|

Nā mea

|

wehewehe

|

|

Inoa Huahana

|

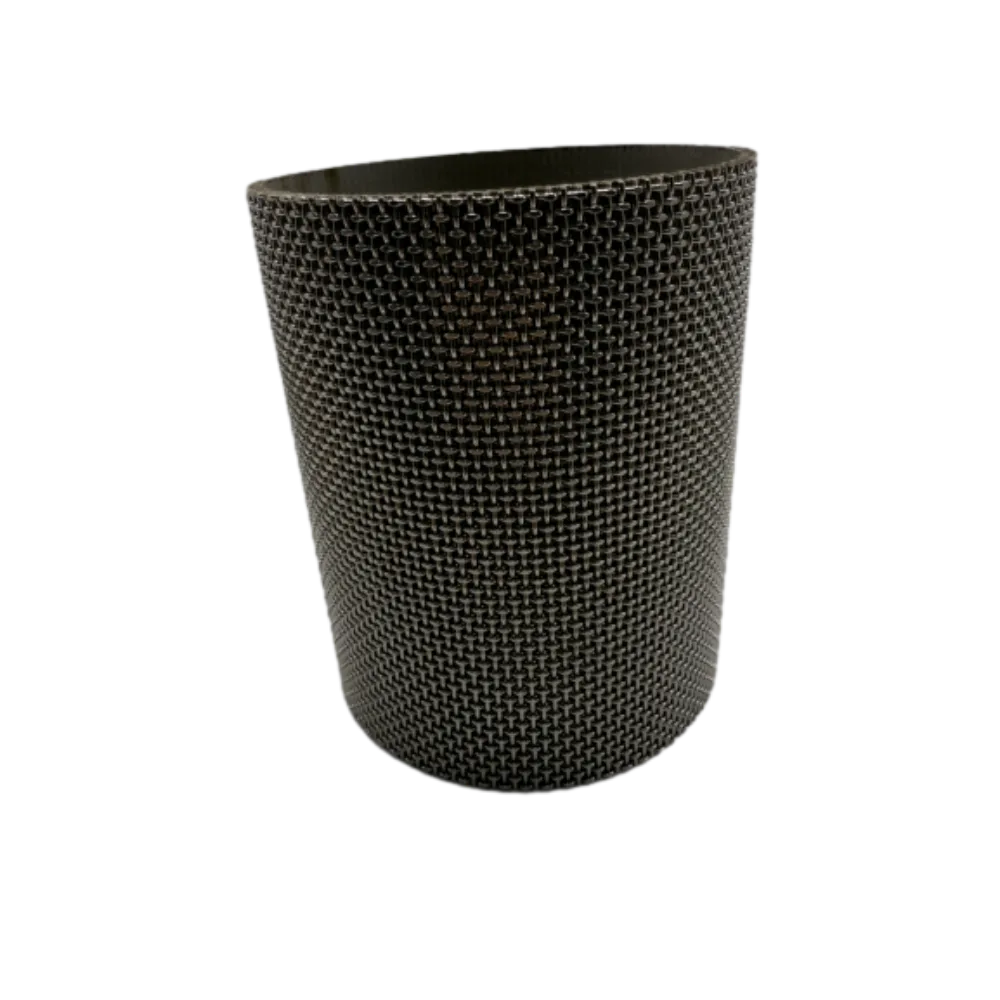

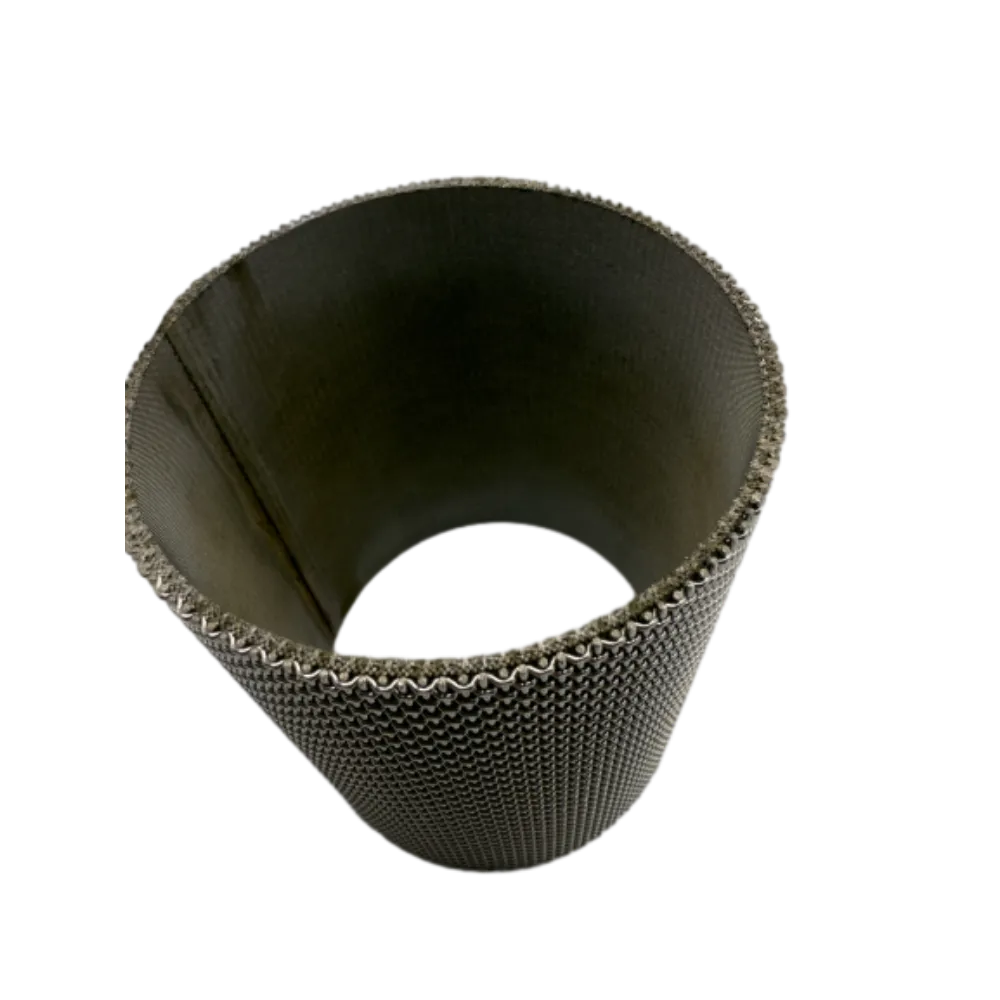

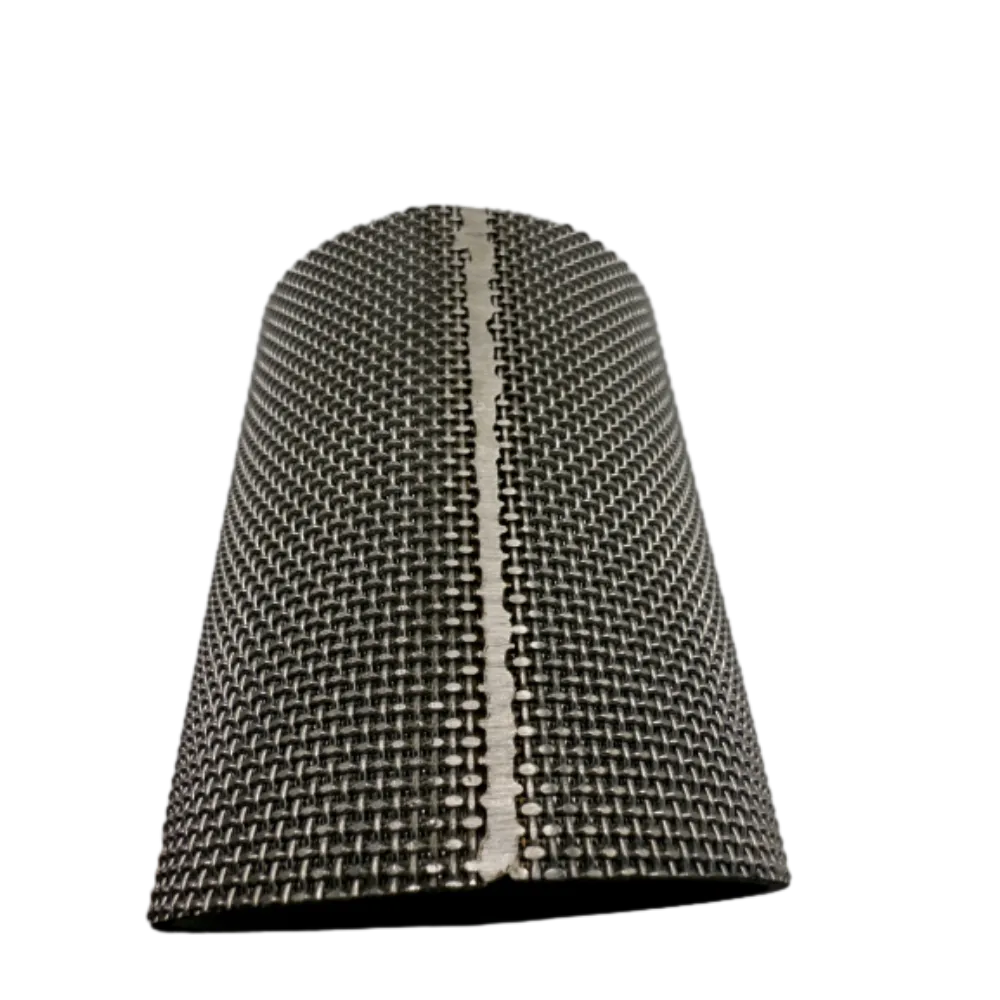

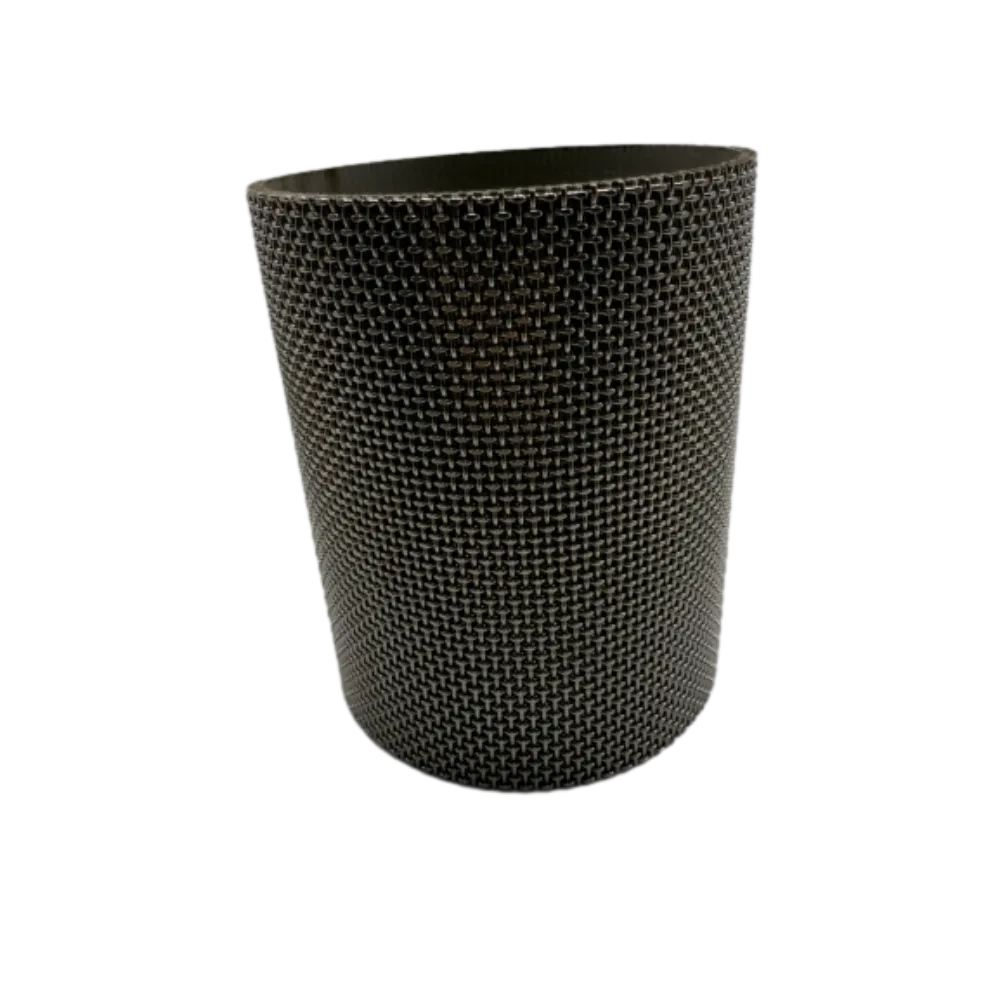

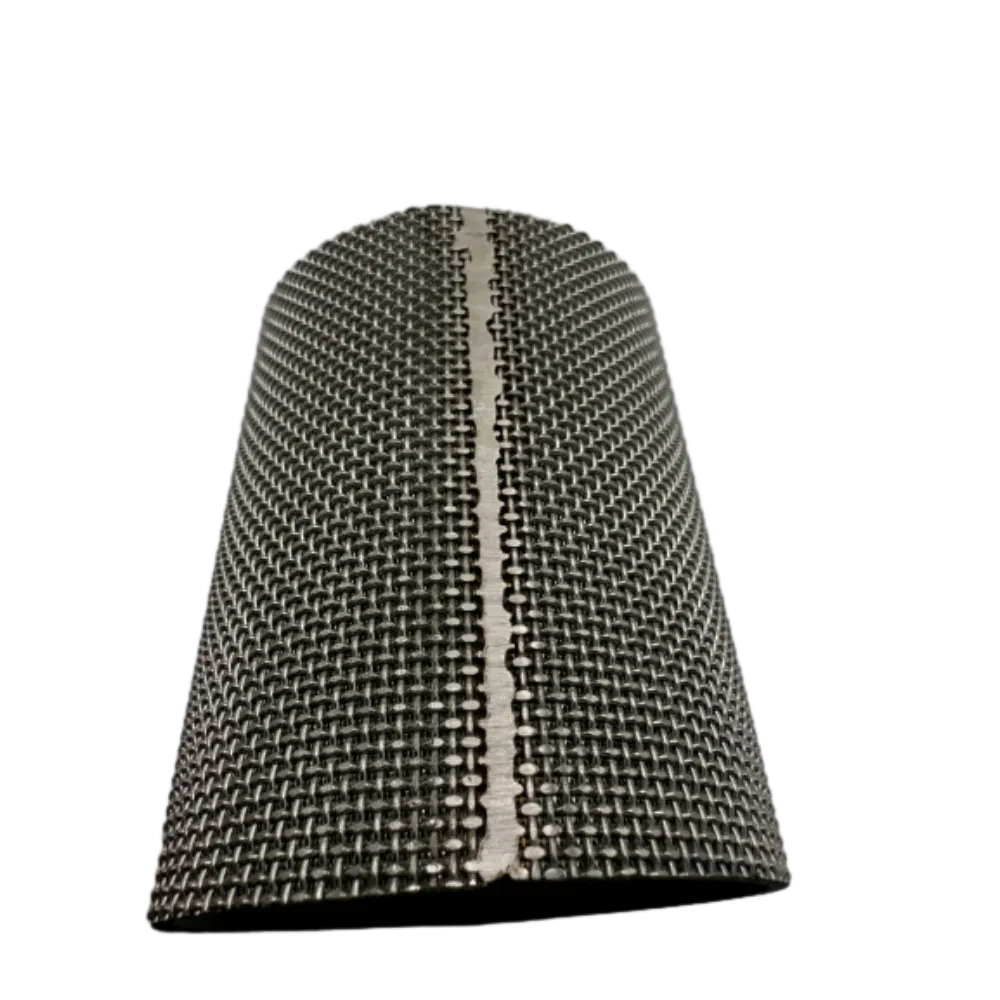

Paipu Uea Mesh Sintered

|

|

Kaʻina Hana Hana

|

1. Sintering: Ma nā wela kiʻekiʻe, hoʻopili ka diffusion o nā mea metala i ka mesh mesh e hana i kahi hale paʻa.

2. Rolling:Ma ke kiʻekiʻe-press rolling, kēlā me kēia mesh layer pili paʻa e hōʻoia i kona mānoanoa like like.

3. ʻoki ʻoki laser/ ʻoki plasma: ʻoki ʻana i ka wili wili i hoʻopaʻa ʻia, e hōʻoia i ka pololei o ka ʻoki ʻana i ka nui a me ke ʻano.

4. Welding: Hoʻohana ʻia no ka hoʻopili ʻana i kahi ʻano cylindrical

|

|

ʻO ke ala ulana ʻia o ka uea uea

|

1. Uli Plain (ʻO ke ʻano ulana maʻamau he mau puka ʻaʻahu a kūpono no ka kānana maʻamau)

2. Twill Weave (Kānana kānana kiʻekiʻe, ʻoi aku ka paʻa o ka hana, kūpono no ka kānana kiʻekiʻe)

3. Dutch Weave(Hoʻokumu ʻia kahi ʻano kānana kiʻekiʻe ma o ka hui ʻana i nā kaula wili a me nā kaula weft maikaʻi, hoʻohana mau ʻia no ka kānana ultrafine)

4. Reverse Dutch Weave (He kiʻekiʻe aʻe ka ikaika a me ka haʻahaʻa haʻahaʻa, kūpono no ka kānana kaomi kiʻekiʻe)

|

|

Nā mea ʻokoʻa

|

1. Ke kila kila (304, 316, 316L)

2. Nickel Alloy(Monel, Hastelloy, Inconel)

3. Mesh Titanium

ETC

|

|

Ka helu o na papa

|

3, 5, 7 papa (a i ʻole ka hoʻonohonoho ʻana i nā ʻāpana he nui)

|

|

Pololei kānana

|

1μm - 200μm (hiki ke hoʻololi ʻia)

|

|

Mānoanoa

|

0.5mm - 5mm (e like me ka helu o nā papa)

|

|

Hole Puka Lahi

|

Hoʻolālā pore gradient no ka kānana kūpono a me ke kahe wai

|

|

Lapaʻau ʻili

|

ʻAkika pickling (Stainless Steel/Carbon kila),

Electrolytic Polishing (Stainless Steel)

Pa'i nikela (Stainless Steel/Carbon Steel)

Anodizing (Aluminum) etc.

|

|

Ka Mahana Hana

|

-200 ℃ a 600 ℃ (ma muli o ka mea)

|

|

Paʻi Paʻi

|

A hiki i 30MPa a i ʻole ke kiʻekiʻe (e like me nā ʻāpana mesh a me ka mānoanoa)

|

|

Paʻa / Kahe ʻana

|

ʻO ke kūpaʻa haʻahaʻa a me ka permeability kiʻekiʻe, kūpono no ke kinoea a me ka kānana wai

|

|

Pale ʻino

|

Kū'ē i nā waikawa, nā alkalis, ka paʻakai paʻakai, a me ka oxidation i nā wahi paʻakikī

|

|

Hana Hoomaemae

|

Backwashing, Ultrasonic hoʻomaʻemaʻe, Kiʻekiʻe-mehana bakena, Kemika hoʻomaʻemaʻe, a hoʻohana hou

|

|

Kaʻina Hana Hana

|

Kiʻekiʻe-mehana vacuum sintering, Rolling, Welding, Stamping

|

|

Nā ʻano i loaʻa

|

Cylindrical, Square, Sheet, Pleated, Nā kiʻi maʻamau i loaʻa

|

|

Nā Hana Hoʻohui

|

Hoʻohui Flange, Kuʻi, Hoʻopili Uila, Paʻi

|

|

Nā wai kūpono

|

He kūpono no nā wai, nā kinoea, nā aila, ka mahu, etc.

|

|

Nā kahua noi

|

Petrochemical, Meaʻai & Mea inu, Lapaʻau Lapaʻau, Hoʻomaʻamaʻa Wai Kaiapuni, Aerospace, ʻOihana Automotive, etc.

|

|

Nā Pono Huahana

|

1. ʻO ka ikaika kiʻekiʻe a me ke kūpaʻa paʻa, ʻaʻole maʻalahi ke hoʻololi

2. Hoʻomaʻemaʻe hou, ola lōʻihi

3. ʻO ka kānana pololei, ka hāʻawi ʻana i ka nui o ka pore

4. Kiʻekiʻe wela a me ka corrosion kū'ē, adaptable i koʻikoʻi kaiapuni

|

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)