|

Into

|

Inkcazo

|

|

Igama lemveliso

|

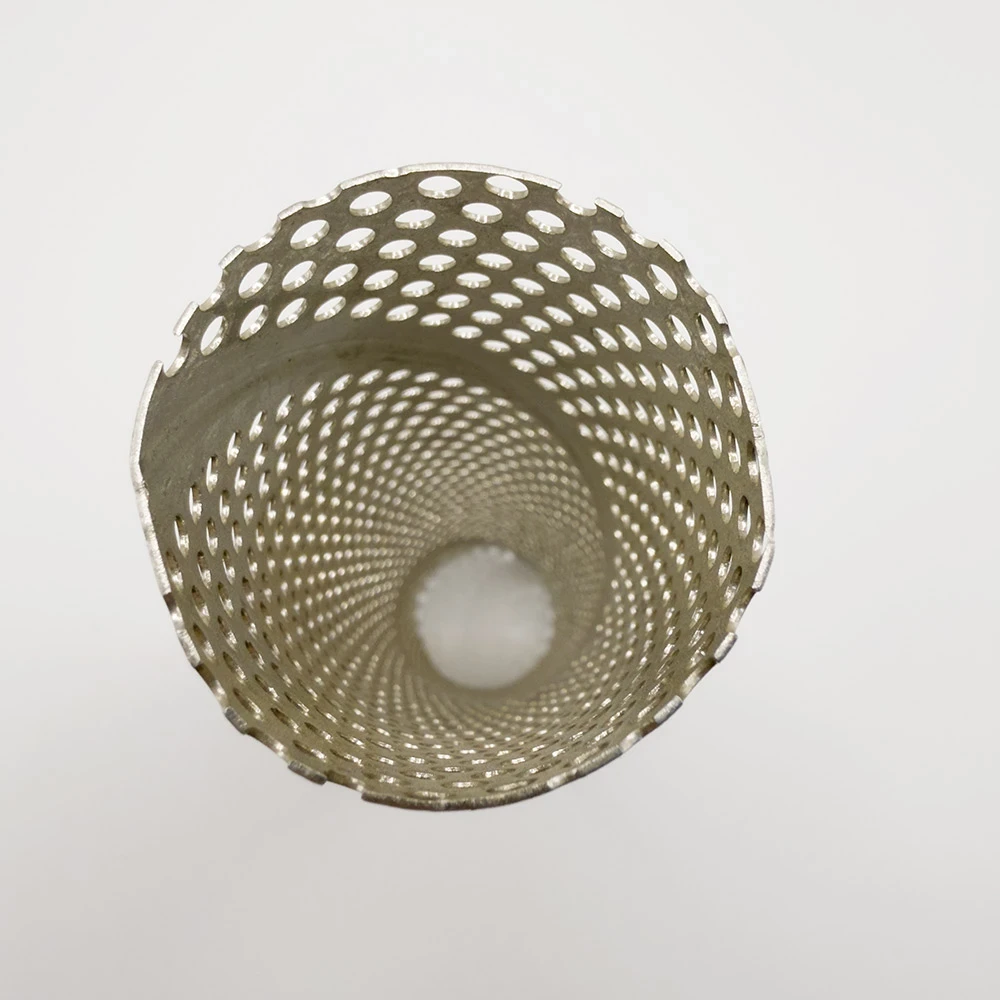

I-Spiral Welded Perforated Tube

|

|

Ekrwada Izinto eziphathekayo

|

1. iStainless Steel (304, 316L)

2. Intsimbi yeCarbon

3. I-Nickel Alloys (Monel, Hastelloy)

4. I-Titanium Alloy, njl.

|

|

Uluhlu lweDayimitha yeTubhu

|

0.5mm - 1000mm (Inokwenzeka ngokwezifiso)

|

|

Ukutyeba kweendonga

|

0.3mm - 5mm (Inokwenzeka ngokwezifiso)

|

|

Ubungakanani bomngxuma

|

0.5mm - 20mm (Iyafumaneka kumngxunya ongqukuva, isikwere, kunye neslot-shaped)

|

|

Open Area ratio

|

I-10% - 60% (Inokwenziwa ngokwezifiso ngokusekelwe kwiimfuno zokucoca)

|

|

Unyango loMphezulu

|

1. I-Pickling (intsimbi engatyiwayo (304, 316L), intsimbi yekhabhoni, ialloy esekwe nickel (iMonel, Hastelloy)

2. Ukupholisha kwe-Electrolytic (intsimbi engenanto (304, 316L), ialloyi esekwe nickel (iMonel, Hastelloy))

3. Sandblasting (Iron, carbon steel, stainless steel (304, 316L), titanium alloy, nickel-based alloy (Monel, Hastelloy))

4. Ukugalela (intsimbi, intsimbi yekhabhoni)

5. Nickel Plating (Iron, carbon steel, stainless steel (304, 316L), ialloys nickel-based (Monel, Hastelloy))

njl.

|

|

Indlela yokuWelding

|

I-Spiral Welding (I-Welding Precision Automated Automated for the Strong and Tyling)

|

|

Ukuxhathisa Uxinzelelo

|

Ukuya kuthi ga kwi-30MPa (Iyahluka ngokusekelwe kwizinto kunye nobukhulu)

|

|

Ukunyangwa kokuMhlwa

|

Ukumelana neeasidi, iialkali, ubushushu obuphezulu, kunye ne-oxidation

|

|

Uhlobo loQhagamshelwano

|

I-Flange Connection, i-Treaded Connection, i-Welded Joint, i-Clamping

|

|

Ulwelo olusebenzayo

|

Ilungele ulwelo, iigesi, i-oyile, umphunga, njl.

|

|

Iindlela zokucoca

|

Ukuhlamba umva, ukuCocwa kweMichiza, ukuCocwa kwe-Ultrasonic, i-High-Temperature Baking

|

|

Iinkalo zeSicelo

|

I-Petroleum, iShishini leMichiza, ukuNyangwa kwamanzi okusiNgqongileyo, uKutya kunye neMichiza, iMetallurgy, iShishini laMandla, iShishini lezeMoto, njl.

|

|

Iimpawu zeMveliso

|

1. Isakhiwo samandla aphezulu kunye noxinzelelo oluhle kakhulu kunye nokumelana nokubola

2. Ukugqobhoza okulinganayo ukwenzela ukuhamba komoya kunye nokucoca

3. Ukuchaneka kwe-spiral welding iqinisekisa ukuhlala kunye nokuthembeka

4. Izinto ezinokwenziwa ngokwezifiso, ubungakanani bomngxuma, kunye nomlinganiselo wendawo evulekileyo kwiimfuno ezahlukeneyo zokuhluza

|

![$ into[isihloko] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)