|

Item

|

Tsanangudzo

|

|

Product Name

|

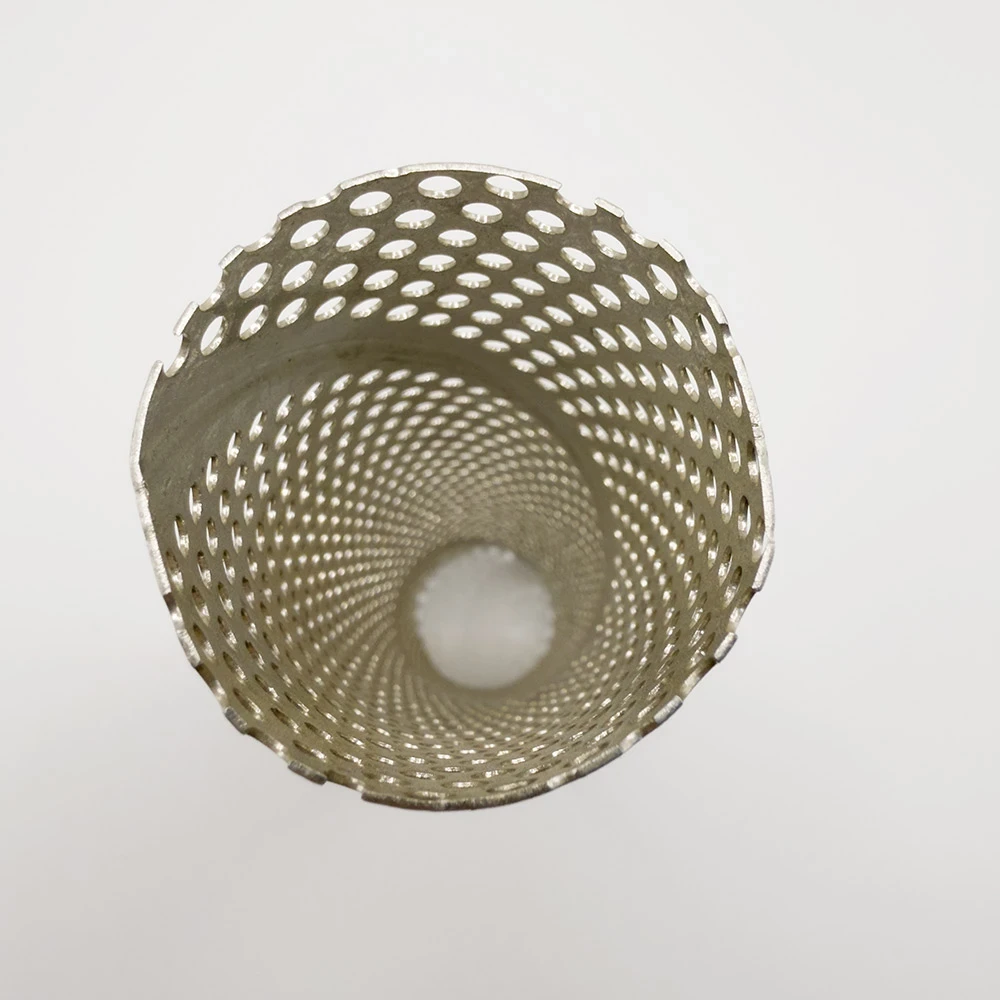

Spiral Welded Perforated Tube

|

|

Raw Material

|

1. Simbi isina Stainless (304, 316L)

2. Carbon Steel

3. Nickel Alloys (Monel, Hastelloy)

4. Titanium Alloy, nezvimwewo.

|

|

Tube Diameter Range

|

0.5mm - 1000mm (Customizable)

|

|

Kukora Kwemadziro

|

0.3mm - 5mm (Customizable)

|

|

Hole Saizi

|

0.5mm - 20mm (Inowanikwa mudenderedzwa, sikweya, uye maburi-akaumbwa maburi)

|

|

Open Area Ratio

|

10% - 60% (Customizable zvichienderana nekusefa zvinodiwa)

|

|

Surface Treatment

|

1. Pickling (Simbi isina simbi (304, 316L), kabhoni simbi, nickel-based alloy (Monel, Hastelloy)

2. Electrolytic Polishing (Simbi isina simbi (304, 316L), nickel-based alloy (Monel, Hastelloy))

3. Sandblasting (Iron, carbon simbi, Stainless simbi (304, 316L), titanium alloy, nickel-based alloy (Monel, Hastelloy))

4. Galvanizing (Simbi, kabhoni simbi)

5. Nickel Plating (Iron, carbon simbi, Stainless simbi (304, 316L), nickel-based alloys (Monel, Hastelloy))

etc.

|

|

Welding Method

|

Spiral Welding (Precision Automated Welding yeSimba uye Chisimbiso)

|

|

Kuramba Kudzvinyirira

|

Kusvikira ku30MPa (Inosiyana zvichienderana nechinhu uye ukobvu)

|

|

Corrosion Resistance

|

Inopikisa acids, alkalis, kupisa kwakanyanya, uye oxidation

|

|

Connection Type

|

Flange Connection, Threaded Connection, Welded Joint, Clamping

|

|

Applicable Fluids

|

Inokodzera zvinwiwa, magasi, oiri, chiutsi, nezvimwe.

|

|

Kuchenesa Nzira

|

Backwashing, Chemical Cleaning, Ultrasonic Cleaning, High-Temperature Baking

|

|

Minda Yekushandisa

|

Petroleum, Chemical Industry, Environmental Water Treatment, Chikafu & Pharmaceuticals, Metallurgy, Power Industry, Automotive Industry, etc.

|

|

Product Features

|

1. Yakakwirira-yakasimba chimiro nekunyanya kudzvinyirira uye kusagadzikana kwemarara

2. Uniform perforation kuitira kunyatsoyerera kwemhepo uye kusefa

3. Precision spiral welding inovimbisa kusimba uye kuvimbika

4. Customizable zvinhu, gomba saizi, uye yakavhurika nzvimbo reshiyo kune siyana filtration zvinodiwa

|

![$chinhu[musoro] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)