Matsala raga

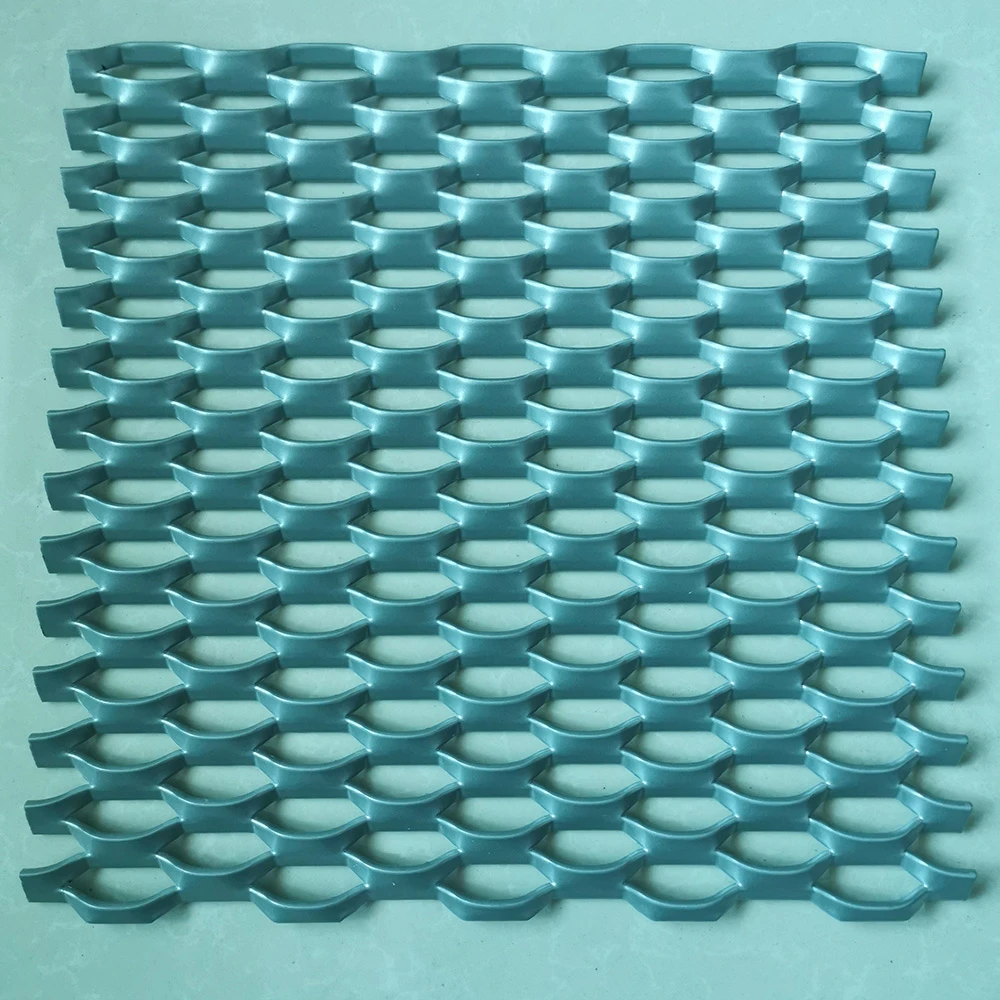

1. Gwajin kayan aiki: Bincika idan kayan raga sun hadu da buƙatun abokin ciniki, kamar bakin karfe, galvanized karfe, aluminum gami, ko wasu kayan da ke jurewa lalata.

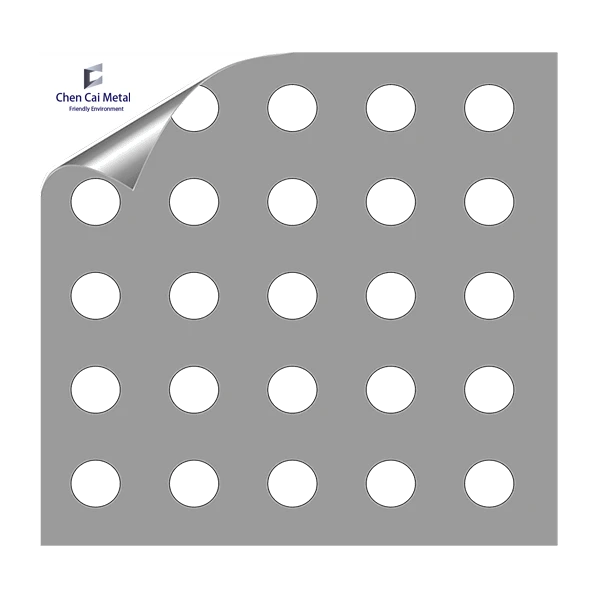

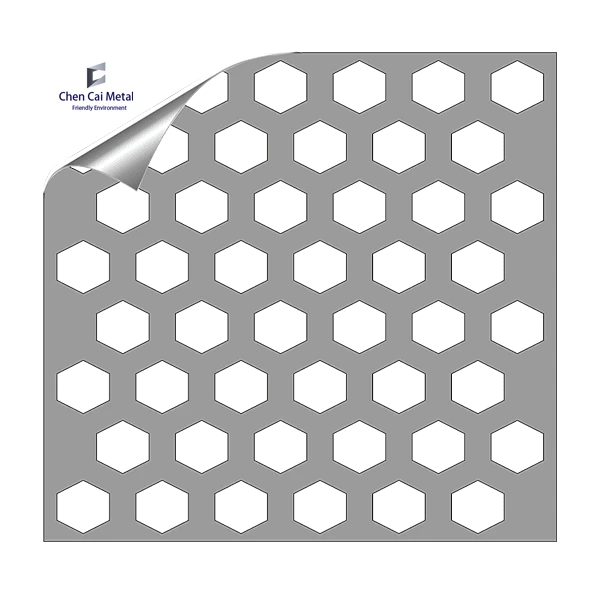

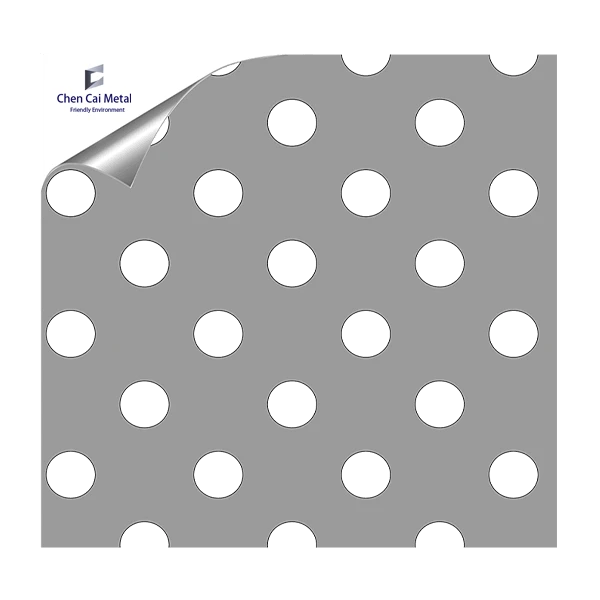

2. Girman raga: Auna ko girman raga na samfurin ya dace da ma'auni na daidaiton tacewa, don guje wa barbashi waɗanda ba za a iya tacewa fiye da ma'auni ko ba za a iya tace su ba.

3. Gano diamita na waya da kauri: Yi amfani da kayan aikin auna ƙwararru don bincika ko wayar ƙarfe ta dace da daidaitaccen diamita na waya ko kuma farantin ya dace da daidaitaccen kauri don tabbatar da buƙatun abokin ciniki.

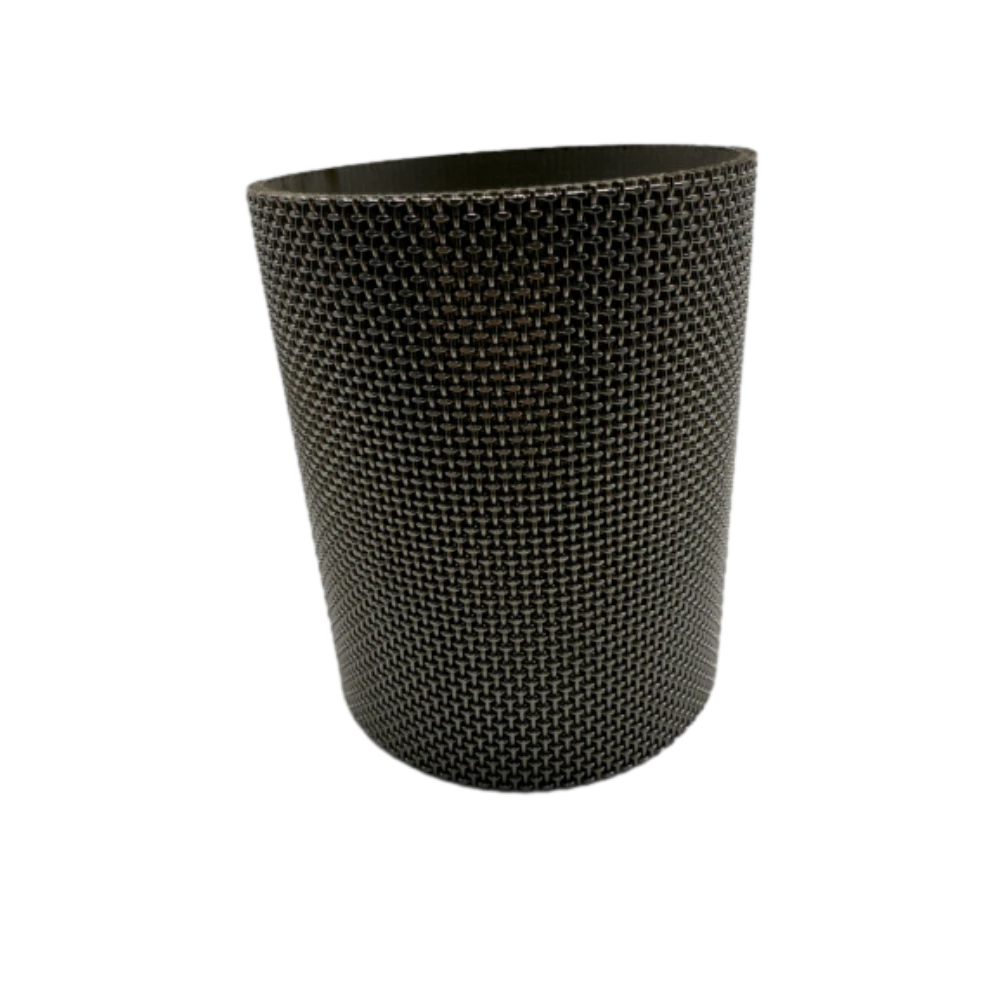

4. Ingancin walda da wuraren haɗin haɗin gwiwa: Bincika ko wuraren walda a kowane wuri daidai ne, tsayayye, da kuma ko akwai wasu walda, karaya, ko bursu, don tabbatar da cewa abokin ciniki ya karɓi samfurin ba tare da ɓarna ko ɗigo ba yayin amfani.

5. Maganin saman: Bincika ko an bi da saman samfurin kamar yadda ake buƙata, kamar electroplating, polishing, spraying, ko electrolysis, da dai sauransu.

6. Gwajin matsin lamba da gwajin karko: auna ƙarfin matsi na samfur ta hanyar kayan aikin ƙwararru don tabbatar da cewa tacewa na iya aiki ƙarƙashin takamaiman ruwan matsa lamba.

7. Duba tsafta: Bincika samfurin don tabon mai, ƙazanta, ko wasu gurɓatattun abubuwa.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)