|

item

|

Paglalarawan

|

|

Pangalan ng Produkto

|

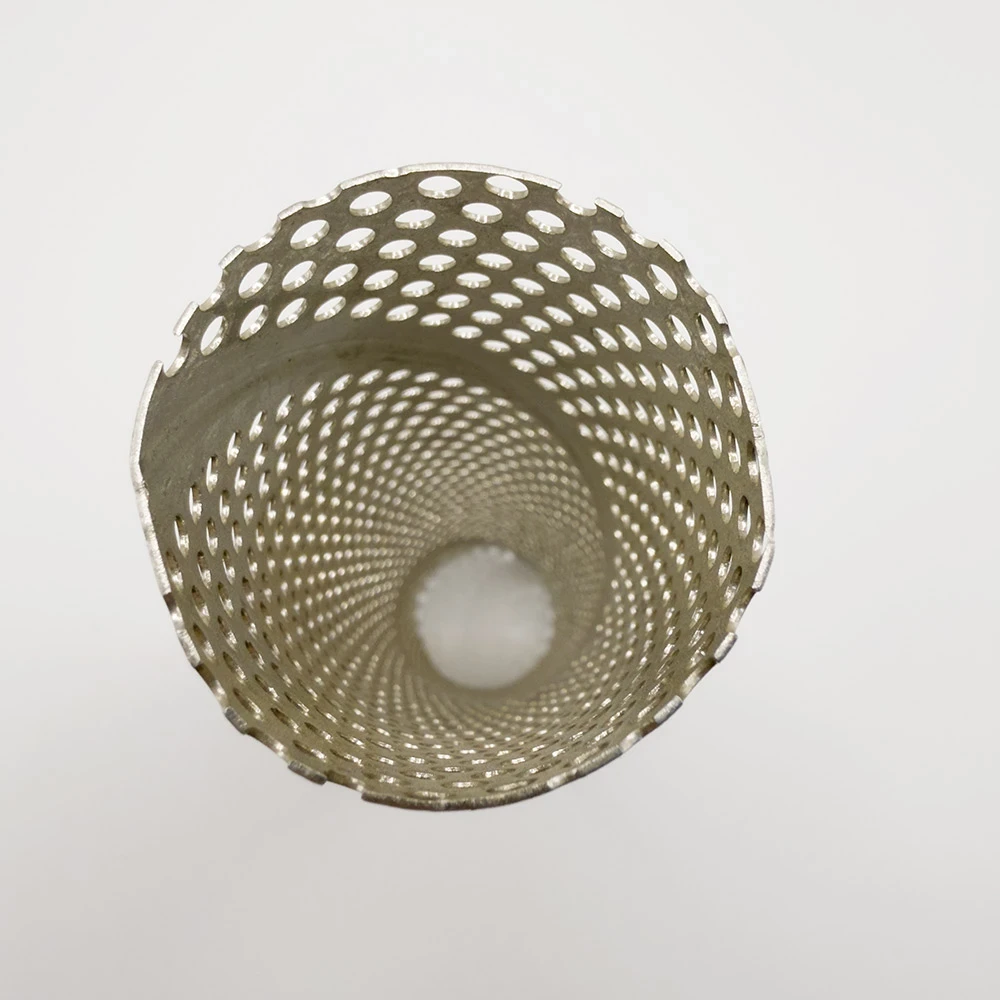

Spiral Welded Perforated Tube

|

|

hilaw Materyal

|

1. Hindi kinakalawang na asero (304, 316L)

2. Carbon Steel

3. Nickel Alloys (Monel, Hastelloy)

4. Titanium Alloy, atbp.

|

|

Saklaw ng Diameter ng Tube

|

0.5mm - 1000mm (Nako-customize)

|

|

Kapal ng pader

|

0.3mm - 5mm (Nako-customize)

|

|

Sukat ng butas

|

0.5mm - 20mm (Available sa bilog, parisukat, at mga butas na hugis slot)

|

|

Open Area Ratio

|

10% - 60% (Nako-customize batay sa mga kinakailangan sa pagsasala)

|

|

Paggamot sa Ibabaw

|

1. Pag-aatsara(Stainless steel (304, 316L), carbon steel, nickel-based alloy (Monel, Hastelloy)

2. Electrolytic Polishing(Stainless steel (304, 316L), nickel-based alloy (Monel, Hastelloy))

3. Sandblasting (Iron, carbon steel, stainless steel (304, 316L), titanium alloy, nickel-based alloy (Monel, Hastelloy))

4. Galvanizing(Bakal, carbon steel)

5. Nickel Plating(Iron, carbon steel, stainless steel (304, 316L), nickel-based alloys (Monel, Hastelloy))

atbp.

|

|

Paraan ng Welding

|

Spiral Welding (Precision Automated Welding para sa Lakas at Sealing)

|

|

Paglaban sa Presyon

|

Hanggang sa 30MPa (Nag-iiba-iba batay sa materyal at kapal)

|

|

Paglaban sa Kaagnasan

|

Lumalaban sa mga acid, alkalis, mataas na temperatura, at oksihenasyon

|

|

Uri ng Koneksyon

|

Flange Connection, Threaded Connection, Welded Joint, Clamping

|

|

Mga Naaangkop na Fluids

|

Angkop para sa mga likido, gas, langis, singaw, atbp.

|

|

Mga Paraan ng Paglilinis

|

Backwashing, Chemical Cleaning, Ultrasonic Cleaning, High-Temperature Baking

|

|

Mga Patlang ng Application

|

Petroleum, Chemical Industry, Environmental Water Treatment, Food & Pharmaceuticals, Metallurgy, Power Industry, Automotive Industry, atbp.

|

|

Mga Tampok ng Produkto

|

1. Mataas na lakas ng istraktura na may mahusay na presyon at paglaban sa kaagnasan

2. Unipormeng pagbutas para sa pinakamainam na airflow at pagsasala

3. Tinitiyak ng precision spiral welding ang tibay at pagiging maaasahan

4. Nako-customize na mga materyales, laki ng butas, at open area ratio para sa iba't ibang pangangailangan sa pagsasala

|

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)