|

Cov khoom

|

Kev piav qhia

|

|

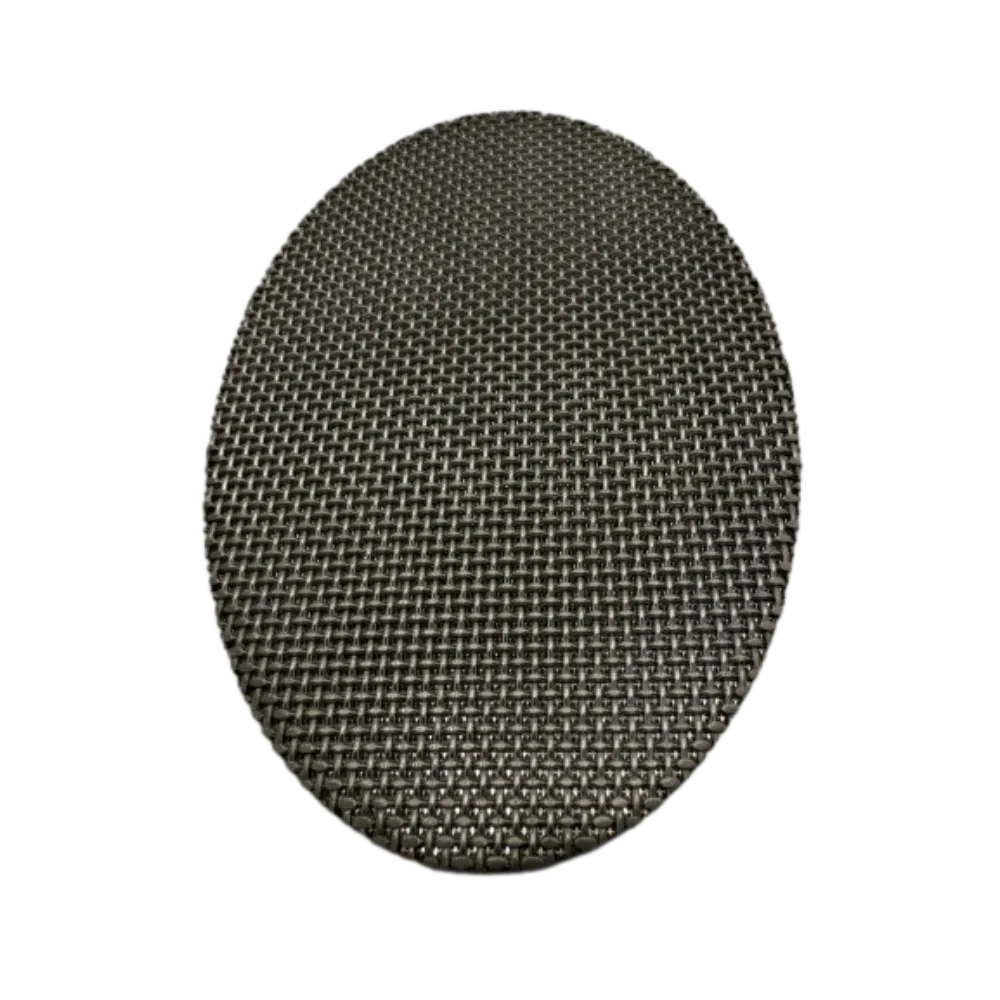

Khoom npe

|

Sintered Hlau Mesh Tube

|

|

Kev tsim khoom

|

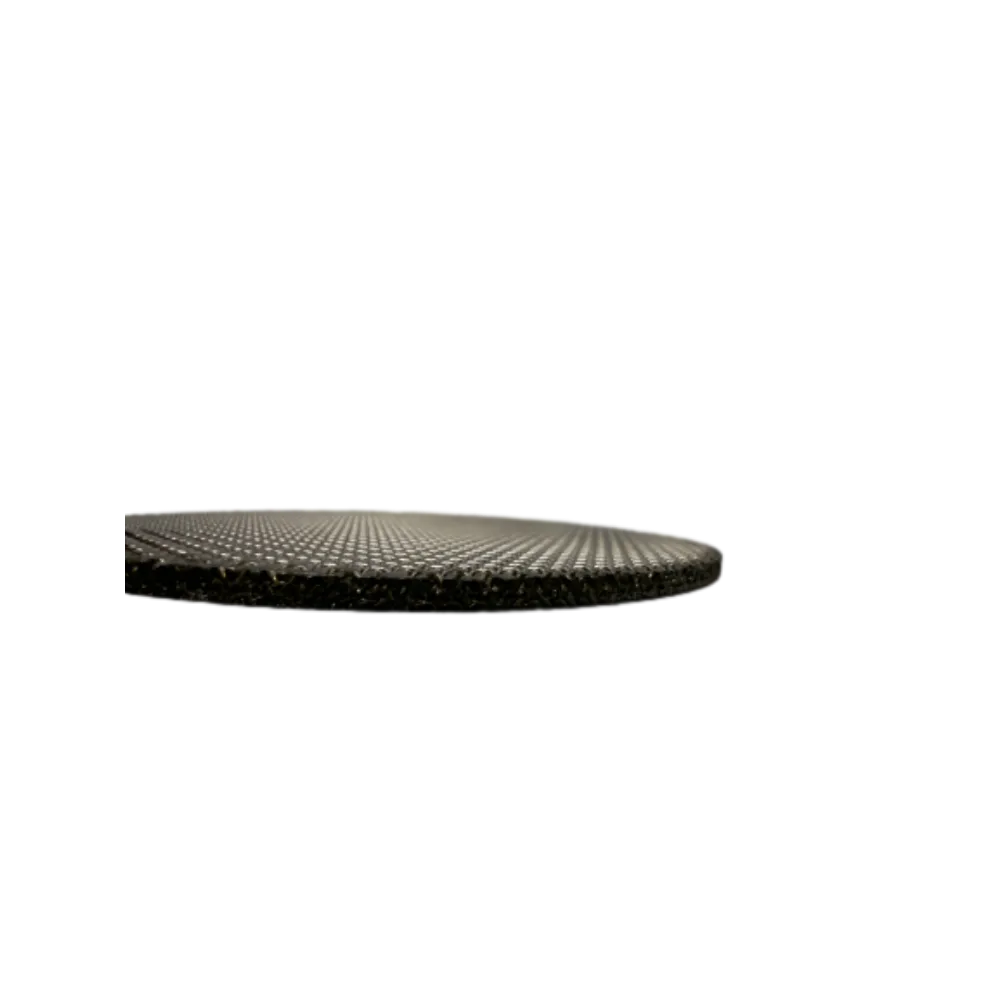

1. Sintering: Thaum kub kub, qhov diffusion ntawm cov khoom hlau khi cov hlau mesh ua ke los tsim cov qauv cohesive

2. Rolling: Los ntawm kev kub siab dov, txhua txheej txheej yog nruj nreem txuas kom ntseeg tau tias nws cov thickness uniformity

3. Laser Txiav / Plasma Txiav: Txiav cov Sintered Hlau Mesh kom paub meej qhov loj thiab cov duab.

|

|

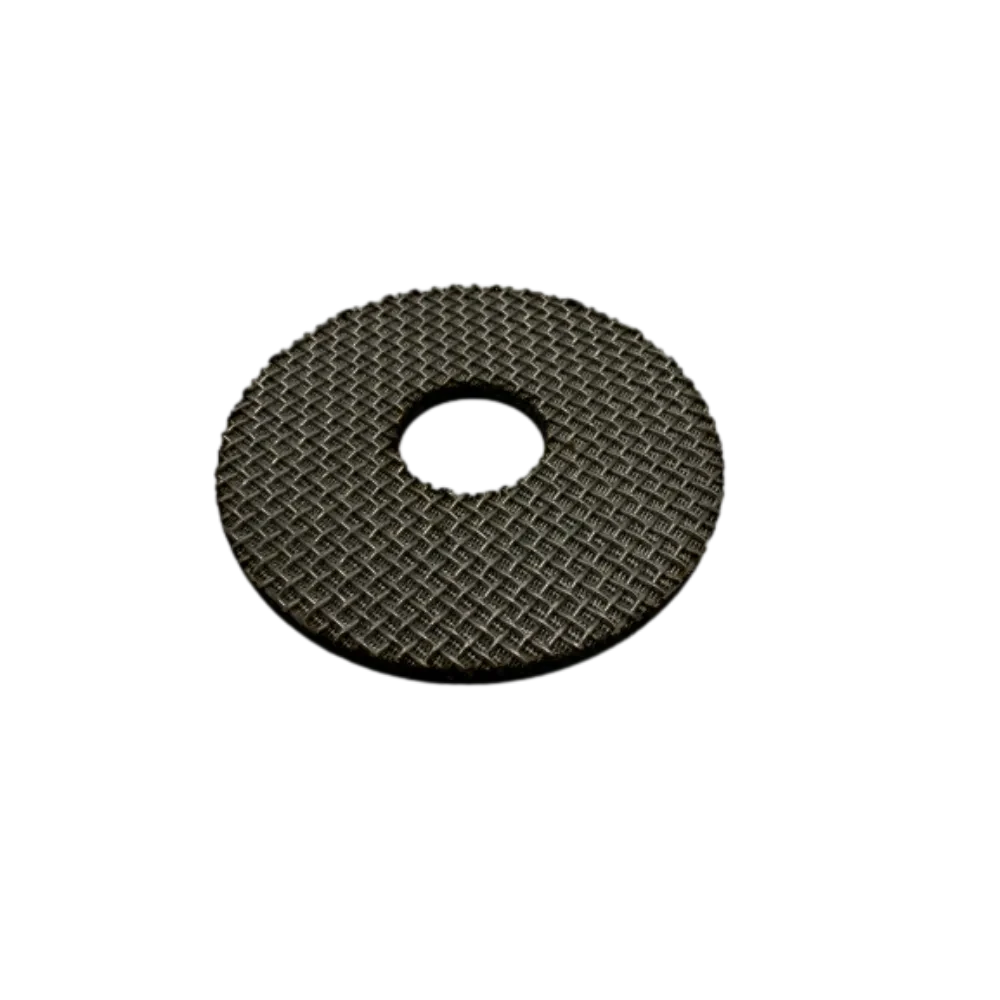

Woven txoj kev ntawm woven hlau mesh

|

1. Plain Weave (Txoj kev weaving feem ntau muaj qhov sib txawv mesh qhov thiab tsim nyog rau kev pom dav dav)

2. Twill Weave (Kev lim dej ntau dua, cov qauv nruj dua, haum rau kev lim dej siab)

3. Dutch Weave (Ib tug high-density filtering qauv yog tsim los ntawm interweaving coarse warp threads thiab zoo weft threads, feem ntau siv rau ultrafine pom)

4. Rov qab Dutch Weave (Muaj zog ntau dua thiab muaj peev xwm thauj khoom, tsim nyog rau kev pom kev siab)

|

|

Lwm yam khoom siv

|

1. Stainless hlau (304, 316, 316L)

2. Nickel Alloy (Monel, Hastelloy, Inconel)

3. Titanium Mesh

ETC

|

|

Number of Layers

|

3, 5, 7 txheej (los yog kho ntau txheej txheej)

|

|

Filtration raug

|

1μm-200μm (Customizable)

|

|

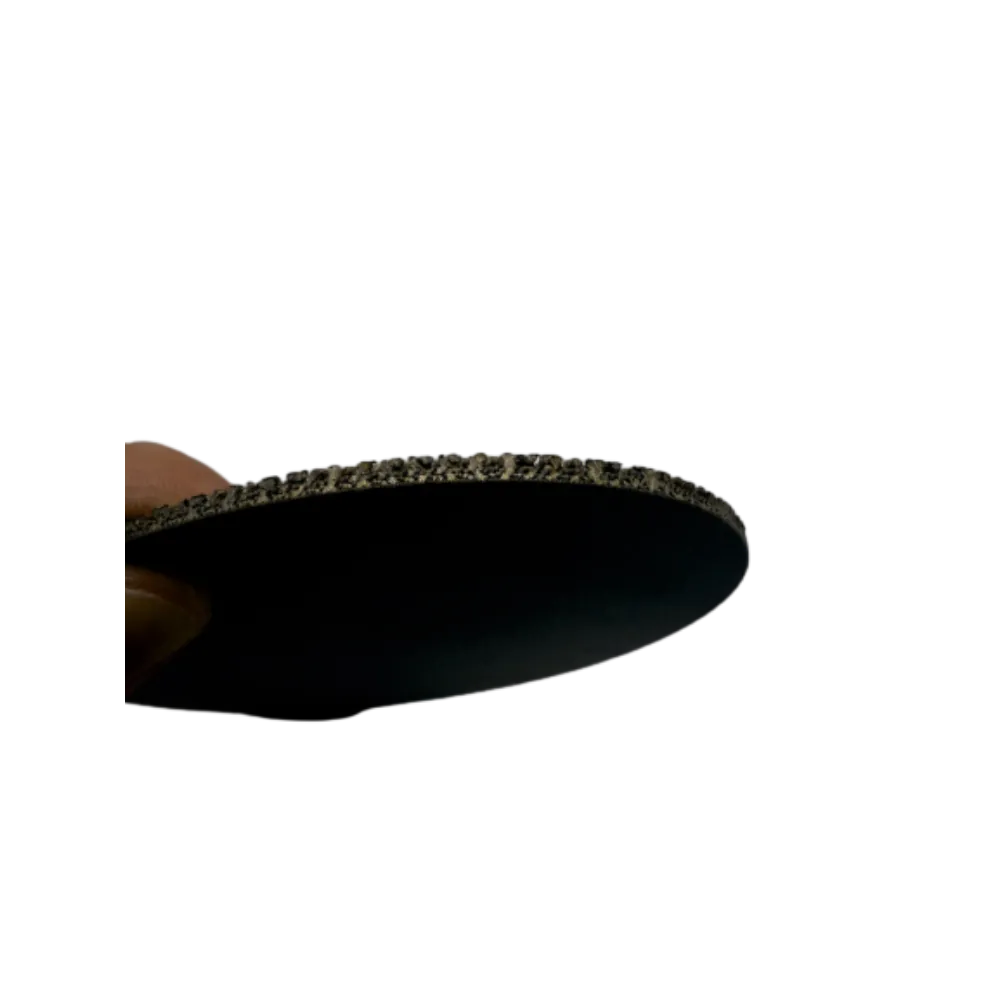

Thickness Ntau

|

0.5mm - 5mm (nws txawv ntawm cov txheej txheem)

|

|

Qhov Loj Distribution

|

Gradient pore tsim rau kev pom zoo thiab cov dej ntws

|

|

Kev kho saum npoo

|

Acid pickling (Stainless hlau / Carbon steel),

Electrolytic Polishing (Stainless hlau)

Nickel plating (Stainless hlau / carbon hlau)

Anodizing (Aluminium) thiab lwm yam.

|

|

Ua haujlwm kub

|

-200 ℃ to 600 ℃ (nyob ntawm cov khoom siv)

|

|

Siab Resistance

|

Txog li 30MPa lossis siab dua (nws txawv raws li cov txheej txheem mesh thiab tuab)

|

|

Permeability / Flow Resistance

|

Tsawg tsis kam thiab siab permeability, haum rau roj thiab kua pom

|

|

Corrosion Resistance

|

Resistant rau acids, alkalis, ntsev tsuag, thiab oxidation nyob rau hauv hnyav ib puag ncig

|

|

Txoj kev ntxuav

|

Backwashing, Ultrasonic tu, Kub-kub ci, tshuaj ntxuav, thiab rov siv tau

|

|

Kev tsim khoom

|

High-temperature nqus sintering, Rolling

|

|

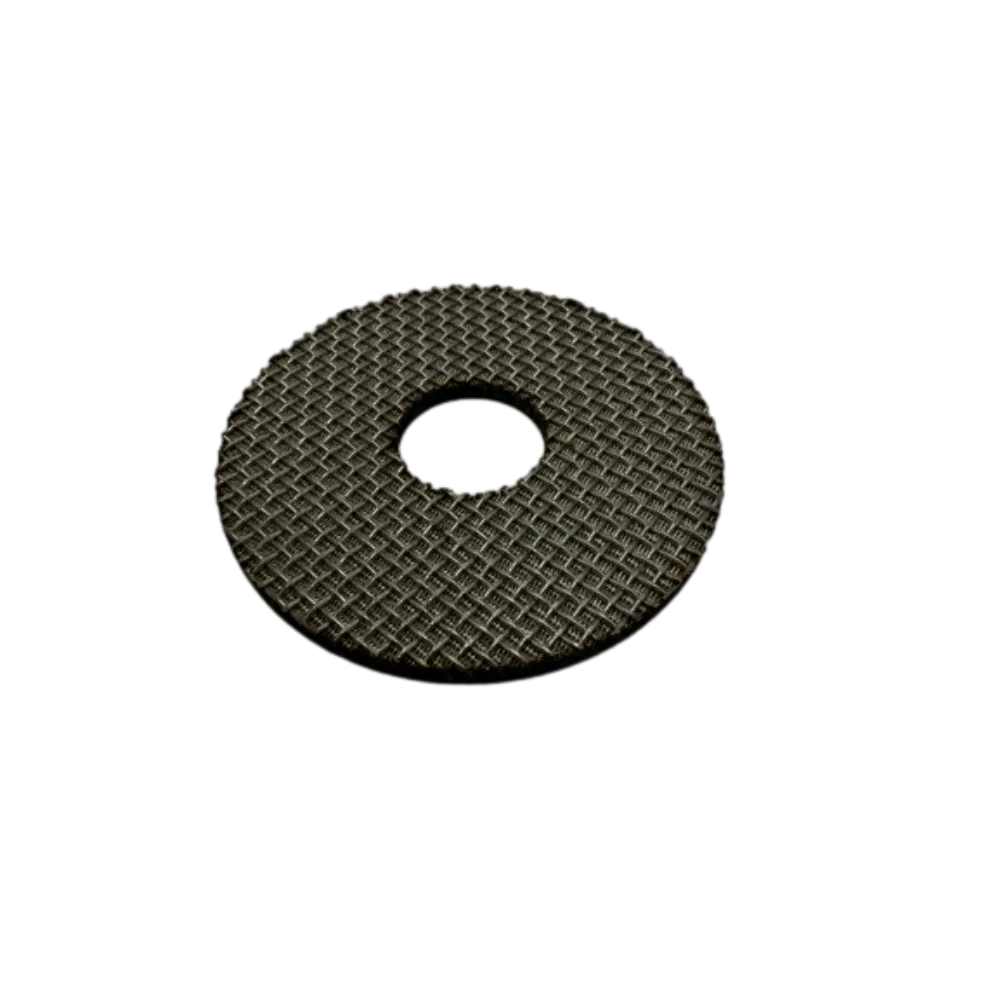

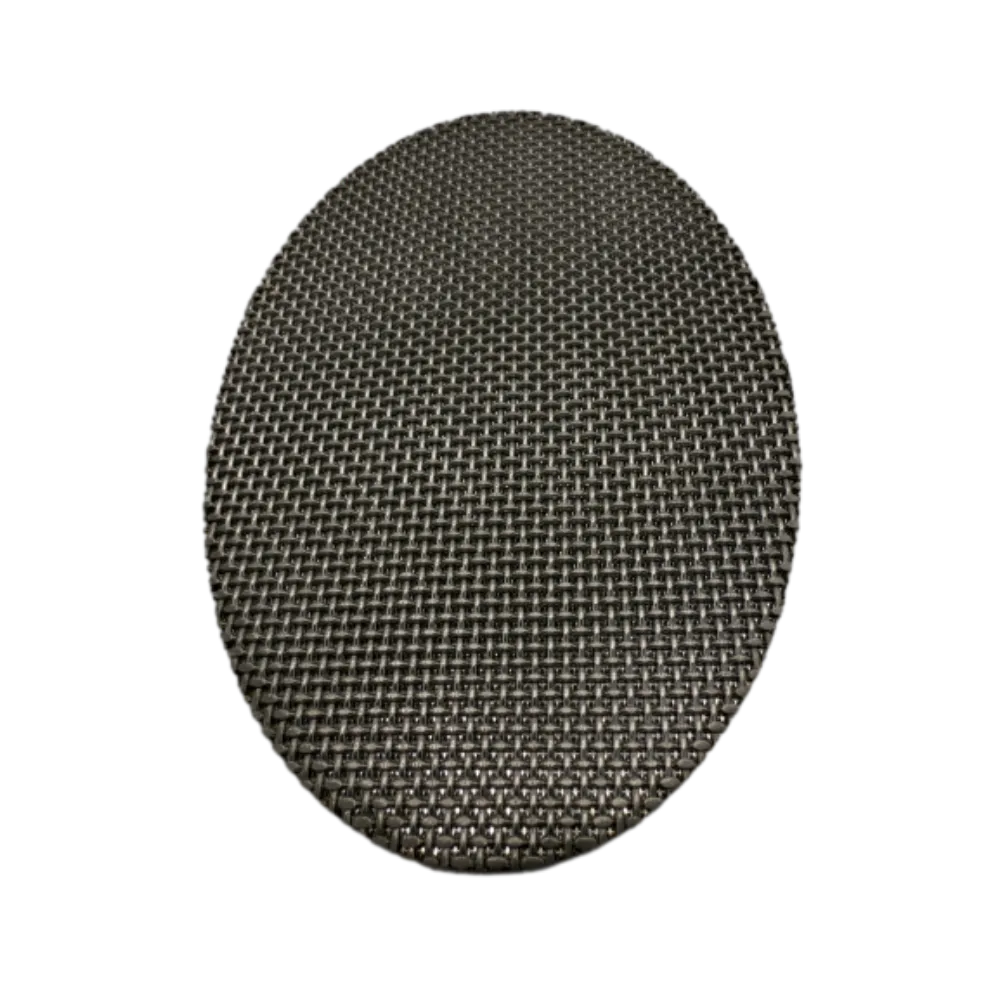

Muaj Cov Duab

|

Cylindrical, Square, Sheet, Pleated, Custom shapes muaj

|

|

Txoj kev sib txuas

|

Flange kev twb kev txuas, Vuam, Threaded kev twb kev txuas, Clamping

|

|

Siv tau cov kua dej

|

Haum rau cov kua, gases, roj, chav, thiab lwm yam.

|

|

Daim ntawv thov teb

|

Petrochemical, Khoom noj khoom haus & dej haus, Pharmaceuticals, Environmental Water Treatment, Aerospace, Automotive Industry, thiab lwm yam.

|

|

Khoom zoo

|

1. Muaj zog thiab siab ua haujlwm, tsis yooj yim rau deform

2. Rov ua kom huv, lub neej ntev

3. Precision filtration, uniform pore loj faib

4. Kub kub thiab corrosion kuj, adaptable rau hnyav ib puag ncig

|

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)