|

Vipengee

|

Maelezo

|

|

Jina la Bidhaa

|

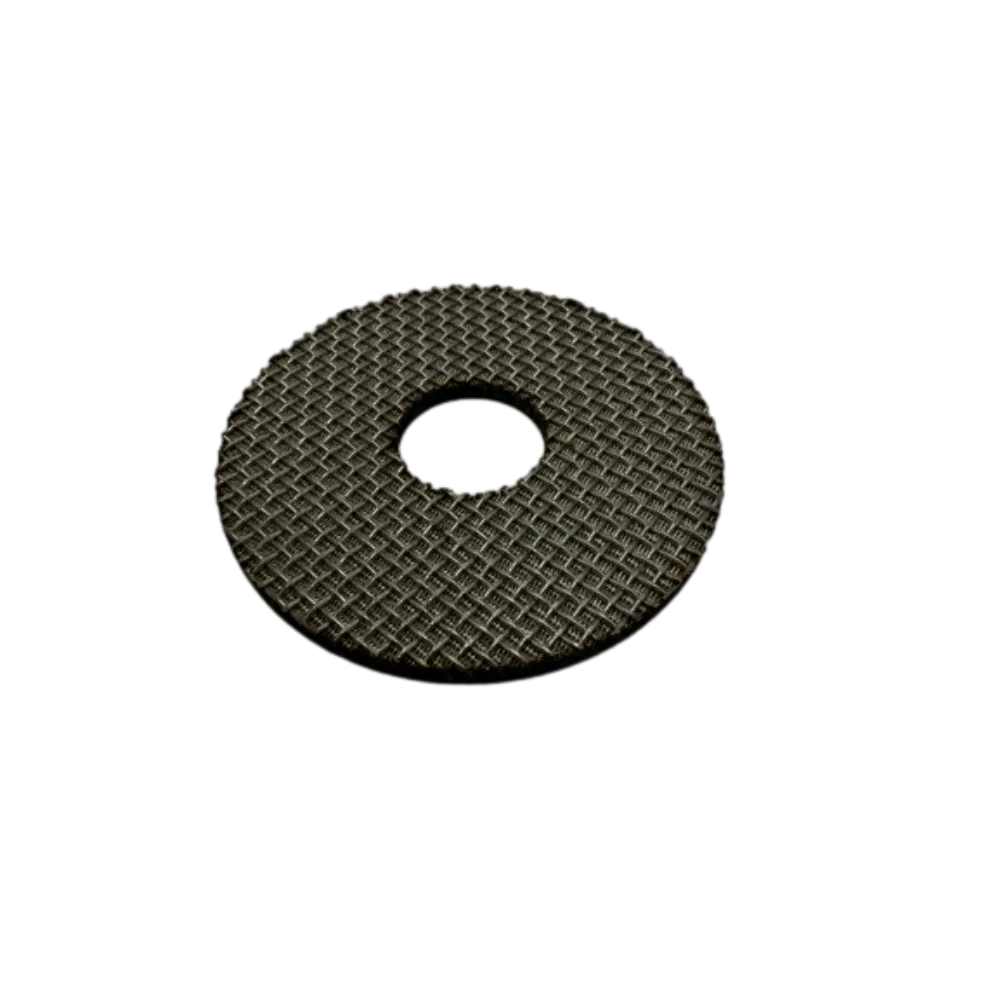

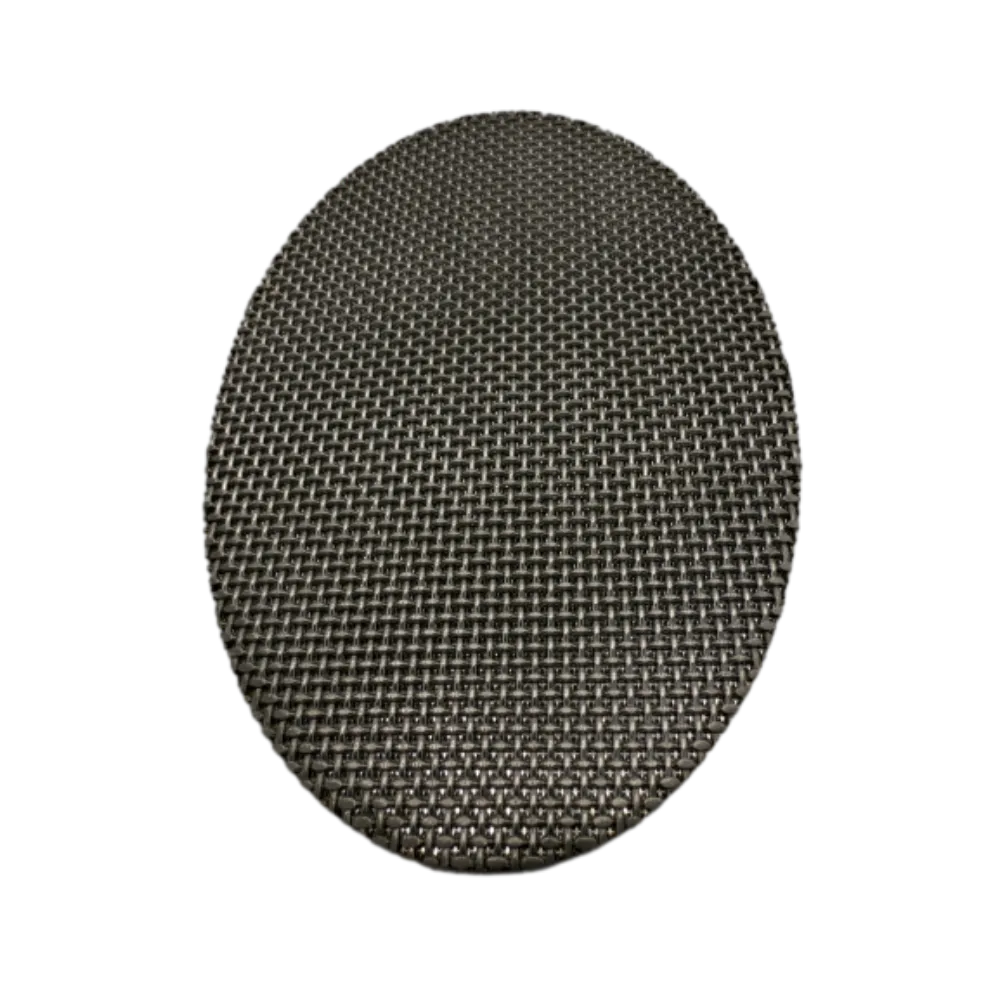

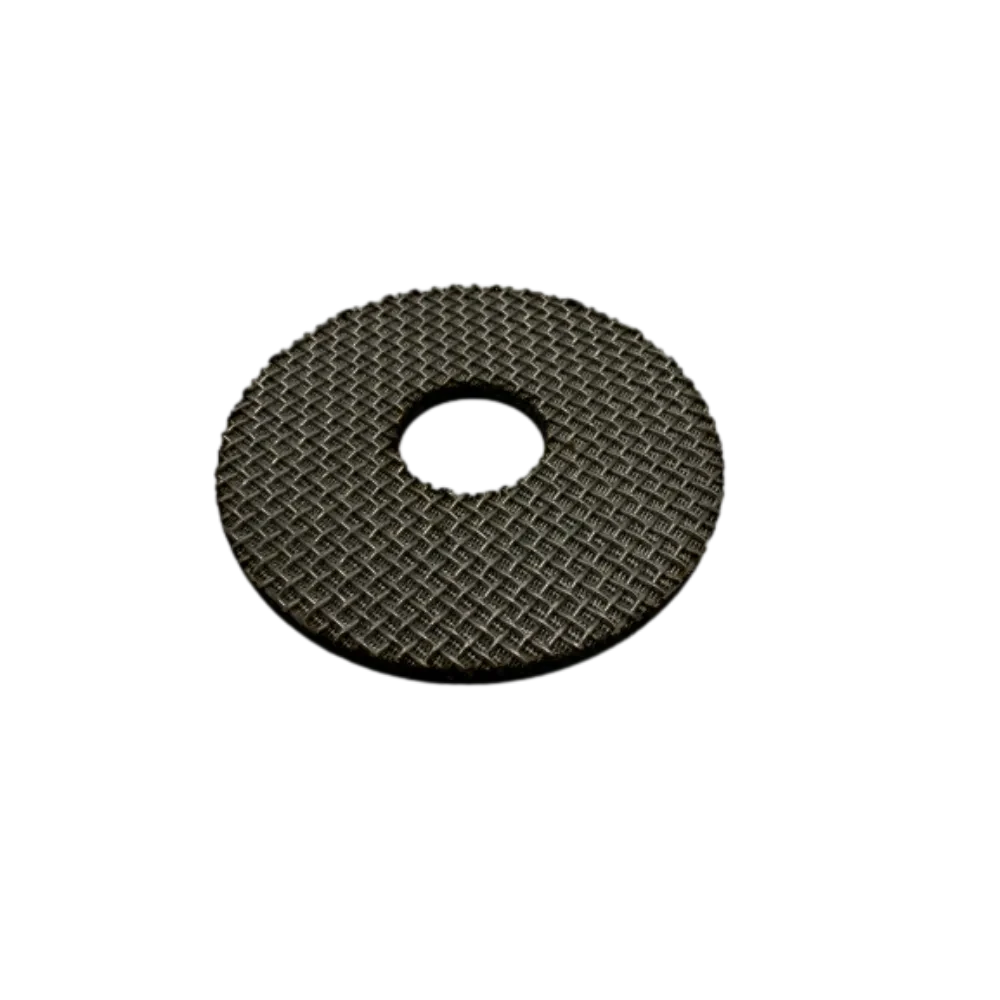

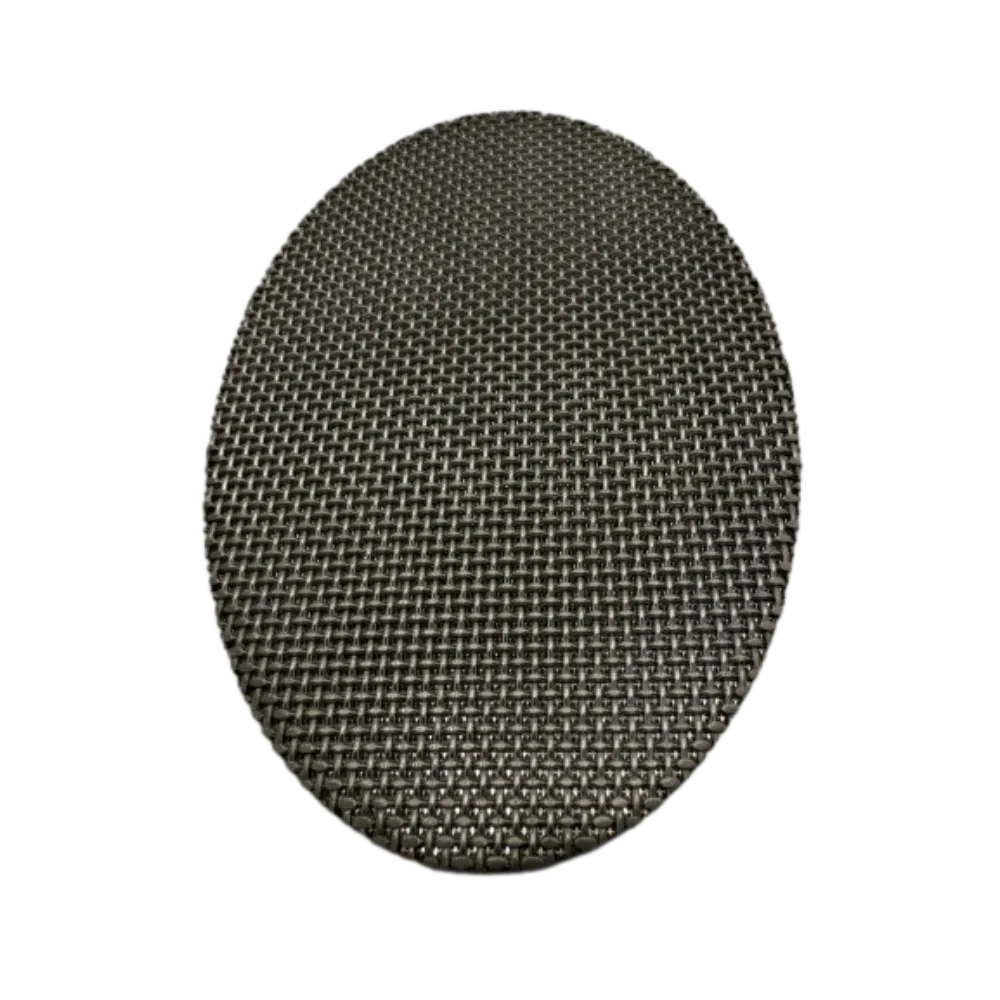

Sintered Wire Mesh Tube

|

|

Mchakato wa Utengenezaji

|

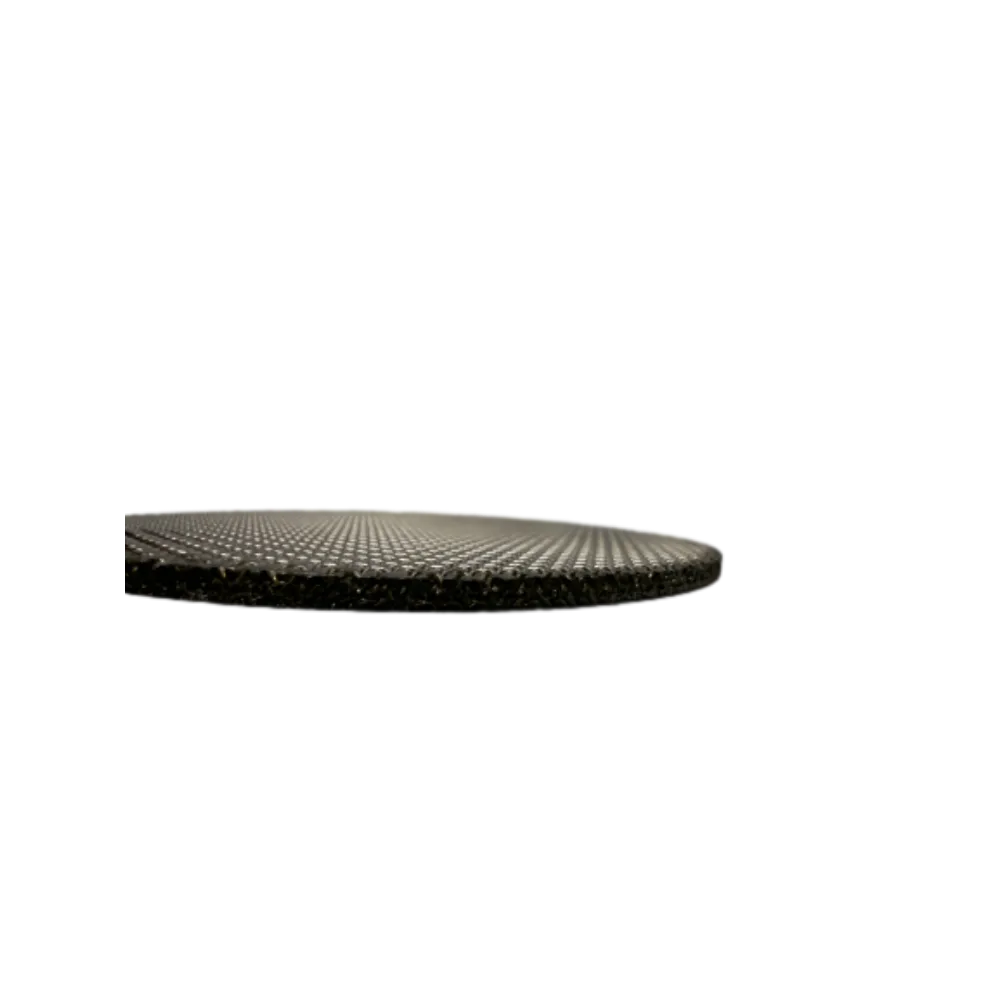

1. Sintering: Katika joto la juu, mgawanyiko wa chembe za chuma huunganisha mesh ya chuma ili kuunda muundo wa kushikamana.

2. Kuviringisha: Kwa kuviringisha kwa shinikizo la juu, kila safu ya matundu imeunganishwa kwa uthabiti ili kuhakikisha usawa wake wa unene.

3. Kukata Laser/Kukata Plasma:Kata Sintered Wire Mesh ili kuhakikisha ukubwa na umbo sahihi.

|

|

Njia iliyofumwa ya matundu ya waya

|

1. Ufumaji Wazi (Njia ya kawaida ya ufumaji ina mashimo ya matundu sare na inafaa kwa uchujaji wa jumla)

2. Twill Weave(Usahihi wa juu wa kuchuja, muundo mkali, unaofaa kwa uchujaji wa usahihi wa juu)

3. Ufumaji wa Kiholanzi(Muundo wa kuchuja wenye msongamano wa juu huundwa kwa kusuka nyuzi tambarare na nyuzi laini za weft, ambazo hutumiwa kwa kawaida kwa uchujaji wa hali ya juu zaidi)

4. Reverse Dutch Weave (Ina nguvu ya juu zaidi na uwezo wa kubeba mzigo, inafaa kwa uchujaji wa shinikizo la juu)

|

|

Nyenzo Mbadala

|

1. Chuma cha pua (304, 316, 316L)

2. Aloi ya Nickel(Monel、Hastelloy、Inconel)

3. Mesh ya Titanium

NK

|

|

Idadi ya Tabaka

|

3, 5, 7 tabaka (au muundo maalum wa tabaka nyingi)

|

|

Usahihi wa Uchujaji

|

1μm - 200μm (inaweza kubinafsishwa)

|

|

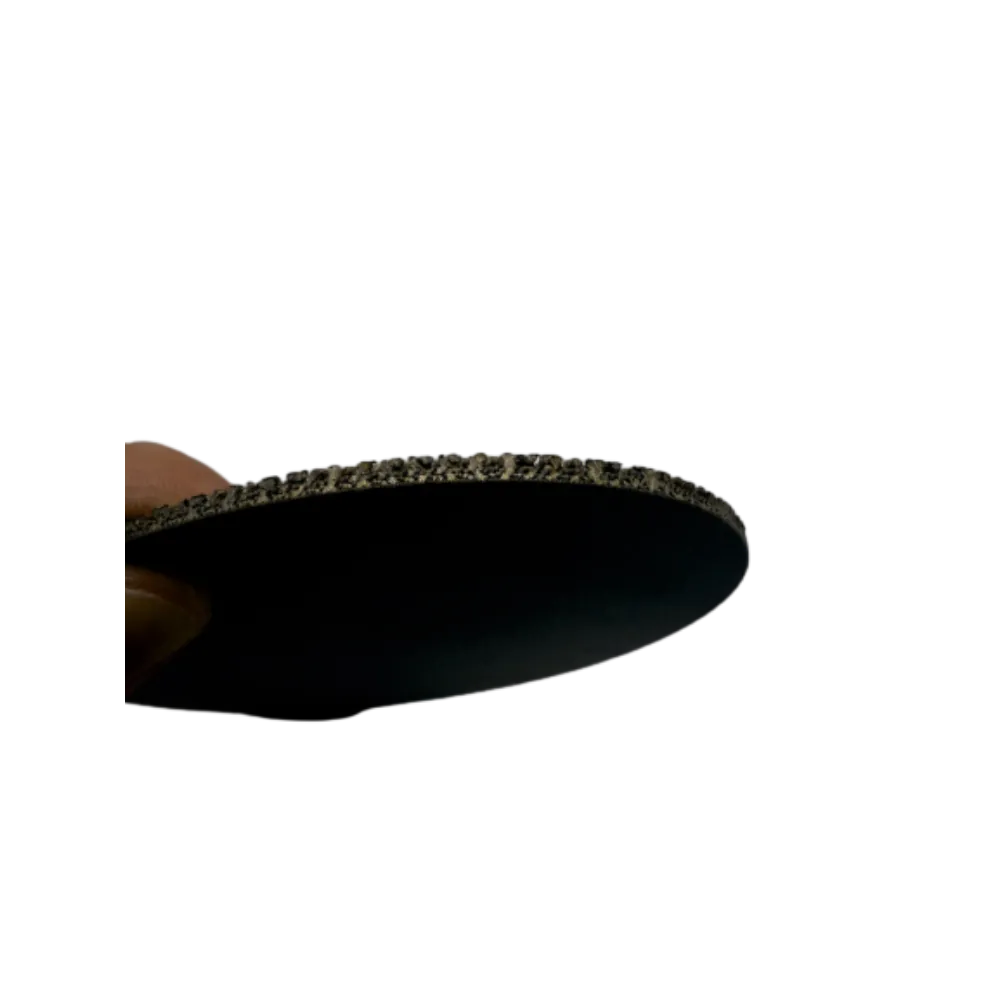

Safu ya Unene

|

0.5mm - 5mm (hutofautiana na idadi ya tabaka)

|

|

Shimo Usambazaji wa ukubwa

|

Muundo wa vinyweleo vya gradient kwa uchujaji bora na mtiririko wa maji

|

|

Matibabu ya uso

|

Kuchuna asidi (Chuma cha pua/Chuma cha Carbon),

Ung'arisha Electrolytic (Chuma cha pua)

Uchombaji wa nikeli (Chuma cha pua/Chuma cha Carbon)

Anodizing (Alumini) nk.

|

|

Joto la Uendeshaji

|

-200 ℃ hadi 600 ℃ (kulingana na nyenzo)

|

|

Upinzani wa Shinikizo

|

Hadi 30MPa au zaidi (hutofautiana kulingana na tabaka za matundu na unene)

|

|

Upenyezaji / Upinzani wa mtiririko

|

Upinzani wa chini na upenyezaji wa juu, unaofaa kwa kuchuja gesi na kioevu

|

|

Upinzani wa kutu

|

Inastahimili asidi, alkali, dawa ya chumvi na uoksidishaji katika mazingira magumu

|

|

Mbinu za Kusafisha

|

Kuosha nyuma, Kusafisha kwa ultrasonic, kuoka kwa halijoto ya juu, Kusafisha kwa kemikali, na kutumika tena

|

|

Mchakato wa Utengenezaji

|

Kunyunyizia utupu wa halijoto ya juu, Rolling

|

|

Maumbo Yanayopatikana

|

Silinda, Mraba, Laha, Iliyopendeza, maumbo maalum yanapatikana

|

|

Mbinu za Kuunganisha

|

Uunganisho wa flange, Kulehemu, Uunganisho wa Threaded, Clamping

|

|

Majimaji Yanayotumika

|

Inafaa kwa vinywaji, gesi, mafuta, mvuke, nk.

|

|

Sehemu za Maombi

|

Petrochemical, Chakula na Kinywaji, Madawa, Matibabu ya Maji ya Mazingira, Anga, Sekta ya Magari, n.k.

|

|

Faida za Bidhaa

|

1. Nguvu ya juu na upinzani wa shinikizo, si rahisi kuharibika

2. Kusafisha mara kwa mara, maisha marefu

3. Uchujaji wa usahihi, usambazaji wa ukubwa wa pore sare

4. Joto la juu na upinzani wa kutu, kukabiliana na mazingira magumu

|

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)