|

Ntho

|

Tlhaloso

|

|

Lebitso la Sehlahiswa

|

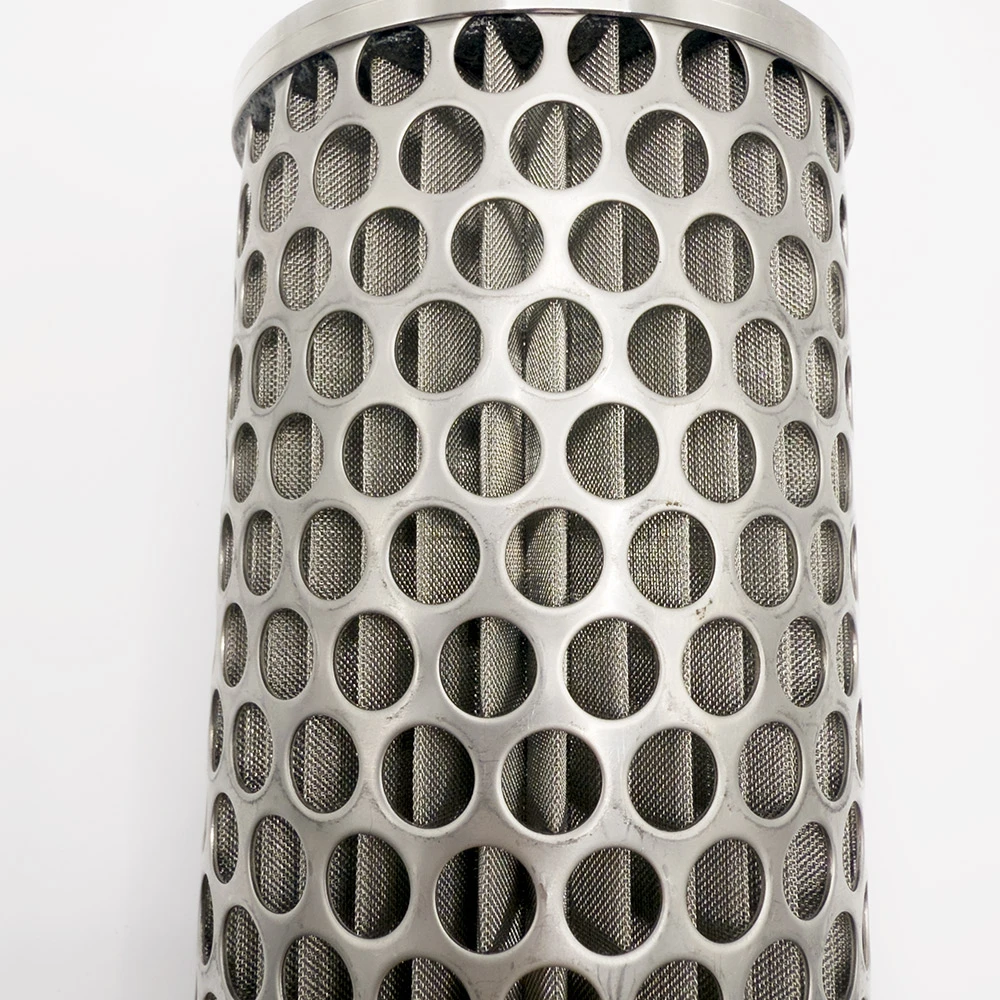

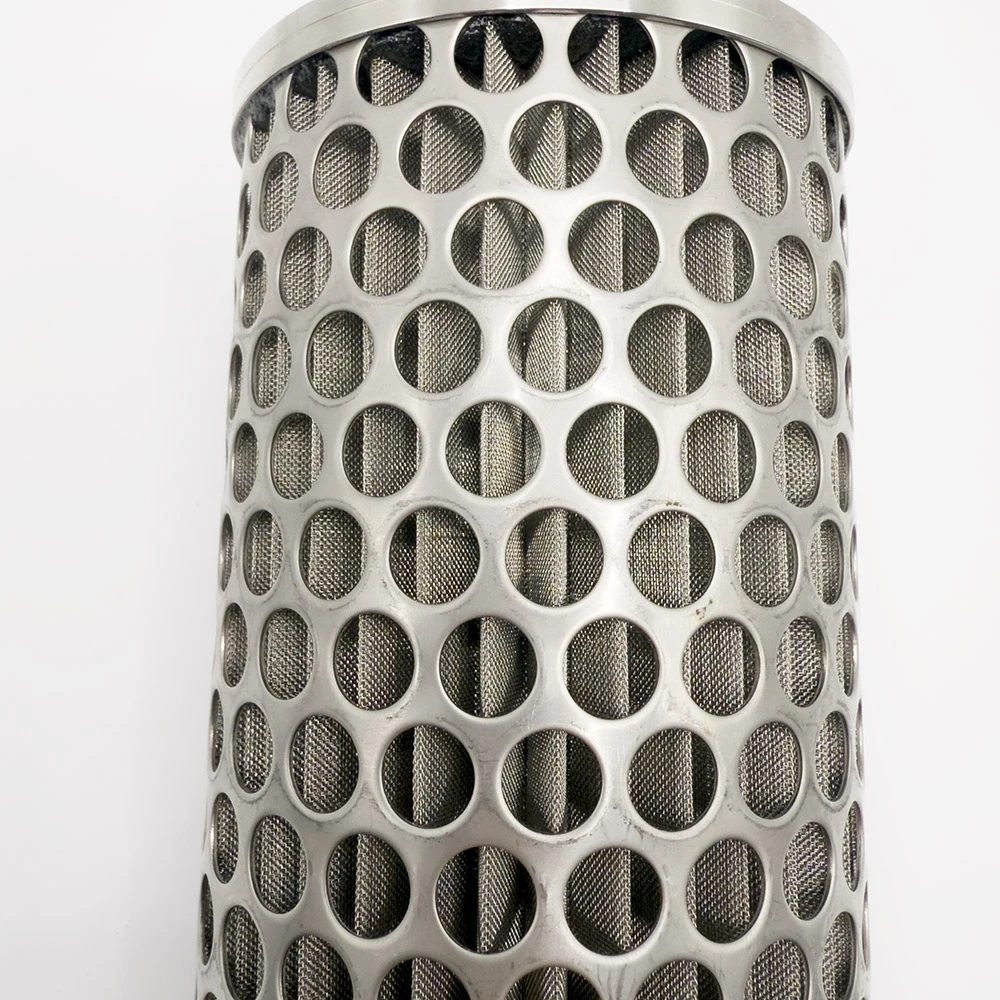

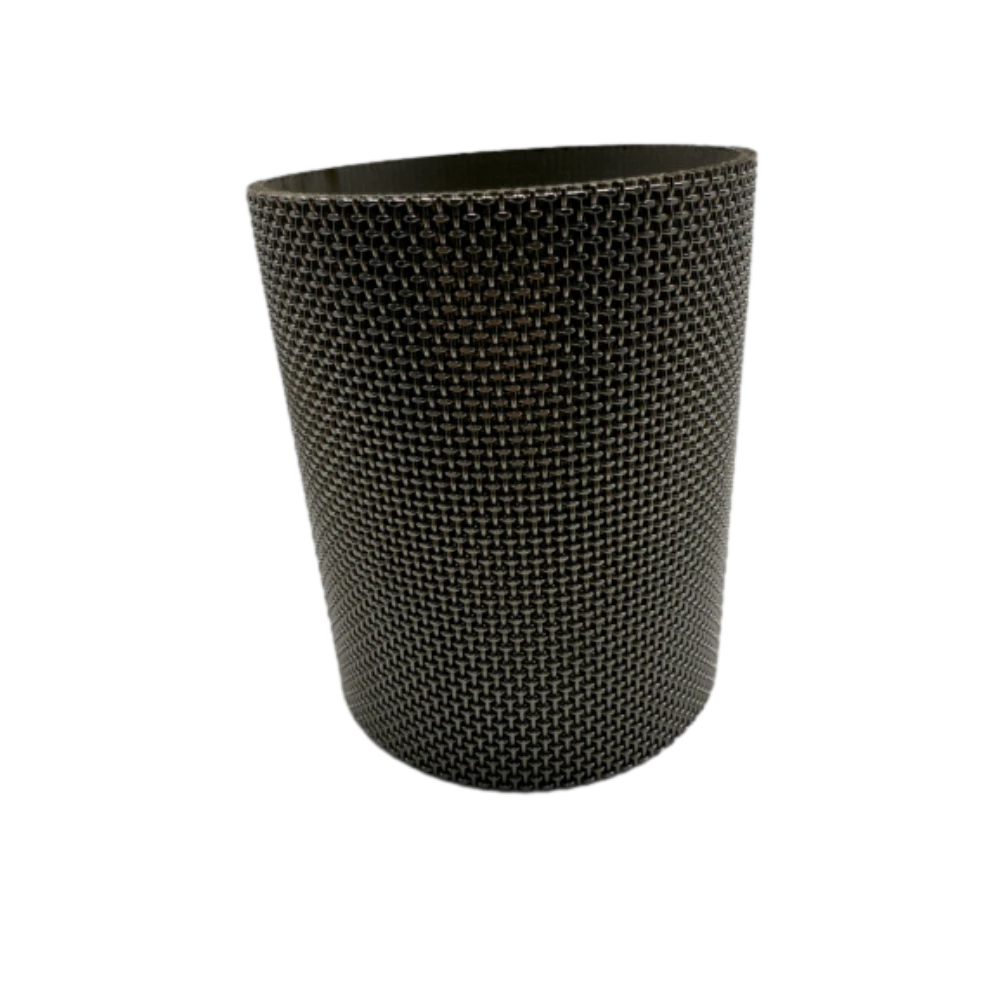

Element ea Sefe ea Indasteri e sa Hlokang

|

|

Lintho tse bonahalang

|

Stainless Steel (304, 316L), Nickel Alloy (Monel, Hastelloy), Titanium Alloy

|

|

Kantle Diameter

|

10mm - 600mm (Ho ka khoneha)

|

| Botenya ba Lerako |

0.3mm - 5mm (O ka khonahala)

|

|

Boholo ba Perforation

|

0.3mm - 10mm (Ho pota-pota, Sekwere, masoba a Slott a teng)

|

|

Sebaka se bulehileng

|

10% - 60% (E ka Itloaetsa ho ea ka Litlhoko tsa ho Filtration)

|

|

Mohlala oa Ho nepahala ha Filtration (μm)

|

|

Aperture size (mm)

|

Ho nepahala ha Filtration (μm)

|

Application

|

|

5.0

|

5000

|

ho ntsha karolo e kgolo

|

|

2.0

|

2000

|

e loketseng bakeng sa ho tlosa maloanlahla a maholo

|

|

1.0

|

1000

|

ho tlosa ditshila tse kgolo tse tiileng

|

|

0.5

|

500

|

ho hapa makumane a metsi

|

|

0.1

|

100

|

Filtration e ntle haholo

|

|

Bakeng sa tlhoekiso e nepahetseng e phahameng (1-50μm),a mokotla o eketsehileng oa sesefa kapa lesela le ka hare e ka kopanngoa le mesh e entsoeng ka tšepe e sa hloekang ho finyella ts'ebetso e phahameng.

O ka rata tlhahiso bakeng sa boholo bo nepahetseng ba lesoba le thepa ho latela kopo ea hau? Ntsebise seo u se hlokang tekanyetso ea ho sefa (μm)!

|

|

|

Kalafo ea Bokaholimo

|

1. Pickling (Stainless steel (304, 316L), carbon steel, nickel-based alloy (Monel, Hastelloy)

2. Electrolytic Polishing (Stainless steel (304, 316L), alloy e thehiloeng ho nickel (Monel, Hastelloy))

3. Sandblasting (Tšepe, carbon steel, stainless steel (304, 316L), motsoako oa titanium, alloy e thehiloeng ho nickel (Monel, Hastelloy))

4. Galvanizing (Tšepe, carbon steel)

5. Nickel Plating (Iron, carbon steel, stainless steel (304, 316L), li-alloys tse thehiloeng ho nickel (Monel, Hastelloy))

etc.

|

|

Mofuta oa Welding

|

Spiral Welding / Seam Welding (E netefatsa Matla a Phahameng le Ts'ebetso ea Tiiso)

|

|

Ho Hanyetsa Khatello

|

Ho fihla ho 30MPa (E ka feto-fetoha ho latela thepa le botenya)

|

|

Khanyetso ea Corrosion

|

E hanana le Asiti le Alkali, e hanana le Mocheso o Phahameng, e hanyetsanang le oxidation

|

|

Mofuta oa Khokahano

|

Khokahano ea Flange, Khokahano ea Khokahano, Khokahano e Welded, Mofuta oa Clamping

|

|

Mekelikeli e sebetsang

|

Mekelikeli, Ligase, Oli, Mouoane, joalo-joalo.

|

|

Mokhoa oa ho hloekisa

|

Ho hlatsoa mokokotlo, ho hloekisa lik'hemik'hale, ho hloekisa ka mokhoa oa Ultrasonic, ho baka ka mocheso o phahameng

|

|

Libaka tsa Kopo

|

Petrochemical, Khase ea Tlhaho, Phekolo ea Metsi a Tikoloho, Lijo le Litlhare, Metallurgy, Indasteri ea Matla, Indasteri ea Likoloi, joalo-joalo.

|

|

Likarolo tsa Sehlahisoa

|

1. Sebopeho sa matla a phahameng, se hanyetsanang le khatello e phahameng le ho senya

2. Perforation e ts'oanang bakeng sa phallo e nepahetseng ea moea le katleho ea ho sefa

3. Theknoloji ea welding e nepahetseng e tiisa ho tšoarella

4. Lisebelisoa tse Customizable, boholo ba lesoba, le porosity ho finyella litlhoko tse khethehileng tsa ho hloekisa

|

![$ntho[sehlooho] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)