|

Nga taonga

|

Whakaahuatanga

|

|

Ingoa Hua

|

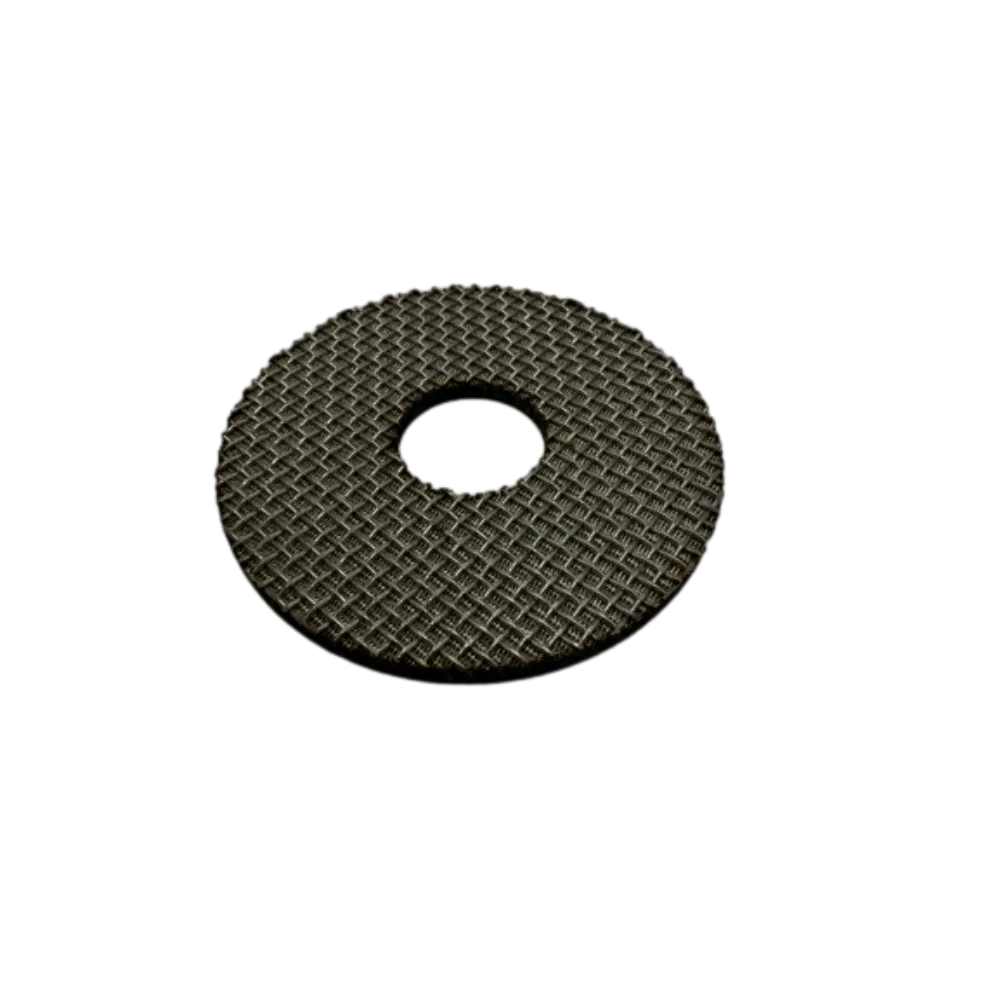

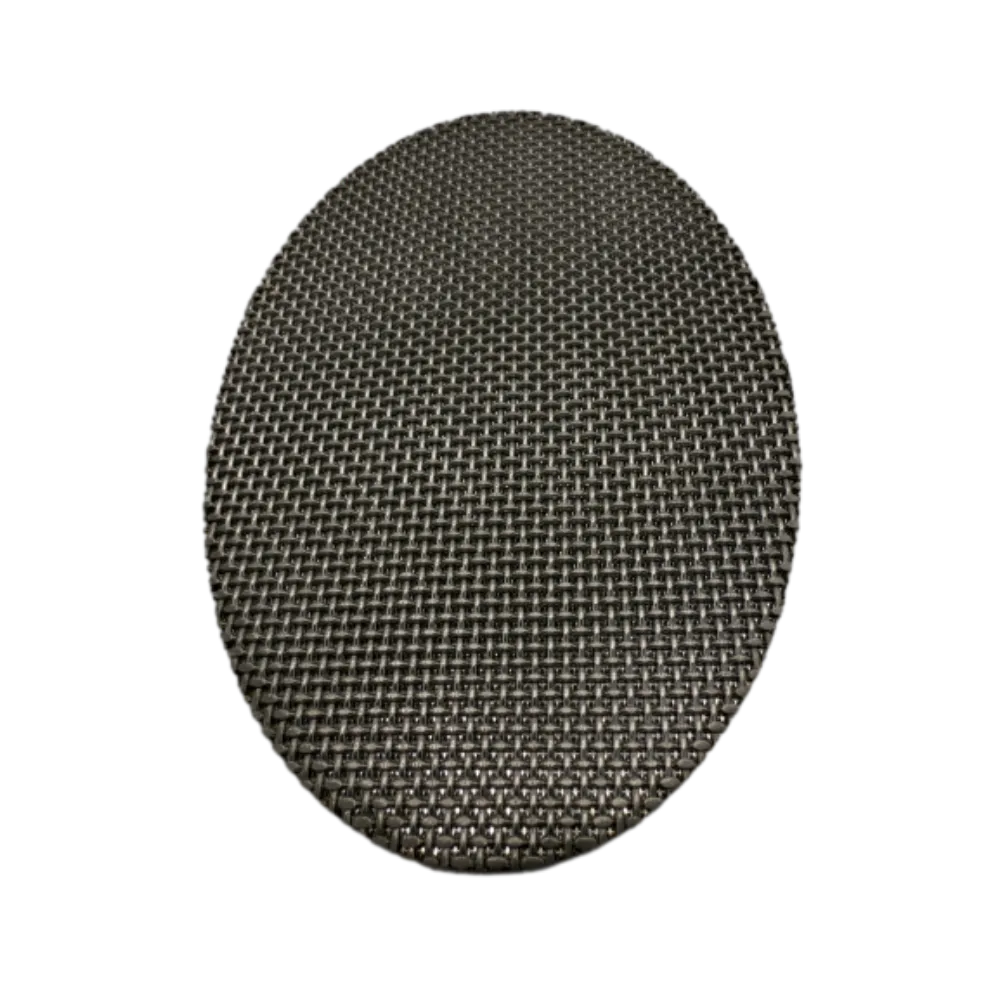

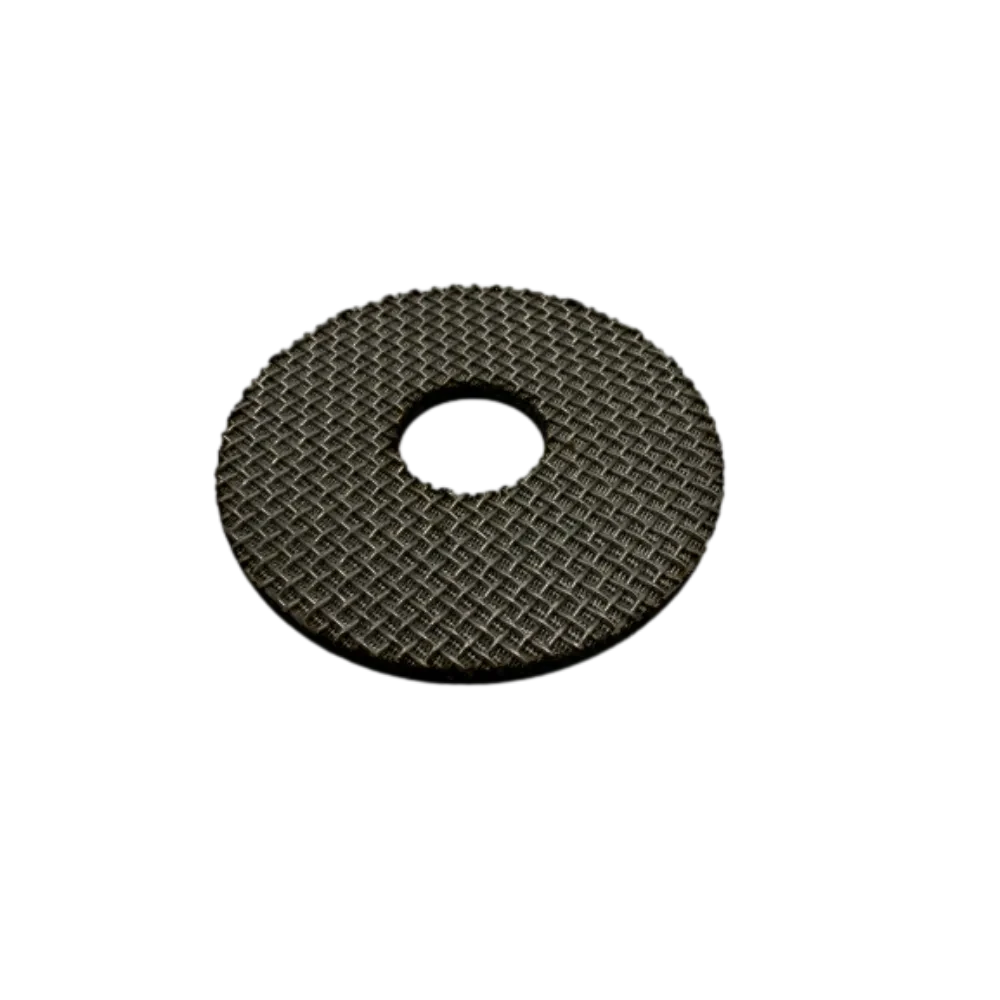

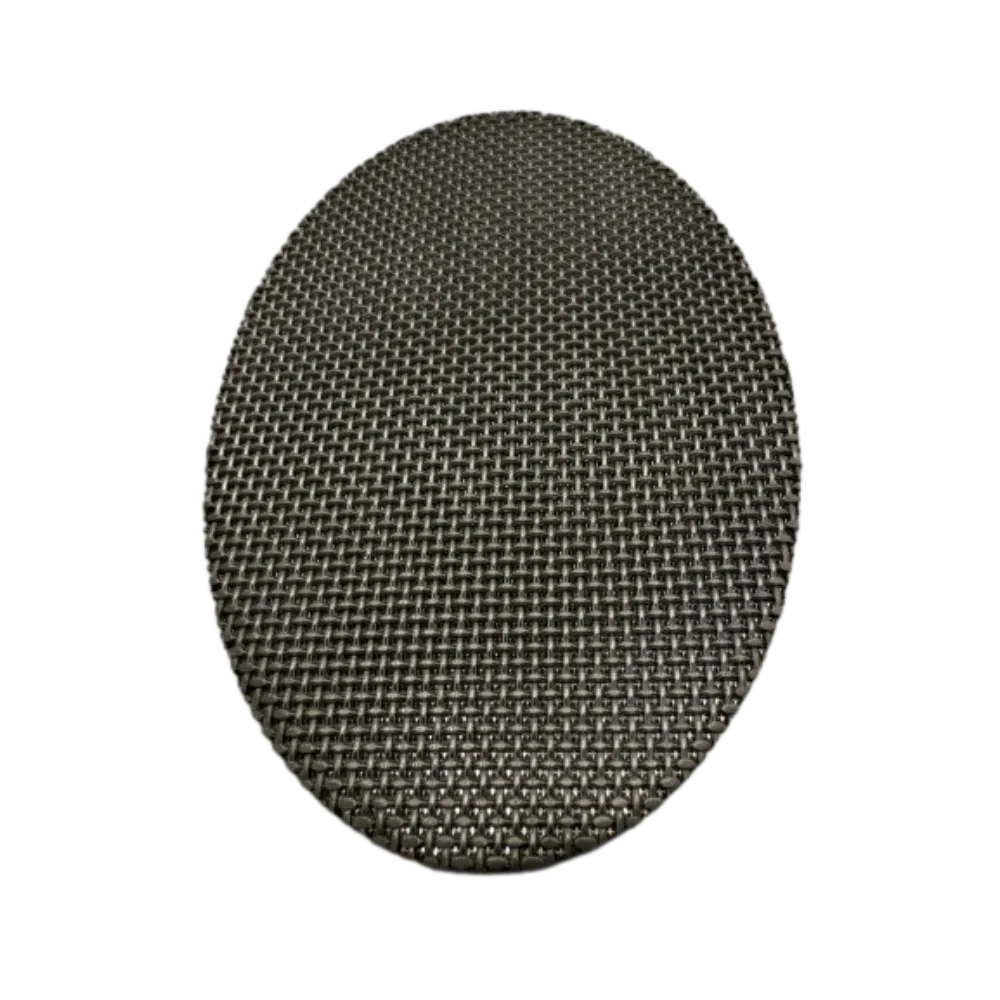

Tube Wire Mesh Sintered

|

|

Tukanga Hangahanga

|

1. Sintering:I te nui o te mahana, ka herea e te whakamaaramatanga o nga matūriki whakarewa te mata whakarewa hei hanga i te hanganga hono.

2. Hurihuri: Ma te pehanga teitei, ka honoa ia paparanga mata kia rite ai tona matotoru.

3. Te Tapahi Taiaho/Te tapahi Plasma: Tapahia te Mata Waea Tiwhi kia tika te rahi me te hanga.

|

|

Raranga ara o whatu waea mata

|

1. Raranga Maama (Ko te tikanga raranga noa he kohao mata rite, he pai mo te tātari whanui)

2. Twill Weave(Te tika ake o te tātari, te hanga kikii, e tika ana mo te tātari tino tika)

3. Raranga Tatimana(Ka hangaia he hanganga tātari kiato nui ma te whiri i nga miro taratara me nga miro weft pai, e whakamahia ana mo te filtration ultrafine)

4. Raranga Tatimana Whakamuri(He kaha ake te kaha me te kaha ki te kawe, e tika ana mo te tātari pehanga teitei)

|

|

Rauemi rereke

|

1. Kowiri tira (304, 316, 316L)

2. Nickel Alloy(Monel, Hastelloy, Inconel)

3. Matau Titanium

ETC

|

|

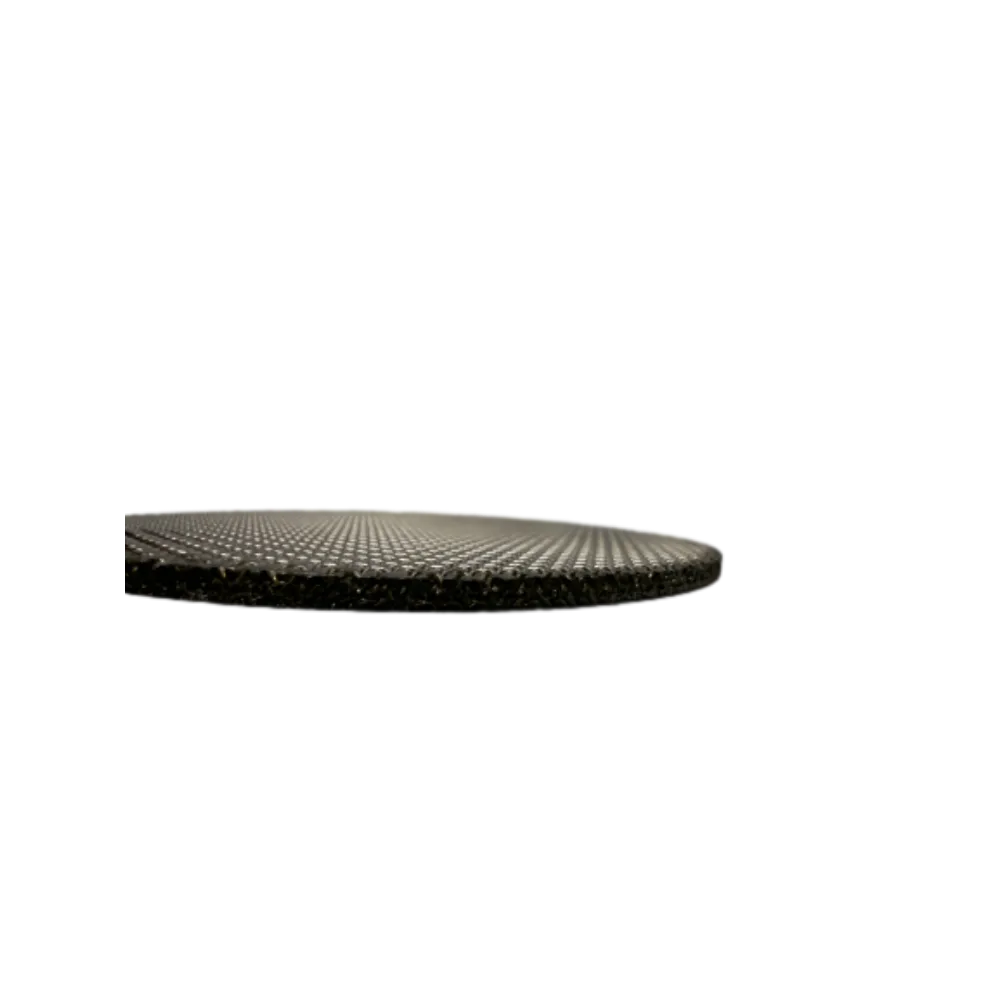

Te maha o nga papa

|

3, 5, 7 nga paparanga (he hanganga paparanga-maha ranei)

|

|

Tikanga Whiriwhiringa

|

1μm - 200μm (ka taea te whakarite)

|

|

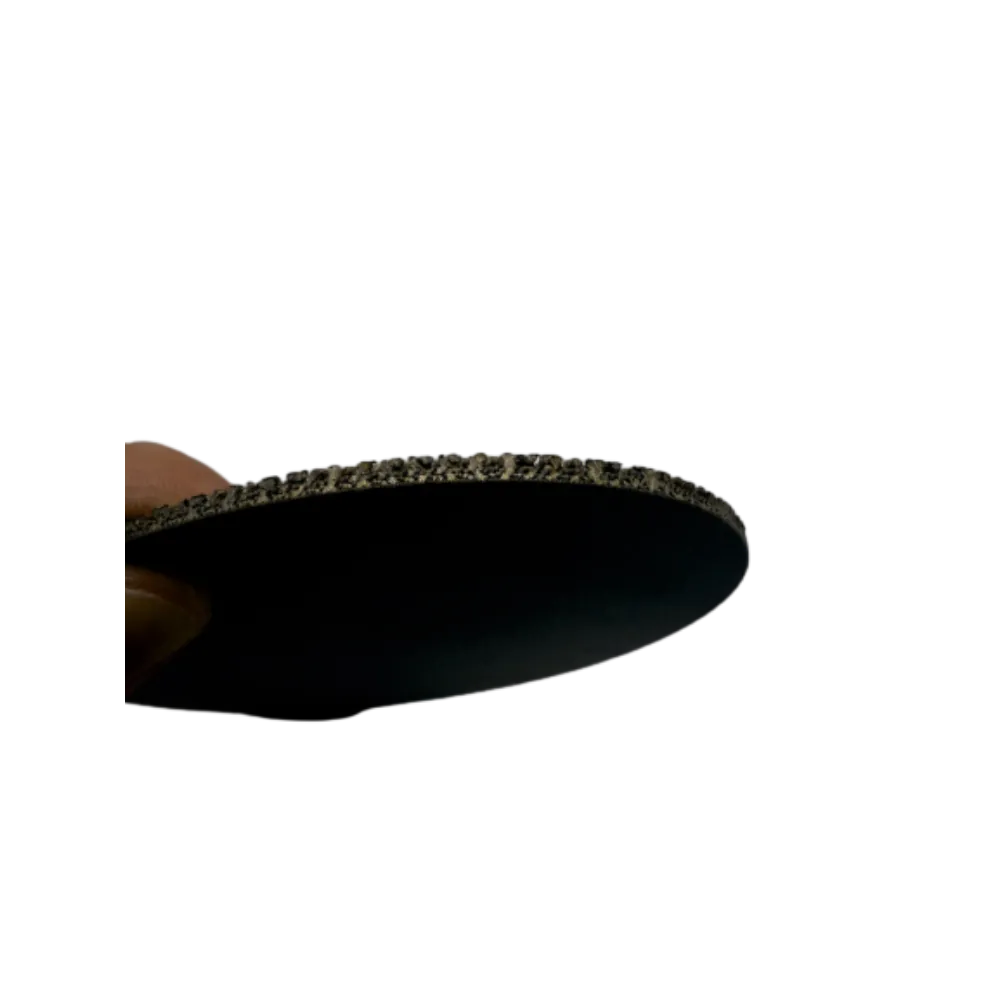

Awhe Matotoru

|

0.5mm - 5mm (he rerekee te maha o nga paparanga)

|

|

Kohao Te Tohatoha Rahi

|

Hoahoa pore rōnaki mo te tātari pai me te rere wai

|

|

Mahinga Mata

|

Pikinga waikawa(Stainless Steel/Carbon maitai),

Whakakorikori Hiko (Stainless Steel)

Whakakikorua Nika (Stainless Steel/Carbon Steel)

Anodizing(Konumohe) etc.

|

|

Te Waahi Mahi

|

-200 ℃ ki te 600 ℃ (i runga i te rauemi)

|

|

Atete Pehenga

|

Tae atu ki te 30MPa teitei ake ranei (he rereke i runga i nga papanga mata me te matotoru)

|

|

Te uruhanga / Rere Atete

|

He iti te parenga me te uruhanga teitei, e tika ana mo te hau me te tātari wai

|

|

Te Waihanga Atete

|

He ātete ki te waikawa, te kawakore, te rehu tote, me te waikura i roto i nga taiao kino

|

|

Tikanga horoi

|

Te horoi i muri, te horoi Ultrasonic, Te tunu i te pāmahana teitei, te horoi matū, me te whakamahi ano

|

|

Tukanga Hangahanga

|

Te wera-te-te-te-mahana korehau sintering, Te hurihuri

|

|

Hanga Watea

|

Porotakaro, Tapawha, Rau, Pleated, Ritenga ahua e waatea ana

|

|

Nga Tikanga Hononga

|

Hononga flange, Welding, hononga miro, Rawhi

|

|

Wai e tika ana

|

He pai mo te wai, hau, hinu, mamaoa, etc.

|

|

Nga Apure Tono

|

Petrochemical, Kai & Inu, Pharmaceuticals, Maimoatanga Wai Taiao, Aerospace, Ahumahi Automotive, etc.

|

|

Hua Painga

|

1. Te kaha me te kaha o te pehanga, kaore i te ngawari ki te whakarereke

2. Ka taea te horoi, te ora roa

3. Tātari pū, tohatoha rahi pore ōrite

4. Te pāmahana teitei me te aukati waikura, ka urutau ki nga taiao kino

|

![$tuemi[taitara] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)