|

Items

|

Tsanangudzo

|

|

Product Name

|

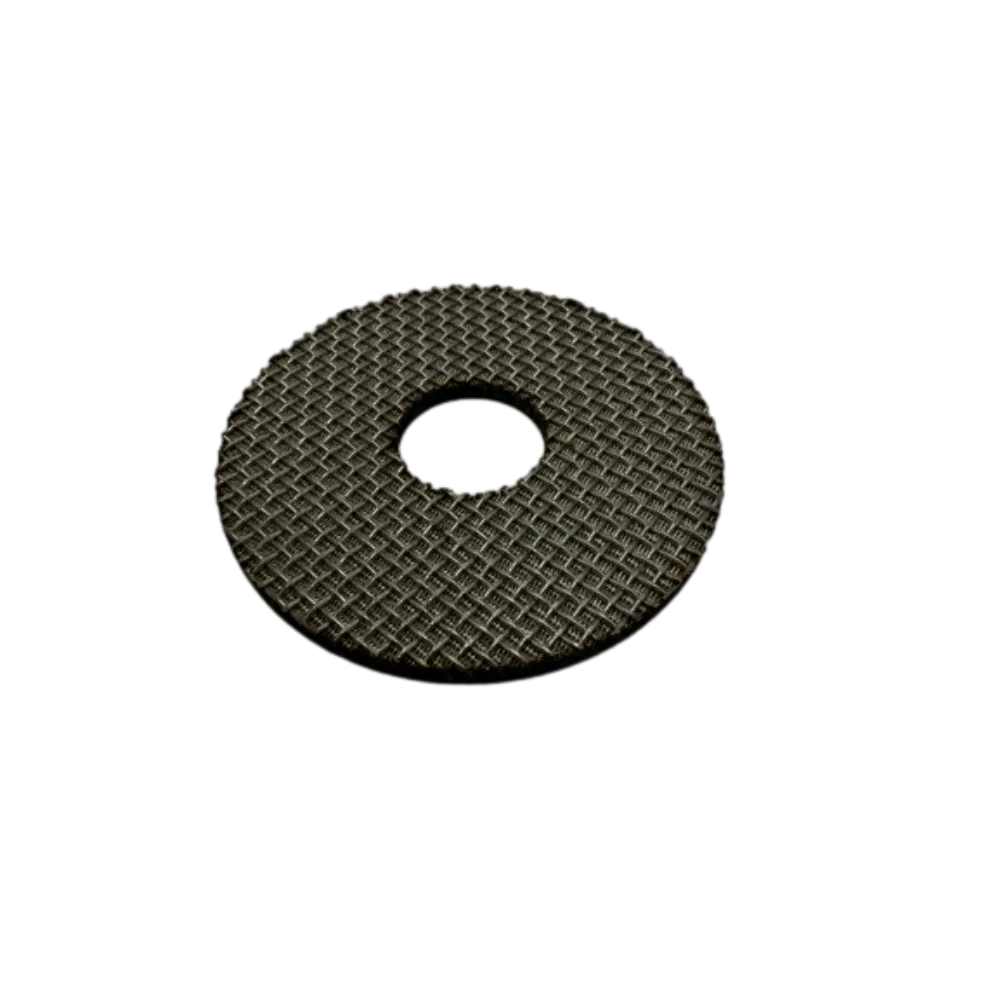

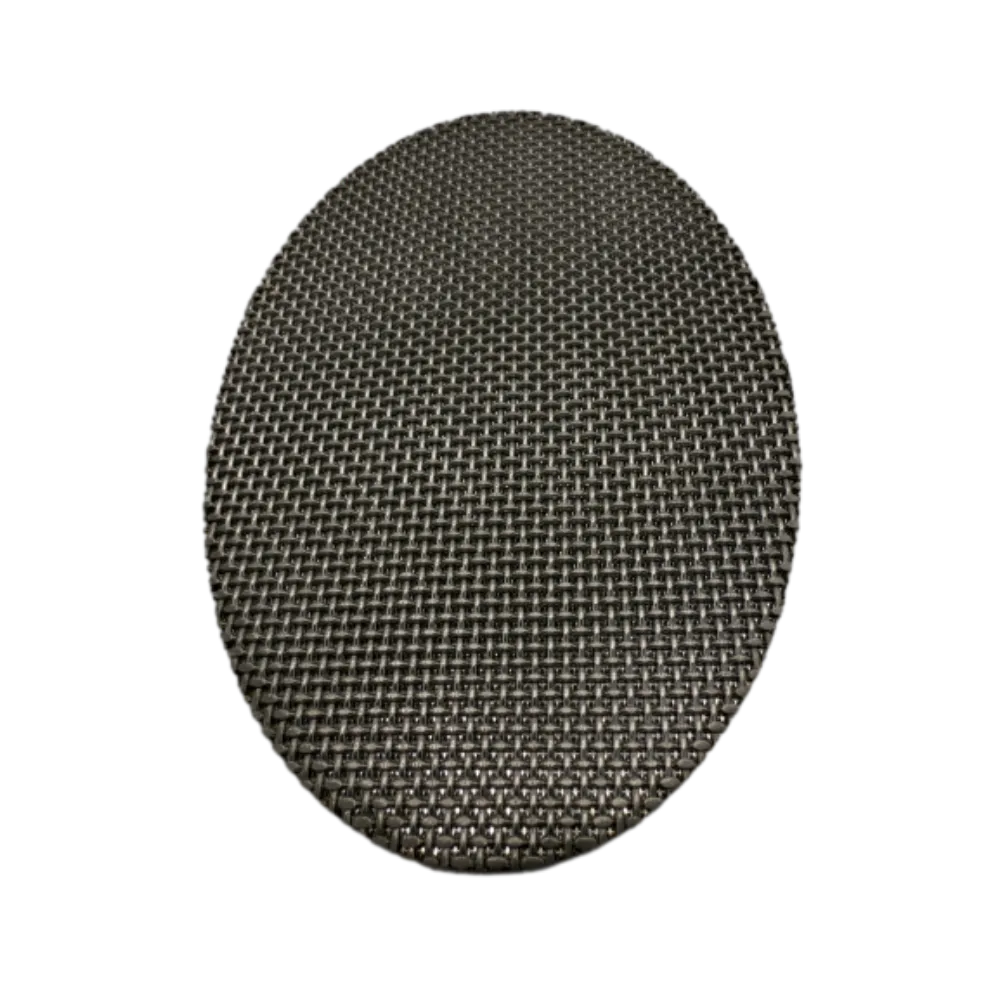

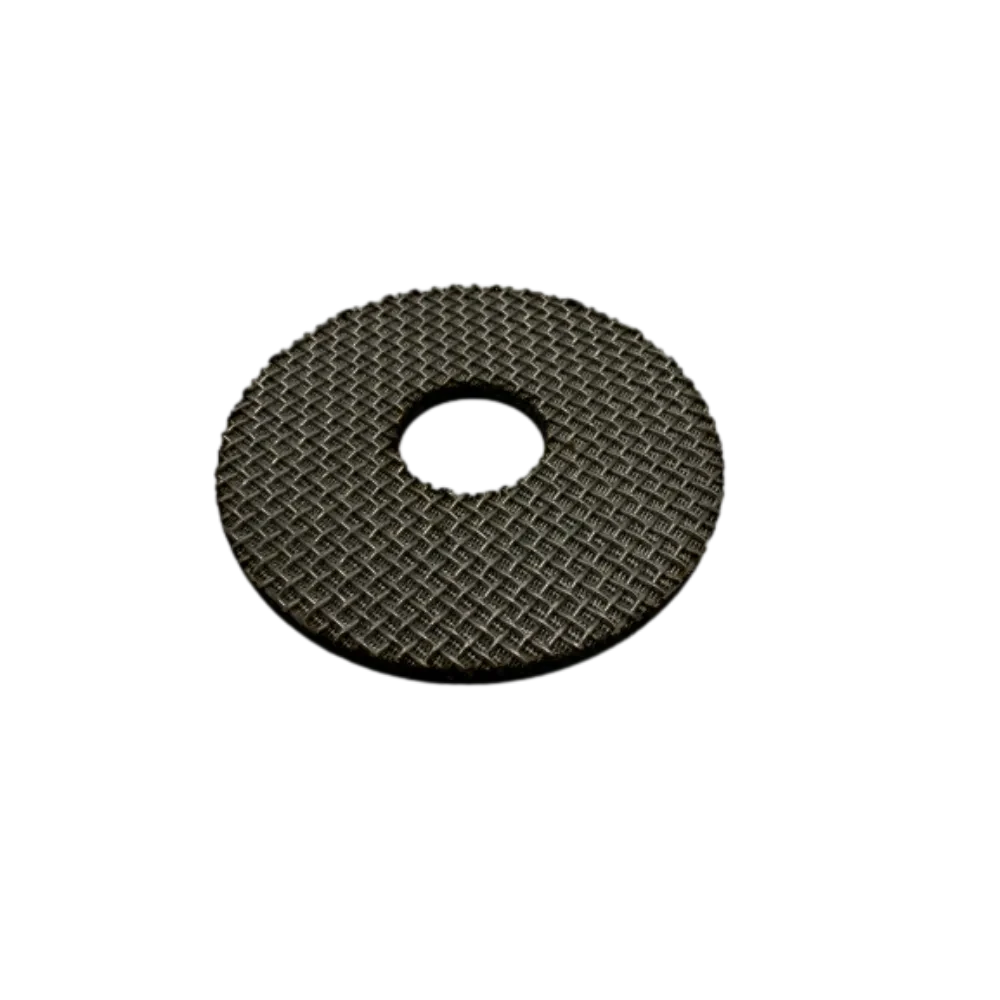

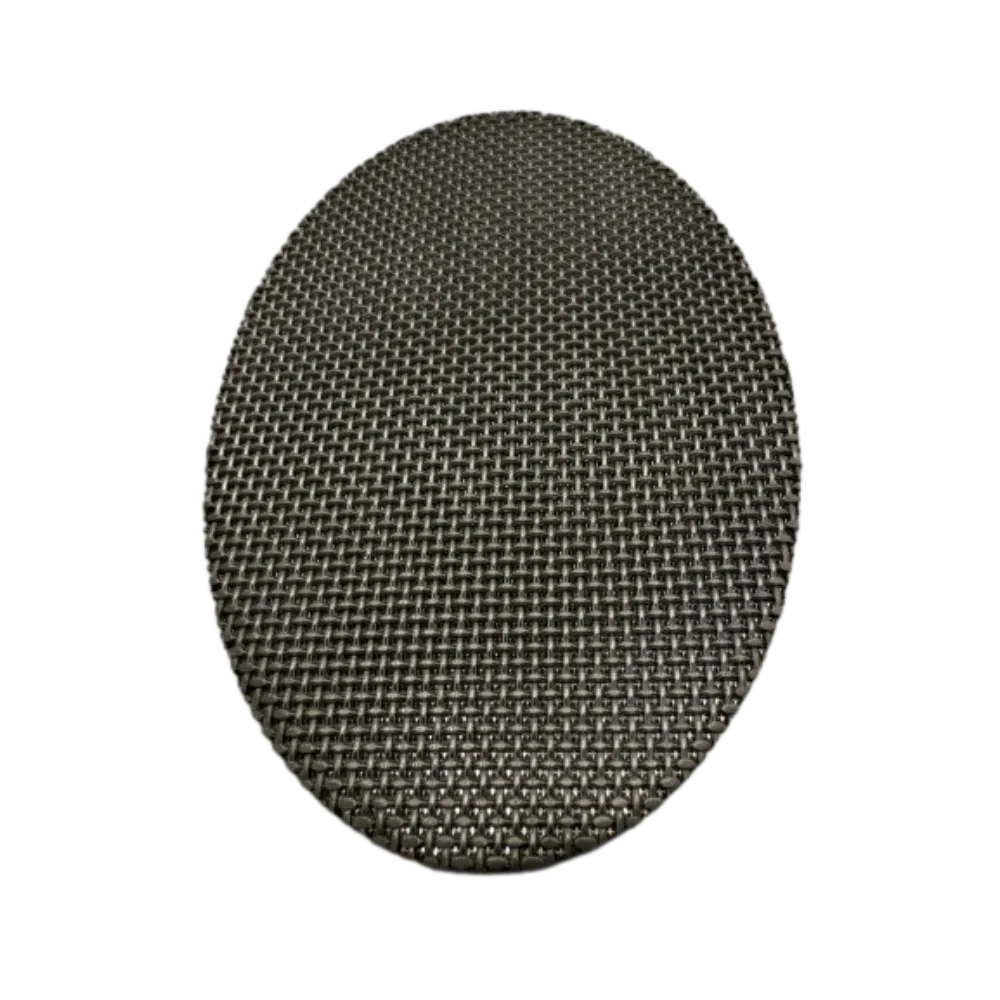

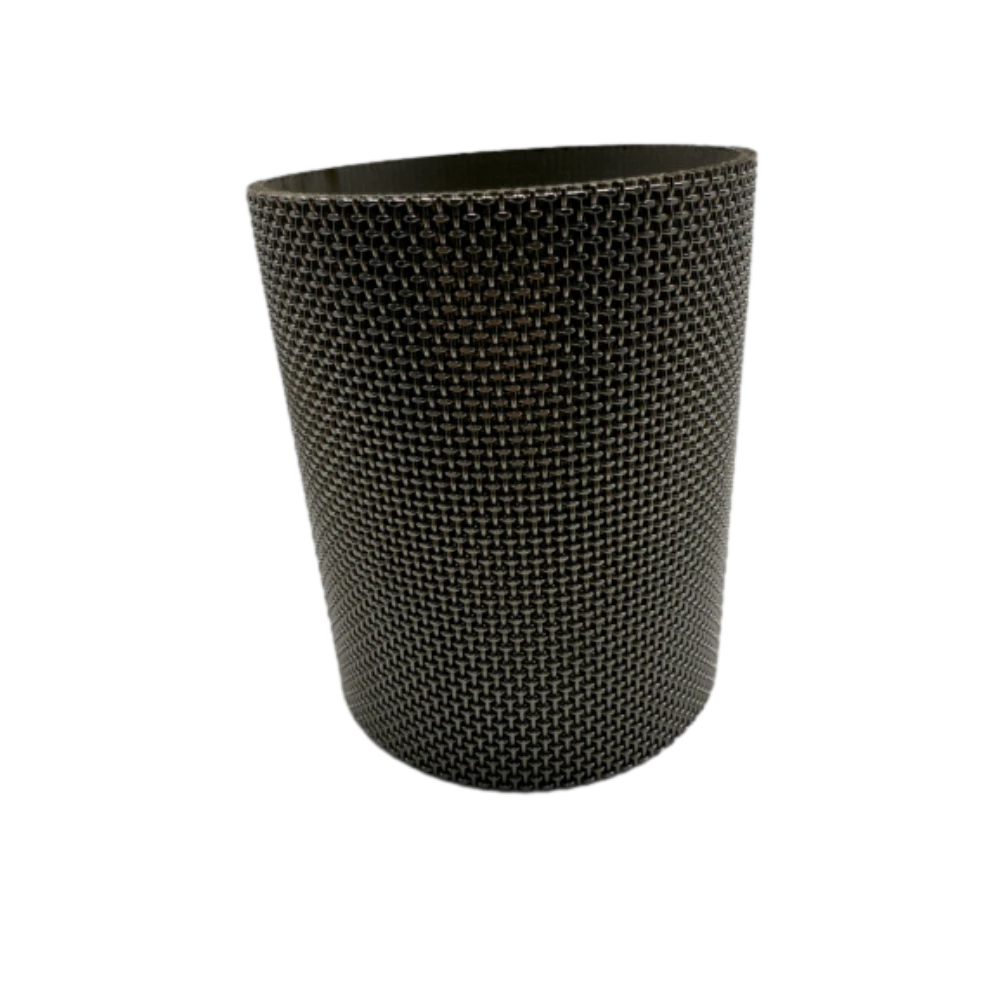

Sintered Wire Mesh Tube

|

|

Manufacturing Process

|

1. Sintering: Pakupisa kwakanyanya, kupararira kwesimbi zvimedu zvinosunga mesh yesimbi pamwechete kuti igadzire chimiro chakabatana.

2. Kukunguruka: Nekumhanyisa-kutenderera kwepamusoro, mesh imwe neimwe layer yakabatana zvakasimba kuti ive nechokwadi chekufanana kwayo.

3. Kucheka kweLaser / Plasma Kucheka: Cheka iyo Sintered Wire Mesh kuti uone saizi chaiyo uye chimiro.

|

|

Yakarukwa nzira yewakarukwa waya mesh

|

1. Plain Weave (Iyo inonyanya kuruka nzira ine maunifomu mesh maburi uye yakakodzera kusefa kwese)

2. Twill Weave(Kunyatsosefa kwepamusoro, chimiro chakasimba, chakakodzera kusefa kwepamusoro-soro)

3. Dutch Weave(A high-density kusefa chimiro chinoumbwa nekurukana kwakakasharara shinda dzewap uye shinda dzakatsetseka, dzinowanzo shandiswa pakusefa kwekupedzisira)

4. Reverse Dutch Weave (Ine simba rakakwirira uye inotakura-inotakura simba, inokodzera high-pressure filtration)

|

|

Zvimwe Zvekushandisa

|

1. Simbi isina Stainless (304, 316, 316L)

2. Nickel Alloy(Monel,Hastelloy,Inconel)

3. Titanium Mesh

ETC

|

|

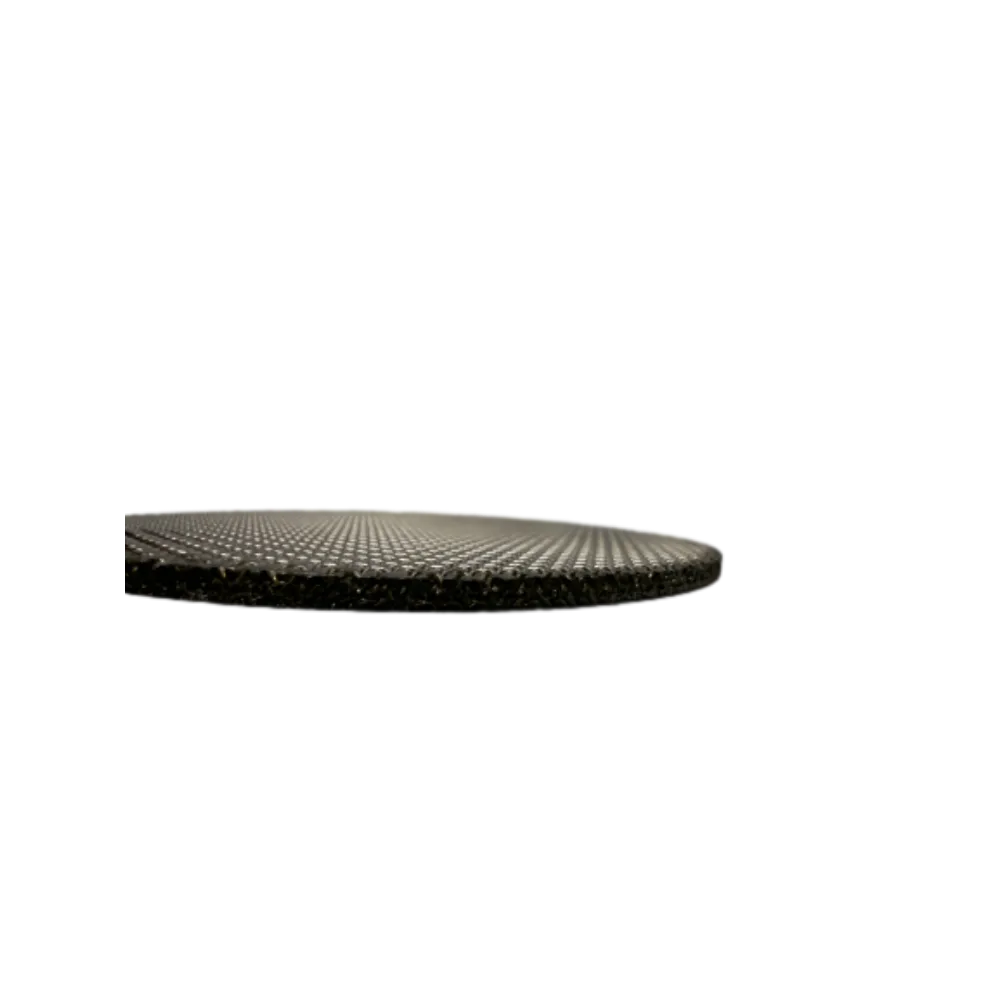

Nhamba yeMatanho

|

3, 5, 7 akaturikidzana (kana akagadziridzwa akawanda-layer chimiro)

|

|

Filtration Accuracy

|

1μm - 200μm (inogoneka)

|

|

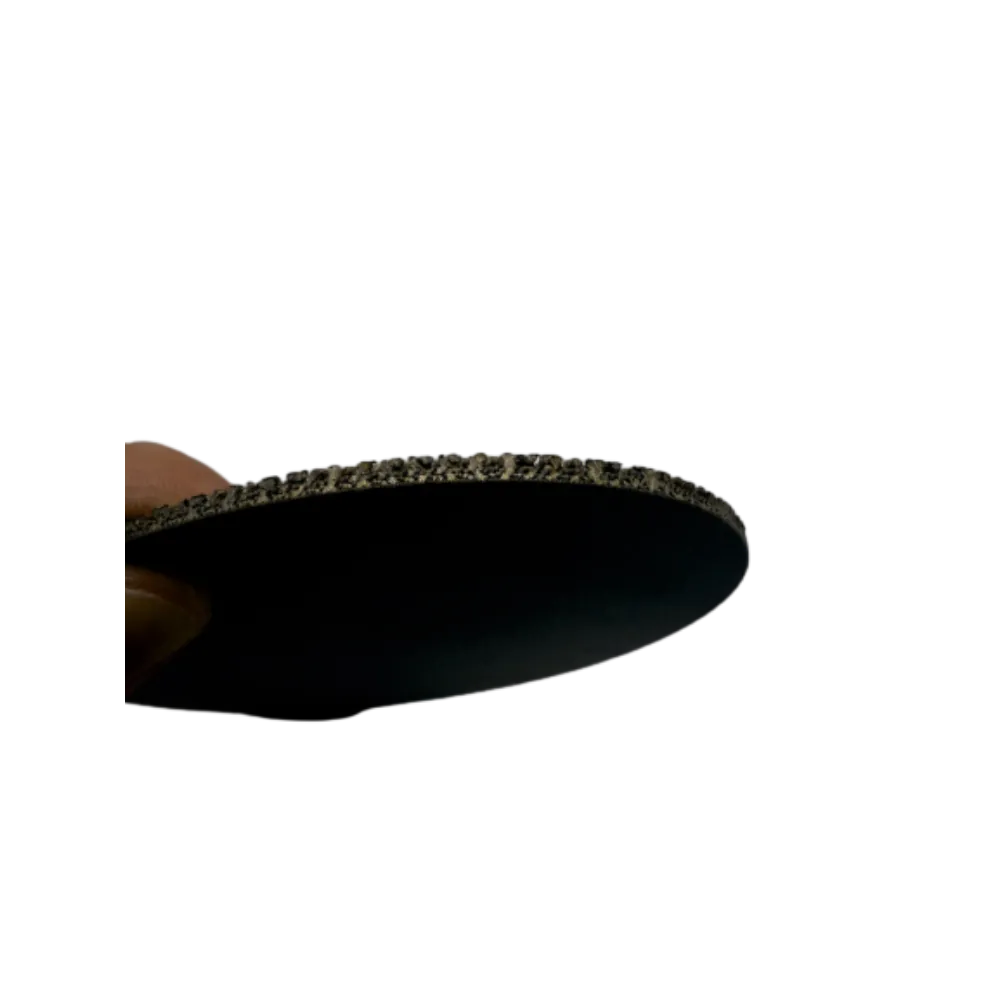

Makobvu Range

|

0.5mm - 5mm (inosiyana nehuwandu hwezvikamu)

|

|

Hole Size Distribution

|

Gradient pore dhizaini yekusefa kwakanaka uye kuyerera kwemvura

|

|

Surface Treatment

|

Acid pickling(Stainless Steel/Carbon steel),

Electrolytic polishing(Stainless Simbi)

Nickel plating (Stainless Simbi/Carbon Steel)

Anodizing (Aluminium) nezvimwewo.

|

|

Operating Temperature

|

-200 ℃ kusvika 600 ℃ (zvichienderana nezvinhu)

|

|

Kuramba Kudzvinyirira

|

Kusvikira ku30MPa kana kupfuura (inosiyana zvichienderana nemesh layer uye ukobvu)

|

|

Permeability / Flow Resistance

|

Kudzikira kupikisa uye kupenya kwepamusoro, kwakakodzera gasi uye kusefa kwemvura

|

|

Corrosion Resistance

|

Inopikisa acids, alkalis, salt spray, uye oxidation munzvimbo dzakaoma

|

|

Kuchenesa Nzira

|

Backwashing, Ultrasonic cleaning, High-temperature baking, Chemical cleaning, and reusable

|

|

Manufacturing Process

|

High-tembiricha vacuum sintering, Rolling

|

|

Available Shapes

|

Cylindrical, Square, Sheet, Pleated, Tsika zvimiro zviripo

|

|

Nzira dzekubatanidza

|

Flange yekubatanidza, Welding, Threaded connection, Clamping

|

|

Applicable Fluids

|

Inokodzera zvinwiwa, magasi, oiri, chiutsi, nezvimwe.

|

|

Minda Yekushandisa

|

Petrochemical, Chikafu & Chinwiwa, Pharmaceuticals, Environmental Water Treatment, Aerospace, Automotive Industry, etc.

|

|

Product Advantages

|

1. High simba uye kumanikidza kuramba, kwete nyore deform

2. Kuchenesa kudzokororwa, hupenyu hurefu

3. Precision filtration, yunifomu pore saizi kugovera

4. Kupisa kwepamusoro uye kusagadzikana kwekuora, kuchinjika kune dzakaoma nharaunda

|

![$chinhu[musoro] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)