|

Into

|

Inkcazo

|

|

Igama lemveliso

|

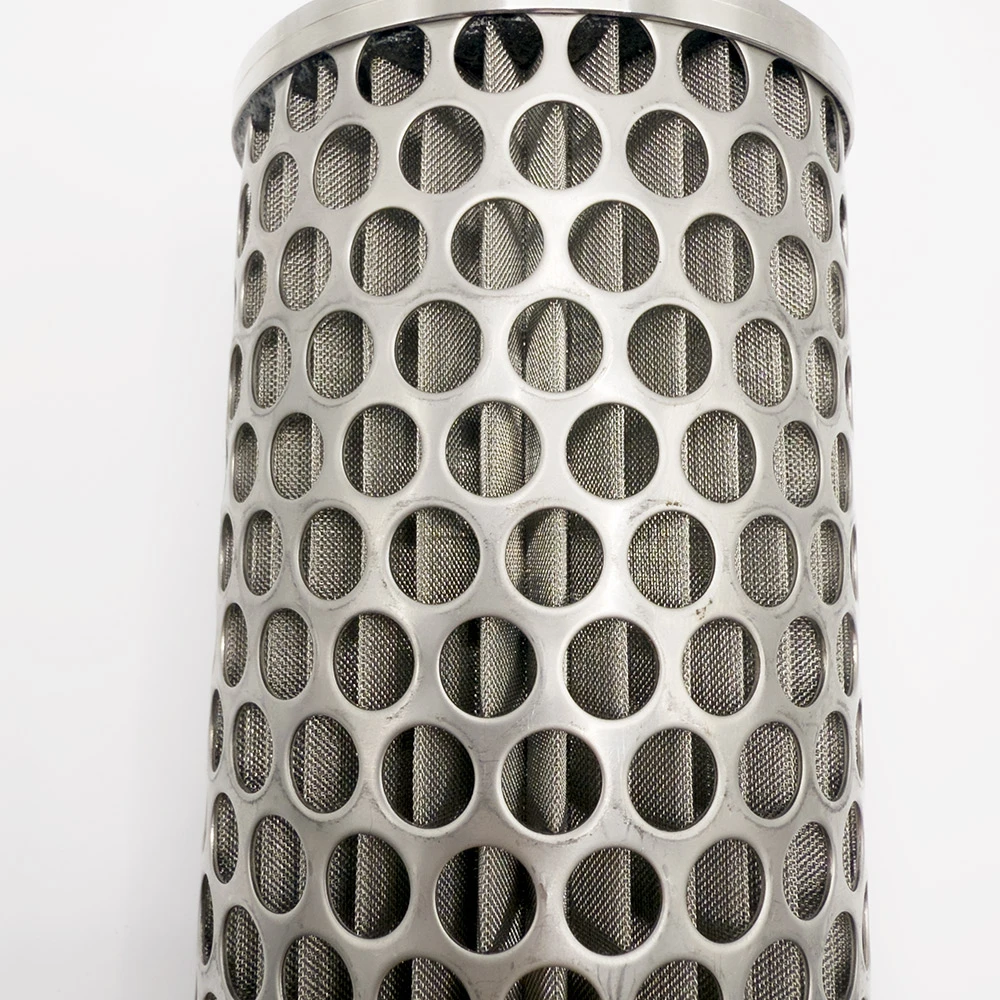

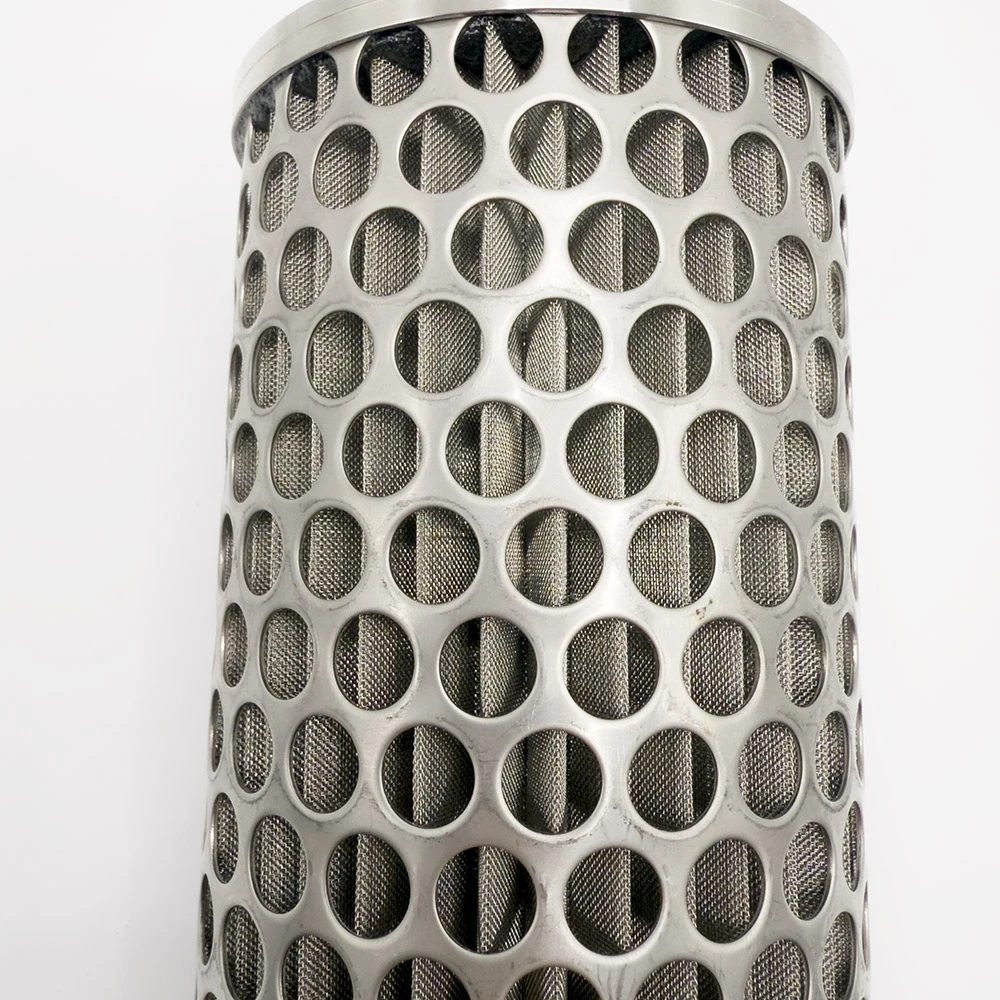

Isixhobo soHluzo lweNtsimbi yeStainless

|

|

Izinto eziphathekayo

|

Insimbi engenaStainless (304, 316L), i-Nickel Alloy (iMonel, iHastelloy), i-Titanium Alloy

|

|

Ububanzi bangaphandle

|

10mm - 600mm (Inokwenzeka ngokwezifiso)

|

| Ukutyeba kweendonga |

0.3mm - 5mm (Inokwenzeka ngokwezifiso)

|

|

Ubungakanani bokugqojozwa

|

0.3mm - 10mm (Round, Square, Imingxuma eMilwe iyafumaneka)

|

|

Indawo evulekileyo

|

I-10% - 60% (Eyenziwe ngokwezifiso ngokuSekwe kwiiMfuno zokuHlunga)

|

|

Umzekelo we Ukuchaneka koHlelo (μm)

|

|

Ubungakanani boMvula (mm)

|

Ukuchaneka koHlelo (μm)

|

Application

|

|

5.0

|

5000

|

ukususwa kwamasuntswana amakhulu

|

|

2.0

|

2000

|

ilungele ukususwa kwenkunkuma enkulu

|

|

1.0

|

1000

|

ukususa ukungcola okukhulu okuqinileyo

|

|

0.5

|

500

|

ukubamba amasuntswana elulwelo

|

|

0.1

|

100

|

Ukuhluzwa okugqibeleleyo

|

|

Kuba ukuhluzwa okuchanekileyo okuphezulu (1-50μm), i ibhegi yokucoca elungileyo eyongezelelweyo okanye ilayini yangaphakathi inokudityaniswa kunye nentsimbi engenasici ene-perforated mesh ukufezekisa ukusebenza okuphezulu.

Ngaba ungathanda ingcebiso kwi ubungakanani obufanelekileyo bokuvula kunye nemathiriyeli ngokusekelwe kwisicelo sakho? Ndazise imfuneko yakho umgangatho wokuhluza (μm)!

|

|

|

Unyango loMphezulu

|

1. I-Pickling (intsimbi engatyiwayo (304, 316L), intsimbi yekhabhoni, ialloy esekwe nickel (iMonel, Hastelloy)

2. Ukupholisha kwe-Electrolytic (intsimbi engenanto (304, 316L), ialloyi esekwe nickel (iMonel, Hastelloy))

3. Sandblasting (Iron, carbon steel, stainless steel (304, 316L), titanium alloy, nickel-based alloy (Monel, Hastelloy))

4. Ukugalela (intsimbi, intsimbi yekhabhoni)

5. Nickel Plating (Iron, carbon steel, stainless steel (304, 316L), ialloys nickel-based (Monel, Hastelloy))

njl.

|

|

Uhlobo lweWelding

|

I-Spiral Welding / i-Seam Welding (Iqinisekisa amandla aPhezulu kunye nokuSebenza kokutywina)

|

|

Ukuxhathisa Uxinzelelo

|

Ukuya kuthi ga kwi-30MPa (Inokulungiswa ngokusekwe kuMathiriyeli kunye nokutyeba)

|

|

Ukunyangwa kokuMhlwa

|

I-Acid kunye ne-Alkali ukumelana, i-High-Temperature Resistant, i-Oxidation Resistant

|

|

Uhlobo loQhagamshelwano

|

I-Flange Connection, i-Treaded Connection, i-Welded Connection, i-Clamping Type

|

|

Ulwelo olusebenzayo

|

Ulwelo, iigesi, ioyile, umphunga, njl.

|

|

Indlela yokucoca

|

Ukuhlamba umva, ukuCocwa kweMichiza, ukuCocwa kwe-Ultrasonic, i-High-Temperature Baking

|

|

Iinkalo zeSicelo

|

I-Petrochemical, igesi yeNdalo, ukuNyangwa kwamanzi okusiNgqongileyo, uKutya kunye neMichiza, iMetallurgy, iShishini laMandla, iShishini lezeMoto, njl.

|

|

Iimpawu zeMveliso

|

1. Isakhiwo esinamandla aphezulu, ukumelana noxinzelelo oluphezulu kunye nokugqwala

2. Ukugqobhoza okufanayo kokuhamba komoya okugqwesileyo kunye nokusebenza kakuhle kokucoca

3. Itekhnoloji ye-welding echanekileyo iqinisekisa ukuqina

4. Izinto ezinokwenziwa ngokwezifiso, ubukhulu bomngxuma, kunye ne-porosity ukuhlangabezana neemfuno ezithile zokucoca

|

![$ into[isihloko] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)