|

Ntho

|

Tlhaloso

|

|

Lebitso la Sehlahiswa

|

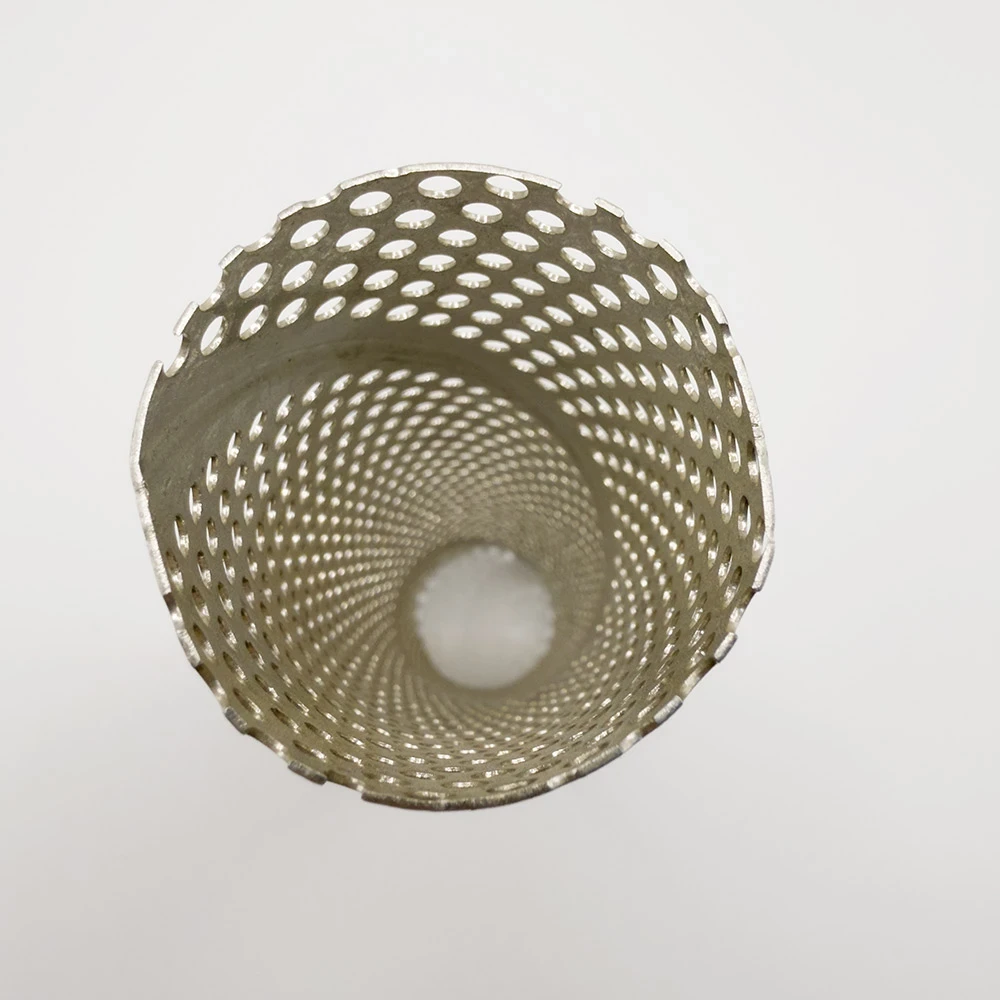

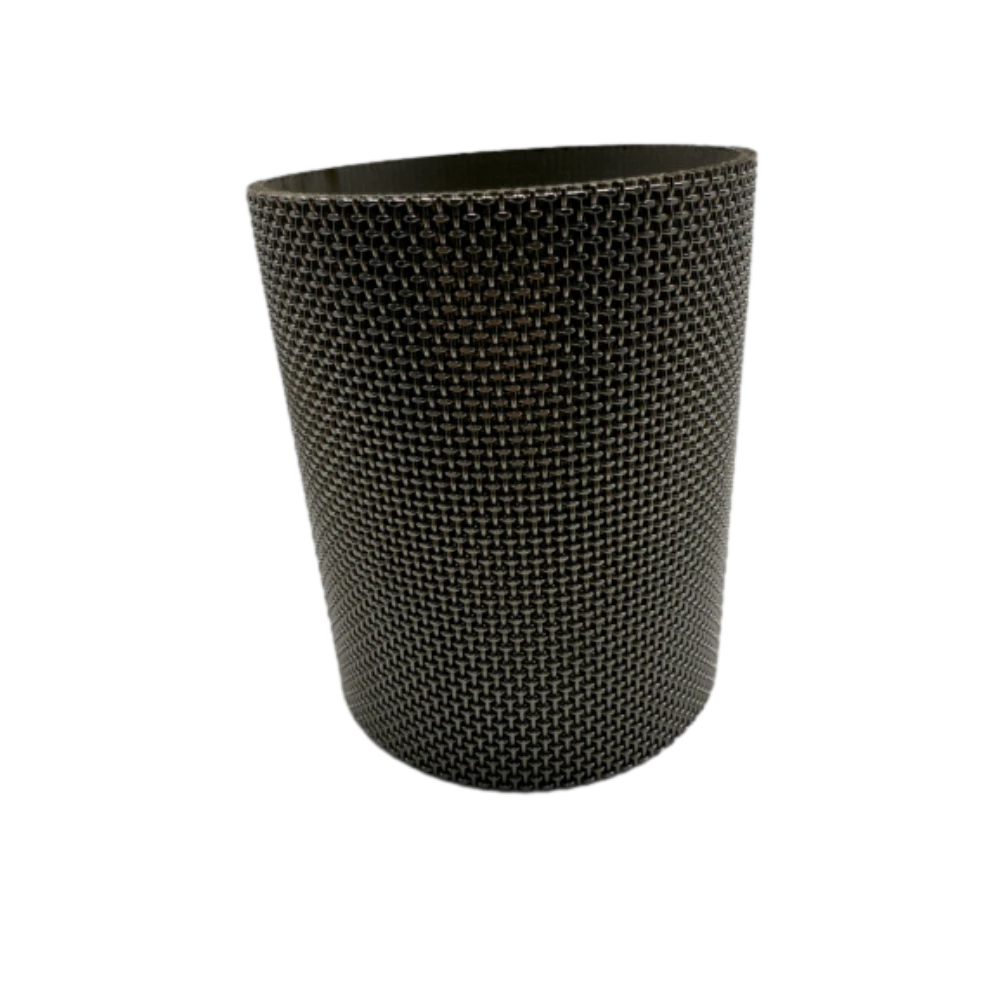

Spiral Welded Perforated Tube

|

|

E tala Lintho tse bonahalang

|

1. Ts'epi e Sebeleng (304, 316L)

2. Tšepe ea Khabone

3. Nickel Alloys (Monel, Hastelloy)

4. Alloy ea Titanium, joalo-joalo.

|

|

Tube Diameter Range

|

0.5mm - 1000mm (Ho ka khoneha)

|

|

Botenya ba Lerako

|

0.3mm - 5mm (O ka khonahala)

|

|

Boholo ba lesoba

|

0.5mm - 20mm (E fumaneha ka mekoti e chitja, e lisekoere le e bōpehileng joaloka slot)

|

|

Open Area Ratio

|

10% - 60% (E ka khonahala ho latela litlhoko tsa ho sefa)

|

|

Kalafo ea Bokaholimo

|

1. Pickling (Stainless steel (304, 316L), carbon steel, nickel-based alloy (Monel, Hastelloy)

2. Electrolytic Polishing (Stainless steel (304, 316L), alloy e thehiloeng ho nickel (Monel, Hastelloy))

3. Sandblasting (Tšepe, carbon steel, stainless steel (304, 316L), motsoako oa titanium, alloy e thehiloeng ho nickel (Monel, Hastelloy))

4. Galvanizing (Tšepe, carbon steel)

5. Nickel Plating (Iron, carbon steel, stainless steel (304, 316L), li-alloys tse thehiloeng ho nickel (Monel, Hastelloy))

etc.

|

|

Mokhoa oa ho Welding

|

Spiral Welding (Precision Automated Welding for Matla le Tiiso)

|

|

Ho Hanyetsa Khatello

|

Ho fihla ho 30MPa (E fapana ho latela thepa le botenya)

|

|

Khanyetso ea Corrosion

|

E hanyetsana le li-acids, alkalis, mocheso o phahameng, le oxidation

|

|

Mofuta oa Khokahano

|

Khokahano ea Flange, Khokahano ea Khoele, Kopanelo e Welded, Clamping

|

|

Mekelikeli e sebetsang

|

E loketse maro, likhase, oli, mouoane, joalo-joalo.

|

|

Mekhoa ea ho Hloekisa

|

Ho hlatsoa mokokotlo, ho hloekisa lik'hemik'hale, ho hloekisa ka mokhoa oa Ultrasonic, ho baka ka mocheso o phahameng

|

|

Libaka tsa Kopo

|

Petroleum, Indasteri ea Lik'hemik'hale, Phekolo ea Metsi a Tikoloho, Lijo le Litlhare, Metallurgy, Indasteri ea Matla, Indasteri ea Likoloi, joalo-joalo.

|

|

Likarolo tsa Sehlahisoa

|

1. Sebopeho se matla se phahameng se nang le khatello e babatsehang le ho hanyetsa kutu

2. Perforation e tšoanang bakeng sa phallo e nepahetseng ea moea le ho sefa

3. Precision spiral welding e tiisa ho tšoarella le ho tšepahala

4. Lisebelisoa tse ka tloahelehang, boholo ba likoti, le likarolo tse bulehileng tsa sebaka bakeng sa litlhoko tse fapaneng tsa ho sefa

|

![$ntho[sehlooho] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)