Mesh ea sefahla

1. Teko ea lintho tse bonahalang: Hlahloba hore na lisebelisoa tsa mesh li finyella litlhoko tsa bareki, tse kang tšepe e sa jeleng paate, tšepe e entsoeng ka masenke, motsoako oa aluminium, kapa lisebelisoa tse ling tse thibelang ho bola.

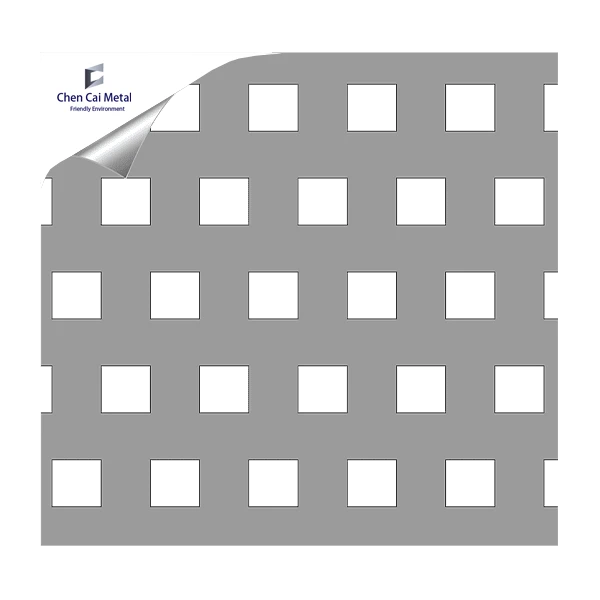

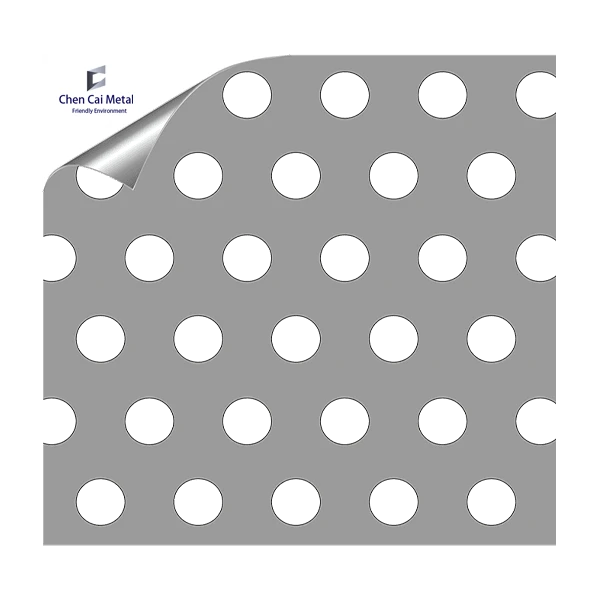

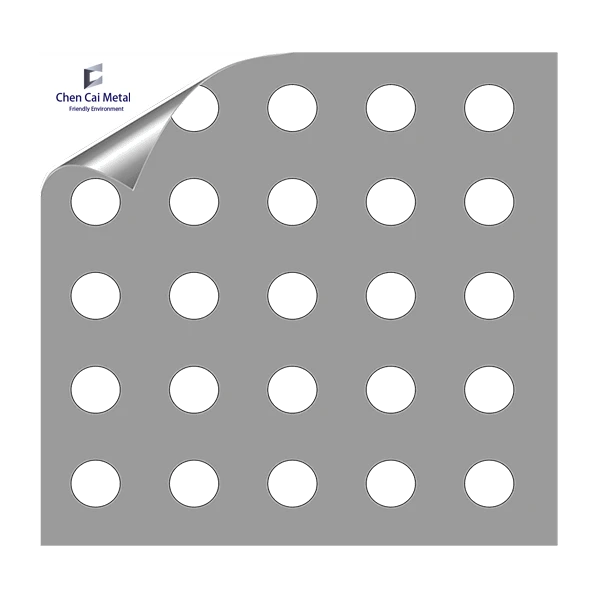

2. Mesh boholo: Lekanya hore na boholo ba marang-rang ba sehlahisoa bo kopana le mokhoa o nepahetseng oa ho hloekisa, ho qoba likaroloana tse ke keng tsa hloekisoa ho feta tekanyo kapa tse ke keng tsa hloekisoa.

3. Ho lemoha bophara ba terata le botenya: Sebelisa lisebelisoa tsa ho lekanya tsa setsebi ho hlahloba hore na terata ea tšepe e kopana le bophara ba terata e tloaelehileng kapa hore na poleiti e kopana le botenya bo tloaelehileng ho netefatsa litlhoko tsa bareki.

4. Boleng ba ho tjheseletsa le lintlha tsa ho hokahanya: Hlahloba hore na lintlha tsa welding sebakeng se seng le se seng li tšoana, li tiile, le hore na ho na le li-welds, fractures, kapa burrs, ho netefatsa hore moreki o fumana sehlahisoa ntle le ho thibela kapa ho lutla nakong ea tšebeliso.

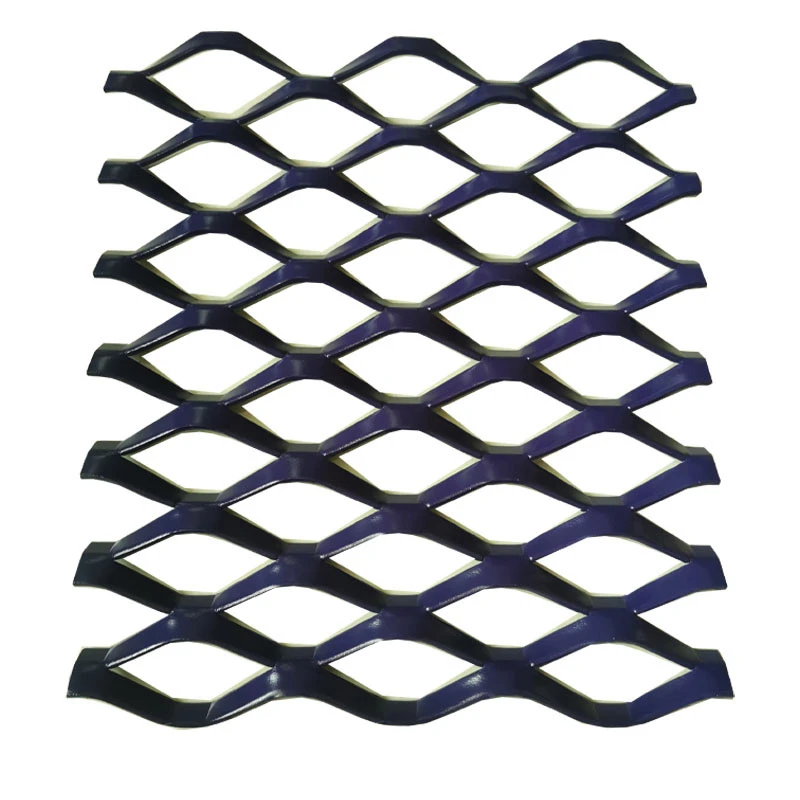

5. Phekolo ea holim'a metsi: Hlahloba hore na bokaholimo ba sehlahisoa bo tšoeroe joalo ka ha ho hlokahala, joalo ka electroplating, polishing, spraying, kapa electrolysis, joalo-joalo.

6. Teko ea khatello le tlhahlobo ea nako e telele: ho lekanya matla a hatellang a sehlahisoa ka lisebelisoa tsa setsebi ho netefatsa hore sefefo se ka sebetsa tlas'a maro a itseng a khatello.

7. Hlahloba bohloeki: Hlahloba sehlahisoa bakeng sa matheba a oli, litšila, kapa litšila tse ling.

![$ntho[sehlooho] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)