|

Items

|

Descriptio

|

|

Product Name

|

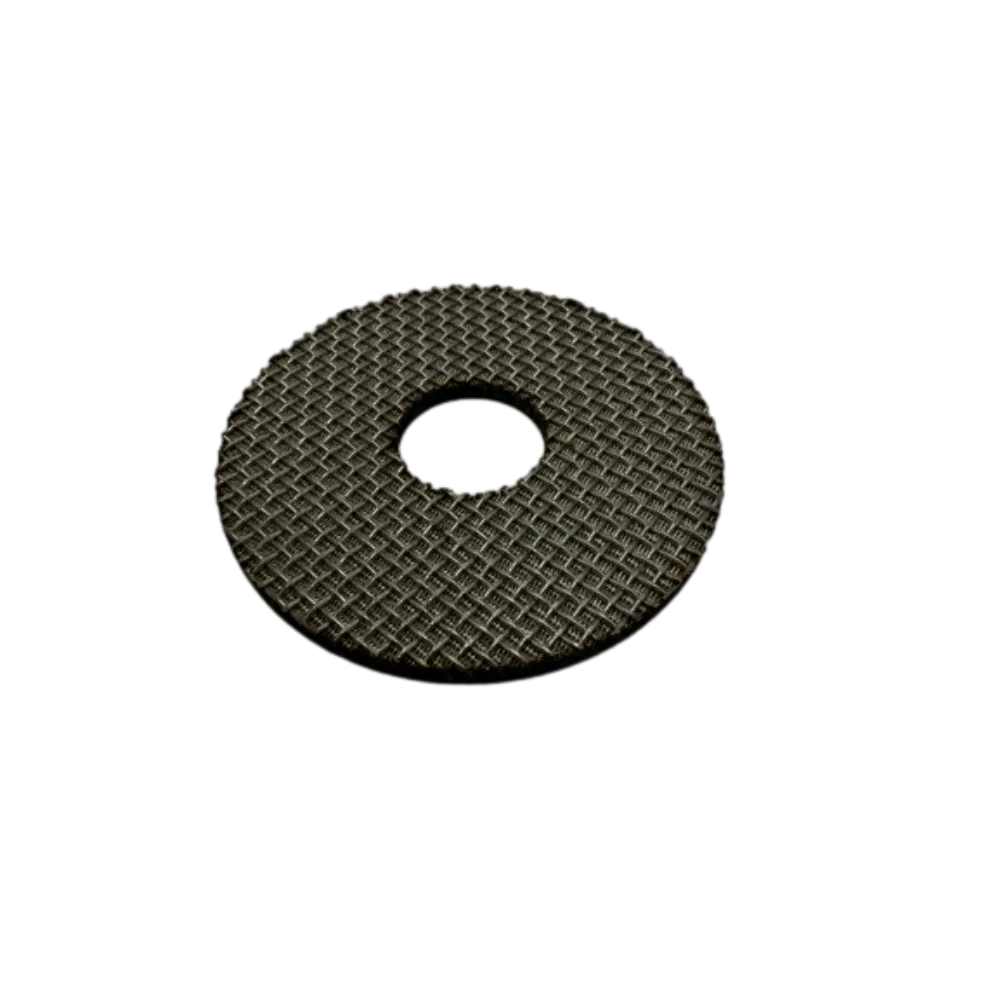

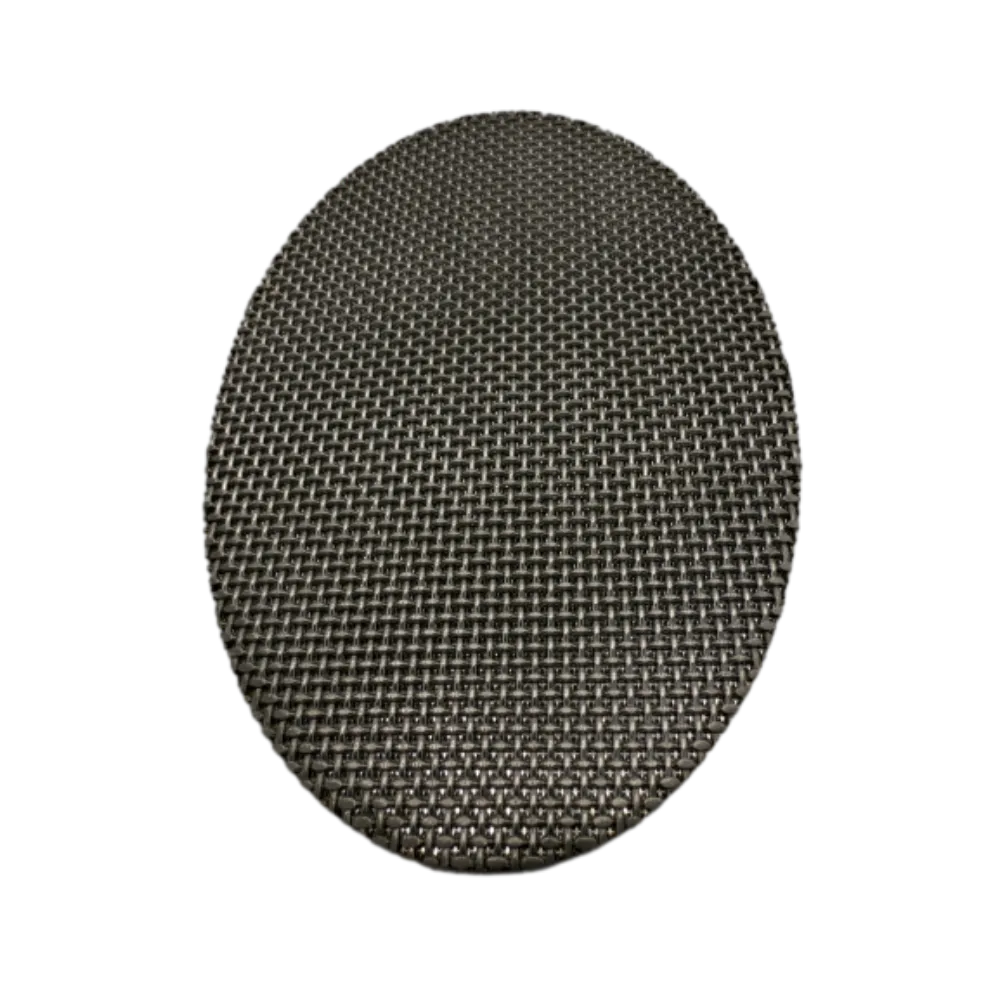

Filum Mesh Tube

|

|

Vestibulum Process

|

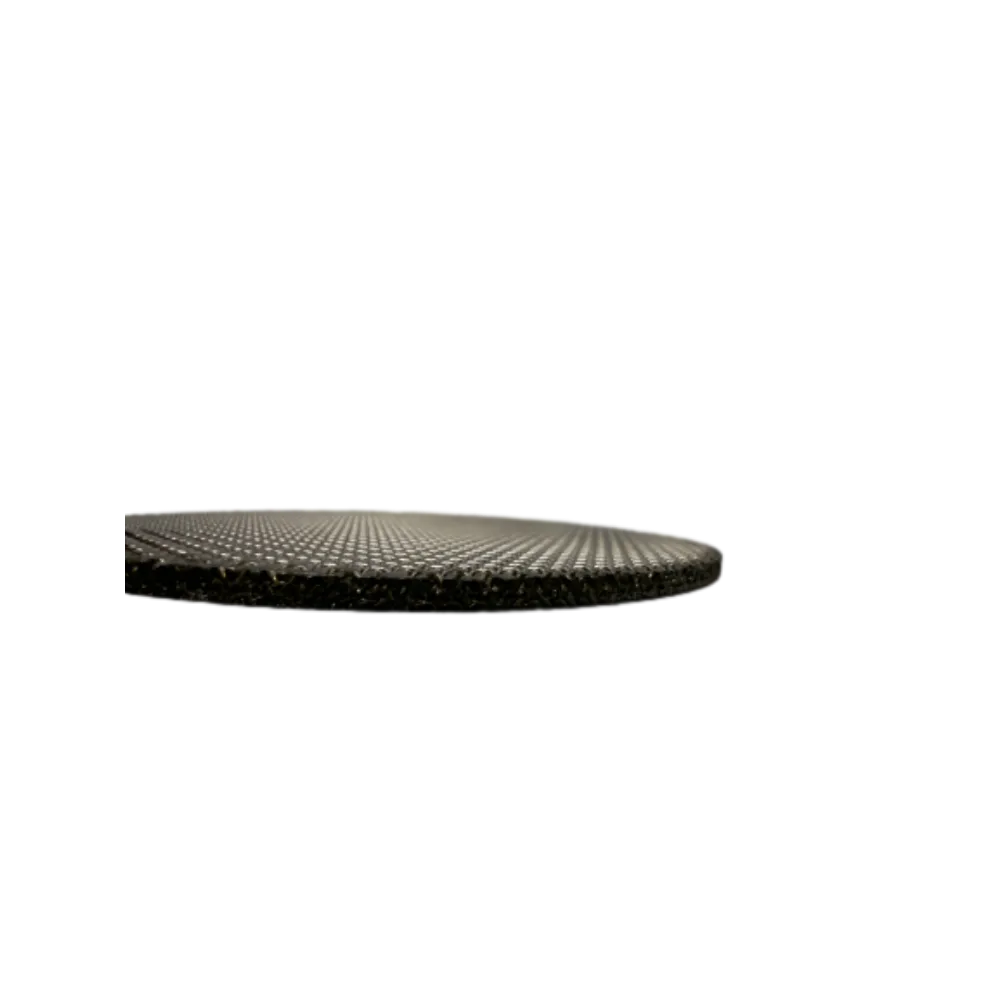

1. Sintering: In altum temperaturis diffusio particularum metallorum ligat reticulum metallicum ad structuram cohaerentis formandam

2. Rolling:Per pressuram altae volubilem, reticulum unumquodque stratum arcte connexum est ut eius crassitudinis aequalitatem servet

3. Laser Secans/Plasma Secans: Secare filum Mesh Sintered ut accuratam magnitudinem et figuram curet.

|

|

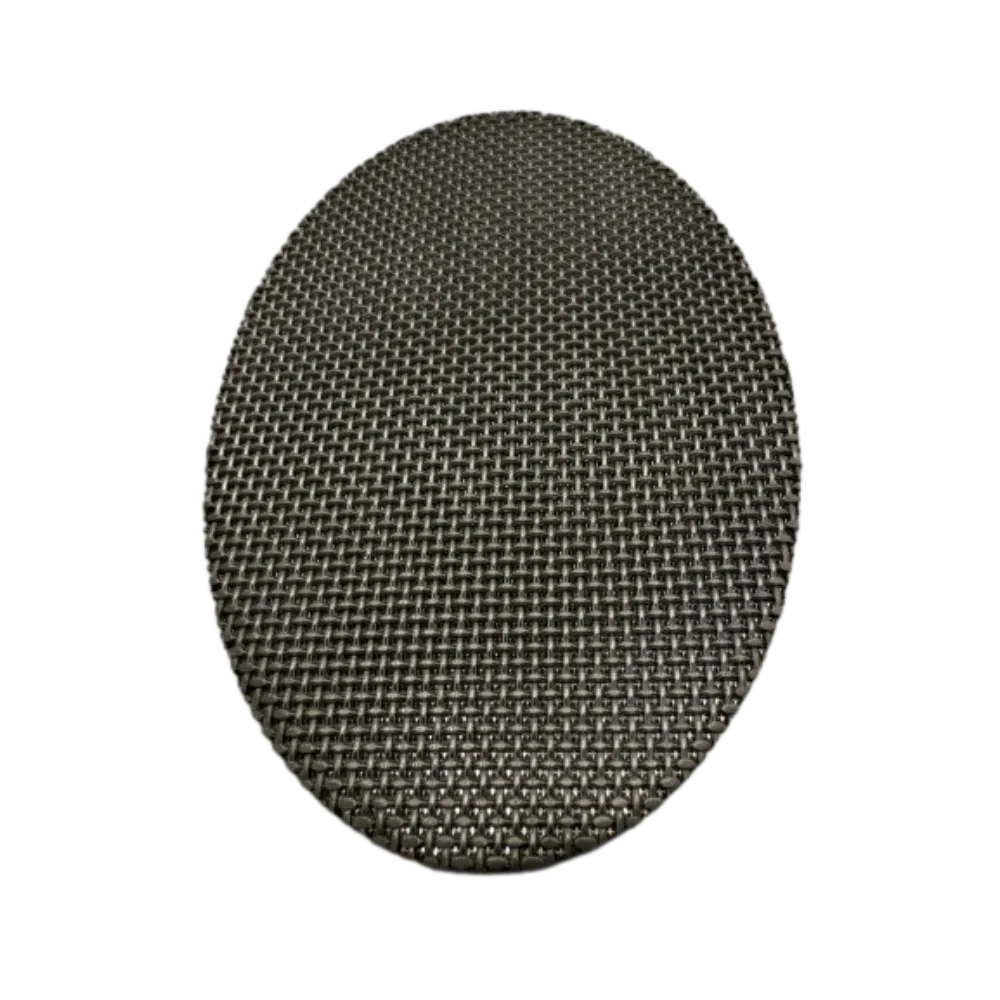

Contexitur via reticulum contextum

|

1. Texere campum (modum frequentissimum texendi modum habet reticulum uniforme perforatum et ad filtationem generalem apta)

2. Twill Texere (percolando altiorem accurationem, structuram arctiorem, aptam ad eliquationem altae subtilitatis)

3. Texere Batavica (Summa densitas eliquandi structura formatur ex stamine crasso stamine et filis subtilibus subtectis, vulgo pro filtratione ultrafine adhibita)

4. Reverse Batavica texere (habet superiorem vires et onus portantes facultatem, apta ad altum pressura filtration)

|

|

Material Alternative

|

1. Steel Steel (304, 316, 316L).

2. Nickel Alloy (Monel、Hastelloy、Inconel)

3. Titanium Mesh

ETC

|

|

Numerus Stratorum

|

3, 5, 7 stratis (vel multi- strati structurae nativus)

|

|

Saccharum officinarum

|

1μm - 200μm (custodibilis)

|

|

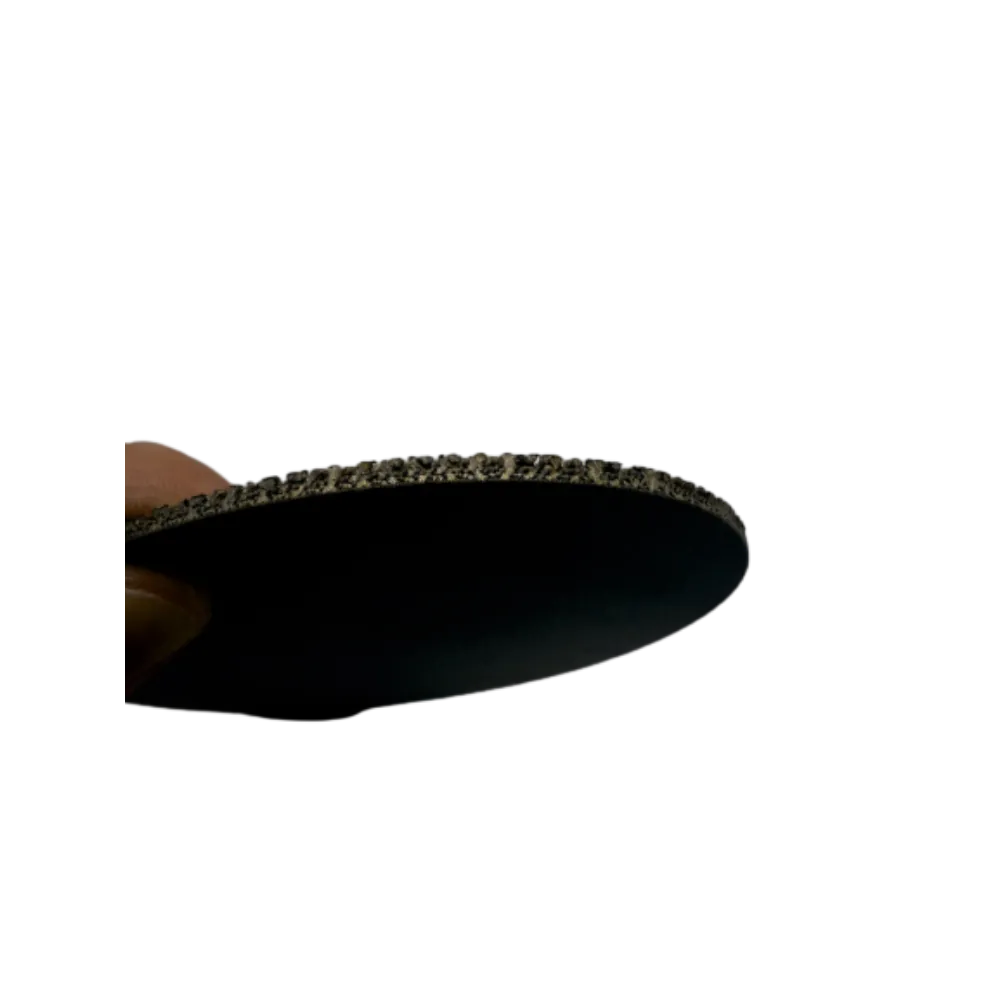

Crassitudo dolor

|

0.5mm - 5mm (variat numerus laminis)

|

|

Foramen Magnitudo Distributio

|

Poro gradui designatio ad filtrationem efficientem et fluxum fluidum

|

|

Superficies Curatio

|

Acidum servantur (Stainless Steel/Carbon steel);

Electrolytic politura (Stainless)

Nickel plating (Steel Steel/Carbon Steel)

Anodizing (Aluminium) etc.

|

|

Temperature operating

|

-200℃ ad 600℃ (prout materia)

|

|

Pressura Repugnantia

|

Ad 30MPa seu superiore (variatur secundum reticulum stratis et crassitudine)

|

|

Permeability / O Resistentia

|

Humilis resistentia et permeabilitas alta, apta gasi et liquida filtration

|

|

Corrosio Resistentia

|

Repugnantia acida, alcali, spuma salis, et oxidatio in ambitus asperos

|

|

Purgatio Methodi

|

Backwashing, ultrasonic purgatio, summus temperatus pistoria, chemica purgatio, et reusable

|

|

Vestibulum Process

|

Summus temperatus vacuum sintering, Rolling

|

|

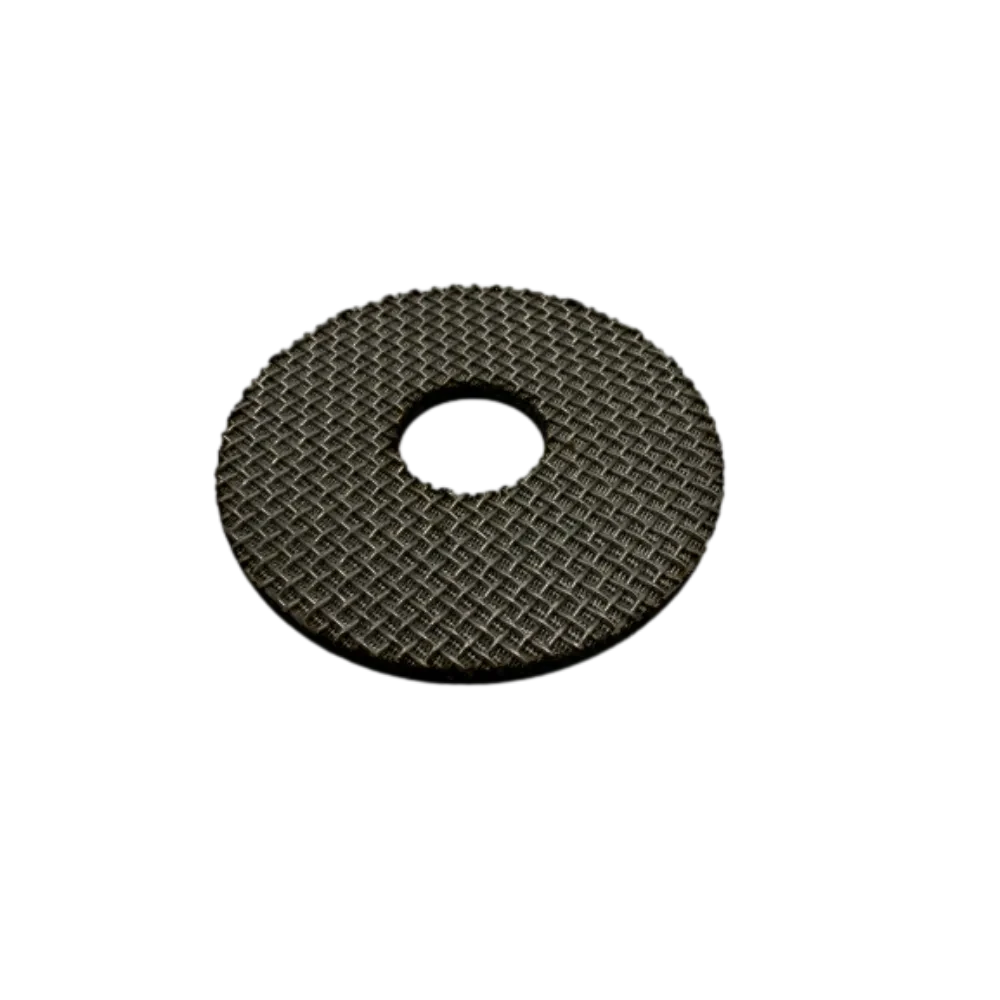

Praesto figurae

|

Cylindrica, Quadratus, Sheet, Pleated, custo- formis praesto

|

|

Connection Methodi

|

Connexio Flangae, Welding, Threaded nexus, Clamping

|

|

Lorem Fluidorum

|

Apta liquoribus, vaporibus, oleis, vaporibus, &c.

|

|

Applicationem Agri

|

Petrochemical, Cibus & Potus, Pharmaceuticals, Aquae curationis Environmentalis, Aerospace, Automotiva Industry, etc.

|

|

Product Commoda

|

1. Maximum robur et pressura resistentia, non facile deformare

2. Repetitio purgatio, longa vita

3. Subtilitas colamentum, uniformis porum amplitudo distributio

4. Temperatio et corrosio resistentia, apta ad ambitus asperos

|

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)