|

Item

|

Katrangan

|

|

Jeneng produk

|

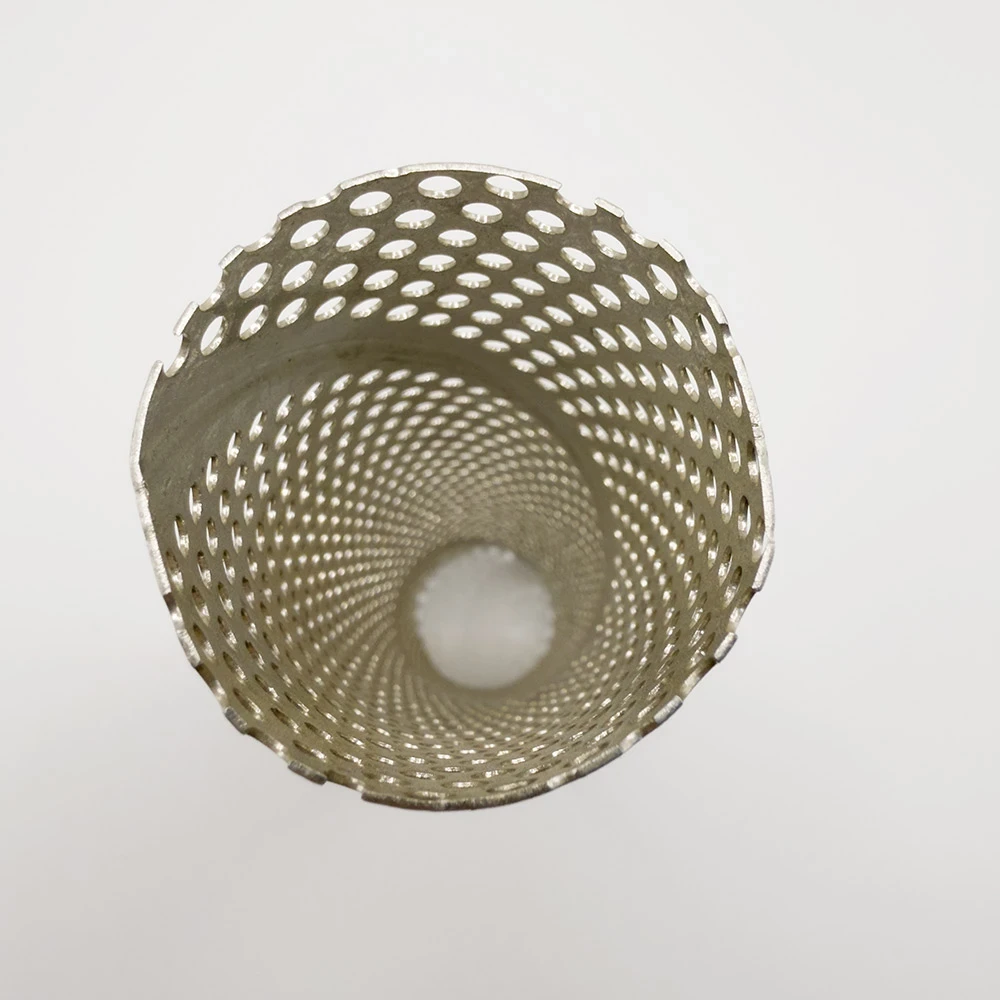

Spiral Welded Perforated Tube

|

|

mentahan Bahan

|

1. Baja Tahan Karat (304, 316L)

2. Baja Karbon

3. Paduan Nikel (Monel, Hastelloy)

4. Titanium Alloy, etc.

|

|

Range Diameter Tabung

|

0.5mm - 1000mm (bisa disesuaikan)

|

|

Kekandelan tembok

|

0.3mm - 5mm (bisa disesuaikan)

|

|

Ukuran bolongan

|

0.5mm - 20mm (Kasedhiya ing bolongan bunder, kothak, lan slot-shaped)

|

|

Rasio Area Terbuka

|

10% - 60% (Bisa disesuaikan adhedhasar syarat filtrasi)

|

|

Perawatan lumahing

|

1. Pengawetan (Baja tahan karat (304, 316L), baja karbon, paduan berbasis nikel (Monel, Hastelloy)

2. Polishing Electrolytic (Baja tahan karat (304, 316L), paduan berbasis nikel (Monel, Hastelloy))

3. Sandblasting (Besi, baja karbon, baja tahan karat (304, 316L), paduan titanium, paduan berbasis nikel (Monel, Hastelloy))

4. Galvanizing (Besi, baja karbon)

5. Pelapisan Nikel(Besi, baja karbon, baja tahan karat (304, 316L), paduan berbasis nikel (Monel, Hastelloy))

lsp.

|

|

Metode Welding

|

Spiral Welding (Precision Automated Welding for Strength and Sealing)

|

|

Tekanan Resistance

|

Nganti 30MPa (Beda-beda adhedhasar materi lan kekandelan)

|

|

Tahan karat

|

Tahan kanggo asam, alkali, suhu dhuwur, lan oksidasi

|

|

Jinis Sambungan

|

Sambungan Flange, Sambungan Utas, Sambungan Welded, Clamping

|

|

Cairan sing ditrapake

|

Cocog kanggo cairan, gas, lenga, uap, lsp.

|

|

Metode Reresik

|

Backwashing, Reresik Kimia, Reresik Ultrasonik, Baking Suhu Dhuwur

|

|

Bidang Aplikasi

|

Petroleum, Industri Kimia, Pengolahan Air Lingkungan, Pangan & Farmasi, Metalurgi, Industri Tenaga, Industri Otomotif, lsp.

|

|

Fitur produk

|

1. Struktur kekuatan dhuwur kanthi tekanan sing apik lan tahan korosi

2. Perforasi seragam kanggo aliran udara lan filtrasi sing optimal

3. Precision spiral welding njamin kekiatan lan linuwih

4. Bahan sing bisa disesuaikan, ukuran bolongan, lan rasio area mbukak kanggo macem-macem kabutuhan filtrasi

|

![$item[judul] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)