|

zavatra

|

Description

|

|

Anaran'ny vokatra

|

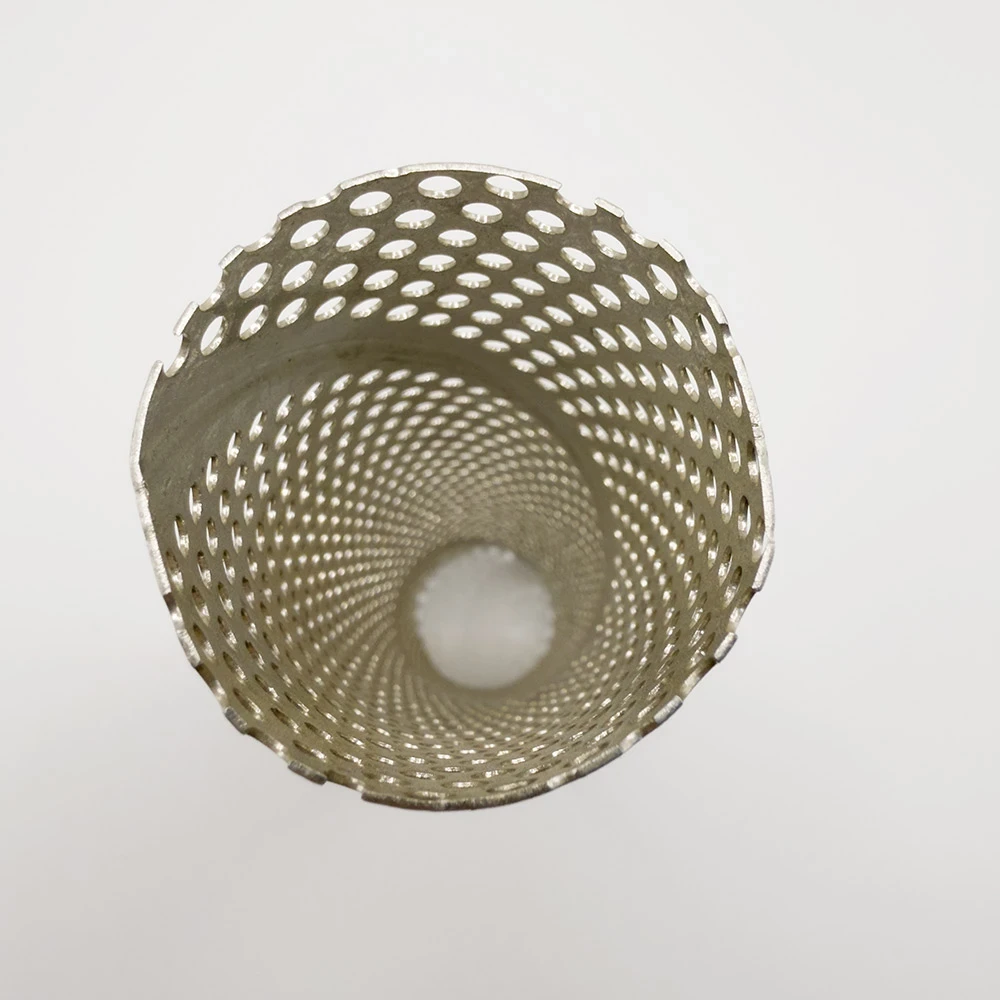

Spiral Welded Perforated Tube

|

|

manta KEVITRA

|

1. vy tsy misy pentina (304, 316L)

2. vy karbônina

3. Nikela (Monel, Hastelloy)

4. Titanium Alloy, sns.

|

|

Savaivony Tube

|

0.5mm - 1000mm (Azo amboarina)

|

|

Haben'ny rindrina

|

0.3mm - 5mm (azo amboarina)

|

|

Haben'ny lavaka

|

0.5mm - 20mm (Azo amin'ny lavaka boribory, efamira ary miendrika slot)

|

|

Ohatry ny faritra misokatra

|

10% - 60% (Azo amboarina araka ny fepetra takian'ny sivana)

|

|

Surface Treatment

|

1. Fanangonana (Stainless vy (304, 316L), vy karbaona, firaka mifototra amin'ny nikela (Monel, Hastelloy)

2. Electrolytic Polishing (Stainless vy (304, 316L), nikela-monina firaka (Monel, Hastelloy))

3. Sandblasting (Vy, vy karbaona, vy tsy misy pentina (304, 316L), firaka titane, firaka mifototra amin'ny nikela (Monel, Hastelloy))

4. Galvanizing (Vy, vy karbaona)

5. Fametahana Nickel (Vy, vy karbaona, vy tsy misy pentina (304, 316L), firaka mifototra amin'ny nikela (Monel, Hastelloy))

Sns

|

|

Fomba welding

|

Fandrefesana Spiral (Welding mandeha ho azy amin'ny tanjaka sy famehezana)

|

|

Fanerena fanoherana

|

Hatramin'ny 30MPa (Miovaova arakaraka ny fitaovana sy ny hateviny)

|

|

Ny fanoherana ny harafesina

|

Mahatohitra ny asidra, ny alkali, ny mari-pana ambony ary ny oxidation

|

|

Karazana fifandraisana

|

Flange Connection, Threaded Connection, Welded Joint, Clamping

|

|

Fluida azo ampiharina

|

Mety amin'ny ranon-javatra, gazy, menaka, etona, sns.

|

|

Fomba fanadiovana

|

Fanasan-damba, fanadiovana simika, fanadiovana ultrasonika, fanaova hafanana avo

|

|

Sahan'ny fampiharana

|

Petroleum, Indostria simika, Fitsaboana ny rano momba ny tontolo iainana, Sakafo sy fanafody, Metallurgie, Indostria Hery, Indostria fiara, sns.

|

|

Endriky ny vokatra

|

1. Firafitra matanjaka avo miaraka amin'ny tsindry tsara sy ny fanoherana ny harafesina

2. Perforation fanamiana ho an'ny fikorianan'ny rivotra sy ny filtration tsara indrindra

3. Miantoka ny faharetana sy ny fahamendrehana ny welding spiral precision

4. Ny fitaovana azo namboarina, ny haben'ny lavaka ary ny tahan'ny faritra misokatra ho an'ny filana filtration isan-karazany

|

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)