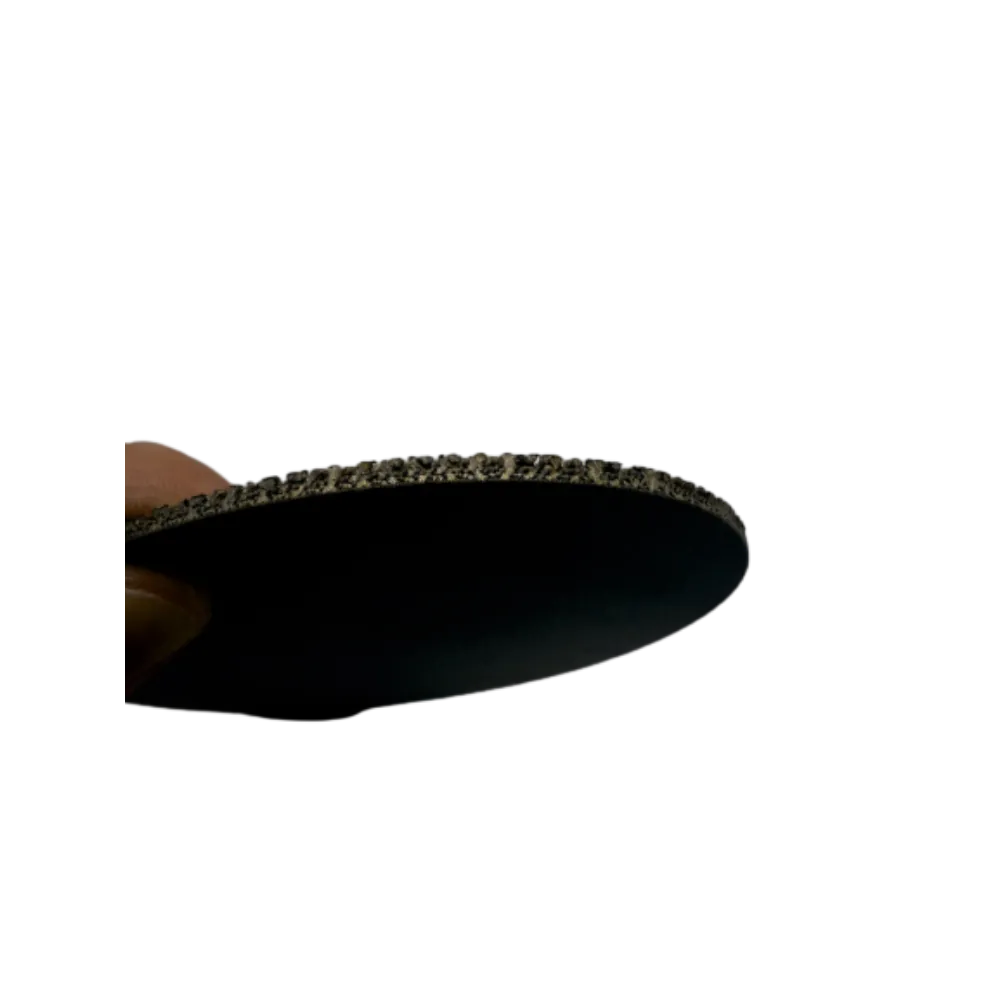

Oke oke

|

0.5mm - 5mm (dị iche site na ọnụ ọgụgụ nke n'ígwé)

|

|

Oghere Nkesa nha

|

Nhazi pore gradient maka nzacha nke ọma na mmiri mmiri

|

|

Ọgwụgwọ elu

|

Acid pickling (igwe anaghị agba nchara / carbon ígwè),

Electrolytic Polishing(igwe anaghị agba nchara)

Nickel plating (igwe anaghị agba nchara / carbon ígwè)

Anodizing (aluminom) wdg.

|

|

Okpomọkụ na-arụ ọrụ

|

-200 ℃ ka 600 ℃ (dabere na ihe onwunwe)

|

|

Nguzogide nrụgide

|

Ruo 30MPa ma ọ bụ karịa (dị iche dabere na ntupu n'ígwé na ọkpụrụkpụ)

|

|

Mwepu / Nguzogide Nfe

|

Nguzogide dị ala na ịdị elu dị elu, kwesịrị ekwesị maka gas na nzacha mmiri mmiri

|

|

Nguzogide corrosion

|

Na-eguzogide acid, alkalis, nnu nnu, na oxidation na gburugburu ebe ọjọọ

|

|

Ụzọ nhicha

|

Ịsacha azụ, ihicha nke ultrasonic, mmiri ọkụ dị elu, nhicha kemịkalụ, na reusable

|

|

Usoro nrụpụta

|

Igwe ọkụ na-ekpo ọkụ dị elu, Rolling

|

|

Ụdị dị

|

Cylindrical, Square, Mpempe akwụkwọ, Pleated, Ụdị ụdị dị

|

|

Ụzọ njikọ

|

Njikọ Flange, Welding, Threaded Connected, Clamping

|

|

Mmiri mmiri ọdabara

|

Kwesịrị ekwesị maka mmiri mmiri, gas, mmanụ, uzuoku, wdg.

|

|

Mpaghara ngwa

|

Petrochemical, nri & ihe ọṅụṅụ, ọgwụ, ọgwụgwọ mmiri gburugburu ebe obibi, Aerospace, Automotive Industry, wdg.

|

|

Uru ngwaahịa

|

1. Ike dị elu na nrụgide nrụgide, ọ dịghị mfe imebi

2. Nhicha ugboro ugboro, ogologo ndụ

3. Nzacha nkenke, nkesa nha pore edo edo

4. Igwe ọkụ dị elu na nguzogide corrosion, na-emegharị na gburugburu ebe dị njọ

|

![$ihe[aha] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)