|

Aitema

|

Fa'amatalaga

|

|

Igoa Oloa

|

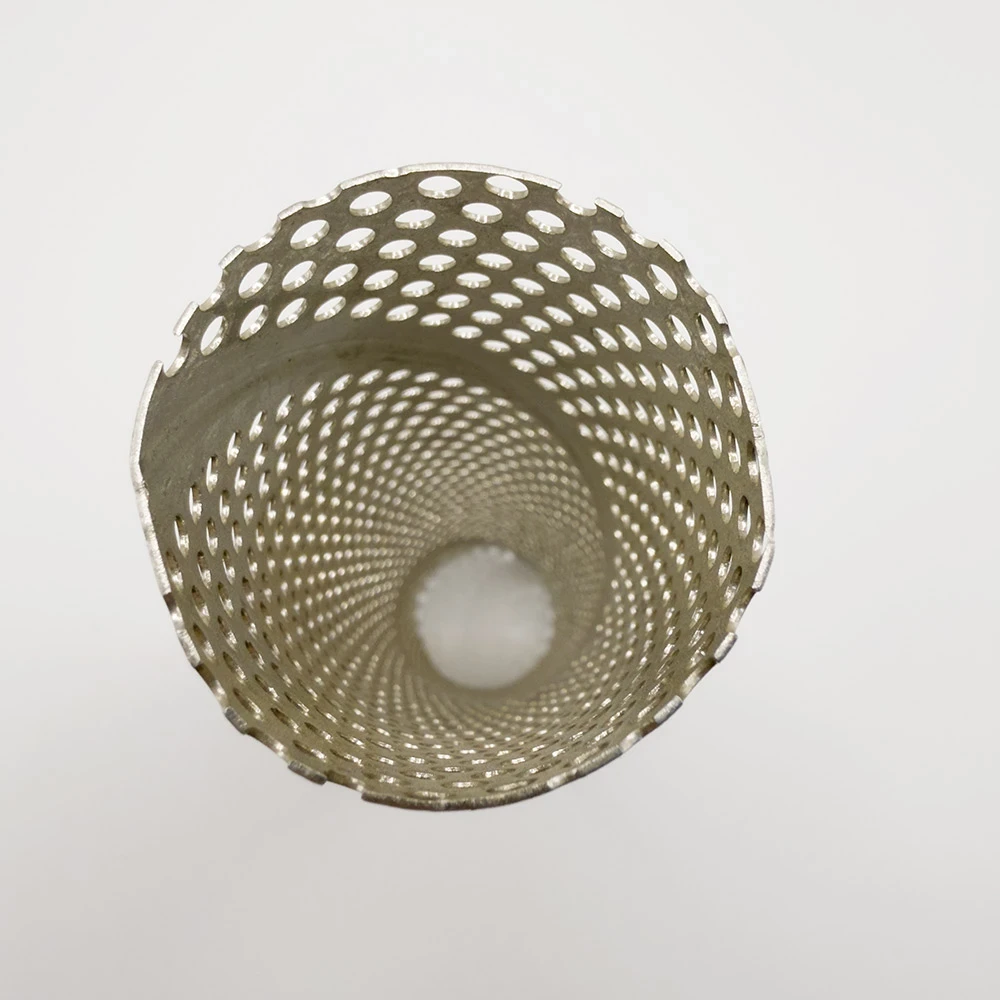

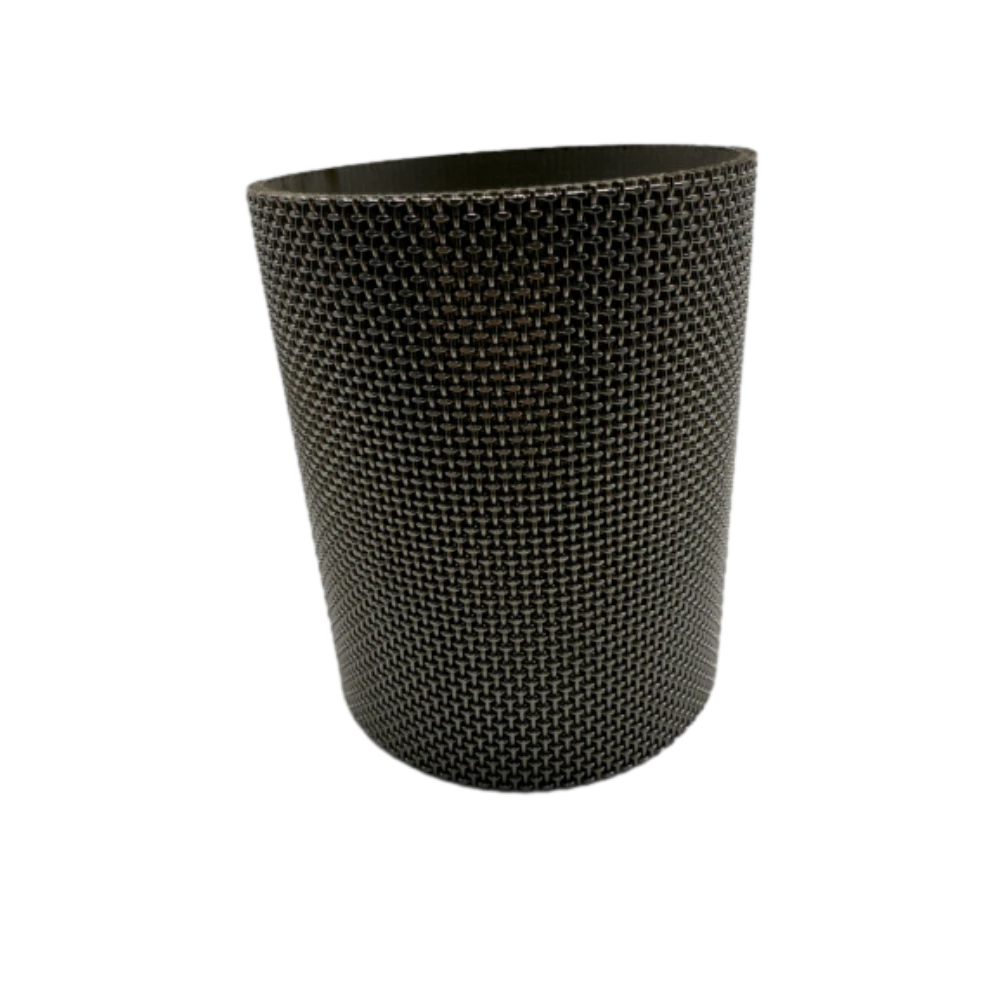

Fa'a'au'au fa'a'au'au fa'alava

|

|

Mata Mea

|

1. Uamea uamea (304, 316L)

2. Uamea Carbon

3. Nikeli Alloys (Monel, Hastelloy)

4. Titanium Alloy, ma isi.

|

|

Fugalaau Diameter Ranga

|

0.5mm - 1000mm (Fa'atonu)

|

|

Malosi o Pa

|

0.3mm - 5mm (Fa'atonu)

|

|

Tele Pu

|

0.5mm - 20mm (E maua ile lapotopoto, sikuea, ma pu fa'atusa)

|

|

Fa'atatau o le Eria Tatala

|

10% - 60% (E mafai ona fa'atulagaina e fa'atatau i mana'oga fa'amama)

|

|

Togafitiga i luga

|

1. Pi'i (Uamea uamea (304, 316L), uamea kaponi, u'amea fa'avae nickel (Monel, Hastelloy)

2. Electrolytic Polishing (Uamea e leai se mea (304, 316L), u'amea fa'avae nickel (Monel, Hastelloy))

3. Sandblasting (Umea, uamea kaponi, uamea u'amea (304, 316L), u'amea titanium, u'amea fa'avae nickel (Monel, Hastelloy))

4. Galvanizing (U'amea, uamea kaponi)

5. Tu'u nikeli (U'amea, uamea kaponi, uamea u'amea (304, 316L), u'amea fa'avae nickel (Monel, Hastelloy))

ma isi.

|

|

Metotia Uelo

|

Uila Fa'ata'amilo (Precision Automated Uelo mo le Malosi ma Faamauga)

|

|

Tete'e o Omiga

|

E oʻo atu i le 30MPa (Fesuiaʻi e faʻatatau i meafaitino ma le mafiafia)

|

|

Tete'e a'e

|

Tete'e i acids, alkalis, vevela maualuga, ma oxidation

|

|

Ituaiga So'oga

|

Feso'ota'iga Flange, Feso'ota'iga filo, So'oga Uso, pipi'i

|

|

Suavai talafeagai

|

E fetaui mo vai, kasa, suauʻu, ausa, ma isi.

|

|

Fa'amama Metotia

|

Fufulu i tua, Fa'amama vaila'au, Fa'amama Ultrasonic, Fa'a'u'u i le vevela maualuga

|

|

Talosaga Fields

|

Suau'u, Alamanuia Vailaau, Siosiomaga Suavai Togafitiga, Mea'ai & Fale Talavai, Metallurgy, Alamanuia Malosiaga, Alamanuia Ta'avale, ma isi.

|

|

Oloa Fa'ailoga

|

1. Faʻatulagaga maualuga-malosi ma sili atu le mamafa ma le faʻafefeteina

2. Tulaga tutusa mo le lelei o le ea ma le faamamaina

3. Sa'o le u'u fa'ameamea e fa'amautinoa ai le tumau ma le fa'amaoni

4. Mea fa'apitoa, pu lapopo'a, ma va'aiga vaega avanoa mo manaoga filtration eseese

|

![$aitema[igoa] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)