|

Item

|

Tsanangudzo

|

|

Product Name

|

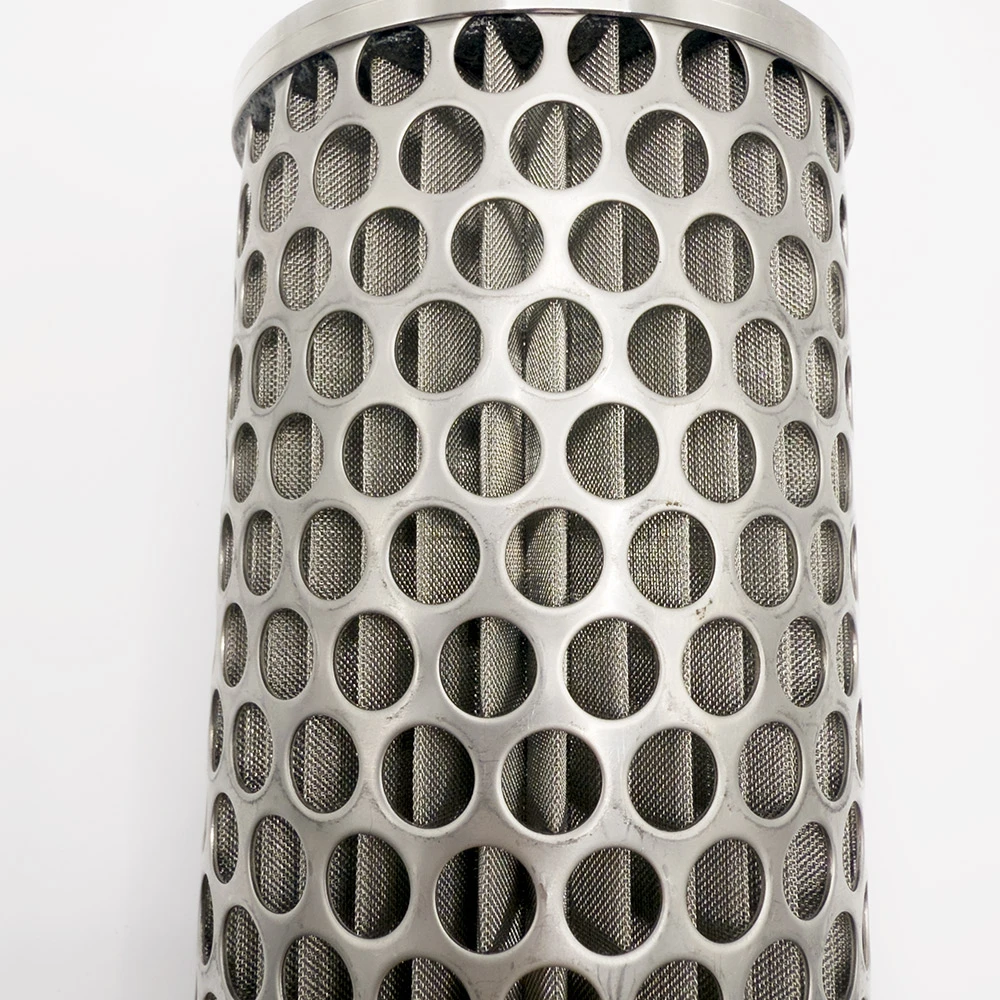

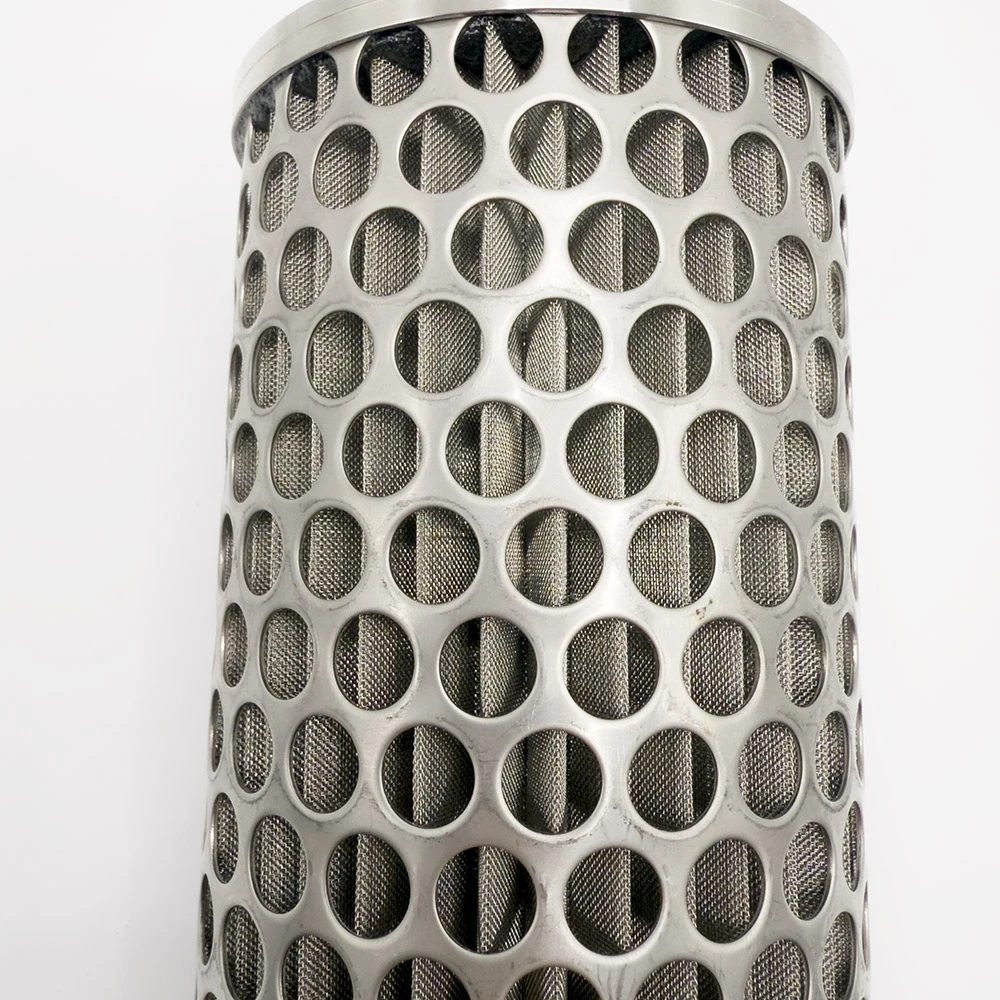

Stainless Steel Industrial Filtration Element

|

|

Material

|

Stainless Simbi (304, 316L), Nickel Alloy (Monel, Hastelloy), Titanium Alloy

|

|

Outer Diameter

|

10mm - 600mm (Customizable)

|

| Kukora Kwemadziro |

0.3mm - 5mm (Customizable)

|

|

Perforation Size

|

0.3mm - 10mm (Kutenderera, Sikweya, Makomba Akatsemuka Anowanikwa)

|

|

Open Area

|

10% - 60% (Customizable Based on Filtration Needs)

|

|

Muenzaniso we Kusefa Kwazvo (μm)

|

|

Aperture size (mm)

|

Kusefa Kwazvo (μm)

|

Application

|

|

5.0

|

5000

|

kubviswa kwechikamu chikuru

|

|

2.0

|

2000

|

yakakodzera kubviswa kwemarara makuru

|

|

1.0

|

1000

|

kubvisa tsvina yakakura yakasimba

|

|

0.5

|

500

|

kutora zvimedu zvemvura

|

|

0.1

|

100

|

Ultra-yakanaka kusefa

|

|

For kusefa kwepamusoro chaiko (1-50μm), an yekuwedzera yakanaka firita bag kana yemukati lining inogona kubatanidzwa nesimbi isina simbi perforated mesh kuti iwane kuita kwepamusoro.

Ungade here kurudziro kune iyo optimal aperture saizi uye zvinhu zvichienderana nekushandisa kwako? Ndizivise zvaunoda chiyero chekusefa (μm)!

|

|

|

Surface Treatment

|

1. Pickling (Simbi isina simbi (304, 316L), kabhoni simbi, nickel-based alloy (Monel, Hastelloy)

2. Electrolytic Polishing (Simbi isina simbi (304, 316L), nickel-based alloy (Monel, Hastelloy))

3. Sandblasting (Iron, carbon simbi, Stainless simbi (304, 316L), titanium alloy, nickel-based alloy (Monel, Hastelloy))

4. Galvanizing (Simbi, kabhoni simbi)

5. Nickel Plating (Iron, carbon simbi, Stainless simbi (304, 316L), nickel-based alloys (Monel, Hastelloy))

etc.

|

|

Welding Type

|

Spiral Welding / Seam Welding (Inovimbisa Kusimba Kwepamusoro uye Kuita Chisimbiso)

|

|

Kuramba Kudzvinyirira

|

Kusvika ku30MPa (Inochinjika Kubva pane Material & Hukobvu)

|

|

Corrosion Resistance

|

Asidhi uye Alkali Inodzivirirwa, Yakakwira-Tembiricha Inodzivirirwa, Inopikisa Oxidation

|

|

Connection Type

|

Flange Connection, Threaded Connection, Welded Connection, Clamping Type

|

|

Applicable Fluids

|

Zvinwiwa, Magasi, Mafuta, Steam, nezvimwe.

|

|

Kuchenesa Nzira

|

Backwashing, Chemical Cleaning, Ultrasonic Cleaning, High-Temperature Baking

|

|

Minda Yekushandisa

|

Petrochemical, Gasi Rakasikwa, Kurapwa Kwemvura Yezvakatipoteredza, Chikafu & Mishonga, Metallurgy, Indasitiri Yemagetsi, Indasitiri Yemotokari, nezvimwe.

|

|

Product Features

|

1. Yakakwirira-yakasimba chimiro, inopesana nepamusoro-soro uye kuora

2. Uniform perforation kuitira kunyatsofambisa mhepo uye kusefa kushanda zvakanaka

3. Precision welding tekinoroji inovimbisa kusimba

4. Customizable zvinhu, gomba saizi, uye porosity kusangana chaiwo filtration zvinodiwa

|

![$chinhu[musoro] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)