|

Atik

|

Deskripsyon

|

|

Non pwodwi

|

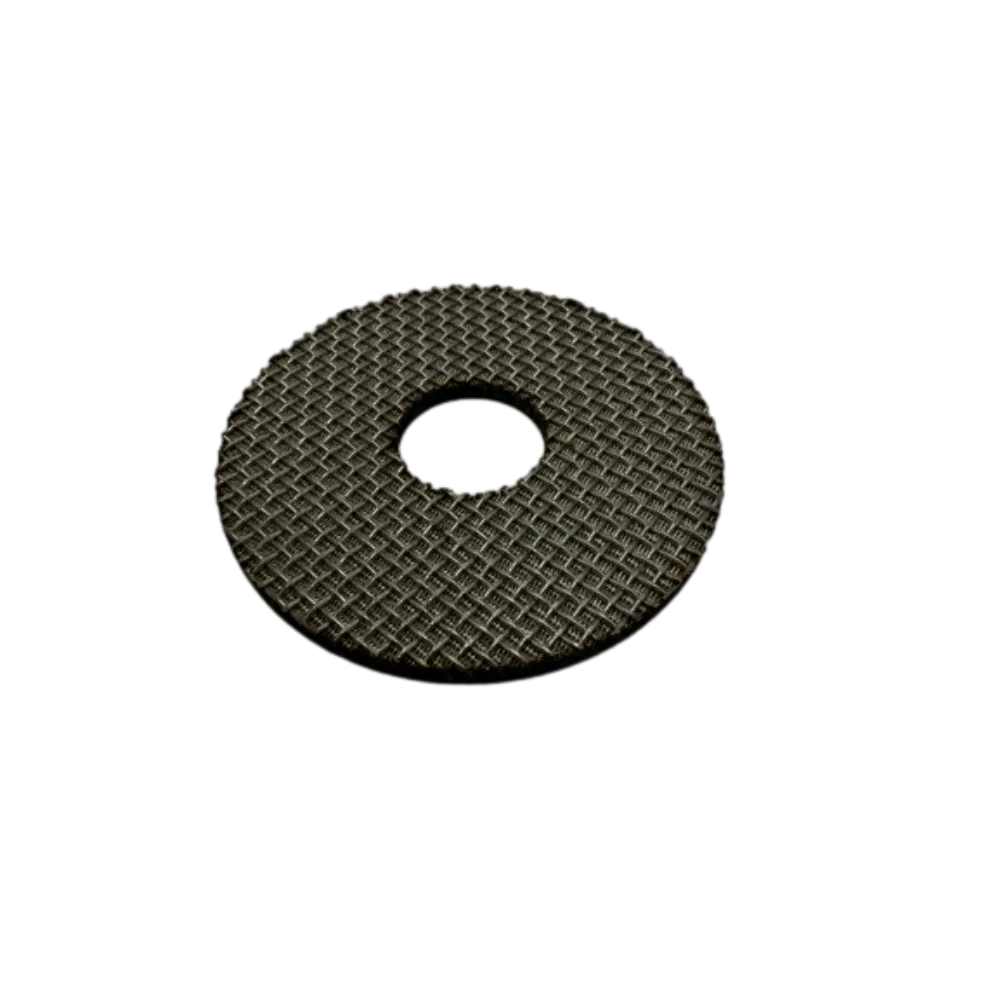

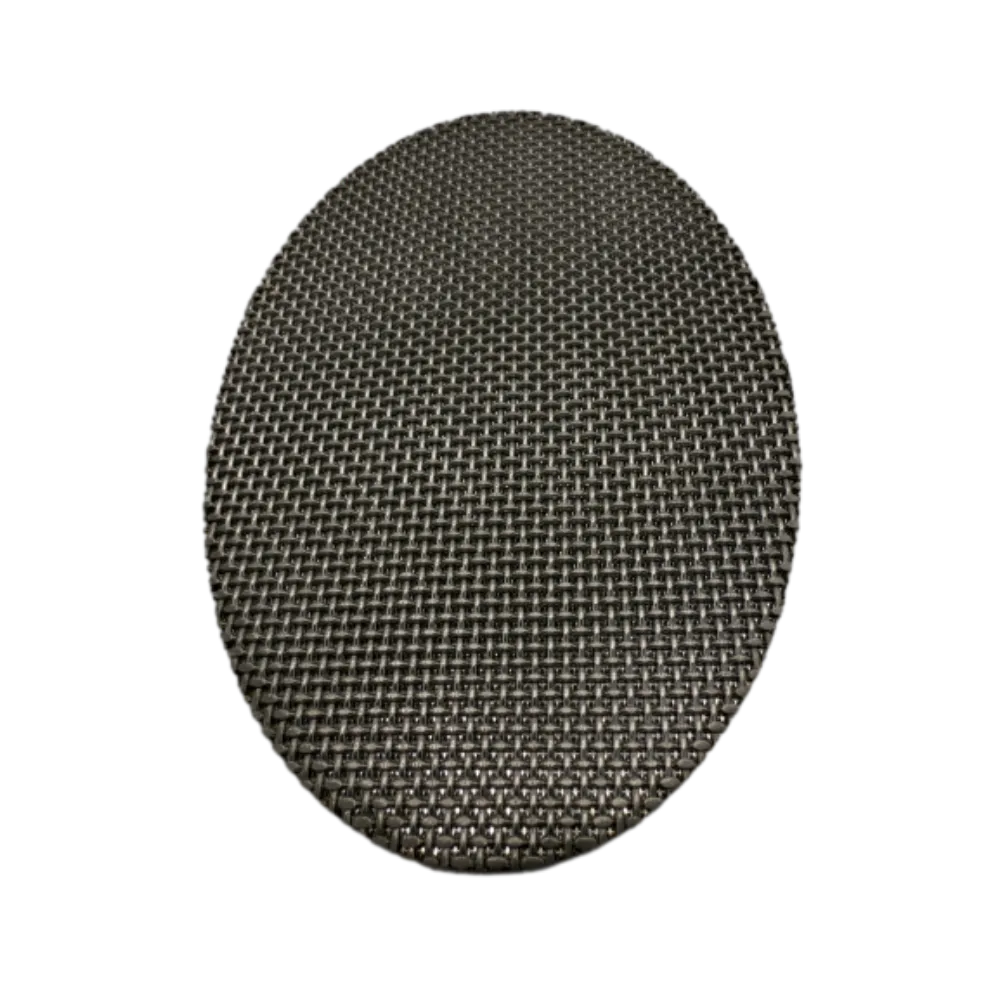

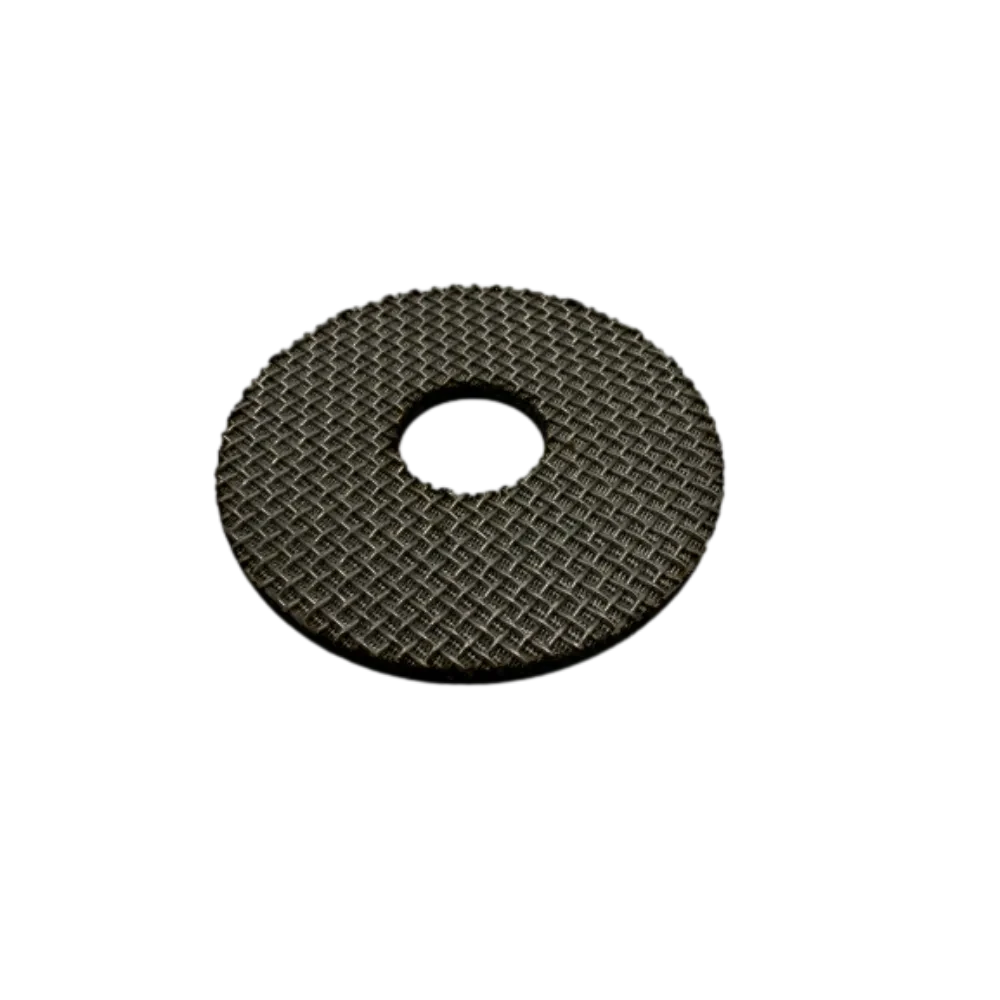

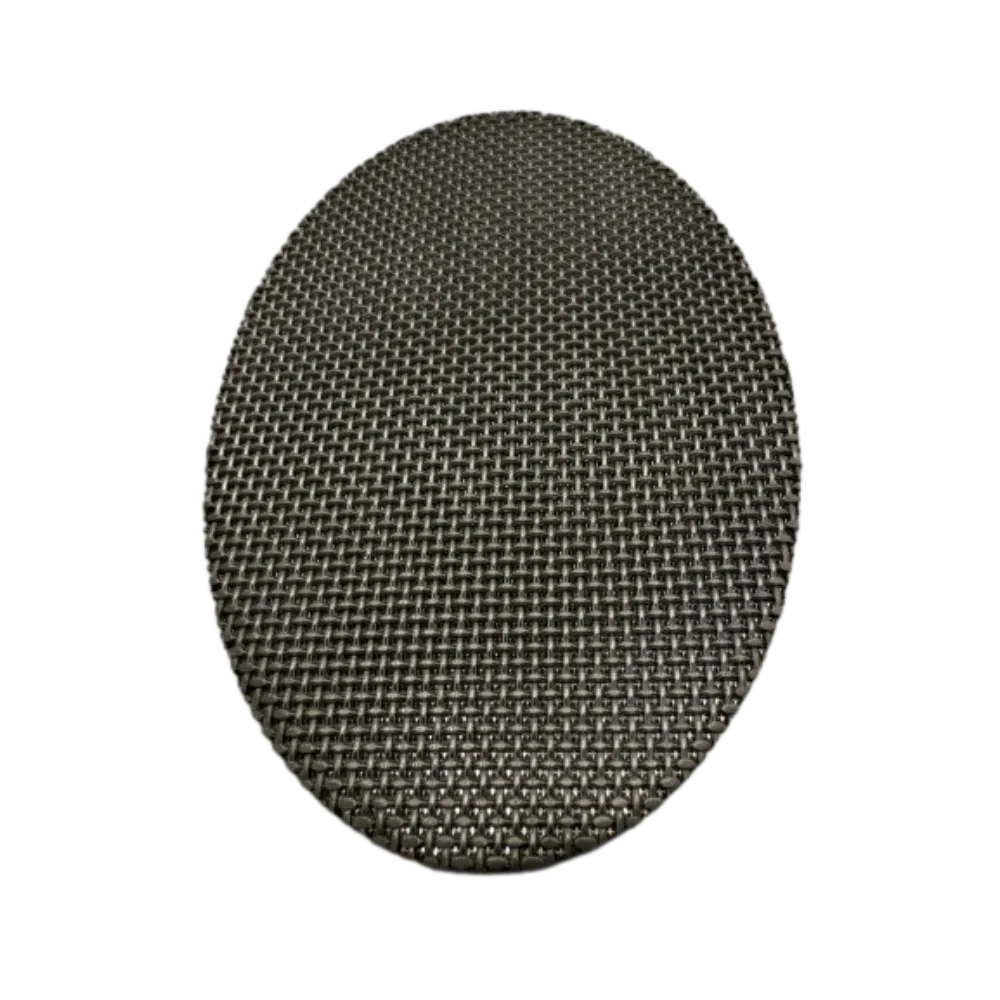

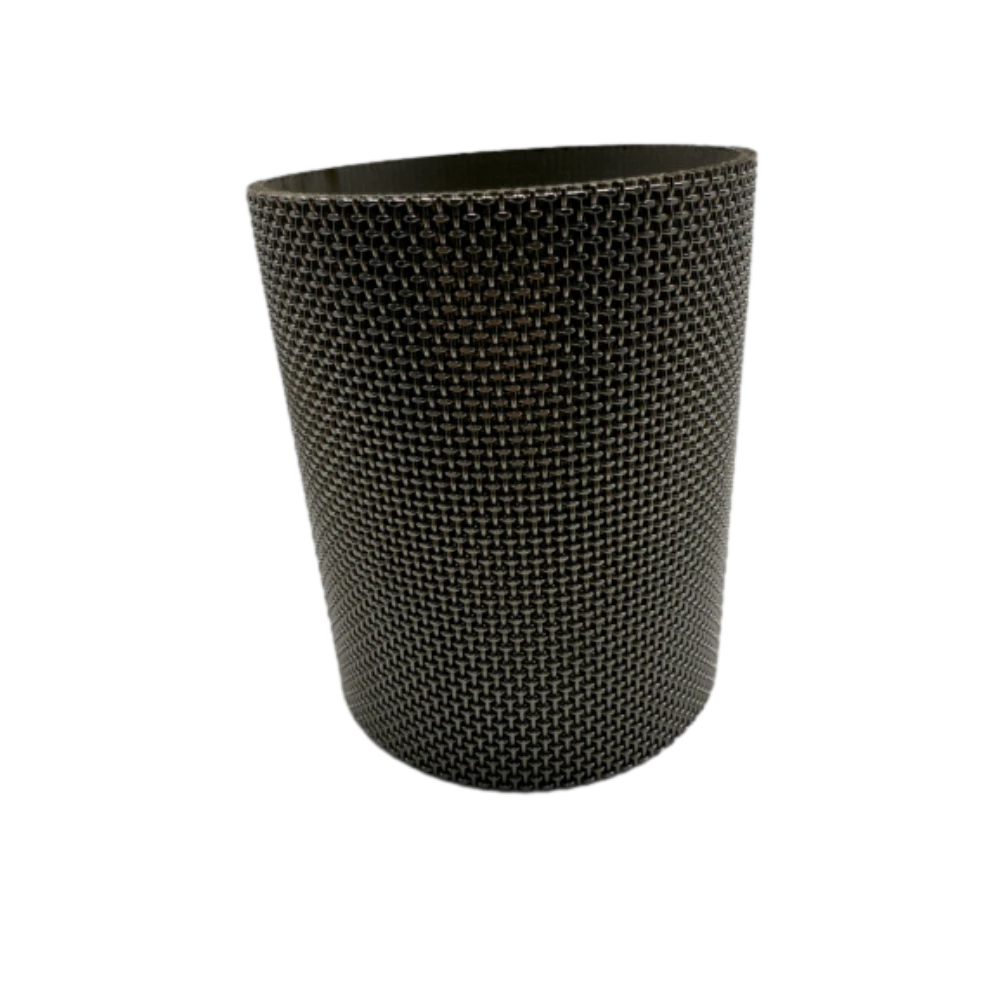

Sintered Fil may Tib

|

|

Pwosesis Faktori

|

1. SINTERING: Nan tanperati ki wo, difizyon an nan patikil metal mare may metal la ansanm yo fòme yon estrikti limenm.

2. Woule: Pa wo-presyon woule, chak kouch may byen konekte pou asire inifòmite epesè li yo.

3. Koupe lazè / Koupe Plasma: Koupe may fil Sintered la pou asire gwosè ak fòm egzak.

|

|

Trikote fason nan may fil trikote

|

1. Plain Weave (Metòd tissage ki pi komen an gen twou may inifòm epi li apwopriye pou filtraj jeneral)

2. Twill Weave (Pi wo presizyon filtraj, estrikti pi sere, apwopriye pou filtraj segondè-presizyon)

3. Dutch Weave (Yon estrikti filtraj wo-dansite ki fòme pa entèse fil koryas chèn ak fil trame amann, souvan itilize pou filtraj ultrafin)

4. Ranvèse Dutch Weave (Gen pi wo fòs ak kapasite chaj-pote, apwopriye pou filtraj wo-presyon)

|

|

Altènatif materyèl

|

1. Nerjaveèi (304, 316, 316L)

2. Nikèl alyaj (Monel、Hastelloy、Inconel)

3. Titàn may

ETC

|

|

Kantite Kouch

|

3, 5, 7 kouch (oswa Customized estrikti milti-kouch)

|

|

Filtrasyon Presizyon

|

1μm - 200μm (personnalisable)

|

|

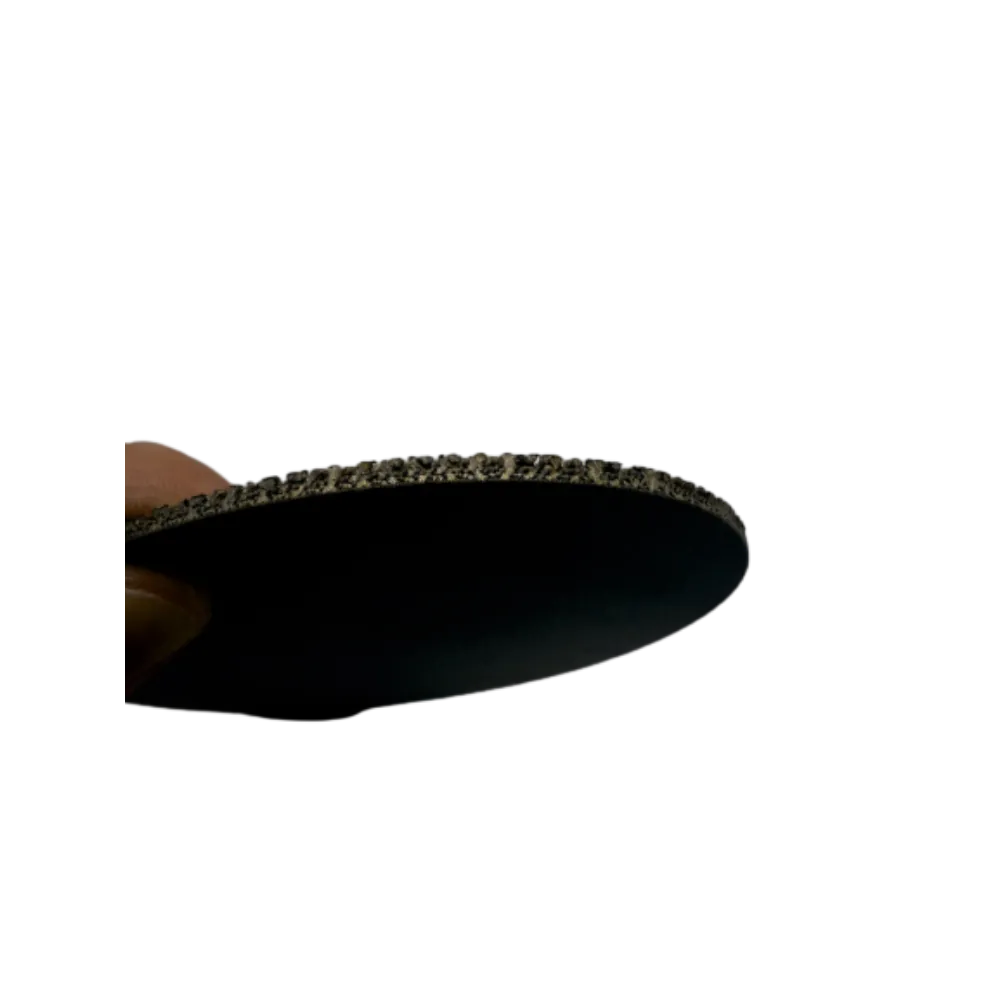

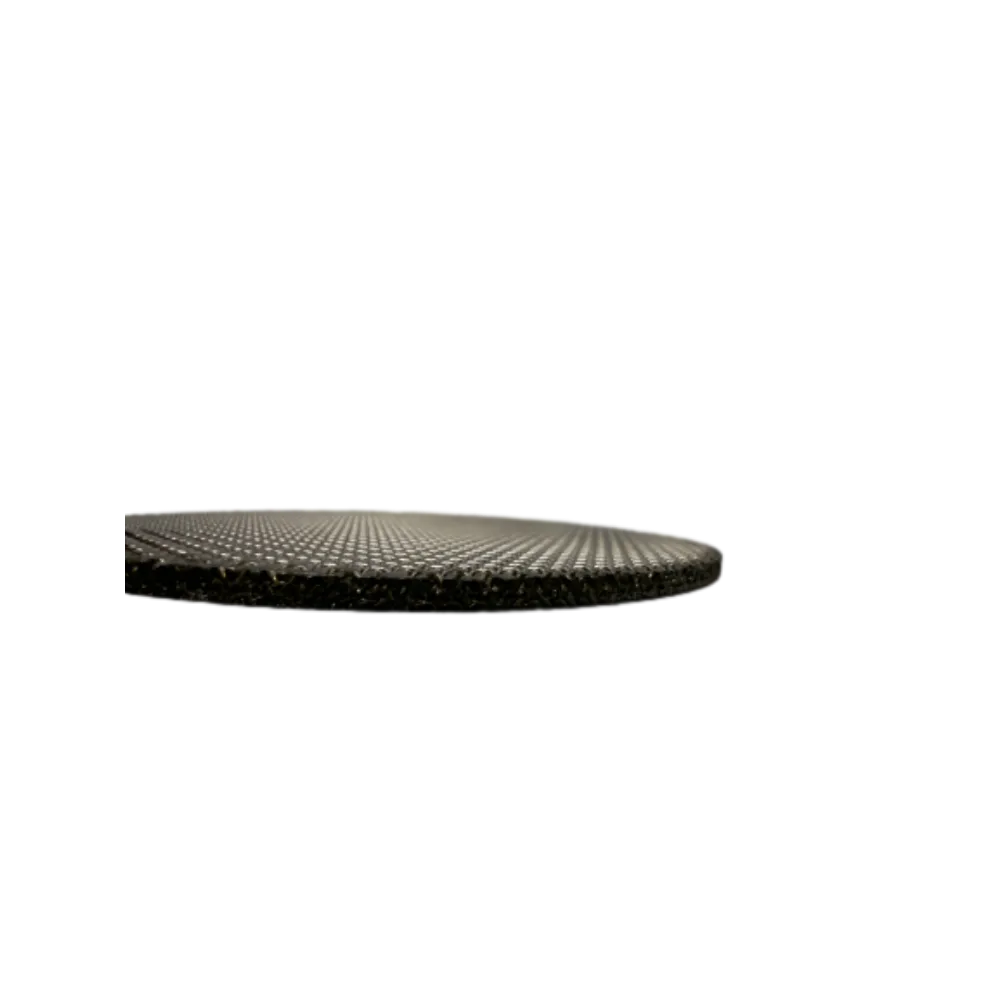

Ranje epesè

|

0.5mm - 5mm (varye selon kantite kouch)

|

|

Twou Distribisyon gwosè

|

Konsepsyon pò gradyan pou filtraj efikas ak koule likid

|

|

Tretman andigman

|

marinated asid (en fe/kabòn fe),

Polisaj elektwolitik (Nerjaveèi)

Nikèl plating (en fe/kabòn fe)

Anodizasyon (aliminyòm) elatriye.

|

|

Tanperati Fonksyònman

|

-200 ℃ a 600 ℃ (selon materyèl)

|

|

Rezistans presyon

|

Jiska 30MPa oswa pi wo (varye selon kouch may ak epesè)

|

|

Pèmeyabilite / Rezistans koule

|

Ba rezistans ak pèmeyabilite segondè, apwopriye pou filtraj gaz ak likid

|

|

Rezistans korozyon

|

Rezistan a asid, alkali, espre sèl, ak oksidasyon nan anviwònman piman bouk

|

|

Metòd netwayaj

|

Backwashing, netwayaj ultrasons, boulanjri segondè-tanperati, netwayaj chimik, ak ki kapab itilize ankò

|

|

Pwosesis Faktori

|

Sintering vakyòm wo-tanperati, Rolling

|

|

Fòm ki disponib

|

Silendrik, kare, fèy, plise, fòm koutim ki disponib

|

|

Metòd Koneksyon

|

Koneksyon bride, soude, koneksyon Threaded, blocage

|

|

Likid ki aplikab yo

|

Apwopriye pou likid, gaz, lwil, vapè, elatriye.

|

|

Jaden aplikasyon yo

|

Petrochimik, Manje & Bwason, Famasetik, Tretman Dlo Anviwònman, Aerospace, Endistri Otomobil, elatriye.

|

|

Avantaj pwodwi yo

|

1. Segondè fòs ak rezistans presyon, pa fasil pou defòme

2. netwayaj repete, lavi ki long

3. Precision filtraj, distribisyon gwosè pò inifòm

4. Segondè tanperati ak rezistans korozyon, adaptab nan anviwònman piman bouk

|

![$atik[tit] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)