|

Kanthu

|

Kufotokozera

|

|

Dzina lazogulitsa

|

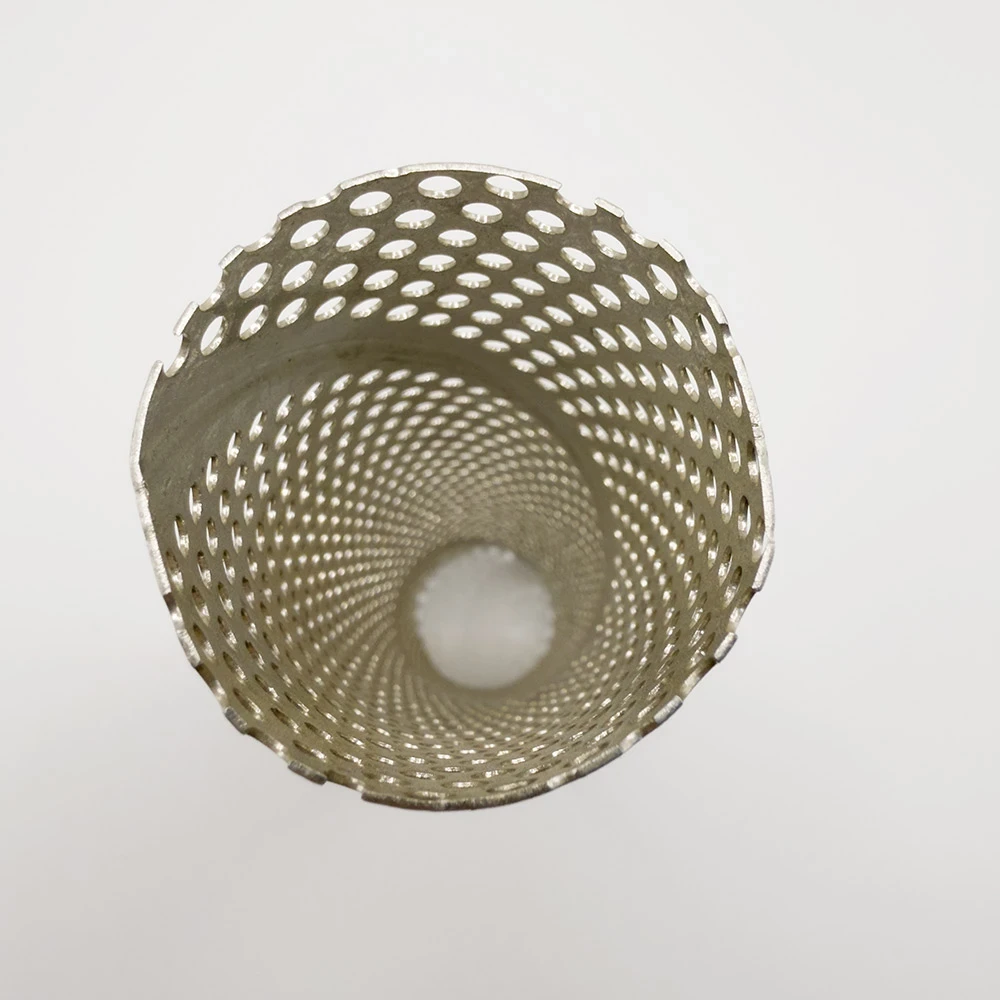

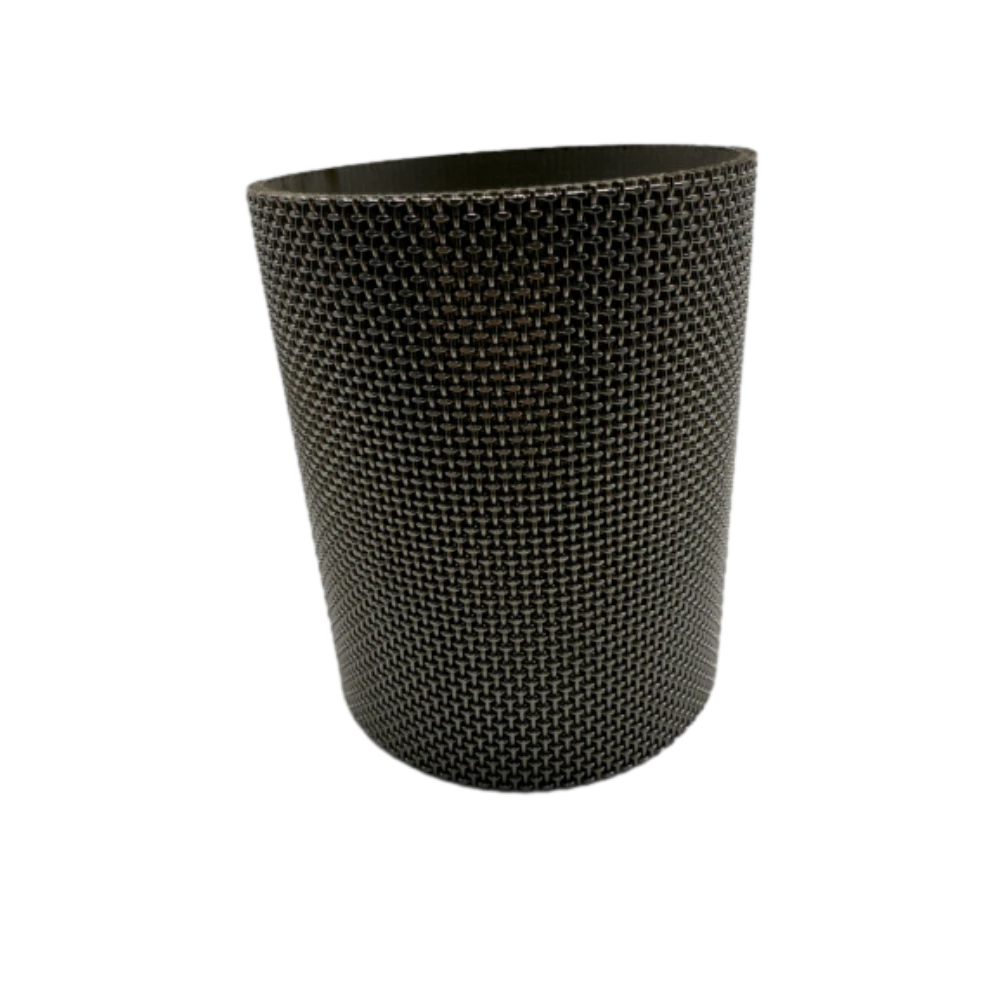

Spiral Welded Perforated Tube

|

|

Yaiwisi Zakuthupi

|

1. Chitsulo chosapanga dzimbiri (304, 316L)

2. Chitsulo cha Mpweya

3. Nickel Alloys (Monel, Hastelloy)

4. Titaniyamu Aloyi, etc.

|

|

Tube Diameter Range

|

0.5mm - 1000mm (mwamakonda)

|

|

Makulidwe a Khoma

|

0.3mm - 5mm (mwamakonda)

|

|

Kukula kwa Hole

|

0.5mm - 20mm (Ikupezeka mu maenje ozungulira, makwerero, ndi ma slot)

|

|

Open Area Ration

|

10% - 60% (Zosintha mwamakonda malinga ndi zofunikira zosefera)

|

|

Chithandizo cha Pamwamba

|

1. Pickling (Chitsulo chosapanga dzimbiri (304, 316L), chitsulo cha carbon, alloy-based alloy (Monel, Hastelloy)

2. Electrolytic Polishing (Chitsulo chosapanga dzimbiri (304, 316L), alloy-based alloy (Monel, Hastelloy))

3. Sandblasting (Iron, carbon steel, chitsulo chosapanga dzimbiri (304, 316L), titaniyamu aloyi, nickel-based alloy (Monel, Hastelloy))

4. Galvanizing (Iron, carbon steel)

5. Nickel Plating (Iron, carbon steel, chitsulo chosapanga dzimbiri (304, 316L), ma aloyi a faifi tambala (Monel, Hastelloy))

ndi zina.

|

|

Njira Yowotcherera

|

Kuwotcherera kwa Spiral (Kuwotcherera Kwachangu Kwambiri Kwamphamvu ndi Kusindikiza)

|

|

Kukaniza Kupanikizika

|

Kufikira 30MPa (Zimasiyanasiyana kutengera zakuthupi ndi makulidwe)

|

|

Kukaniza kwa Corrosion

|

Kugonjetsedwa ndi zidulo, alkalis, kutentha kwambiri, ndi okosijeni

|

|

Mtundu Wolumikizira

|

Kulumikizana kwa Flange, Kulumikizana Kwamizere, Kulumikizana Kowotchedwa, Kumanga

|

|

Kugwiritsa Ntchito Madzi

|

Oyenera zakumwa, mpweya, mafuta, nthunzi, etc.

|

|

Njira Zoyeretsera

|

Backwashing, Chemical Cleaning, Akupanga Kuyeretsa, Kutentha Kwambiri Kuphika

|

|

Minda Yofunsira

|

Petroleum, Chemical Viwanda, Environmental Water Treatment, Food & Pharmaceuticals, Metallurgy, Power Industry, Automotive Industry, etc.

|

|

Zogulitsa Zamankhwala

|

1. Mapangidwe apamwamba kwambiri omwe ali ndi mphamvu zambiri komanso kukana dzimbiri

2. Kubowola kofananako kuti mpweya uziyenda bwino komanso kusefa

3. Kuwotcherera kozungulira kolondola kumatsimikizira kulimba komanso kudalirika

4. Zida zosinthika, kukula kwa dzenje, ndi magawo otseguka azinthu zosiyanasiyana zosefera

|

![$chinthu[mutu] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)