|

Item

|

Description

|

|

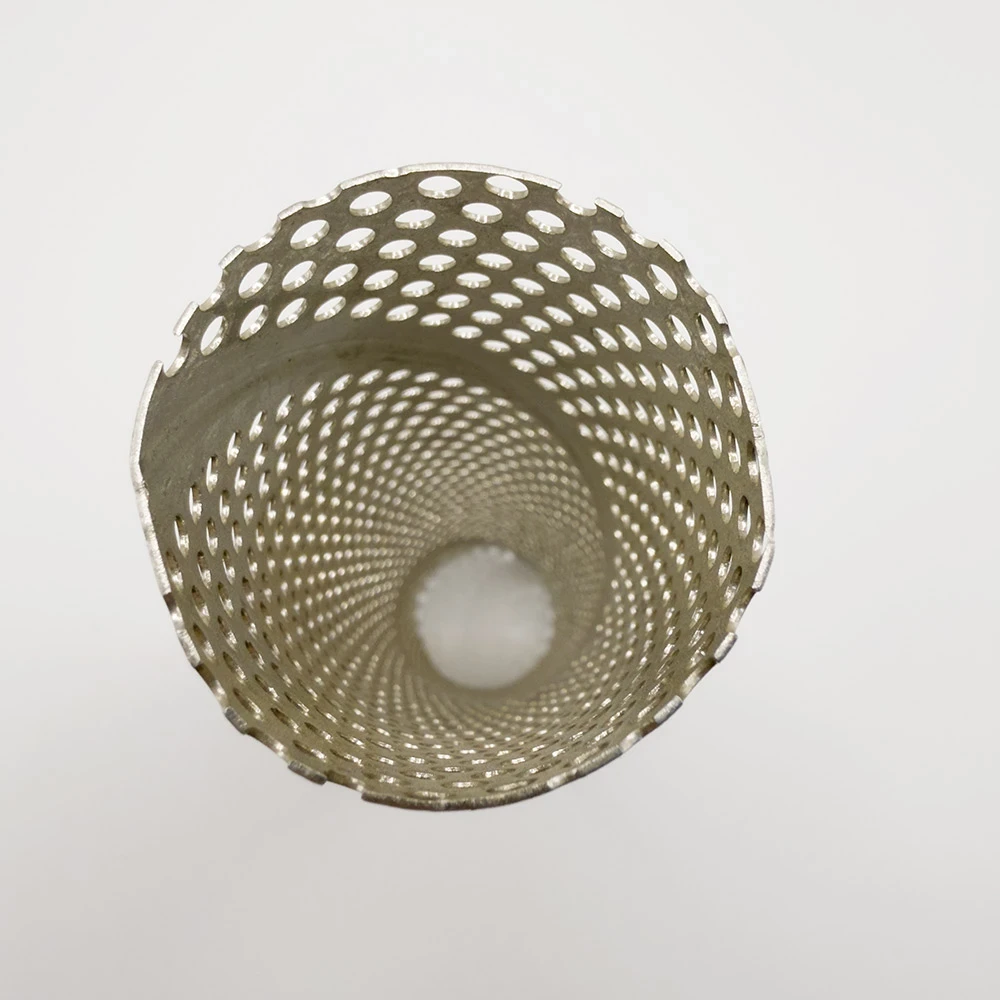

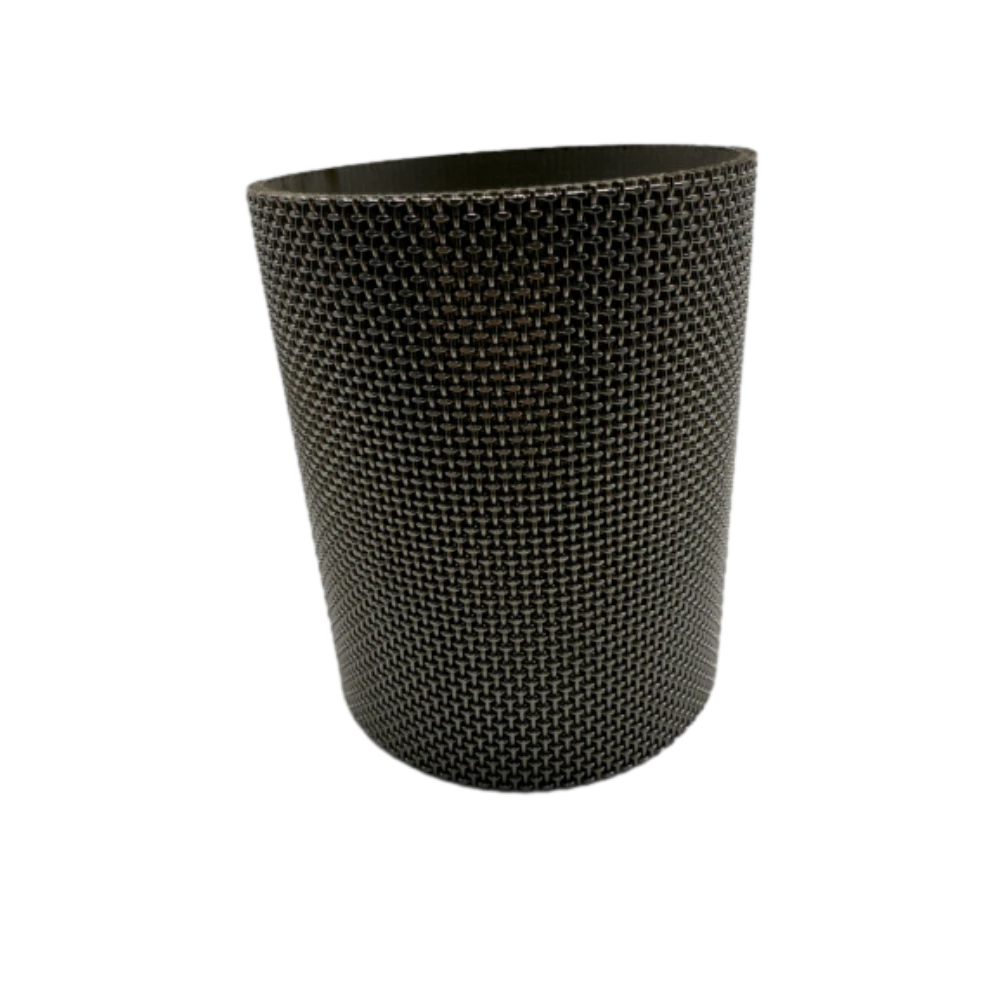

Product Name

|

Spiral Welded Perforated Tube

|

|

Raw Material

|

1. Stainless Steel (304, 316L)

2. Carbon Steel

3. Nickel Alloys (Monel, Hastelloy)

4. Titanium Alloy, etc.

|

|

Tube Diameter Range

|

0.5mm - 1000mm (Customizable)

|

|

Wall Thickness

|

0.3mm - 5mm (Customizable)

|

|

Hole Size

|

0.5mm - 20mm (Available in round, square, and slot-shaped holes)

|

|

Open Area Ratio

|

10% - 60% (Customizable based on filtration requirements)

|

|

Surface Treatment

|

1. Pickling(Stainless steel (304, 316L), carbon steel, nickel-based alloy (Monel, Hastelloy)

2. Electrolytic Polishing(Stainless steel (304, 316L), nickel-based alloy (Monel, Hastelloy))

3. Sandblasting (Iron, carbon steel, stainless steel (304, 316L), titanium alloy, nickel-based alloy (Monel, Hastelloy))

4. Galvanizing(Iron, carbon steel)

5. Nickel Plating(Iron, carbon steel, stainless steel (304, 316L), nickel-based alloys (Monel, Hastelloy))

etc.

|

|

Welding Method

|

Spiral Welding (Precision Automated Welding for Strength and Sealing)

|

|

Pressure Resistance

|

Up to 30MPa (Varies based on material and thickness)

|

|

Corrosion Resistance

|

Resistant to acids, alkalis, high temperatures, and oxidation

|

|

Connection Type

|

Flange Connection, Threaded Connection, Welded Joint, Clamping

|

|

Applicable Fluids

|

Suitable for liquids, gases, oils, steam, etc.

|

|

Cleaning Methods

|

Backwashing, Chemical Cleaning, Ultrasonic Cleaning, High-Temperature Baking

|

|

Application Fields

|

Petroleum, Chemical Industry, Environmental Water Treatment, Food & Pharmaceuticals, Metallurgy, Power Industry, Automotive Industry, etc.

|

|

Product Features

|

1. High-strength structure with excellent pressure and corrosion resistance

2. Uniform perforation for optimal airflow and filtration

3. Precision spiral welding ensures durability and reliability

4. Customizable materials, hole sizes, and open area ratios for various filtration needs

|

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)