|

Harytlar

|

Düşündiriş

|

|

Haryt ady

|

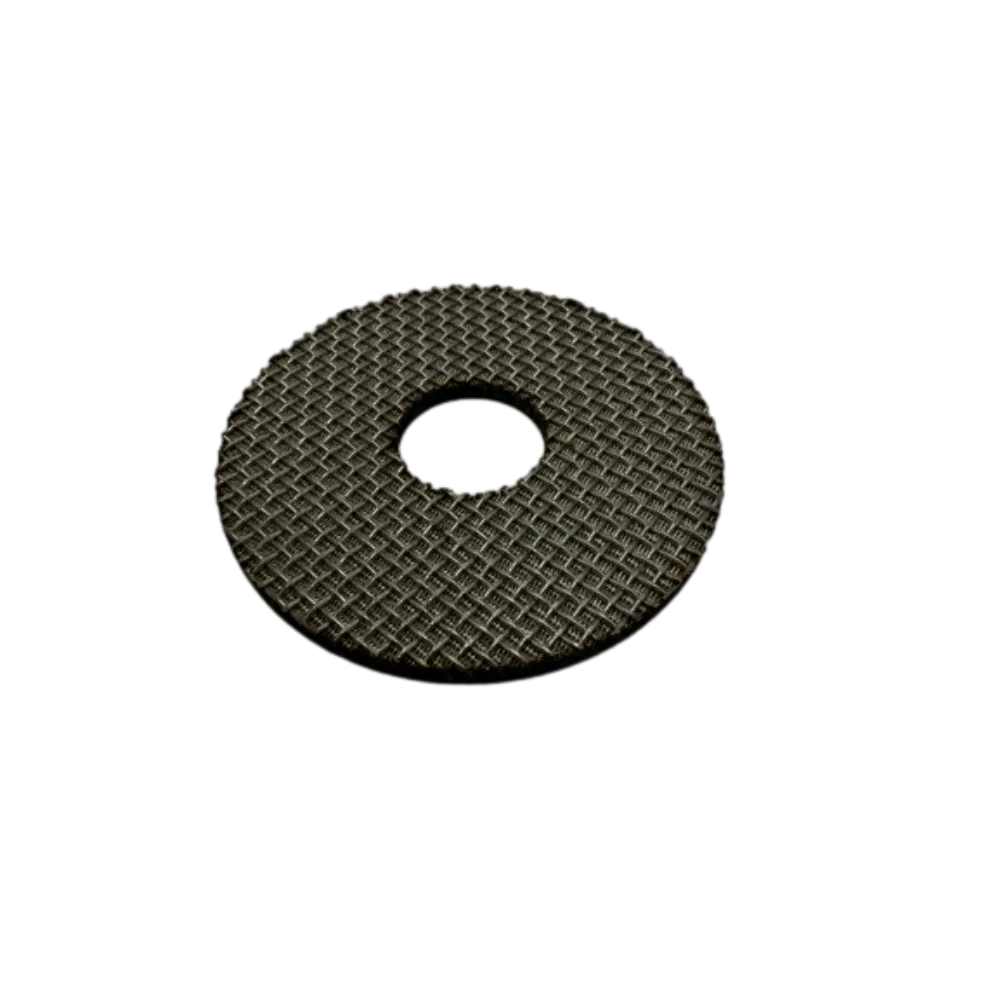

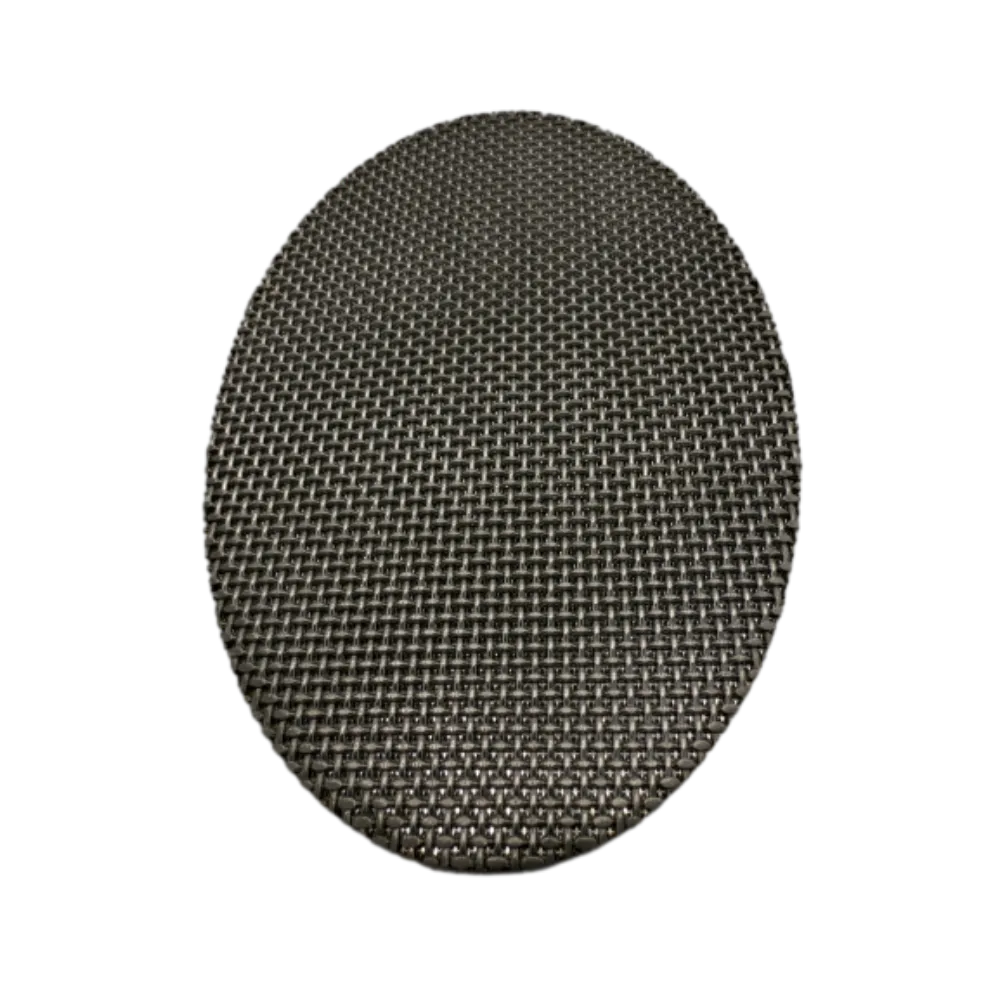

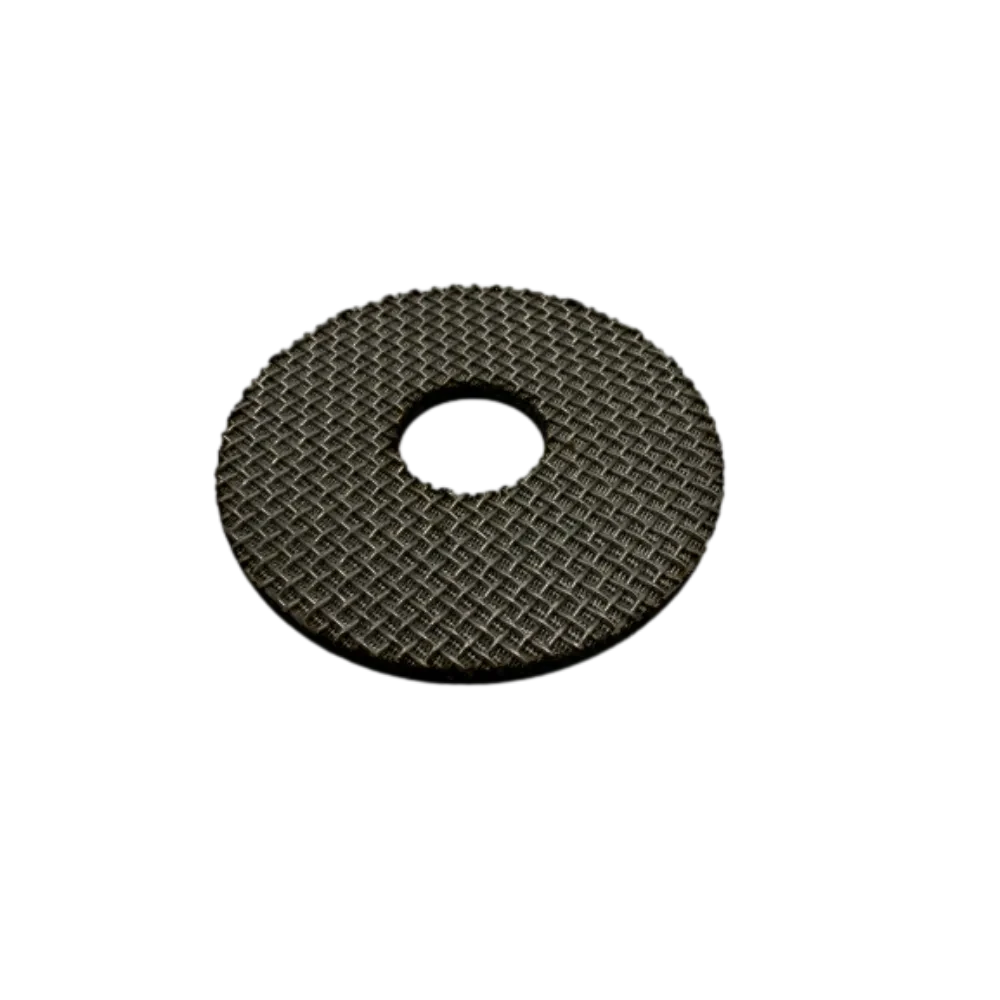

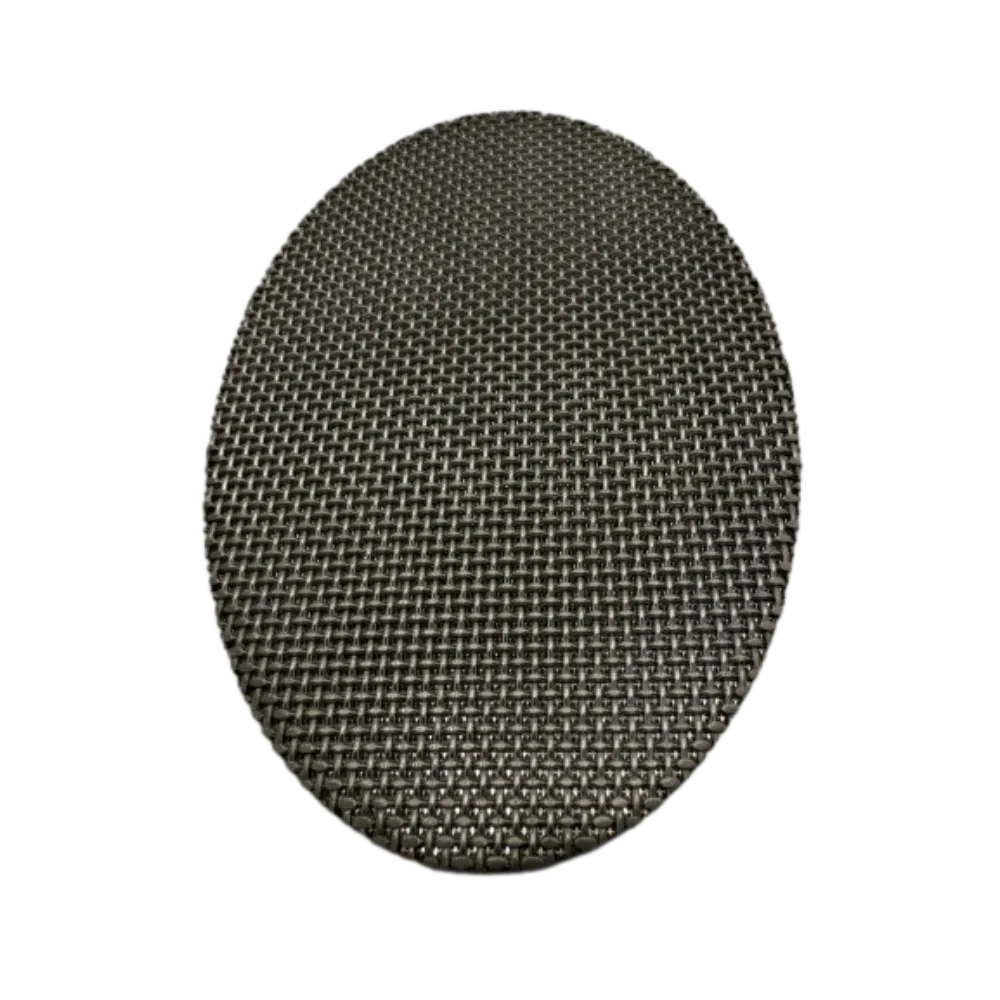

Sintirlenen simli turba

|

|

Önümçilik prosesi

|

1.

2. Rolling high pressureokary basyşly togalanmak bilen, galyňlygyň birmeňzeşligini üpjün etmek üçin her gatlak gatlagy berk birikdirilýär

3. Lazer kesmek / Plazma kesmek precise Sintirlenen sim toruny takyk ululygyny we görnüşini üpjün etmek üçin kesiň.

|

|

Dokalan sim torunyň dokalan usuly

|

1. Tekiz dokamak (Iň köp ýaýran dokma usuly birmeňzeş tor deşiklerine eýe we umumy süzgüç üçin amatly)

2. Twill dokma (Has ýokary süzgüç takyklygy, has berk gurluş, ýokary takyklykly süzgüç üçin amatly)

3.

4. Ters Gollandiýaly dokma (Has ýokary güýçli we ýük göterijilik ukyby, ýokary basyşly süzgüç üçin amatly)

|

|

Material alternatiwalar

|

1. Poslamaýan polat (304, 316, 316L)

2. Nikel garyndysy (Monel 、 Hastelloý con Inconel)

3. Titan Meş

ETC

|

|

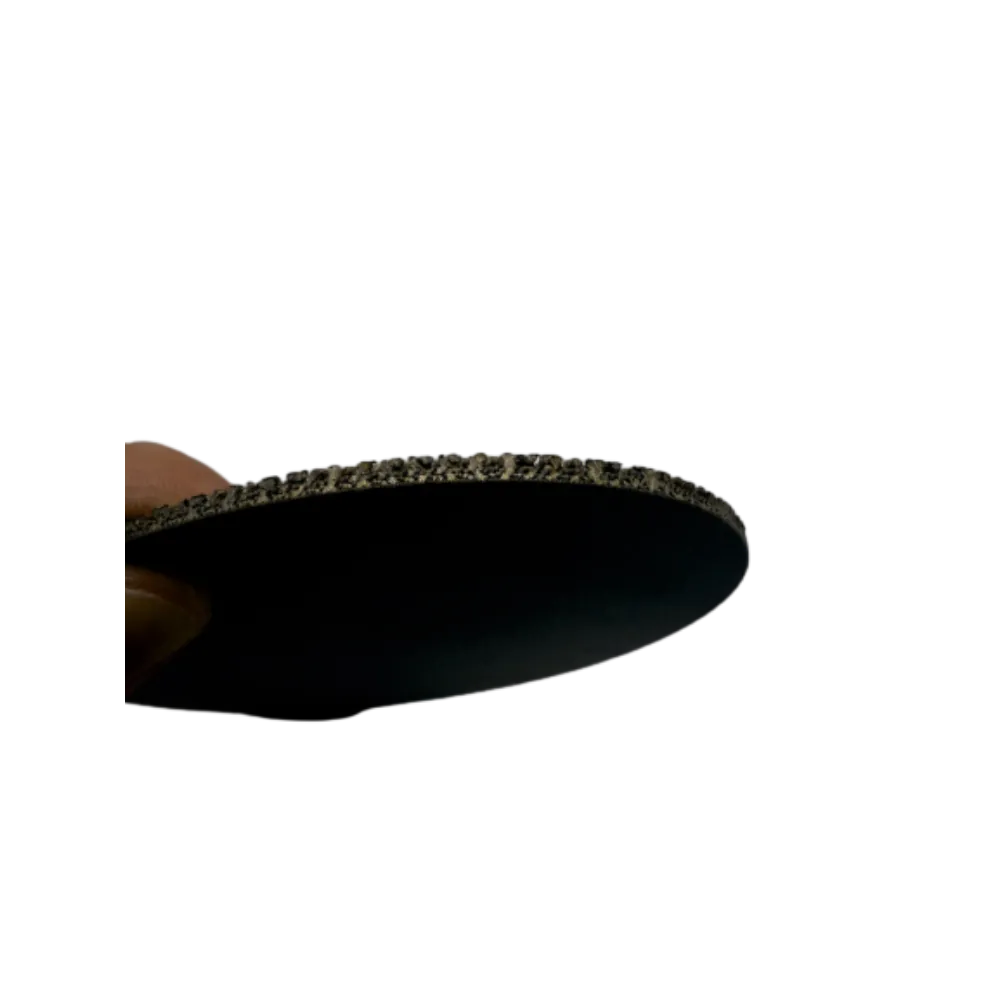

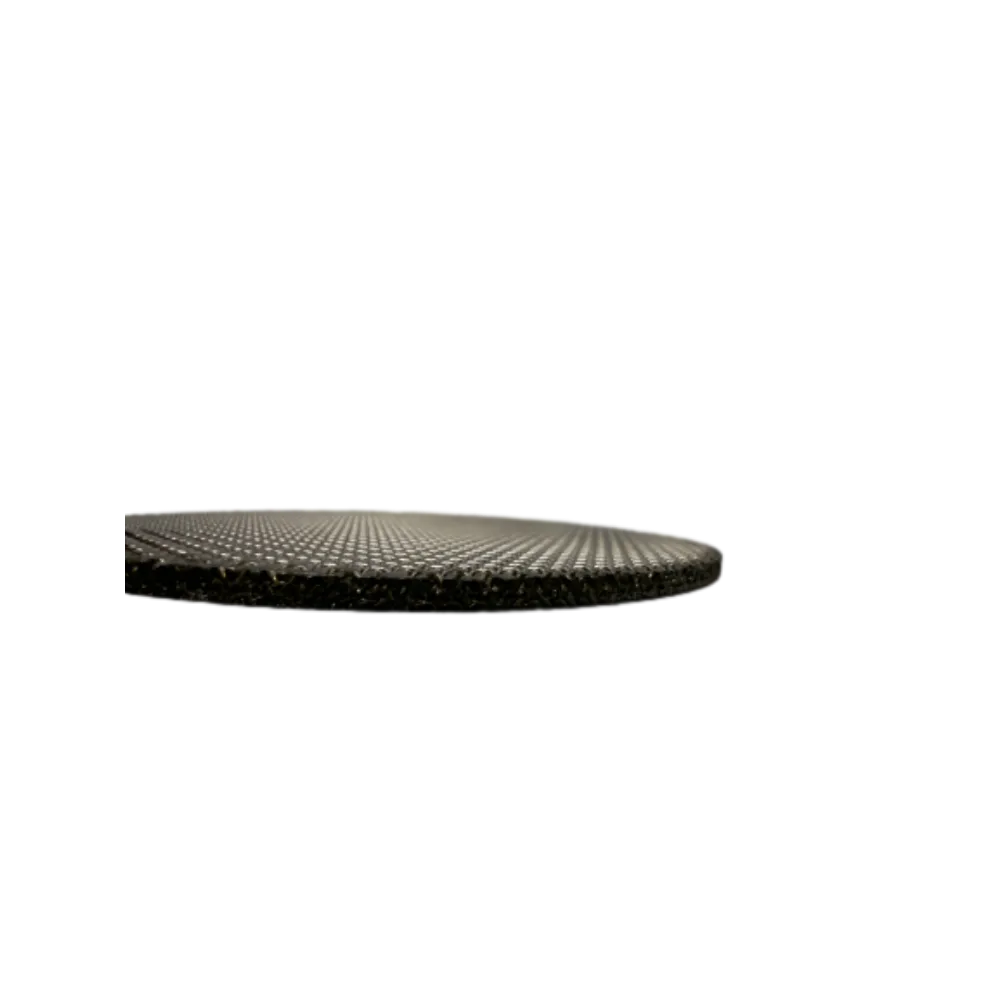

Gatlaklaryň sany

|

3, 5, 7 gatlak (ýa-da ýöriteleşdirilen köp gatlakly gurluş)

|

|

Filtrasiýa takyklygy

|

1μm - 200μm (düzülip bilner)

|

|

Galyňlyk aralygy

|

0,5mm - 5mm (gatlaklaryň sanyna görä üýtgeýär)

|

|

Deşik Ölçeg paýlanyşy

|

Netijeli süzgüç we suwuklyk akymy üçin gradient gözenek dizaýny

|

|

Faceerüsti bejermek

|

Kislotany duzlamak (Poslamaýan polat / uglerod polat),

Elektrolitiki polishing (Poslamaýan polat)

Nikel örtük (Poslamaýan polat / uglerod polat)

Anodizasiýa (alýumin) we ş.m.

|

|

Işleýiş temperaturasy

|

-200 600 600 ℃ (materiallara baglylykda)

|

|

Basyşa garşylyk

|

30MPa ýa-da has ýokary (tor gatlaklaryna we galyňlygyna görä üýtgeýär)

|

|

Ygtyýarlylyk / akym garşylygy

|

Gaz we suwuk süzgüç üçin pes garşylyk we ýokary geçirijilik

|

|

Poslama garşylyk

|

Kislotalara, aşgarlara, duz sepmäge we agyr şertlerde okislenmä garşy

|

|

Arassalamak usullary

|

Yza ýuwmak, Ultrasoniki arassalamak, temperatureokary temperaturaly çörek bişirmek, Himiki arassalamak we gaýtadan ulanmak

|

|

Önümçilik prosesi

|

Temperatureokary temperaturaly wakuum sintezi, Rolling

|

|

Elýeterli şekiller

|

Silindr görnüşli, kwadrat, list, göwnejaý, ýörite şekiller bar

|

|

Baglanyş usullary

|

Flanes baglanyşygy, kebşirlemek, ýüplük birikmesi, gysmak

|

|

Ulanylýan suwuklyklar

|

Suwuklyklar, gazlar, ýaglar, bug we ş.m.

|

|

Programma meýdanlary

|

Nebit-himiýa, azyk we içgi, derman önümleri, daşky gurşawy arassalamak, howa we kosmos, awtoulag senagaty we ş.m.

|

|

Önümiň artykmaçlyklary

|

1. strengthokary güýç we basyşa garşylyk, deformasiýa aňsat däl

2. Gaýtalanýan arassalamak, uzak ömür

3. Takyk süzgüç, gözenegiň ululygynyň paýlanyşy

4. severeokary temperatura we poslama garşylyk, agyr şertlere uýgunlaşdyrylýar

|

![$ element [ady] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)