|

Atik

|

Deskripsyon

|

|

Non pwodwi

|

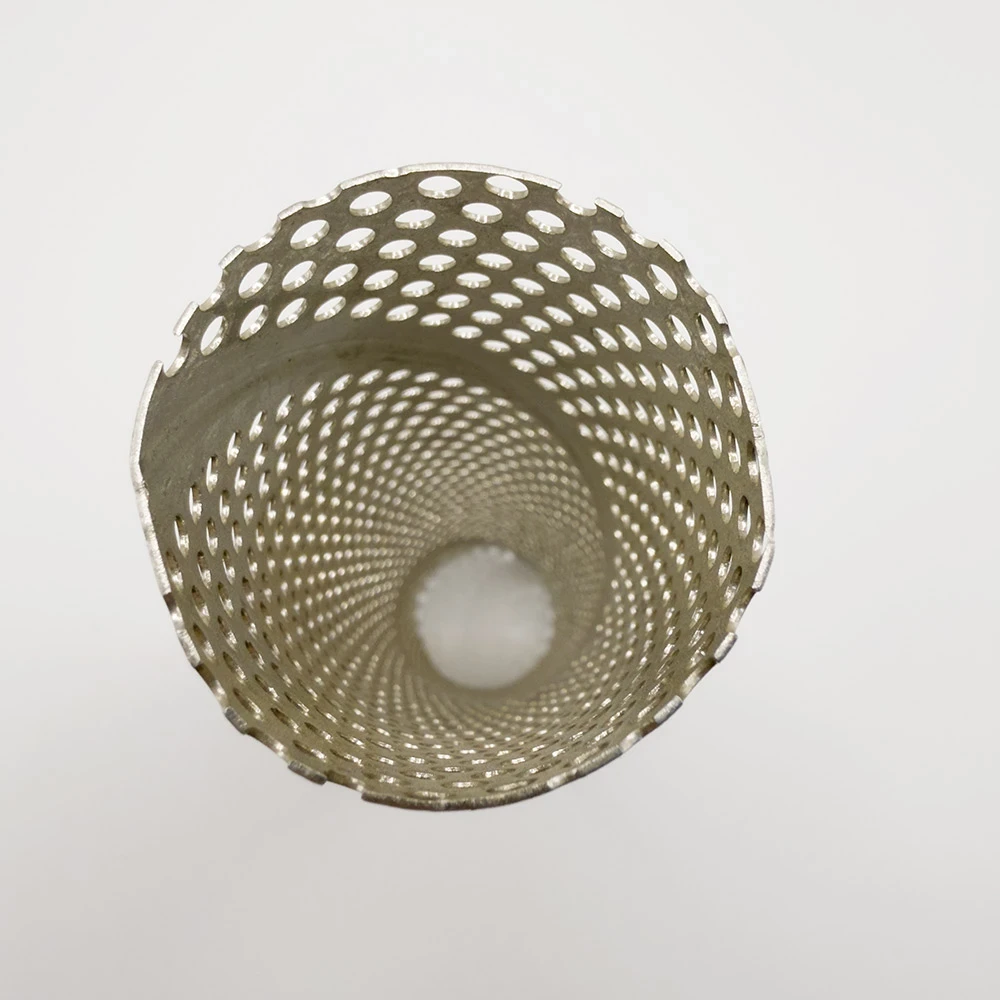

Espiral soude Tib Perforé

|

|

kri Materyèl

|

1. Nerjaveèi (304, 316L)

2. Kabòn Steel

3. Nikèl alyaj (Monel, Hastelloy)

4. Titàn Alloy, elatriye.

|

|

Tib Dyamèt Range

|

0.5mm - 1000mm (Personnalisable)

|

|

Epesè miray la

|

0.3mm - 5mm (Personnalisable)

|

|

Gwosè twou

|

0.5mm - 20mm (Disponib nan twou wonn, kare, ak twou ki gen fòm fant)

|

|

Pwopòsyon Zòn Louvri

|

10% - 60% (Personalize ki baze sou kondisyon filtraj)

|

|

Tretman andigman

|

1. marinated(Nerjaveèi (304, 316L), asye kabòn, alyaj ki baze sou nikèl (Monel, Hastelloy)

2. Polisaj elektwolitik (Nerjaveèi (304, 316L), alyaj ki baze sou nikèl (Monel, Hastelloy))

3. Sandblasting (fè, kabòn asye, asye pur (304, 316L), alyaj Titàn, alyaj ki baze sou nikèl (Monel, Hastelloy))

4. galvanize (fè, kabòn asye)

5. Nickel Plating (fè, kabòn asye, asye pur (304, 316L), alyaj ki baze sou nikèl (Monel, Hastelloy))

elatriye.

|

|

Metòd soude

|

Soudi espiral (soudi otomatik presizyon pou fòs ak sele)

|

|

Rezistans presyon

|

Jiska 30MPa (varye selon materyèl ak epesè)

|

|

Rezistans korozyon

|

Rezistan a asid, alkali, tanperati ki wo, ak oksidasyon

|

|

Kalite Koneksyon

|

Koneksyon bride, koneksyon Threaded, Joint soude, blocage

|

|

Likid ki aplikab yo

|

Apwopriye pou likid, gaz, lwil, vapè, elatriye.

|

|

Metòd netwayaj

|

Backwashing, netwayaj chimik, netwayaj ultrasons, boulanjri wo-tanperati

|

|

Jaden aplikasyon yo

|

Petwòl, endistri chimik, tretman dlo anviwònman, manje ak famasetik, metaliji, endistri pouvwa, endistri otomobil, elatriye.

|

|

Karakteristik pwodwi

|

1. High-fòs estrikti ak presyon ekselan ak rezistans korozyon

2. Inifòm pèforasyon pou airflow optimal ak filtraj

3. Precision espiral soude asire durability ak fyab

4. Customizable materyèl, gwosè twou, ak rapò zòn ouvè pou divès bezwen filtraj

|

![$atik[tit] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)