|

'ikamu

|

wehewehe

|

|

Inoa Huahana

|

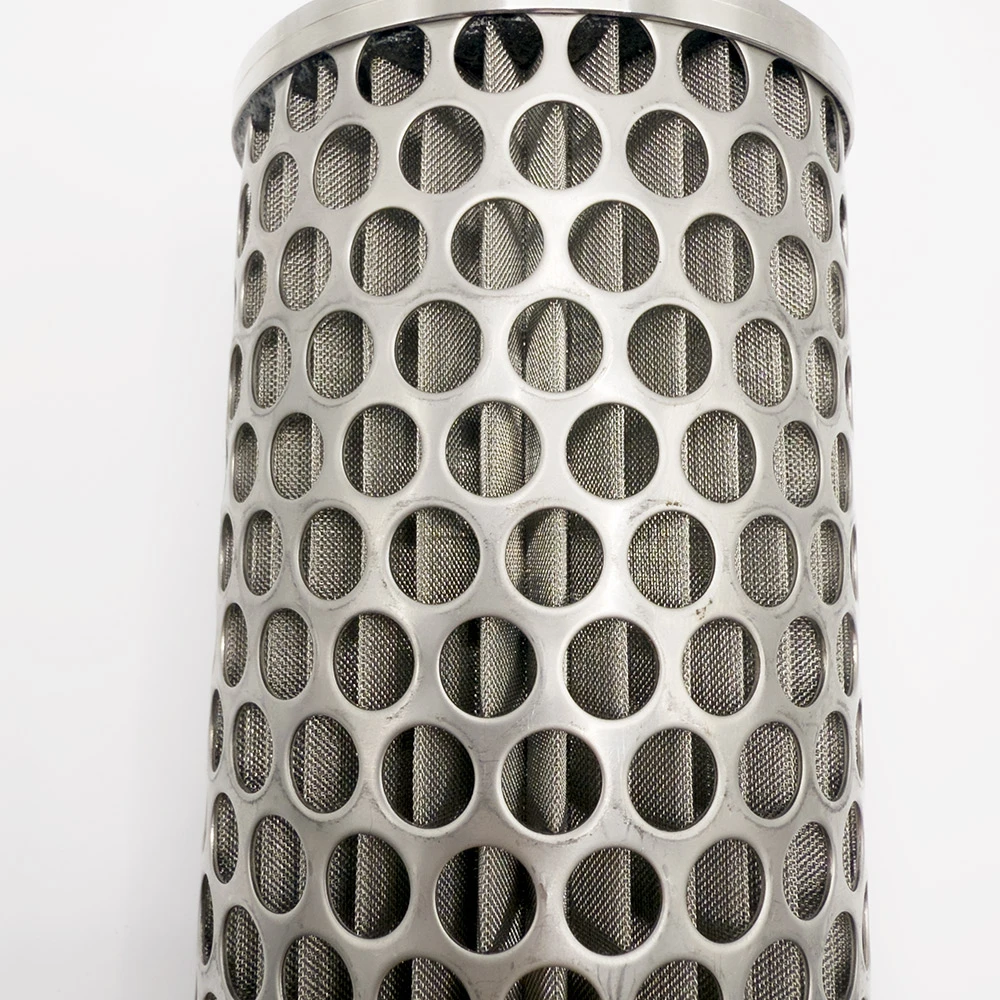

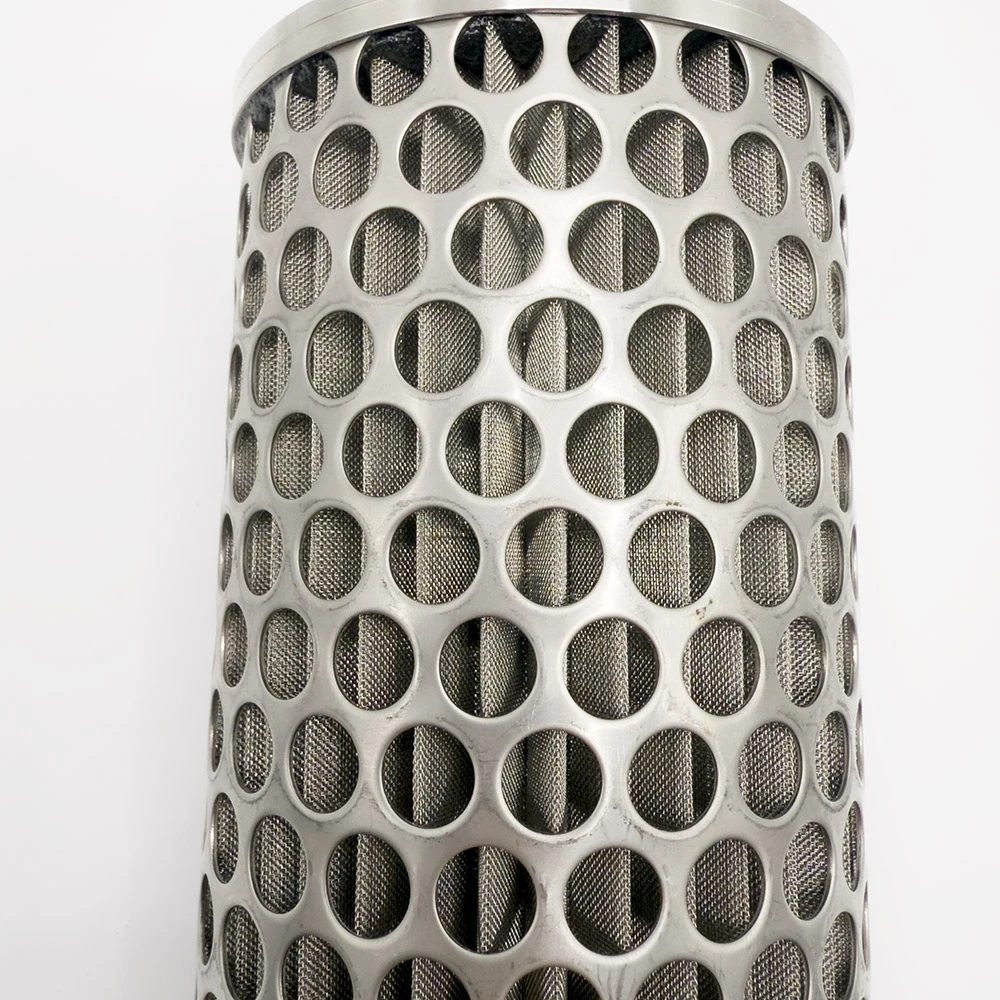

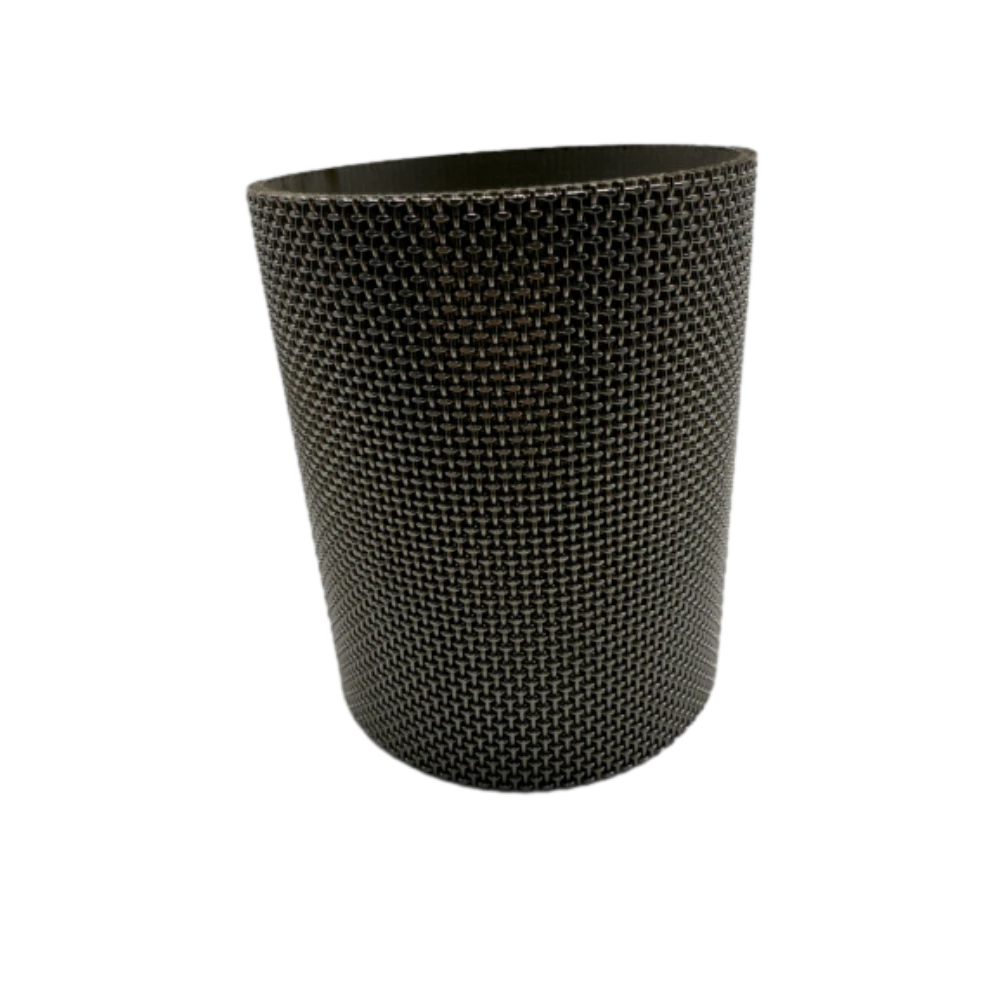

ʻElemu kānana ʻenehana ʻenehana

|

|

Mea waiwai

|

Ke kila kila (304, 316L), Alloy Nickel (Monel, Hastelloy), Alloy Titanium

|

|

Anawaena waho

|

10mm - 600mm (Hiki ke hoʻololi ʻia)

|

| Mānoanoa Pā |

0.3mm - 5mm (Hoʻopilikino ʻia)

|

|

Ka nui o ka perforation

|

0.3mm - 10mm (Rāpuni, Hāhā, Loaʻa nā puka ʻāwīwī)

|

|

Wahi Hāmama

|

10% - 60% (Hoʻopilikino ʻia ma muli o nā pono kānana)

|

|

Laʻana o ʻO ka pololei kānana (μm)

|

|

Nui Aperture (mm)

|

ʻO ka pololei kānana (μm)

|

Application

|

|

5.0

|

5000

|

ka wehe ʻana i nā ʻāpana nui

|

|

2.0

|

2000

|

kūpono no ka wehe ʻana i nā ʻōpala nui

|

|

1.0

|

1000

|

ka wehe ʻana i nā haumia paʻa nui

|

|

0.5

|

500

|

ka hopu ʻana i nā ʻāpana wai

|

|

0.1

|

100

|

ʻO kāna kānana maikaʻi loa

|

|

No ka mea ʻoi aku ka pololei kānana (1-50μm), he ʻeke kānana maikaʻi hou a i ʻole ka uhi o loko hiki ke hoʻohui ʻia me ke kila kuhiliʻole perforated mesh e hoʻokō i ka hana ʻoi aku ka maikaʻi.

Makemake ʻoe i ʻōlelo paipai no ka ka nui aperture kūpono a me ka mea ma muli o kāu noi? E haʻi mai iaʻu i kāu makemake maʻamau kānana (μm)!

|

|

|

Lapaʻau ʻili

|

1. Pickling(Stainless steel (304, 316L), carbon steel, nickel-based alloy (Monel, Hastelloy)

2. Electrolytic Polishing (Stainless steel (304, 316L), nickel-based alloy (Monel, Hastelloy))

3. Sandblasting (Ka hao, ke kila kalapona, ke kila kuhiliʻole (304, 316L), ka huila titanium, ka huila nickel-based (Monel, Hastelloy))

4. Hoʻolauea (Hao, hao kalapona)

5. Pa'i nikeli(Hao, hao kalapona, kila kuhiliʻole (304, 316L), nā huila nickel-based (Monel, Hastelloy))

etc.

|

|

ʻAno wiliwili

|

Welding Spiral / Seam Welding (E hōʻoia i ka ikaika kiʻekiʻe a me ka hana hoʻopaʻa ʻana)

|

|

Paʻi Paʻi

|

A hiki i 30MPa (Hoʻololi ʻia e pili ana i nā mea a me ka mānoanoa)

|

|

Pale ʻino

|

Kaʻakika a me ka Alkali Kū'ē, Kū'ē Kū'ē kiʻekiʻe, Kū'ē'Oxidation

|

|

ʻAno Hoʻohui

|

Hoʻohui Flange, Hoʻohui Uila, Hoʻohui Welded, ʻAno Clamping

|

|

Nā wai kūpono

|

Nā wai, nā kinoea, nā ʻaila, ka mahu, a pēlā aku.

|

|

Hana Hoomaemae

|

Holoi hope, Hoʻomaʻemaʻe Kemika, Hoʻomaʻemaʻe Ultrasonic, Baking Mahana Kiʻekiʻe

|

|

Nā kahua noi

|

Petrochemical, Natural Gas, Environmental Water Treatment, Food & Pharmaceutical, Metallurgy, Power Industry, Automotive Industry, etc.

|

|

Nā hiʻohiʻona huahana

|

1. ʻO ka hoʻolālā ikaika kiʻekiʻe, kū'ē i ke kaomi kiʻekiʻe a me ka corrosion

2. ʻAʻahu hoʻokahi no ka maikaʻi o ka ea a me ka pono kānana

3. ʻO ka ʻenehana kuʻi pololei pololei e hōʻoia i ka lōʻihi

4. Nā mea hiki ke hoʻopili ʻia, ka nui o ka lua, a me ka porosity e hoʻokō i nā pono kānana kikoʻī

|

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)