|

Abubuwa

|

Bayani

|

|

Sunan samfur

|

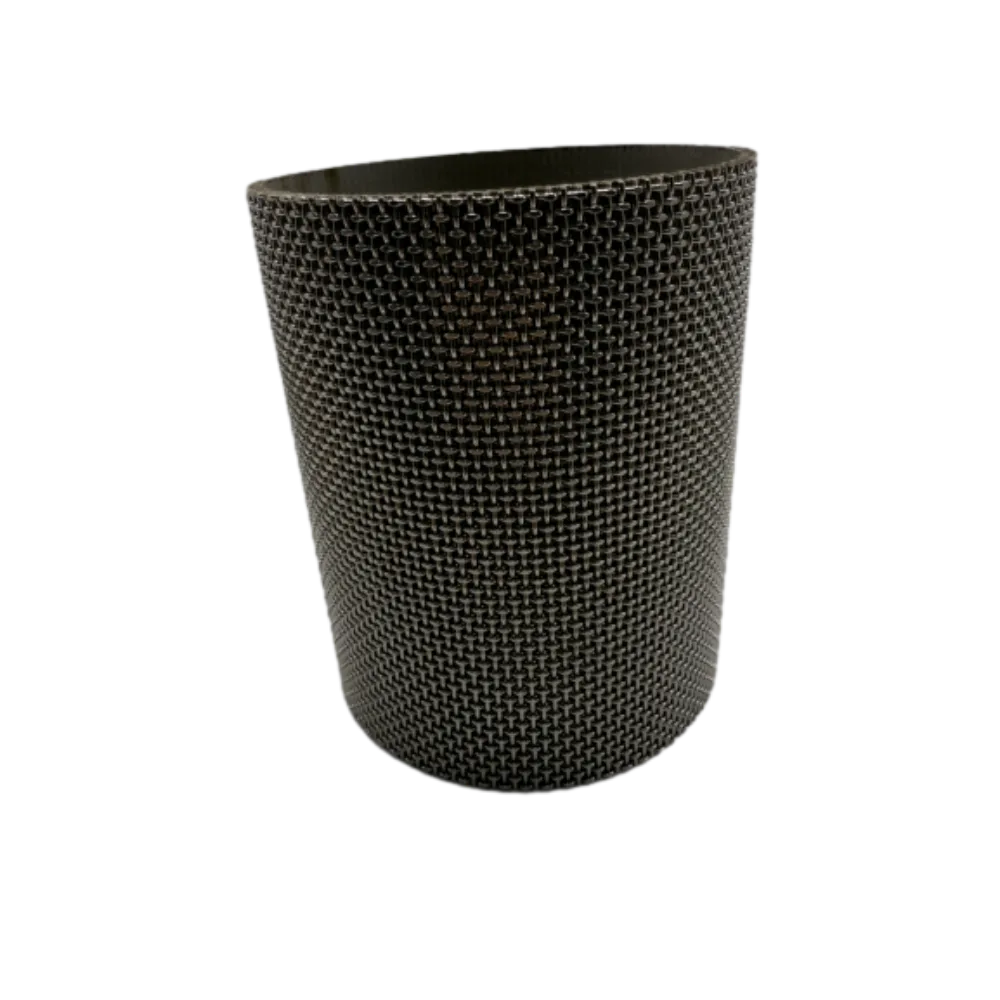

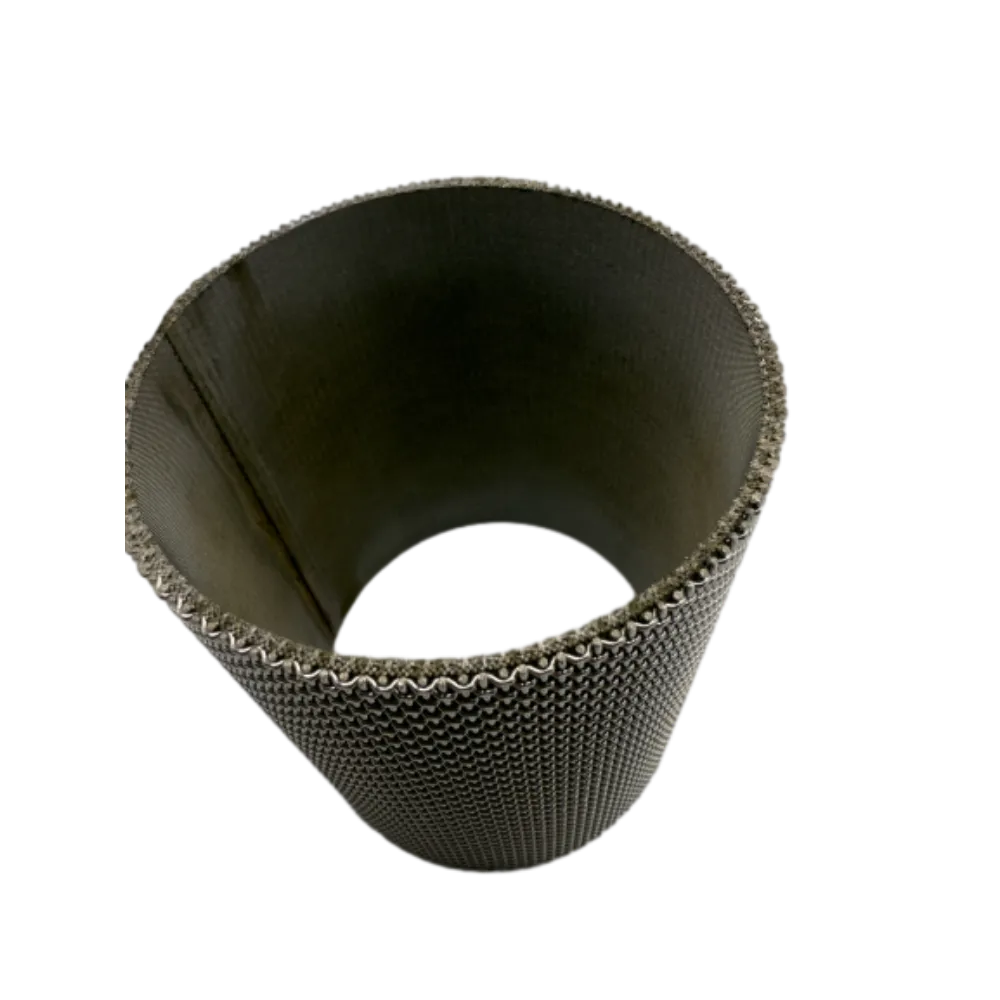

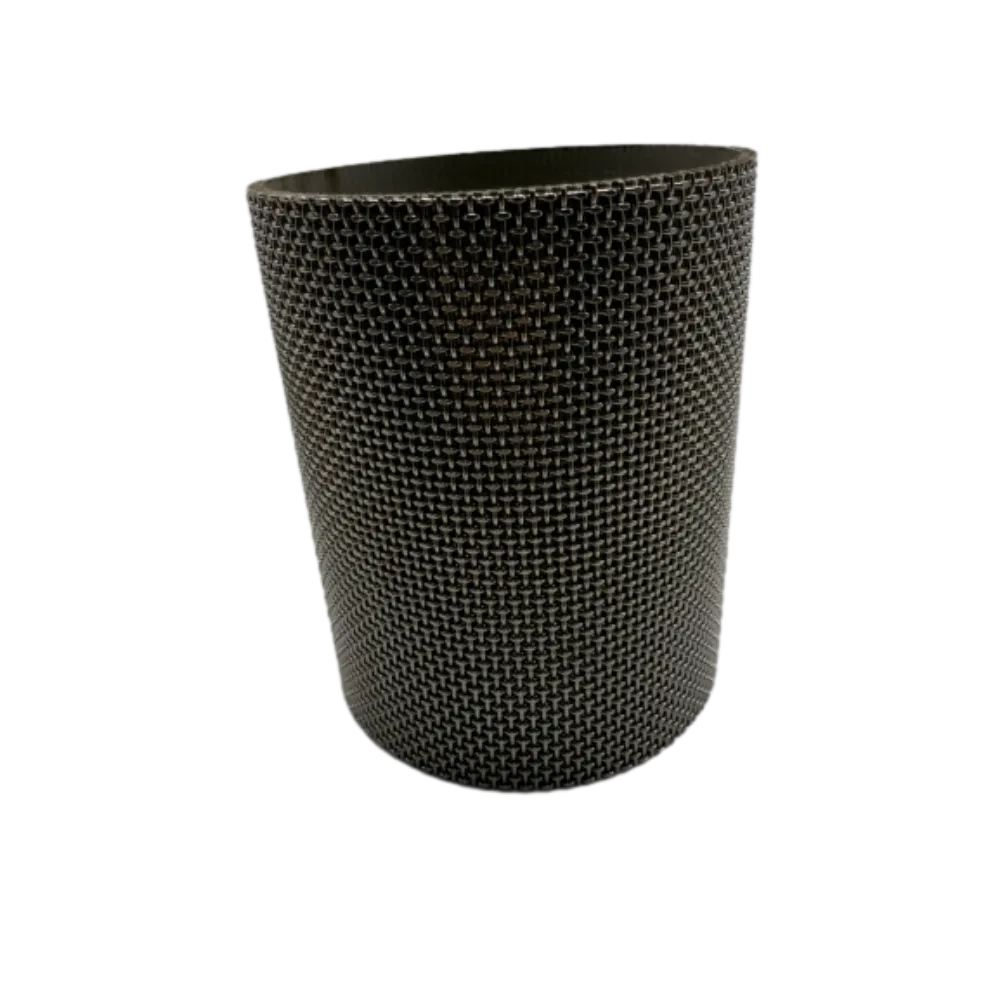

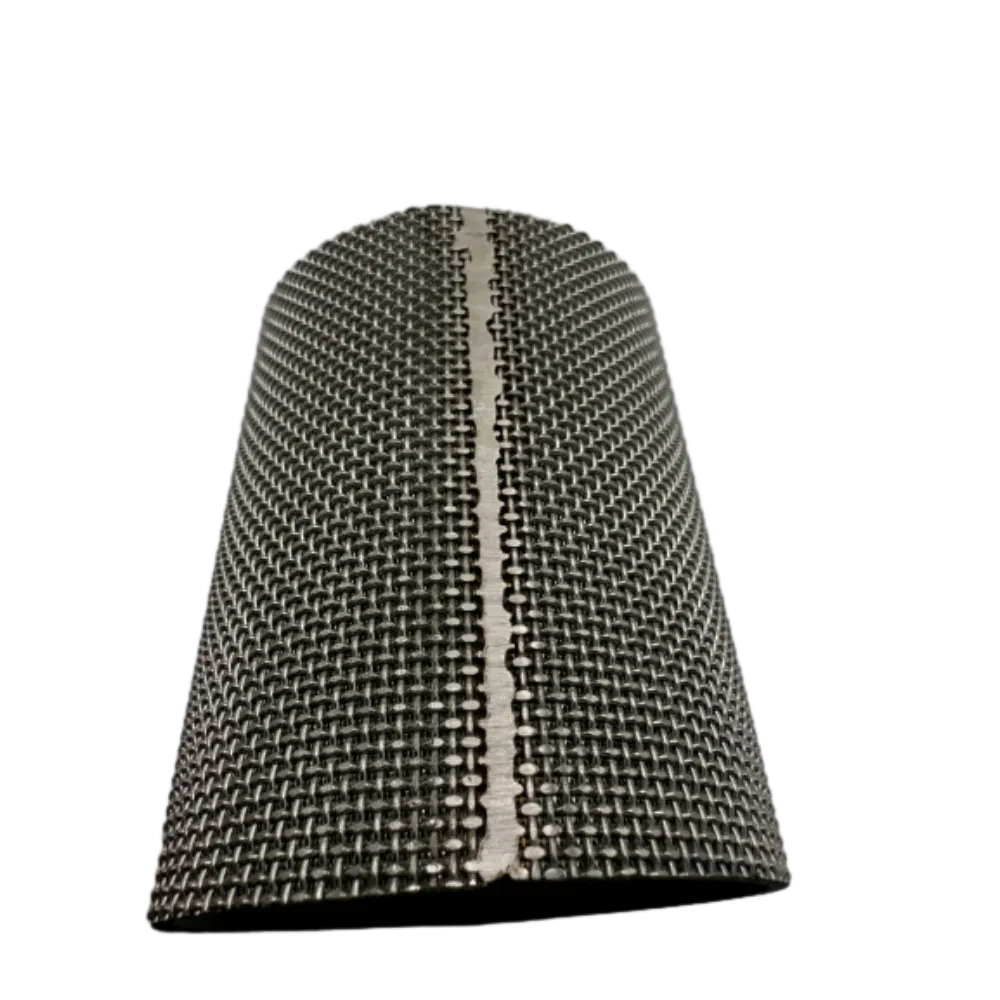

Sintered Wire Mesh Tube

|

|

Tsarin Masana'antu

|

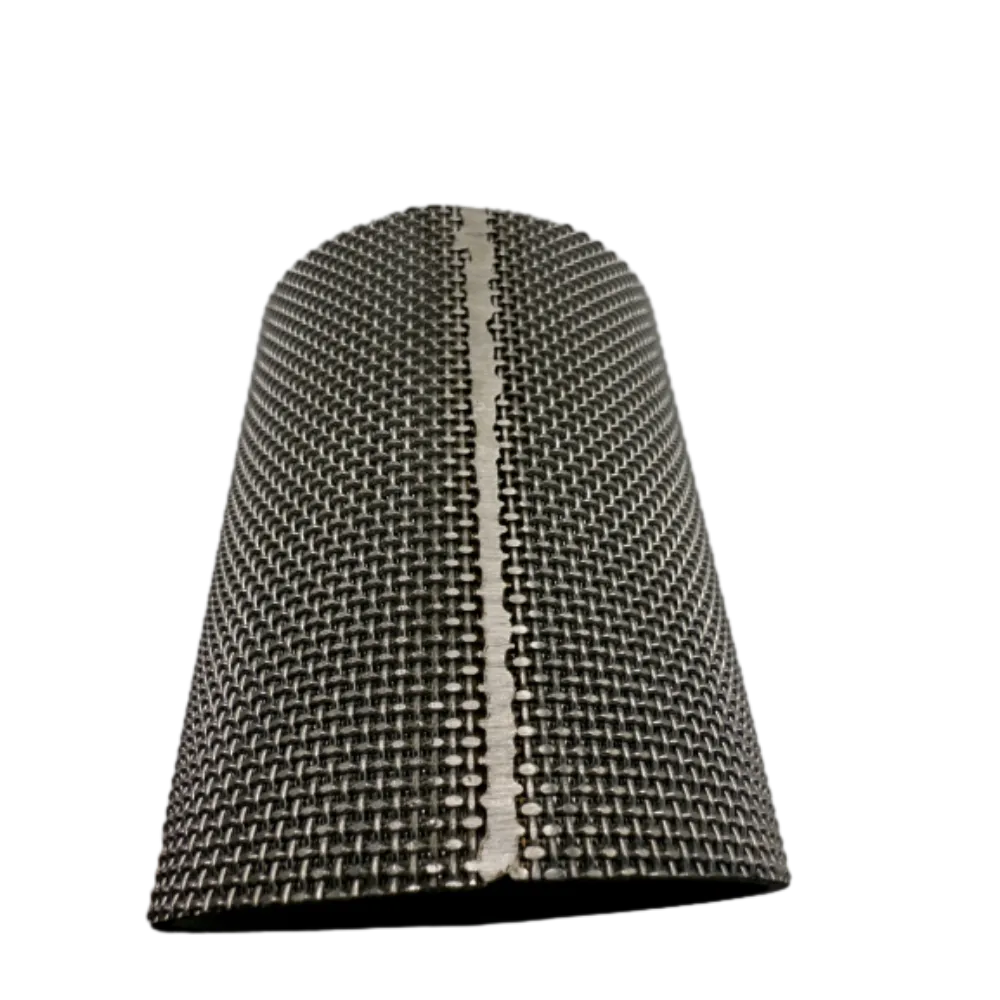

1. Sintering: A yanayin zafi mai yawa, yaduwar barbashi na ƙarfe yana ɗaure ragar ƙarfe tare don samar da tsarin haɗin gwiwa.

2. Mirgina: Ta hanyar jujjuyawa mai ƙarfi, kowane Layer raga yana haɗa tam don tabbatar da daidaiton kauri.

3. Yanke Laser / Plasma Yanke: Yanke ragamar Waya ta Sintered, Tabbatar cewa yankan daidai ne a girman da siffar.

4. Welding: Ana amfani da shi don waldawa cikin siffar silinda

|

|

Hanyar saƙa na ragar waya

|

1. Saƙa na fili (Hanyar saƙar da aka fi sani tana da ramuka iri ɗaya kuma ta dace da tacewa gabaɗaya)

2. Twill Weave(Higher tacewa daidaito, tighter tsarin, dace da high-daidaici tace)

3. Yaren Yaren mutanen Holland (Tsarin tacewa mai girma yana samuwa ta hanyar saka zaren warp masu kyau da zaren saƙa masu kyau, waɗanda aka saba amfani da su don tacewa)

4. Reverse Dutch Weave (Yana da ƙarfi mafi girma da ƙarfin ɗaukar nauyi, dace da tacewa mai ƙarfi)

|

|

Material Madadin

|

1. Bakin Karfe (304, 316, 316L)

2. Nickel Alloy (Monel, Hastelloy, Inconel)

3. Titanium Mesh

ETC

|

|

Yawan Layers

|

3, 5, 7 yadudduka (ko na musamman Multi-Layer tsarin)

|

|

Daidaiton Tacewa

|

1μm - 200μm (wanda za a iya sabawa)

|

|

Rage Kauri

|

0.5mm - 5mm (ya bambanta da adadin yadudduka)

|

|

Ramin Rarraba Girma

|

Ƙirar ƙura mai ƙyalli don ingantaccen tacewa da kwararar ruwa

|

|

Maganin Sama

|

Acid pickling (Bakin Karfe / Carbon Karfe),

Electrolytic Polishing (Bakin Karfe)

Nickel plating (Bakin Karfe/Carbon Karfe)

Anodizing (Aluminum) da dai sauransu.

|

|

Yanayin Aiki

|

-200 ℃ zuwa 600 ℃ (dangane da kayan)

|

|

Juriya na matsin lamba

|

Har zuwa 30MPa ko mafi girma (ya bambanta dangane da ragamar yadudduka da kauri)

|

|

Lalacewa / Juriya ta Guda

|

Low juriya da kuma high permeability, dace da gas da ruwa tacewa

|

|

Juriya na Lalata

|

Mai jure wa acid, alkalis, fesa gishiri, da oxidation a cikin yanayi mara kyau

|

|

Hanyoyin Tsaftacewa

|

Backwashing, Ultrasonic tsaftacewa, High-zazzabi yin burodi, Chemical tsaftacewa, da kuma sake amfani

|

|

Tsarin Masana'antu

|

Matsakaicin zafin jiki, mirgine, walda, tambari

|

|

Akwai Siffofin

|

Silindrical, Square, Sheet, Pleated, Akwai siffofi na musamman

|

|

Hanyoyin haɗi

|

Haɗin Flange, Welding, Threaded Connected, Clamping

|

|

Matsalolin Ruwa

|

Ya dace da ruwa, gas, mai, tururi, da sauransu.

|

|

Filin Aikace-aikace

|

Petrochemical, Abinci & Abin sha, Pharmaceuticals, Maganin Ruwa na Muhalli, Aerospace, Automotive Industry, da dai sauransu.

|

|

Amfanin Samfur

|

1. Babban ƙarfi da juriya na matsa lamba, ba sauƙin lalata ba

2. Maimaita tsaftacewa, tsawon rai

3. Daidaitaccen tacewa, rarraba girman pore iri ɗaya

4. Babban zafin jiki da juriya na lalata, daidaitawa zuwa yanayin yanayi

|

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)