|

Aitema

|

Fa'amatalaga

|

|

Igoa Oloa

|

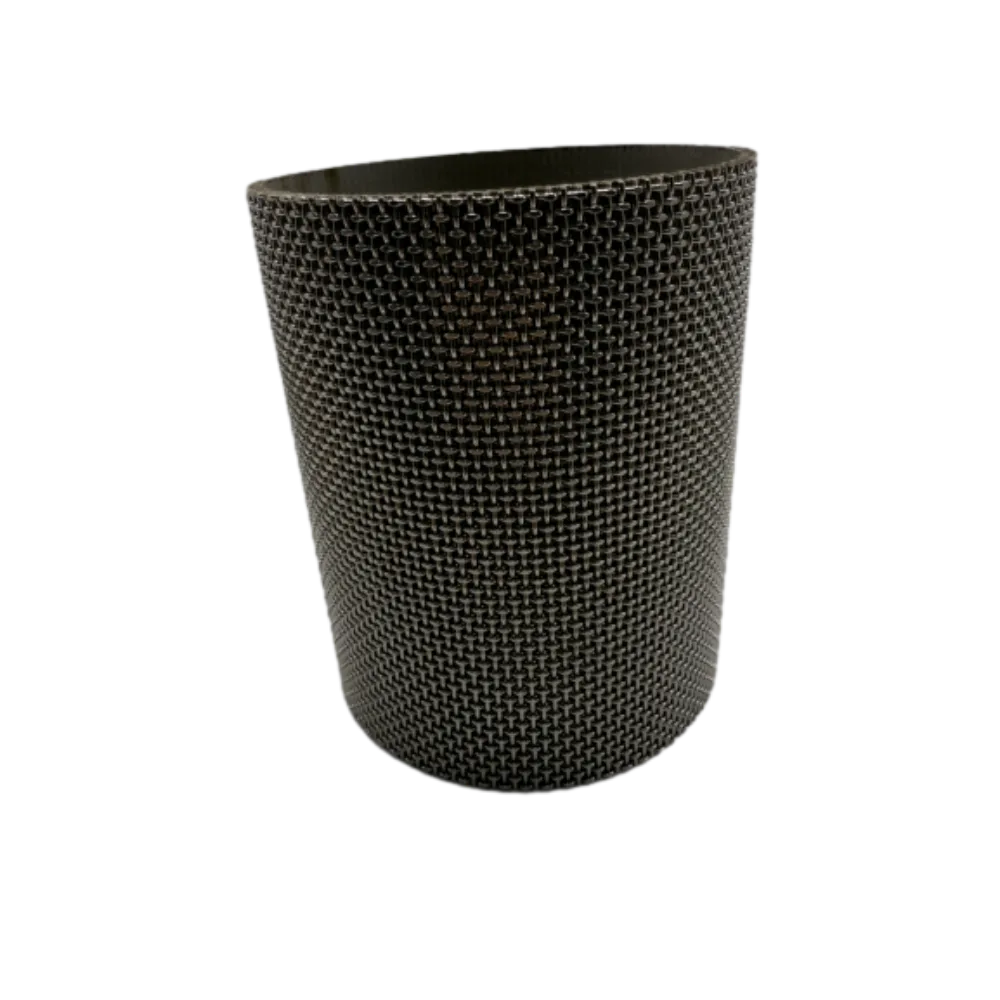

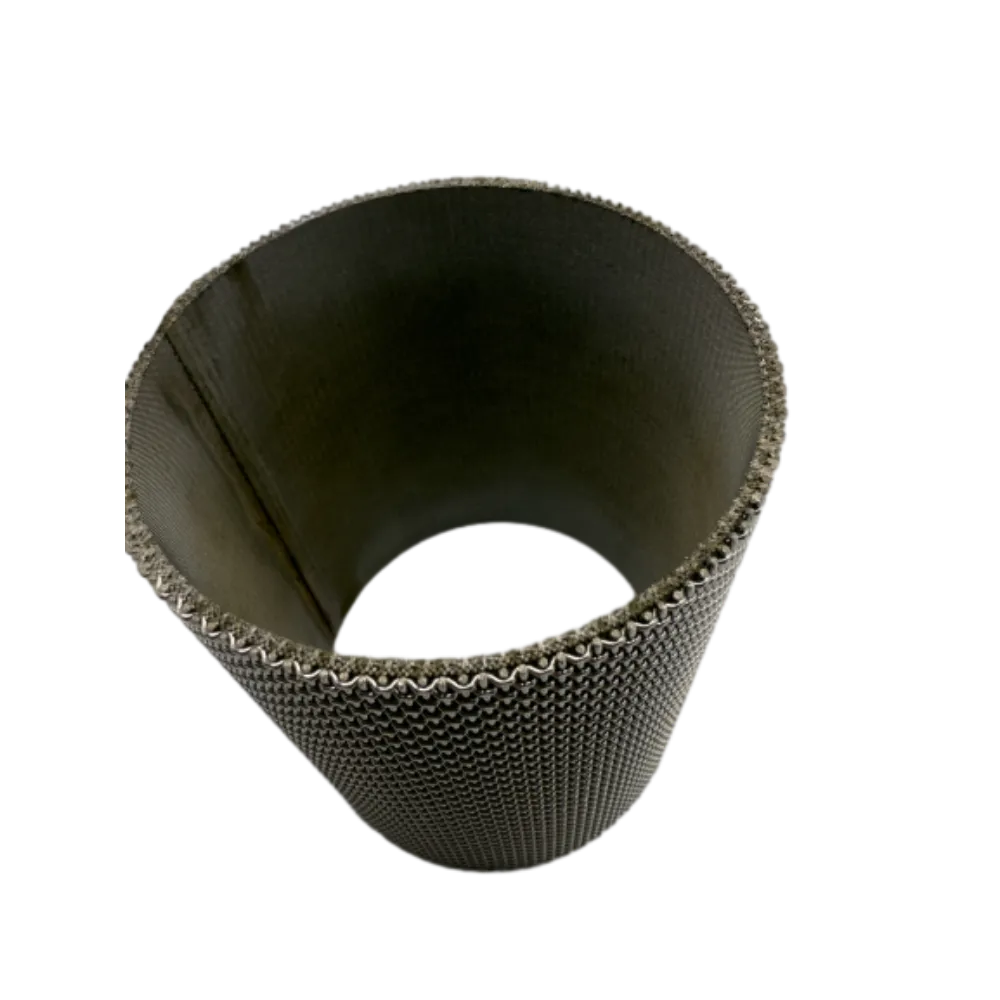

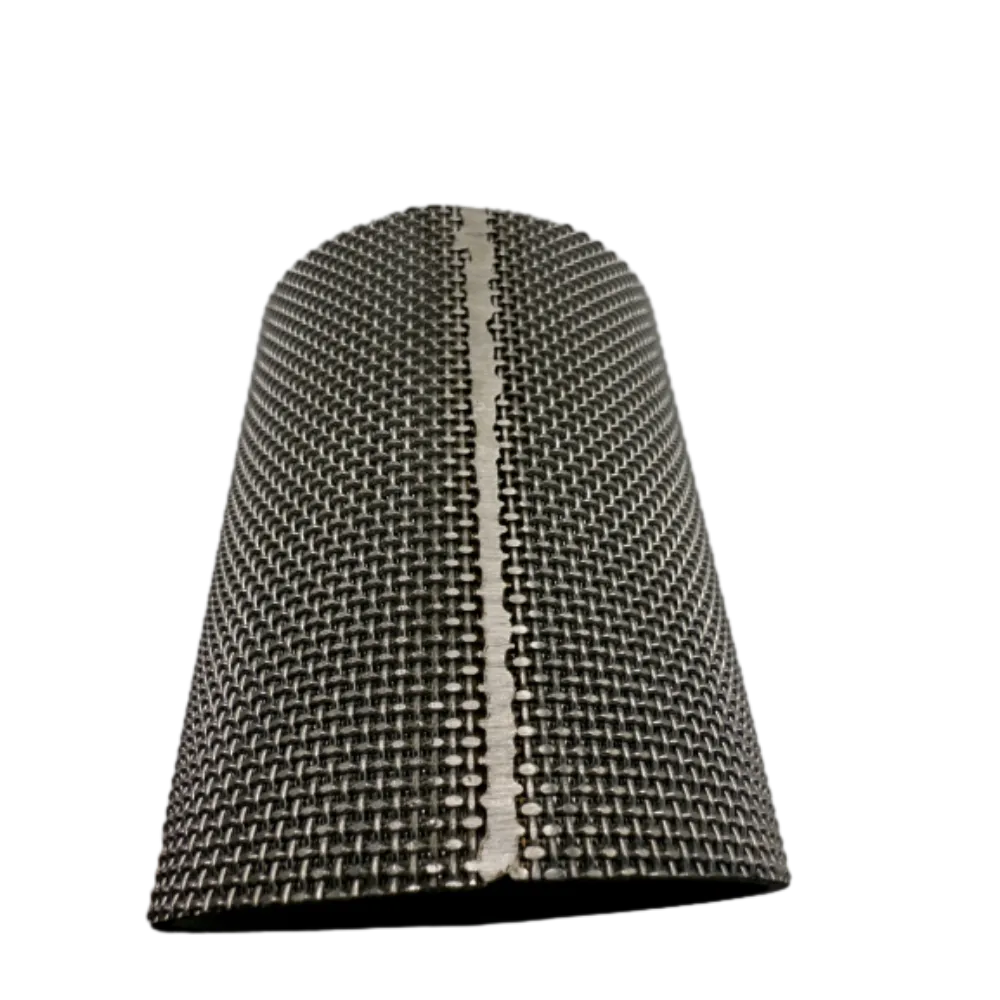

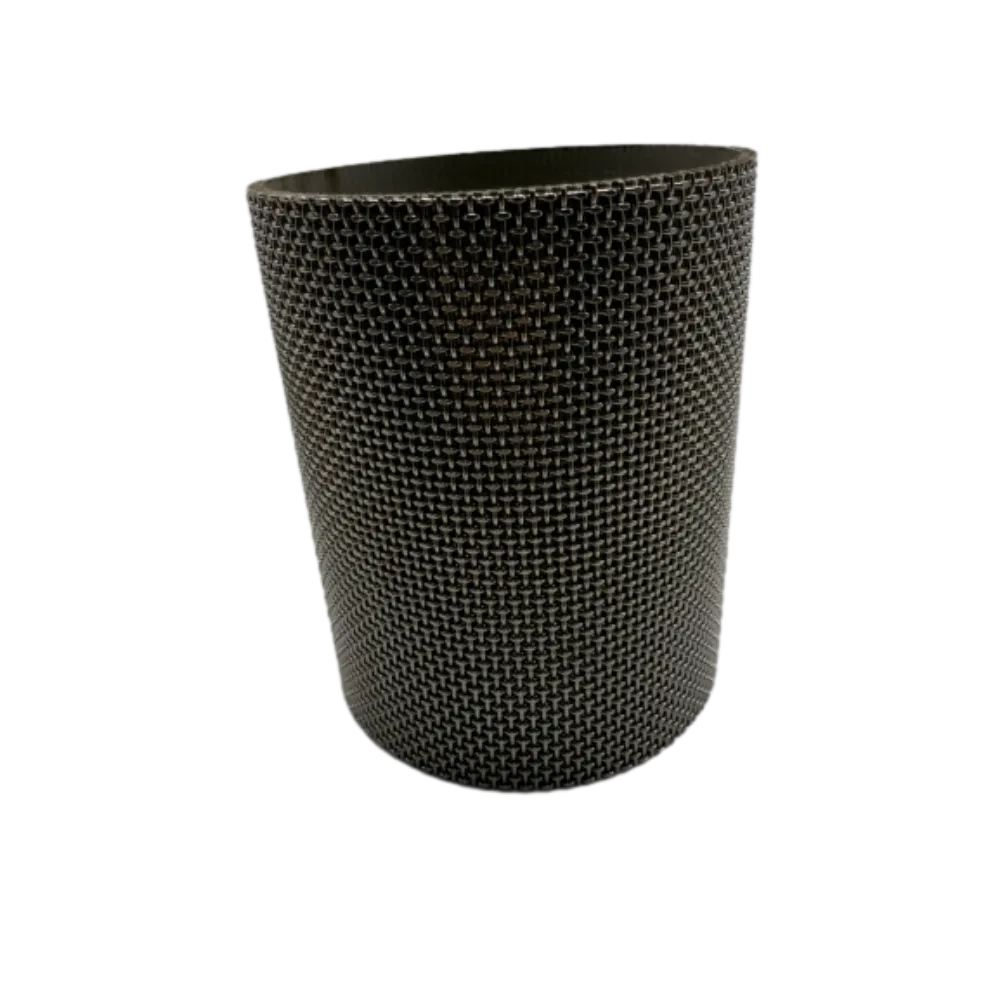

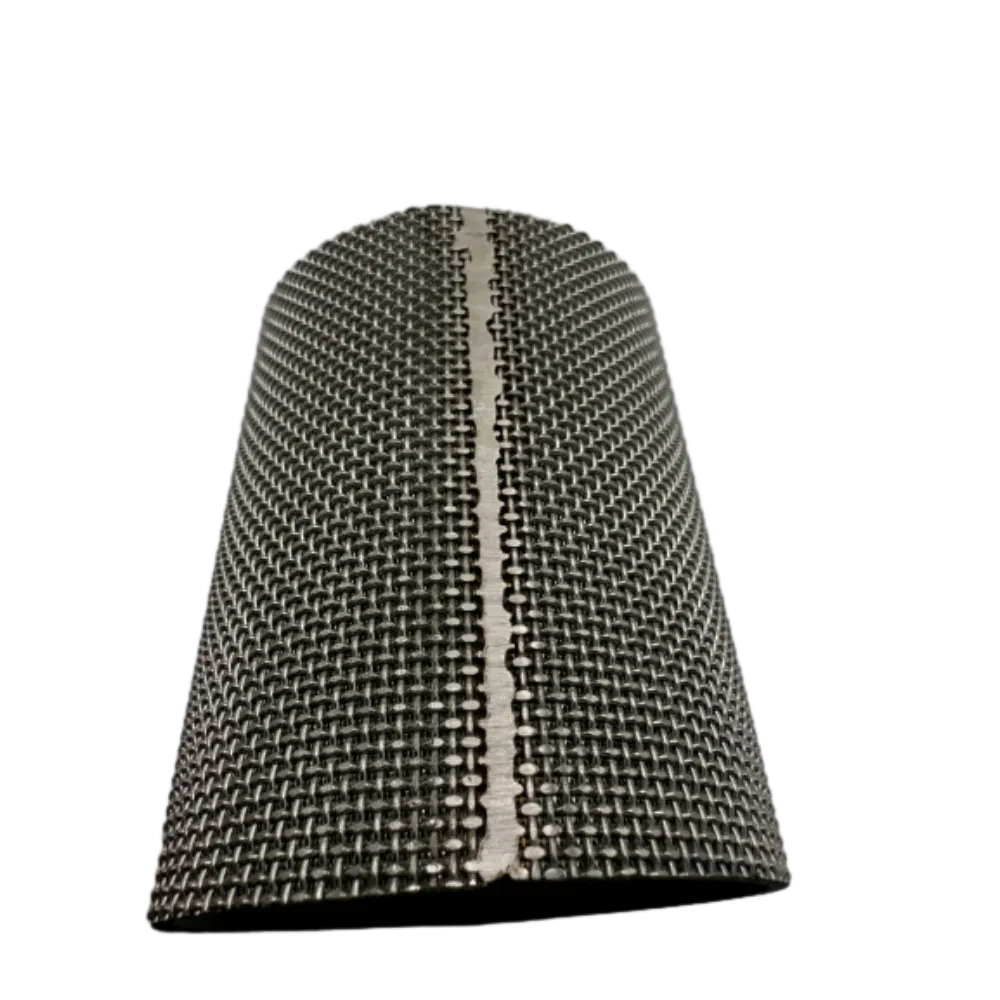

Uaea Mesh Tube

|

|

Fa'agasologa o Gaosi

|

1. Sintering: I le maualuga o le vevela, o le faʻasalalauina o vaega uʻamea e fusia faatasi ai le uʻamea e fausia ai se fausaga faʻatasi

2. Ta'avale: E ala i le ta'avale maualuga, o lo'o feso'ota'i fa'amau ta'itasi ta'itasi e fa'amautinoa ai le tutusa o lona mafiafia.

3. Tipiina leisa/Otiotiina Plasma: tipiina uaea Mesh Sintered, Ia mautinoa o le tipi e saʻo i le lapopoa ma foliga.

4. Uila: Fa'aaogaina mo le ueloina i se foliga fa'asili

|

|

Lalaga ala o lalaga uaea

|

1. Lalaga Lalaga (O le auala sili ona masani lalaga e maua ai pu mata toniga ma e talafeagai mo filtration lautele)

2. Twill Weave(Sa'o sa'o fa'asili maualuga, fa'afuga fa'amau, talafeagai mo le fa'amama sa'o maualuga)

3. Lalaga Dutch(O se fausaga fa'amama maualuga e fa'avaeina e ala i le lalagaina o filo fa'afefe ma filo lalaga lelei, e masani ona fa'aoga mo ultrafine filtration)

4. Reverse Dutch Weave(E maualuga le malosi ma le gafatia o le avega, talafeagai mo le faʻamamaina o le mamafa)

|

|

Meafaitino Su'i

|

1. Uamea uamea (304, 316, 316L)

2. Nikeli Alloy(Monel, Hastelloy, Inconel)

3. Mesh Titanium

ETC

|

|

Numera o Laega

|

3, 5, 7 laulau (poʻo le faʻatulagaina o fausaga faʻapipiʻi tele)

|

|

Sa'o o le filiga

|

1μm - 200μm (fa'atonu)

|

|

Va'aiga Mafiafia

|

0.5mm - 5mm (ese'ese i le aofa'i o laulau)

|

|

Pu Tele Faasoa

|

Fuafuaga pore Gradient mo le faamamaina lelei ma le tafe o le vai

|

|

Togafitiga i luga

|

Acid pickling(Stainless Steel/Carbon steel),

Uila fa'aeletise(Stainless Steel)

Uila nikeli

Anodizing (Aluminium) ma isi.

|

|

Galulue Vevela

|

-200 ℃ i le 600 ℃ (faʻalagolago i mea)

|

|

Tete'e o Omiga

|

E oʻo atu i le 30MPa pe sili atu (e fesuisuiaʻi faʻavae i luga o faʻailoga mata ma le mafiafia)

|

|

Mauaina / Fa'asaga Fa'asaga

|

Le maualalo teteʻe ma maualuga permeability, talafeagai mo kesi ma vai filtration

|

|

Tete'e a'e

|

E tetee atu i acids, alkalis, masima masima, ma oxidation i siosiomaga faigata

|

|

Fa'amama Metotia

|

Fufulu i tua, fa'amama Ultrasonic, taoina o le vevela maualuga, fa'amama vaila'au, ma toe fa'aaogaina

|

|

Fa'agasologa o Gaosi

|

Sintering vacuum maualuga-vevela, Ta'avale, Uila, Stamping

|

|

Avanoa Fa'atusa

|

Cylindrical, Square, Sheet, Pleated, Custom shapes available

|

|

Auala So'oga

|

Feso'ota'iga fu'a, U'u, So'oga filo, Fa'amau

|

|

Suavai talafeagai

|

E fetaui mo vai, kasa, suauʻu, ausa, ma isi.

|

|

Talosaga Fields

|

Petrochemical, Mea'ai & Meainu, Pharmaceuticals, Si'osi'omaga Suavai Togafitiga, Aerospace, Alamanuia Ta'avale, ma isi.

|

|

Tulaga Lelei

|

1. Malosi maualuga ma le faʻamalosi malosi, e le faigofie ona faʻaleagaina

2. Fa'amama toe fai, ola umi

3. Sa'o filtration, tufatufa lapoa pore tutusa

4. maualuga le vevela ma le corrosion tetee, fetuutuunai i siosiomaga faigata

|

![$aitema[igoa] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)