|

Items

|

Description

|

|

Product Name

|

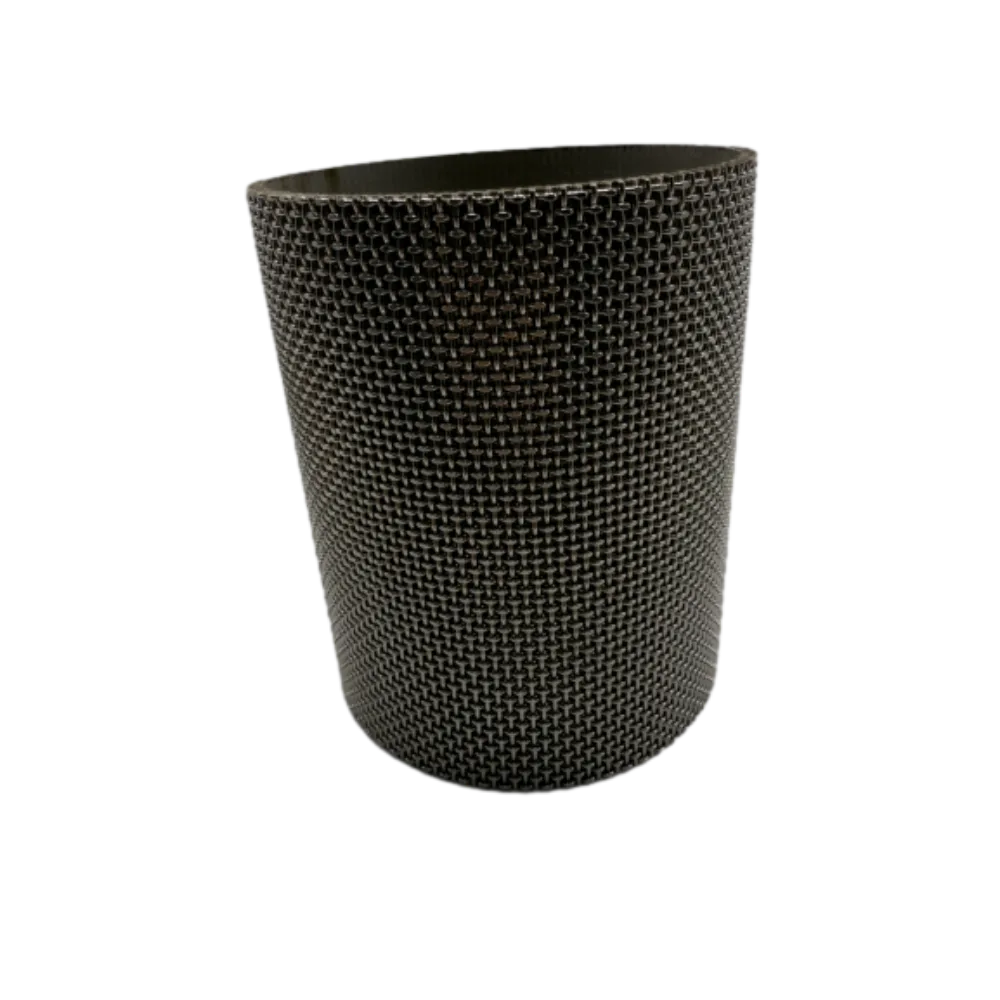

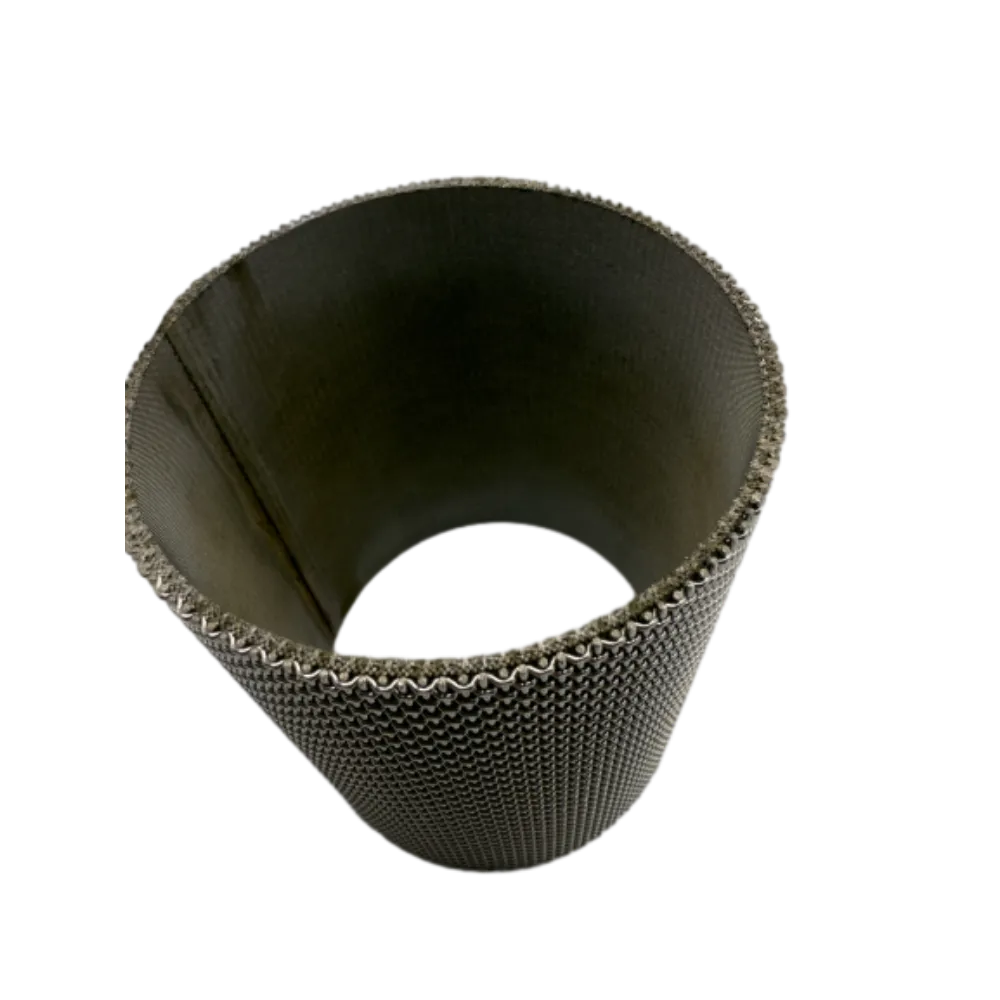

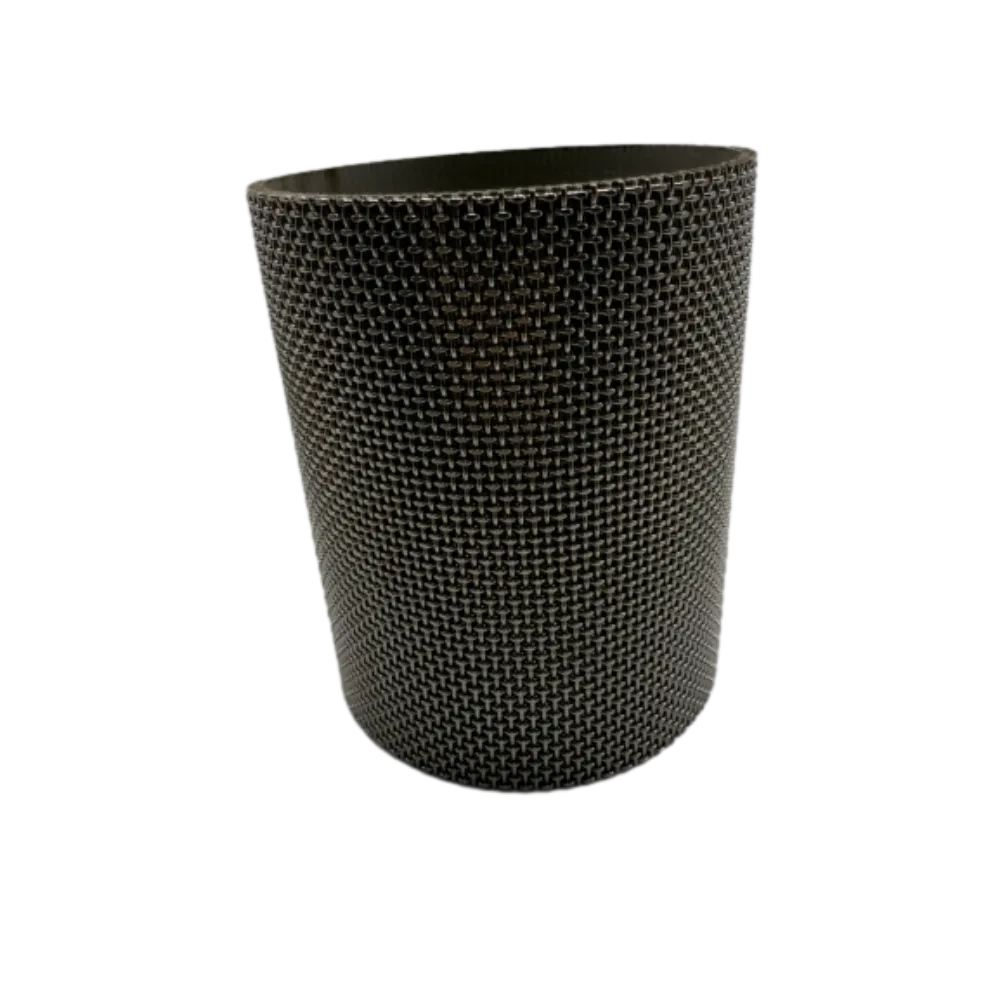

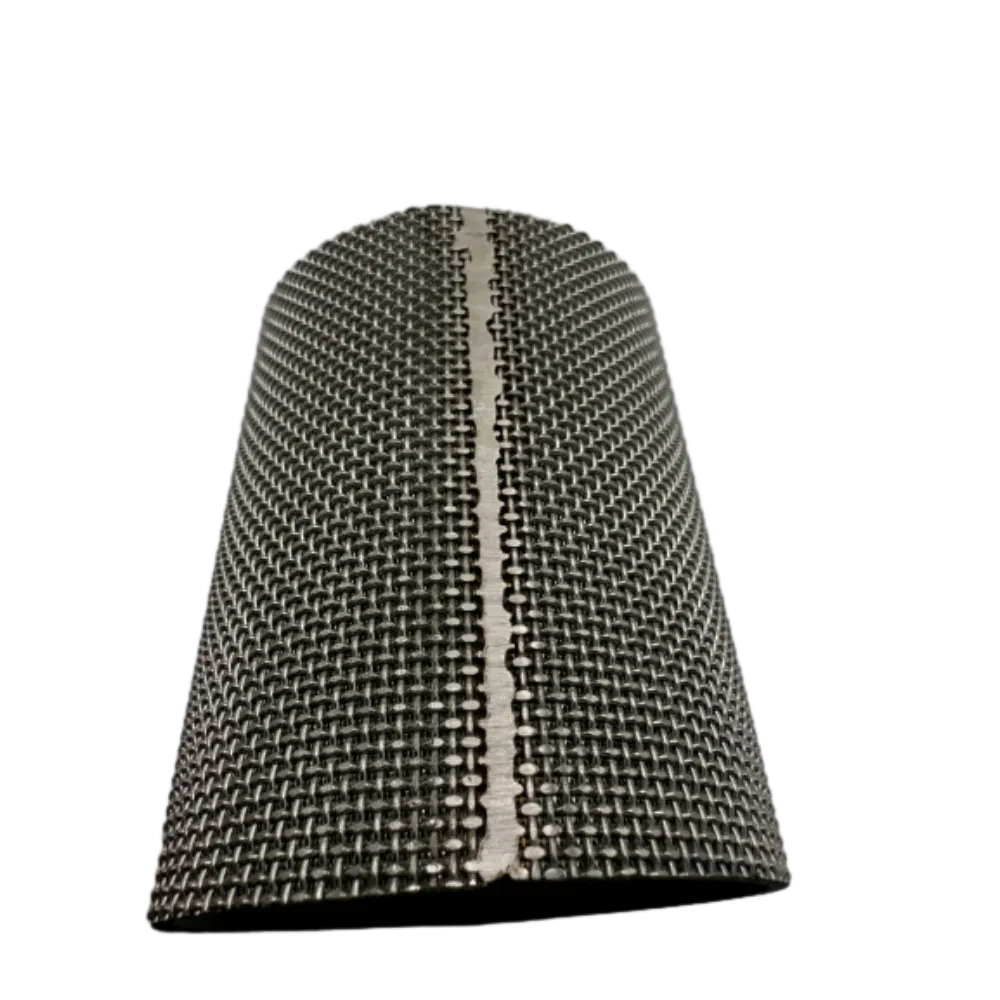

Sintered Wire Mesh Tube

|

|

Manufacturing Process

|

1. Sintering:At high temperatures, the diffusion of metal particles binds the metal mesh together to form a cohesive structure

2. Rolling:By high-pressure rolling, each mesh layer is tightly connected to ensure its thickness uniformity.

3. Laser Cutting/Plasma Cutting:Cutting Sintered Wire Mesh,Ensure that the cutting is precise in size and shape.

4. Welding:Used for welding into a cylindrical shape

|

|

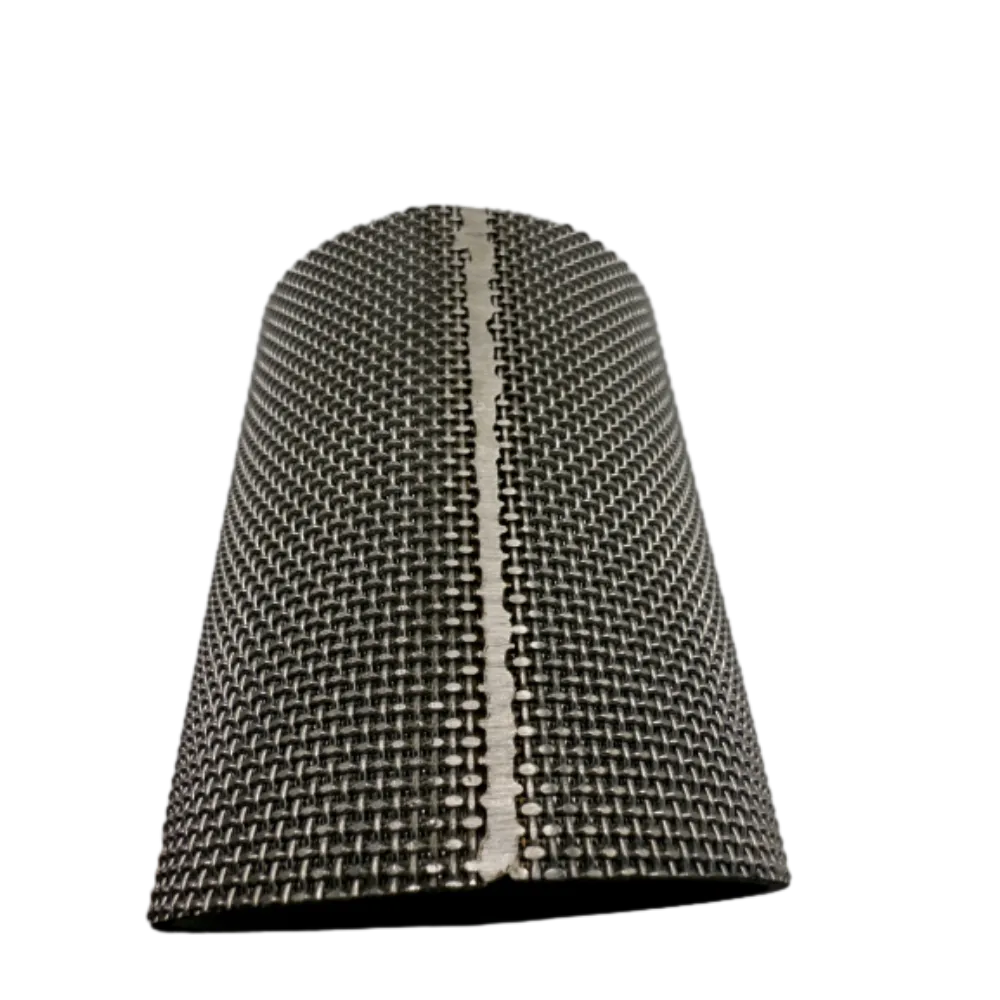

Woven way of woven wire mesh

|

1. Plain Weave (The most common weaving method has uniform mesh holes and is suitable for general filtration)

2. Twill Weave(Higher filtering accuracy, tighter structure, suitable for high-precision filtering)

3. Dutch Weave(A high-density filtering structure is formed by interweaving coarse warp threads and fine weft threads, commonly used for ultrafine filtration)

4. Reverse Dutch Weave(Has higher strength and load-bearing capacity, suitable for high-pressure filtration)

|

|

Material Alternatives

|

1. Stainless Steel (304, 316, 316L)

2. Nickel Alloy(Monel、Hastelloy、Inconel)

3. Titanium Mesh

ETC

|

|

Number of Layers

|

3, 5, 7 layers (or customized multi-layer structure)

|

|

Filtration Accuracy

|

1μm - 200μm (customizable)

|

|

Thickness Range

|

0.5mm - 5mm (varies by the number of layers)

|

|

Hole Size Distribution

|

Gradient pore design for efficient filtration and fluid flow

|

|

Surface Treatment

|

Acid pickling(Stainless Steel/Carbon steel),

Electrolytic Polishing(Stainless Steel)

Nickel plating(Stainless Steel/Carbon Steel)

Anodizing(Aluminum) etc.

|

|

Operating Temperature

|

-200℃ to 600℃ (depending on material)

|

|

Pressure Resistance

|

Up to 30MPa or higher (varies based on mesh layers and thickness)

|

|

Permeability / Flow Resistance

|

Low resistance and high permeability, suitable for gas and liquid filtration

|

|

Corrosion Resistance

|

Resistant to acids, alkalis, salt spray, and oxidation in harsh environments

|

|

Cleaning Methods

|

Backwashing, Ultrasonic cleaning, High-temperature baking, Chemical cleaning, and reusable

|

|

Manufacturing Process

|

High-temperature vacuum sintering, Rolling, Welding, Stamping

|

|

Available Shapes

|

Cylindrical, Square, Sheet, Pleated, Custom shapes available

|

|

Connection Methods

|

Flange connection, Welding, Threaded connection, Clamping

|

|

Applicable Fluids

|

Suitable for liquids, gases, oils, steam, etc.

|

|

Application Fields

|

Petrochemical, Food & Beverage, Pharmaceuticals, Environmental Water Treatment, Aerospace, Automotive Industry, etc.

|

|

Product Advantages

|

1. High strength and pressure resistance, not easy to deform

2. Repeatable cleaning, long life

3. Precision filtration, uniform pore size distribution

4. High temperature and corrosion resistance, adaptable to harsh environments

|

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)