|

Abu

|

Bayani

|

|

Sunan samfur

|

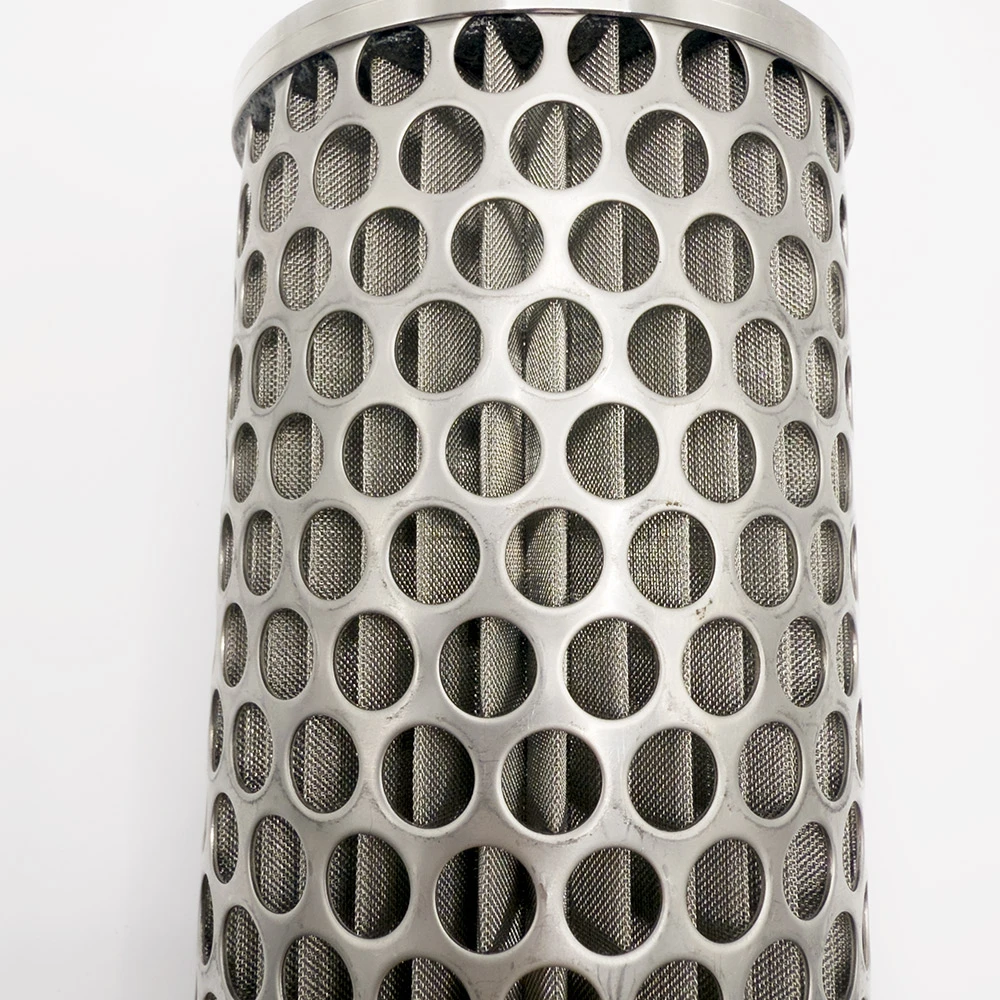

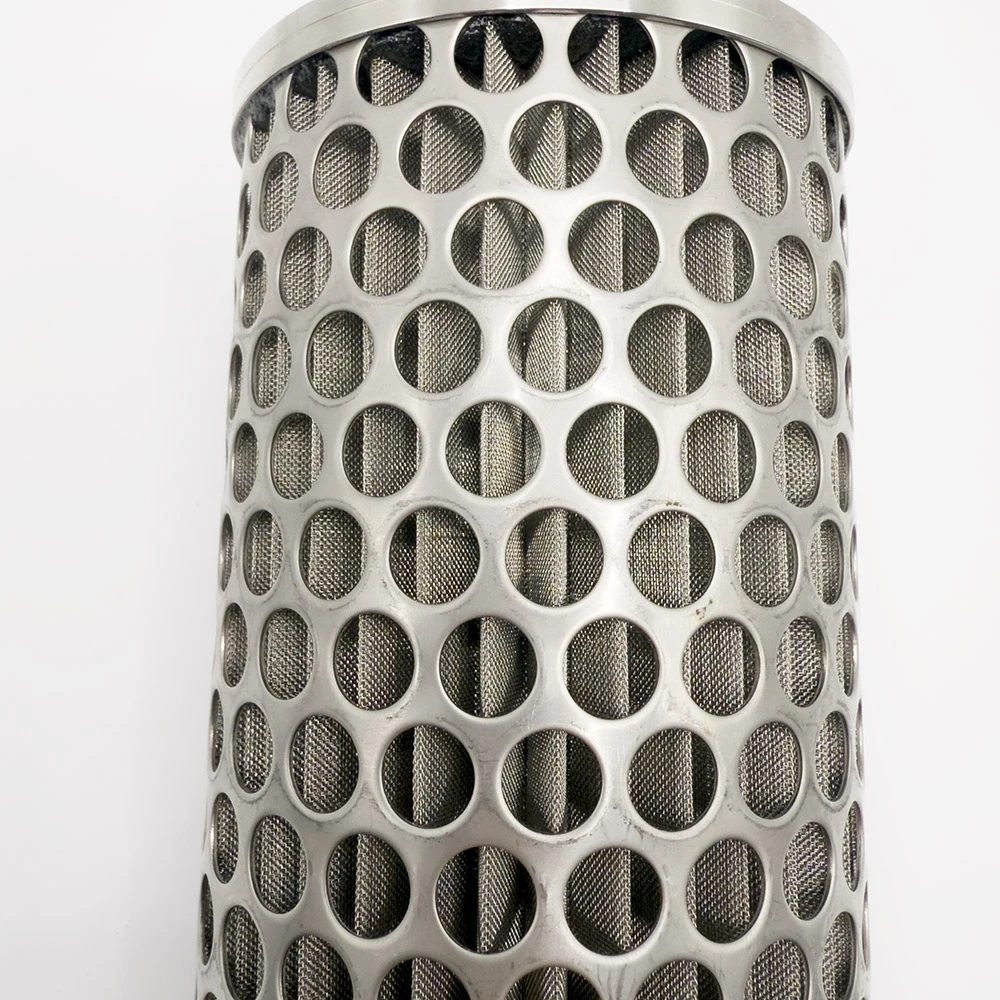

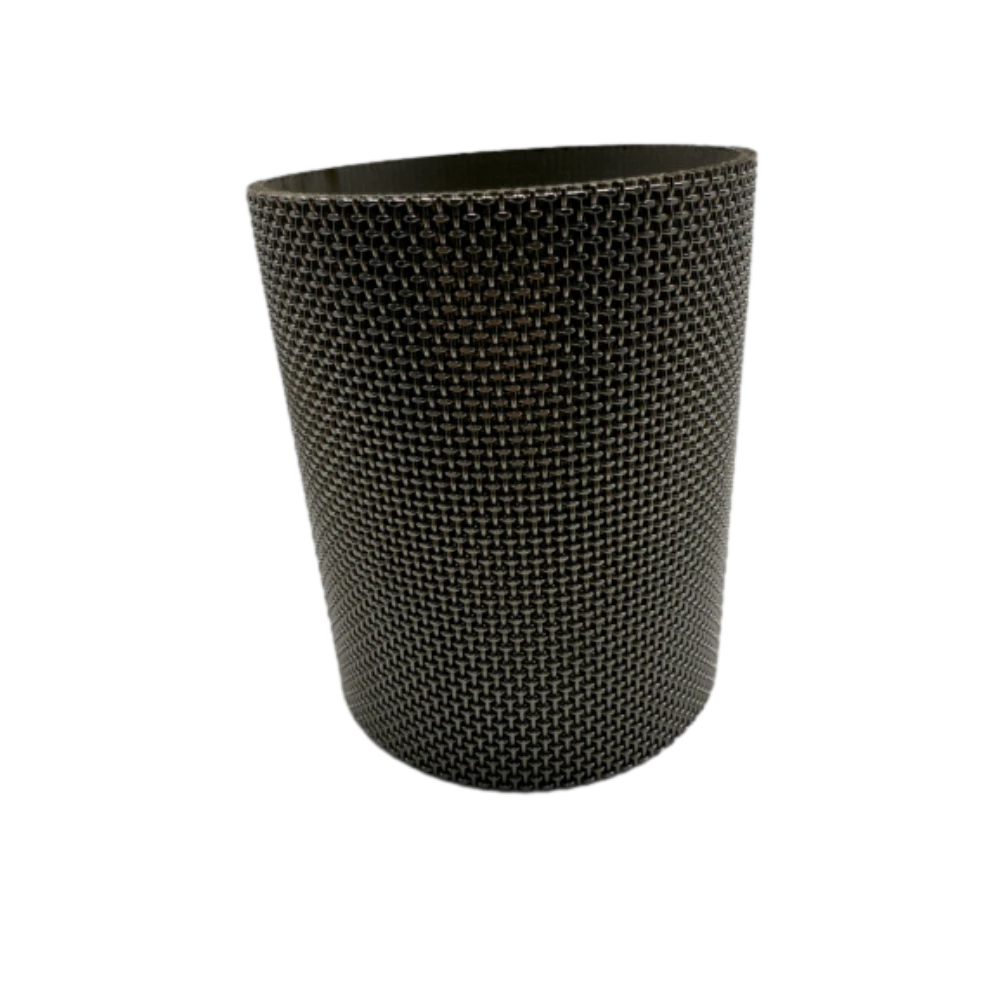

Bakin Karfe Filtration Element

|

|

Kayan abu

|

Bakin Karfe (304, 316L), Nickel Alloy (Monel, Hastelloy), Titanium Alloy

|

|

Diamita na waje

|

10mm - 600mm (Na'urar Na'ura)

|

| Kaurin bango |

0.3mm - 5mm (Na'urar Na'ura)

|

|

Girman Perforation

|

0.3mm - 10mm (Zagaye, Square, Akwai Ramin Ramin)

|

|

Bude Wuri

|

10% - 60% (Na'urar Na'urar ta dogara da Buƙatun Tacewa)

|

|

Misalin Daidaitaccen Tacewa (μm)

|

|

Girman Budawa (mm)

|

Daidaitaccen Tacewa (μm)

|

Application

|

|

5.0

|

5000

|

babban cirewar barbashi

|

|

2.0

|

2000

|

dace da manyan tarkace cire

|

|

1.0

|

1000

|

cire mafi girma m ƙazanta

|

|

0.5

|

500

|

kama ruwa barbashi

|

|

0.1

|

100

|

Ultra-lafiya tacewa

|

|

Domin mafi girma madaidaicin tacewa (1-50μm), an ƙarin jakar tacewa mai kyau ko rufin ciki za a iya hadedde da bakin karfe perforated raga don cimma m aiki.

Kuna son shawara ga mafi kyau duka buɗaɗɗen girma da abu bisa aikace-aikacenku? Sanar da ni abin da kuke bukata mizanin tacewa (μm)!

|

|

|

Maganin Sama

|

1. Pickling (Bakin Karfe (304, 316L), carbon karfe, nickel na tushen gami (Monel, Hastelloy)

2. Electrolytic Polishing (Bakin Karfe (304, 316L), nickel na tushen gami (Monel, Hastelloy))

3. Sandblasting (Iron, carbon karfe, bakin karfe (304, 316L), titanium gami, nickel na tushen gami (Monel, Hastelloy))

4. Galvanizing (Iron, carbon karfe)

5. Nickel Plating (Iron, carbon karfe, bakin karfe (304, 316L), nickel na tushen gami (Monel, Hastelloy))

da dai sauransu.

|

|

Nau'in walda

|

Karkataccen Welding / Seam Welding (Yana Tabbatar da Babban Ƙarfi da Ayyukan Rufewa)

|

|

Juriya na matsin lamba

|

Har zuwa 30MPa (Mai daidaitawa Dangane da Material & Kauri)

|

|

Juriya na Lalata

|

Acid da Alkali Resistant, High-Temperature Resistant, Oxidation Resistant

|

|

Nau'in Haɗi

|

Haɗin Flange, Haɗin Zare, Haɗin Welded, Nau'in ƙullawa

|

|

Matsalolin Ruwa

|

Liquid, Gases, Oils, Steam, da dai sauransu.

|

|

Hanyar Tsaftacewa

|

Wanke baya, Chemical Cleaning, Ultrasonic Cleaning, High-Zazzabi Baking

|

|

Filin Aikace-aikace

|

Petrochemical, Natural Gas, muhalli Ruwa Jiyya, Abinci & Pharmaceutical, Metallurgy, Power Industry, Automotive Industry, da dai sauransu.

|

|

Siffofin Samfur

|

1. Tsarin ƙarfi mai ƙarfi, juriya ga babban matsin lamba da lalata

2. Uniform perforation ga mafi kyau duka iska kwarara da tacewa yadda ya dace

3. Madaidaicin fasahar waldawa yana tabbatar da dorewa

4. Abubuwan da za a iya daidaita su, girman rami, da porosity don saduwa da takamaiman bukatun tacewa

|

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)