Oil and Gas Filtration Systems

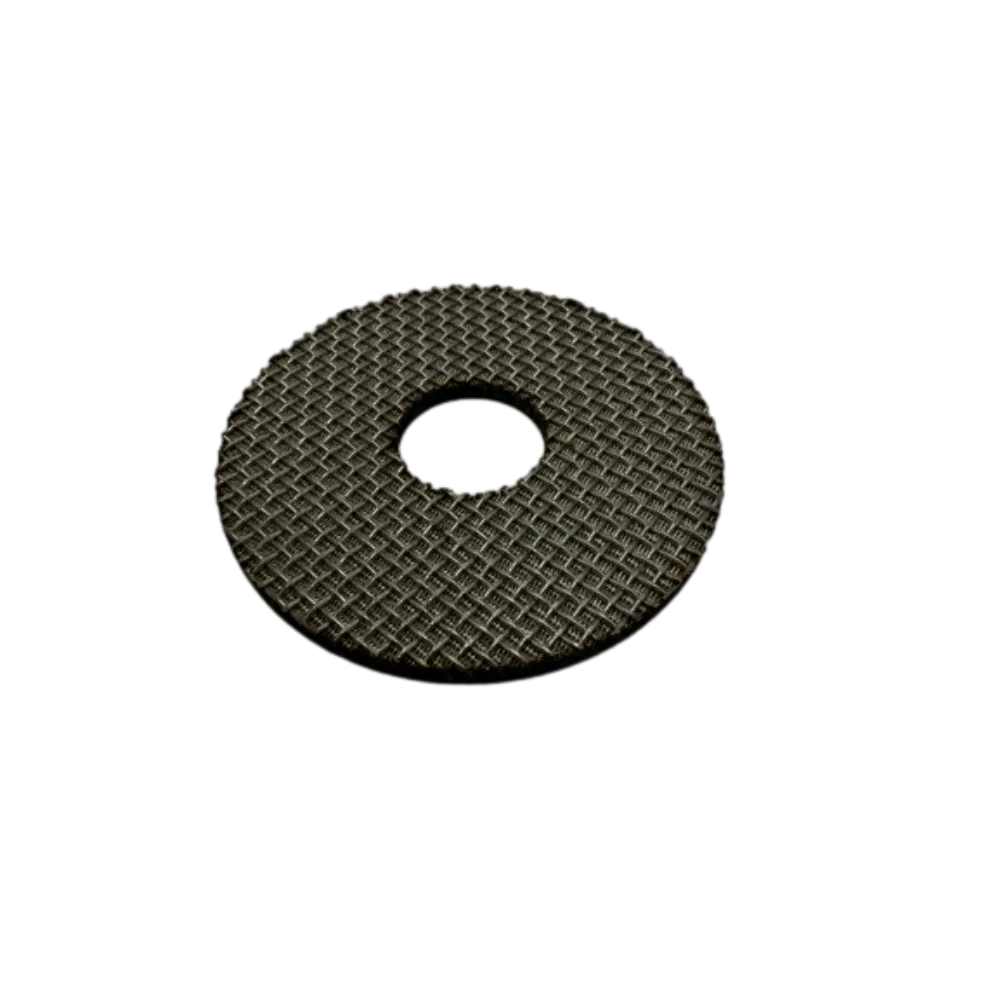

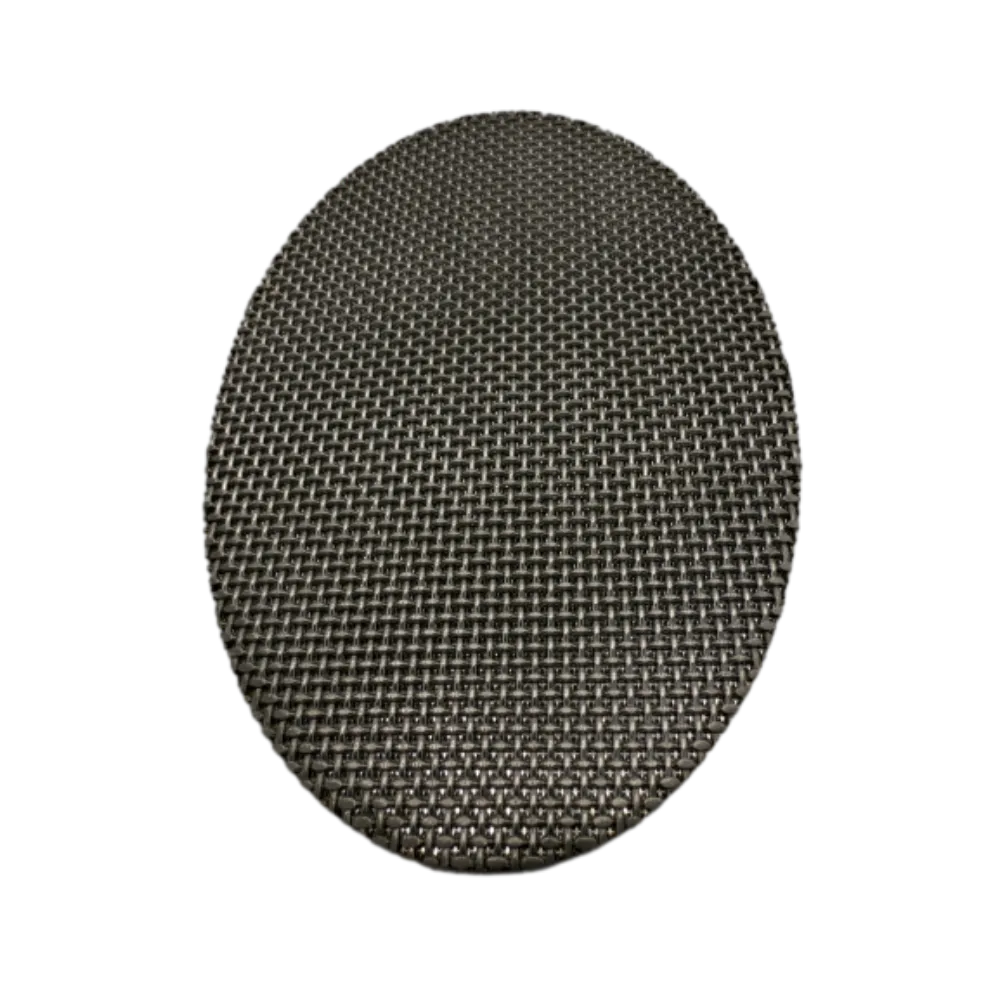

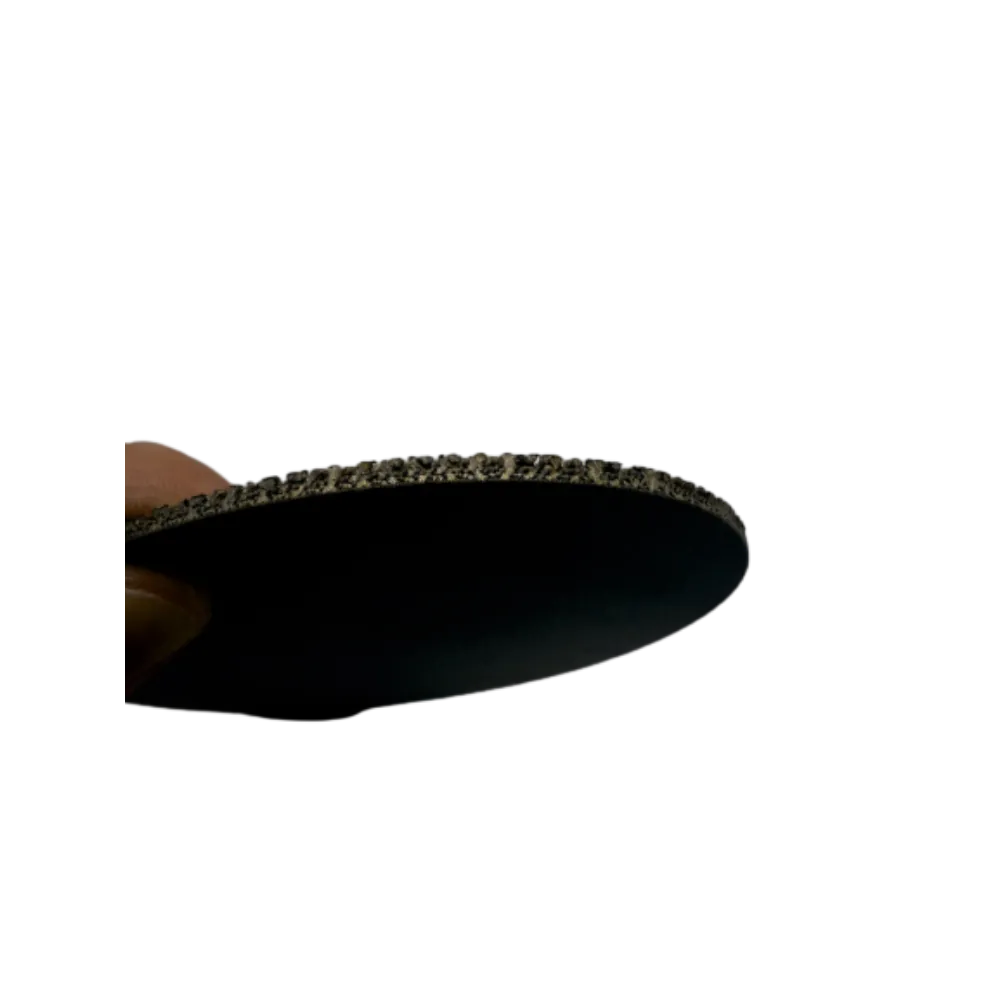

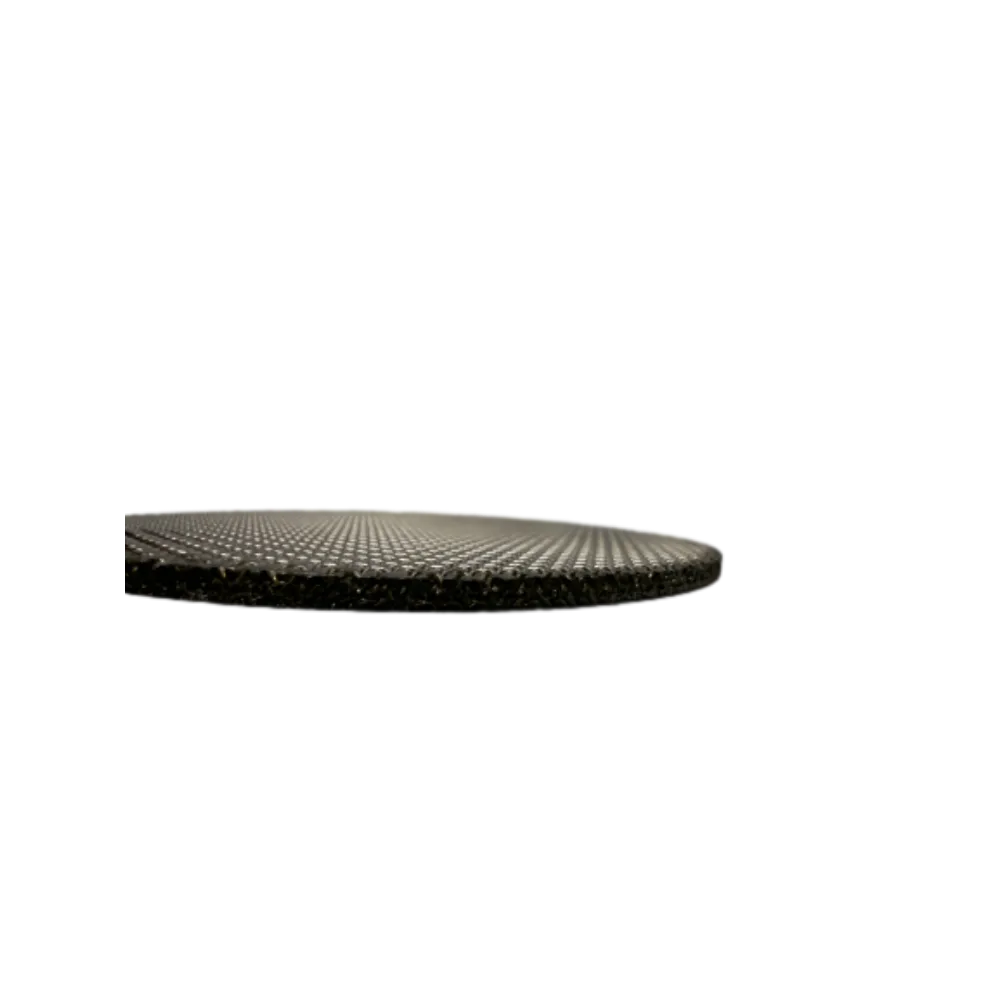

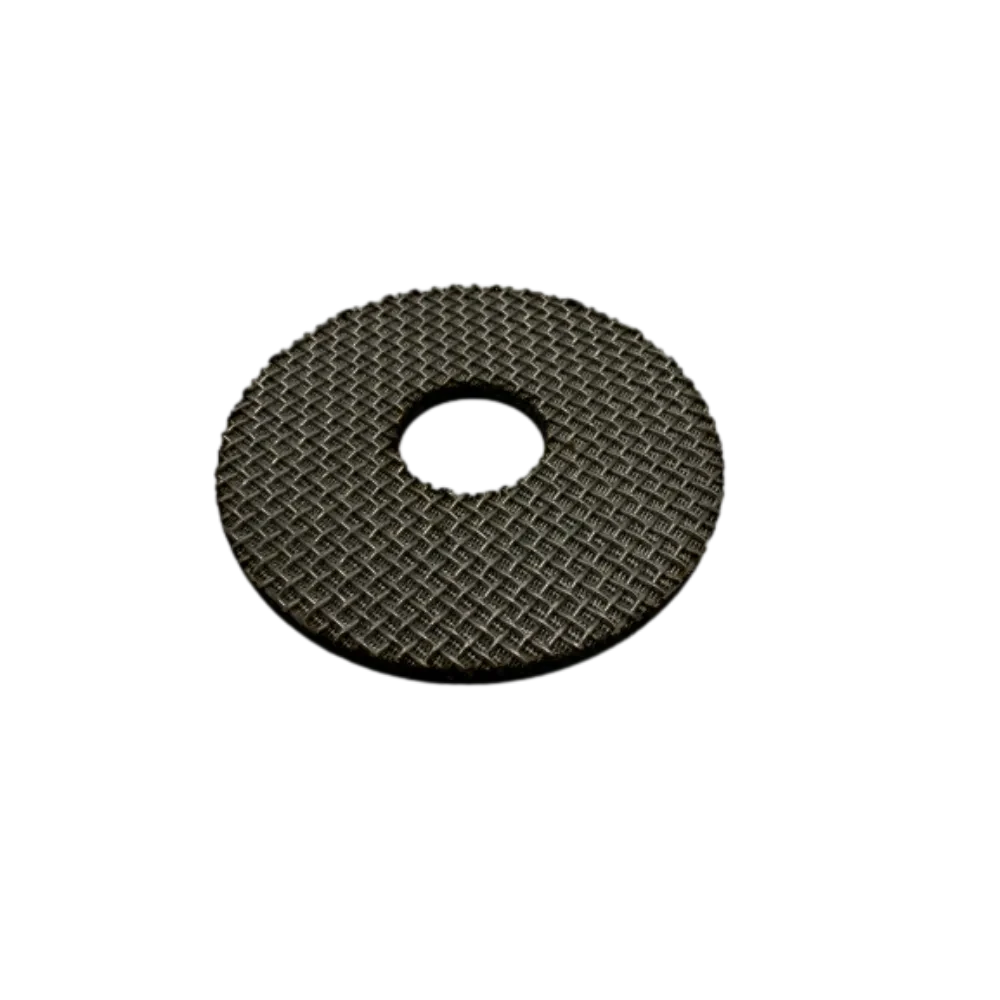

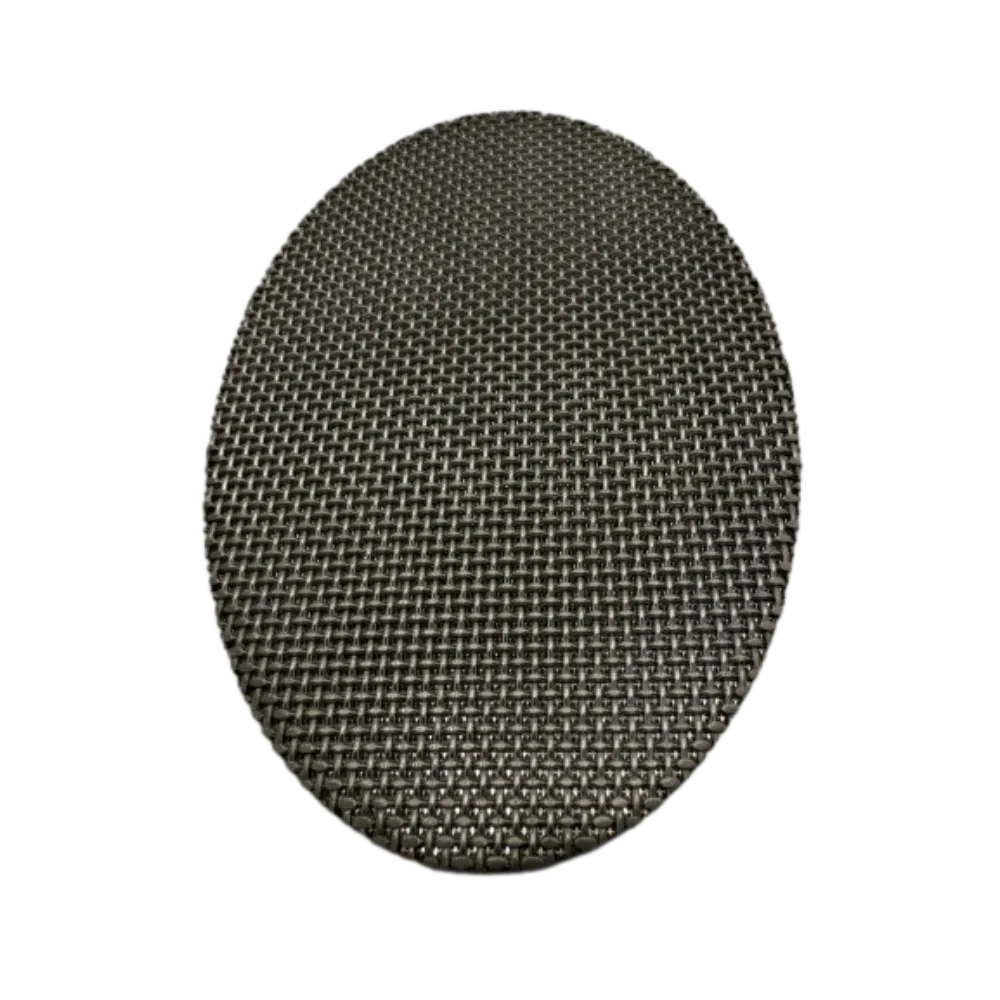

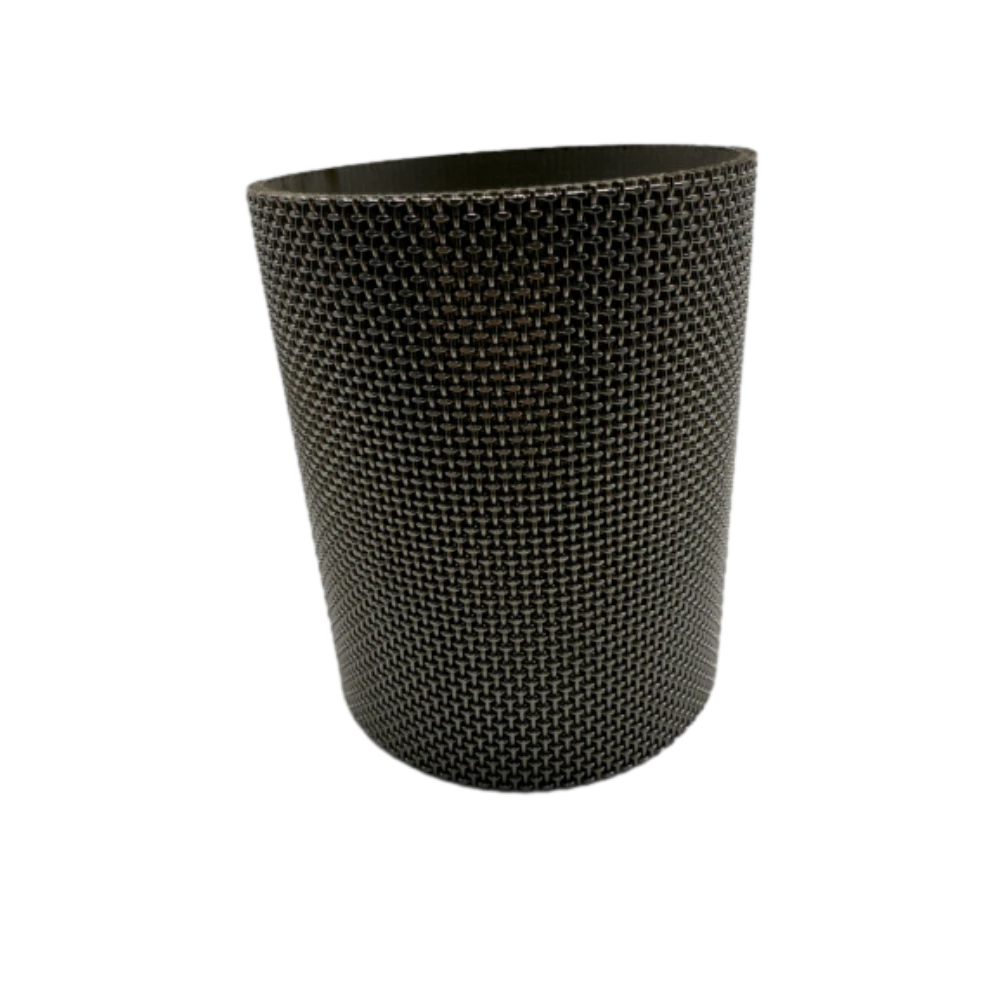

In the oil and gas industry, stainless steel sintered mesh discs are used to filter out impurities and particulates from crude oil, gas, and other fluids. The high filtration efficiency provided by sintered mesh discs is crucial for ensuring the longevity and efficiency of equipment such as pumps, valves, and filters. These discs are highly effective at capturing contaminants while maintaining high flow rates, making them ideal for use in upstream and downstream oil and gas operations, including wellhead filtration, pipeline maintenance, and desalting units. Their robust design and chemical resistance ensure long-term durability in harsh operating conditions.

![$item[標題] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)