|

Item

|

Description

|

|

Product Name

|

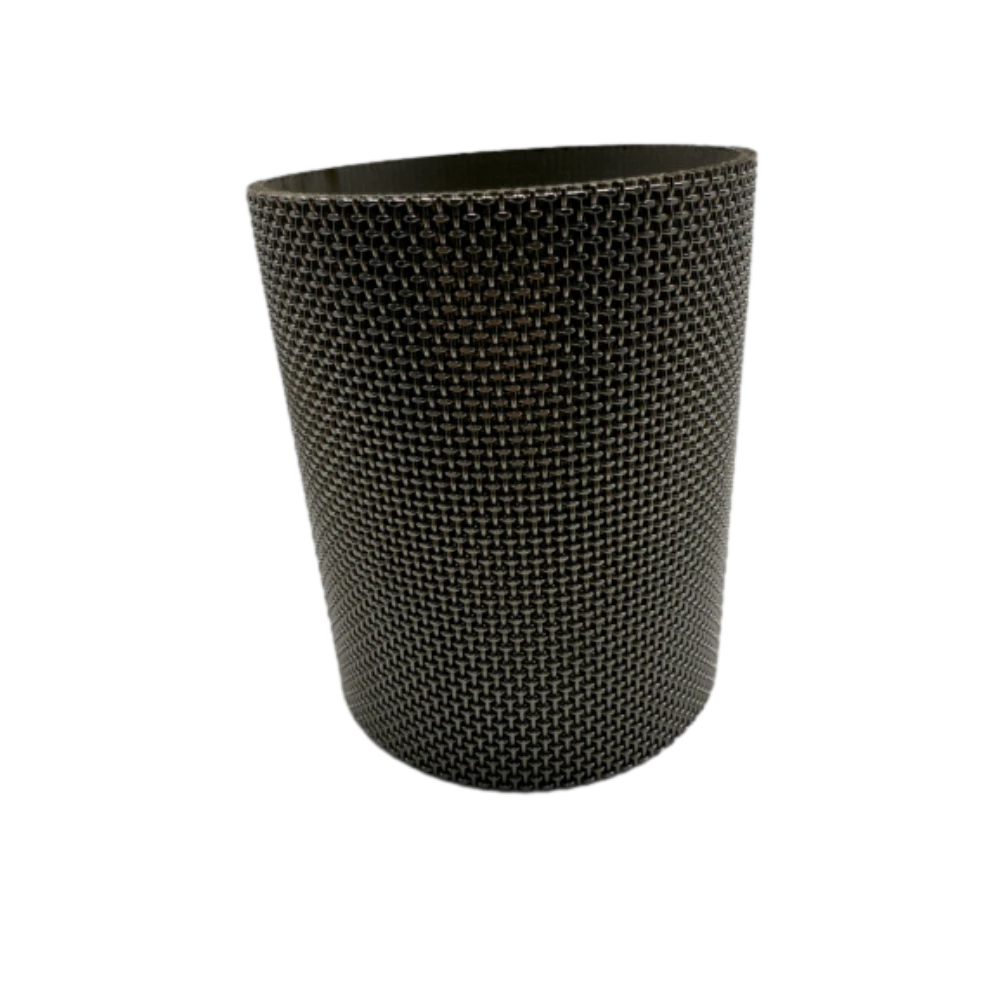

Y-Strainer Filter Mesh

|

|

Material

|

Stainless Steel (304, 316L), Carbon Steel, Nickel-Based Alloys (Monel, Hastelloy), Titanium Alloys, etc.

|

|

Mesh Size

|

Customizable according to filtration requirements

|

|

Wire Diameter

|

0.1mm - 5mm (customizable)

|

|

Filtration Precision

|

5μm - 2000μm (depending on mesh size)

|

|

Structure

|

Single-layer or multi-layer mesh with reinforced frame

|

|

Surface Treatment

|

1. Pickling(Stainless steel (304, 316L), carbon steel, nickel-based alloy (Monel, Hastelloy)

2. Electrolytic Polishing(Stainless steel (304, 316L), nickel-based alloy (Monel, Hastelloy))

3. Sandblasting (Iron, carbon steel, stainless steel (304, 316L), titanium alloy, nickel-based alloy (Monel, Hastelloy))

4. Galvanizing(Iron, carbon steel)

5. Nickel Plating(Iron, carbon steel, stainless steel (304, 316L), nickel-based alloys (Monel, Hastelloy))

etc.

|

|

Welding Method

|

Precision spot welding, TIG welding, laser welding

|

|

Pressure Resistance

|

Up to 30MPa (varies with material and thickness)

|

|

Corrosion Resistance

|

Acid & alkali resistant, high-temperature resistant, oxidation resistant

|

|

Connection Type

|

Flange connection, threaded connection, welded connection, clamp type

|

|

Applicable Fluids

|

Liquids, gases, oils, steam, etc.

|

|

Cleaning Method

|

Backwashing, chemical cleaning, ultrasonic cleaning, high-temperature baking

|

|

Application Fields

|

Petroleum & chemical industry, natural gas, environmental water treatment, food & pharmaceutical, metallurgy, power plants, automotive industry, etc.

|

|

Product Features

|

1. High-strength structure, pressure and corrosion-resistant

2. Uniform mesh opening for excellent permeability

3. Advanced welding technology ensures durability

4. Customizable materials, mesh sizes, and filtration precision to meet specific requirements

|

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)