|

Tūemi

|

Whakaahuatanga

|

|

Ingoa Hua

|

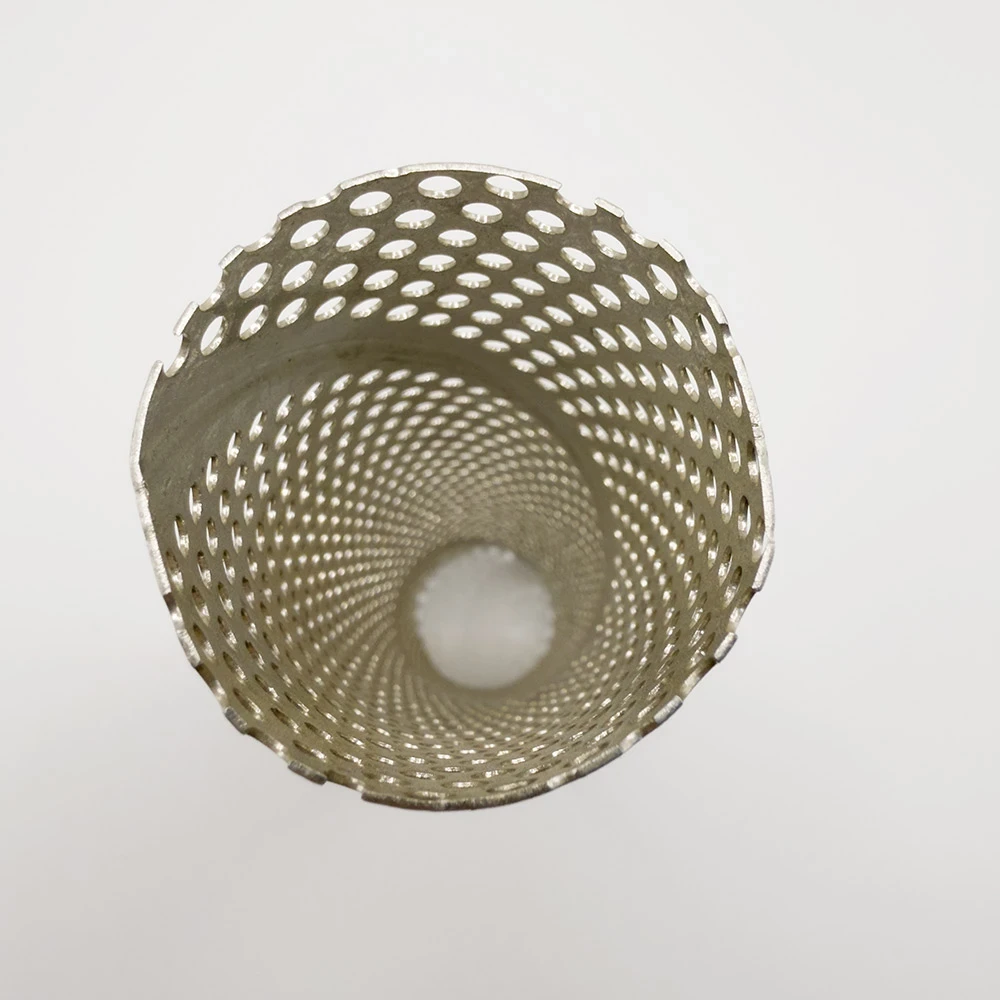

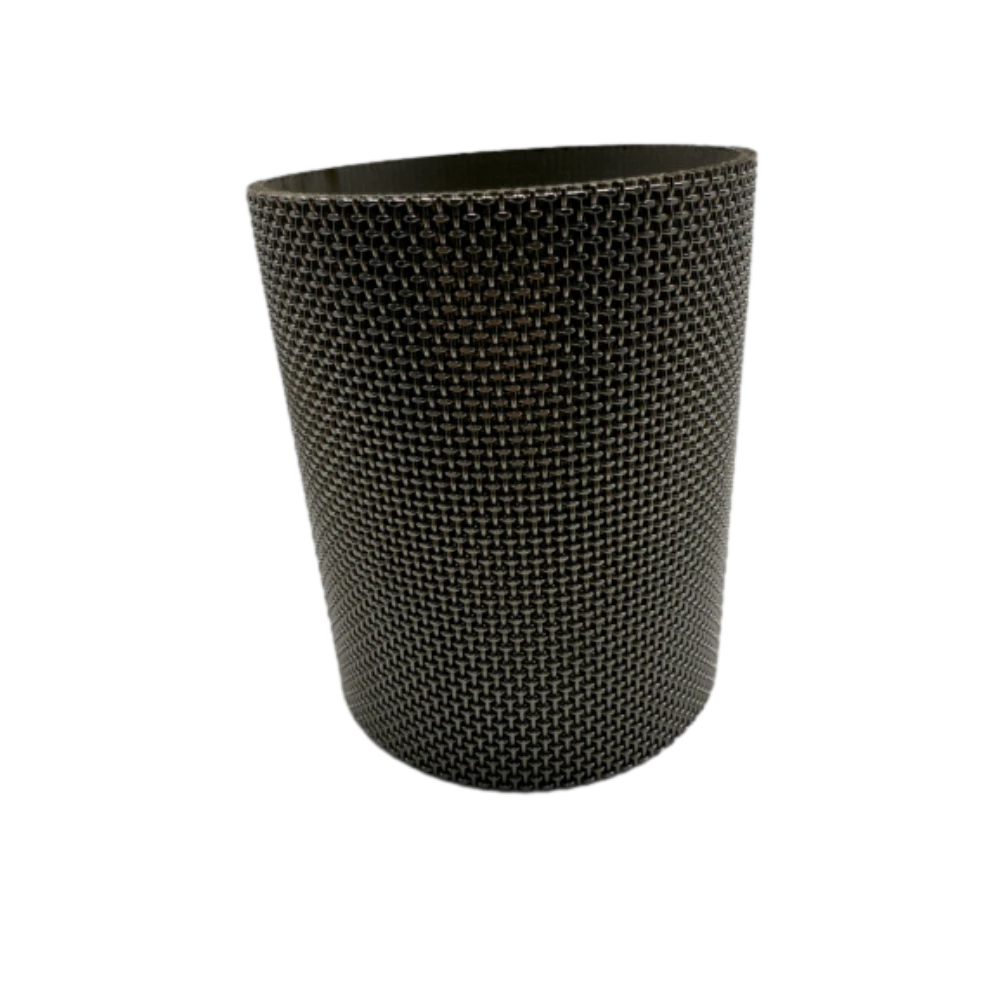

Porowhita Welded Perforated Tube

|

|

Matau Rauemi

|

1. Kowiri tira (304, 316L)

2. Waowa Steel

3. Nickel Alloys (Monel, Hastelloy)

4. Titanium Alloy, etc.

|

|

Tube Diameter Range

|

0.5mm - 1000mm (Ka taea te whakarite)

|

|

Matotoru pakitara

|

0.3mm - 5mm (Ka taea te whakarite)

|

|

Rahi Puka

|

0.5mm - 20mm (Kei te waatea i roto i nga kohao porowhita, tapawha me te ahua mokowhiti)

|

|

Owehenga Rohe Tuwhera

|

10% - 60% (Ka taea te whakarite i runga i nga whakaritenga tātari)

|

|

Mahinga Mata

|

1. Pika(Te rino korewa (304, 316L), te rino waro, te koranu nickel-based (Monel, Hastelloy)

2. Whakakorikori Hiko(Te tira korewa (304, 316L), te koranu nickel-based (Monel, Hastelloy))

3. Sandblasting (Rino, waro maitai, kowiri tira (304, 316L), titanium alloy, nickel-based alloy (Monel, Hastelloy))

4. Piauau (rino, waro maitai)

5. Whakakikorua Nikeli(Rino, rino waro, rino kowiri (304, 316L), koranu hanga-nika (Monel, Hastelloy))

etc.

|

|

Tikanga Welding

|

Wehenga Tirohanga (Precision Automated Welding mo te Kaha me te Hiri)

|

|

Atete Pehenga

|

Tae atu ki te 30MPa (He rereke i runga i te papanga me te matotoru)

|

|

Te Waihanga Atete

|

He ātete ki te waikawa, te kawakore, te pāmahana teitei, me te hāora

|

|

Momo Hononga

|

Hononga Flange, Hononga Miro, Hononga paiherea, Rawhi

|

|

Wai e tika ana

|

He pai mo te wai, hau, hinu, mamaoa, etc.

|

|

Tikanga horoi

|

Te horoi i muri, te horoi matū, te horoi irahiko, te tunu i te pāmahana teitei

|

|

Nga Apure Tono

|

Te hinu, Te Ahumahi Matū, Te Tiaki Wai Taiao, Te Kai me te Rongoa, Te Metallurgy, Te Ahumahi Hiko, Te Ahumahi Ahumahi, etc.

|

|

Nga waahanga hua

|

1. Ko te hanganga kaha teitei me te kaha o te pehanga me te parenga waikura

2. He rite te hangai mo te rere o te hau me te tātari

3. Whakapumautia te mauroa me te pono o te whakapiri torino

4. Ko nga rauemi ka taea te whakarite, te rahi o te kohao, me te owehenga waahi tuwhera mo nga momo hiahia tātari

|

![$tuemi[taitara] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)