|

Lintho

|

Tlhaloso

|

|

Lebitso la Sehlahiswa

|

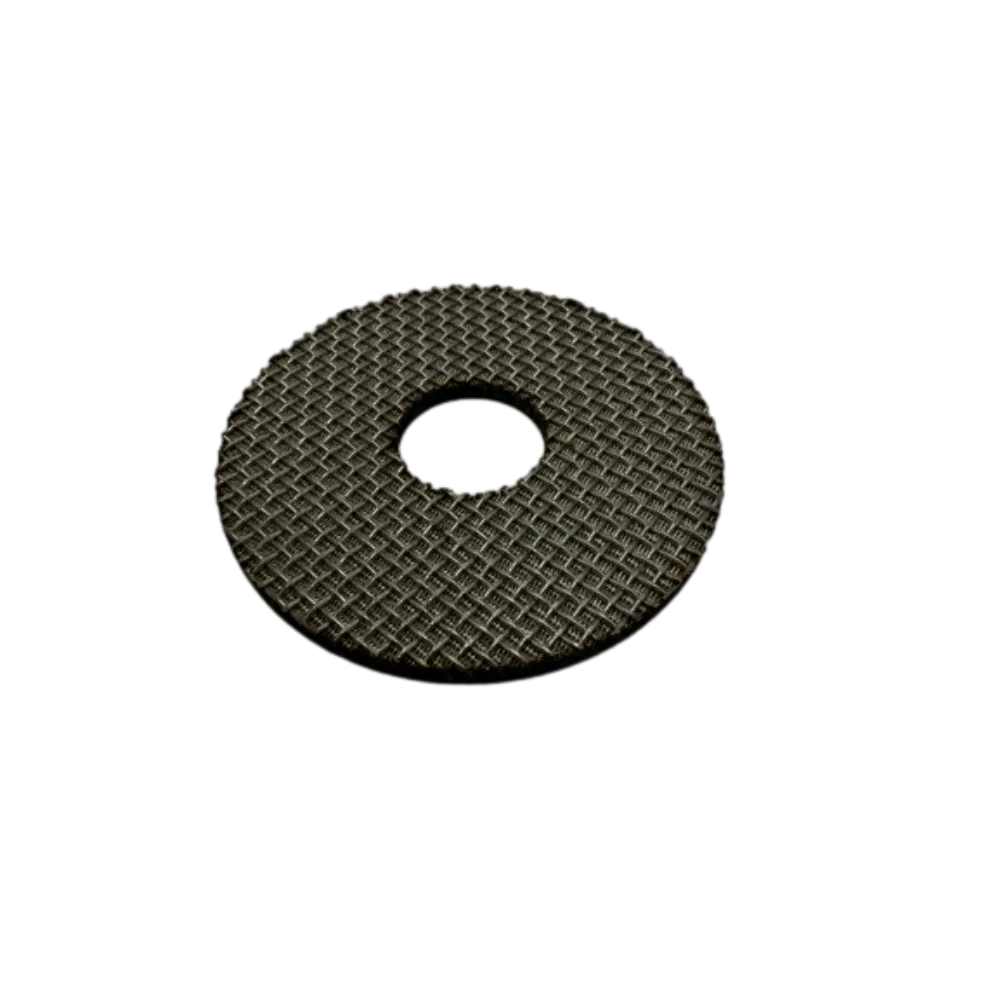

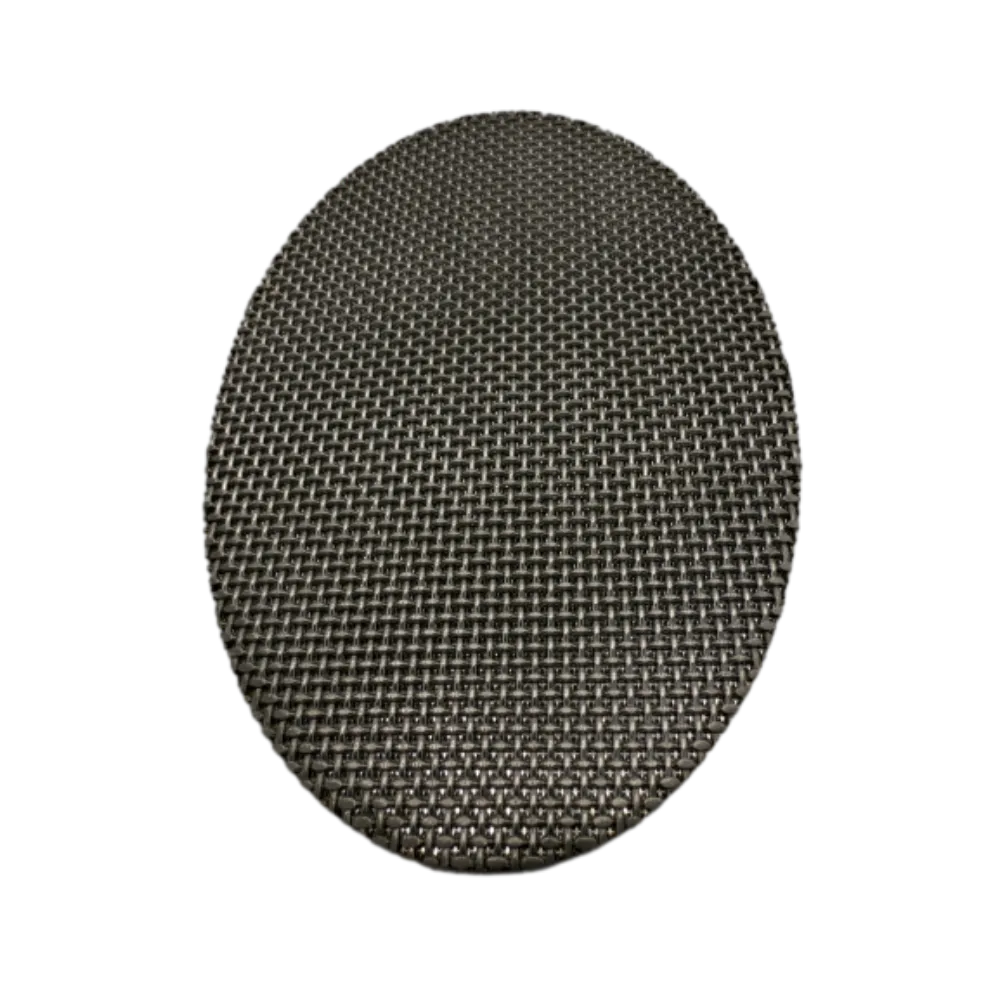

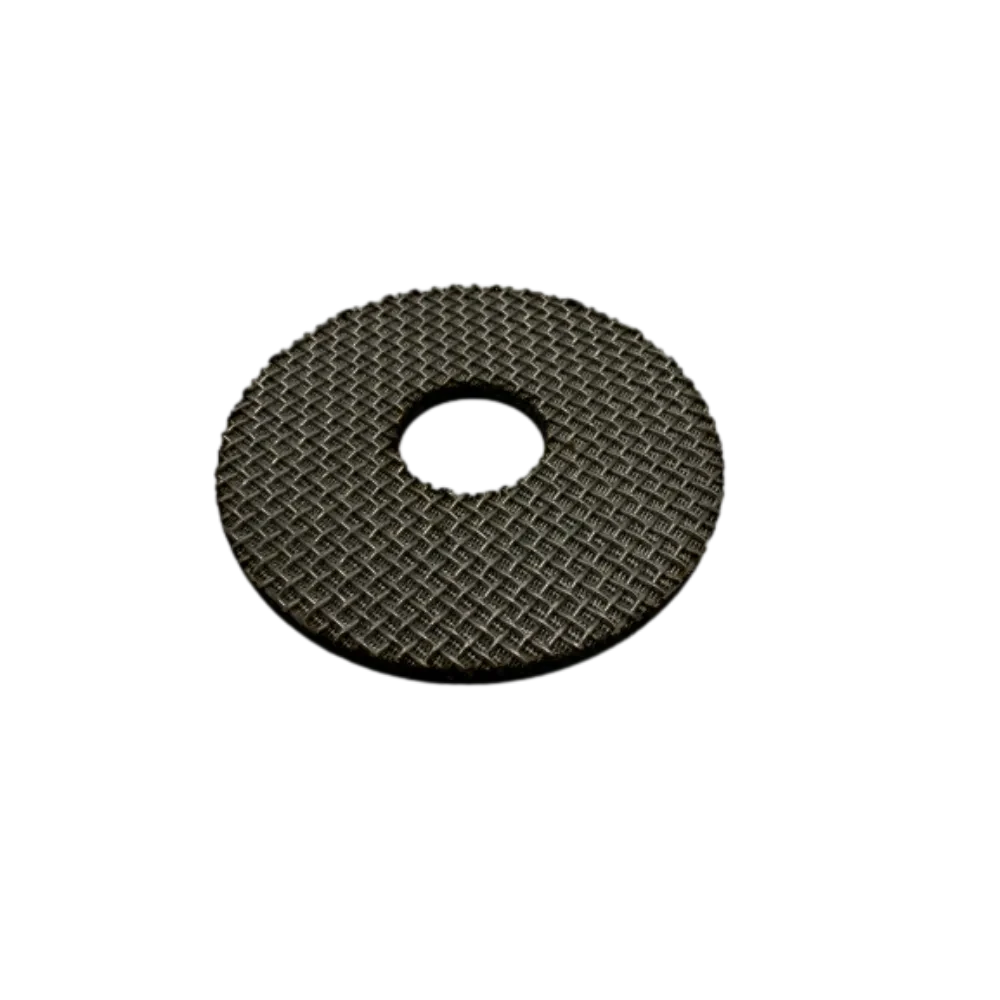

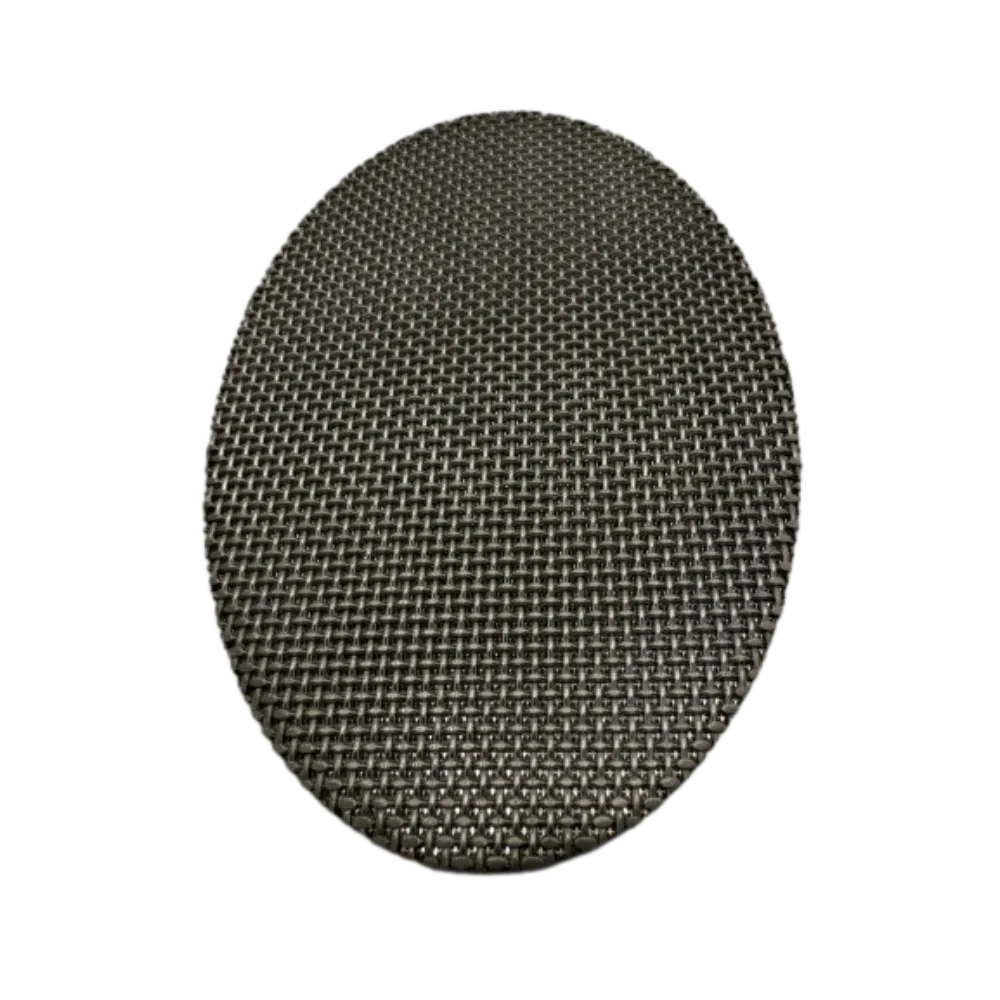

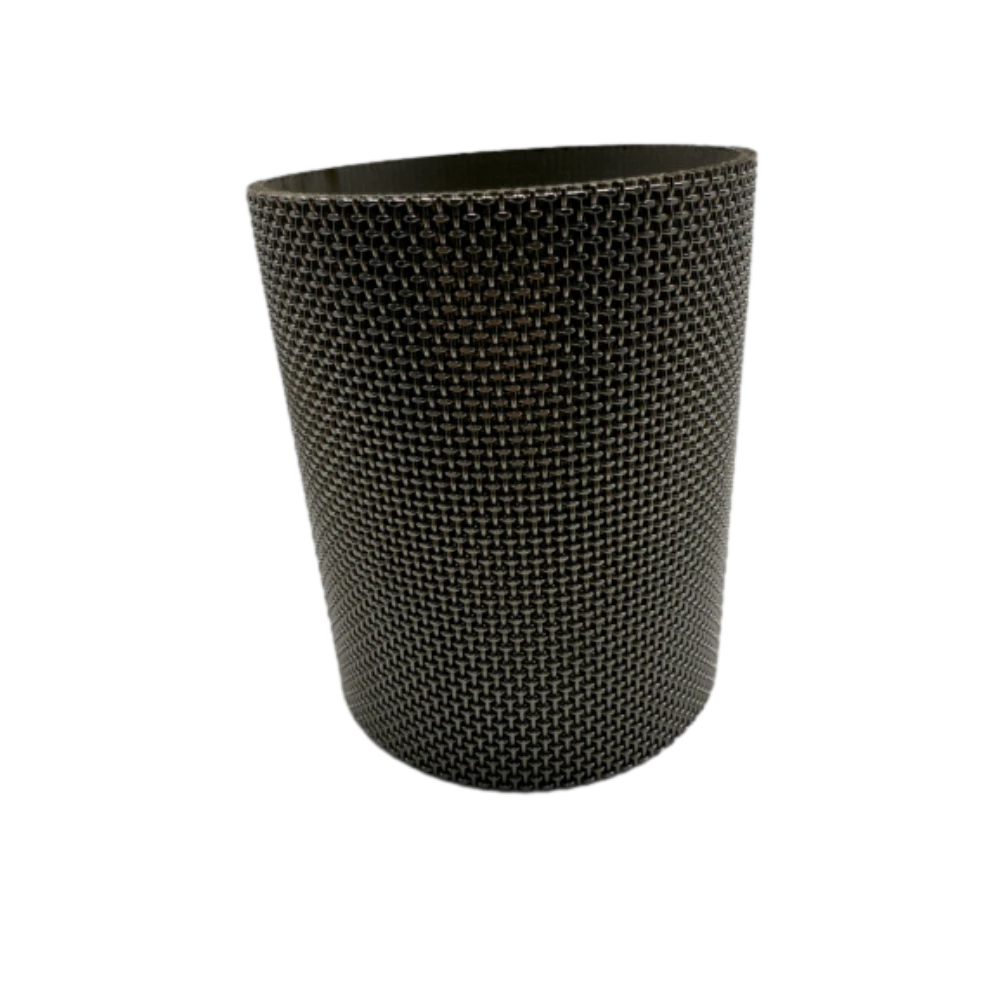

Sintered Wire Mesh Tube

|

|

Mokhoa oa Tlhahiso

|

1. Sintering: Ha lithempereichara tse phahameng, phallo ea likaroloana tsa tšepe e kopanya letlooeng la tšepe hammoho ho etsa sebopeho se momahaneng.

2. Rolling: Ka ho bilika ha khatello e phahameng, lera le leng le le leng le hokahantsoe ka thata ho netefatsa botenya ba lona.

3. Laser Cutting / Plasma Cutting: Seha Sintered Wire Mesh ho netefatsa boholo le sebopeho se nepahetseng.

|

|

Mokhoa o lohiloeng oa letlooeng le lohiloeng

|

1. Plain Weave (Mokhoa o tloaelehileng oa ho loha o na le masoba a tšoanang a letlooeng 'me o loketse ho sefa ka kakaretso)

2. Twill Weave(Ho nepahala ho holimo ho sefang, sebopeho se thata, se loketseng ho sefa ka mokhoa o nepahetseng haholo)

3. Dutch Weave(Mohaho o sefang o matla haholo o etsoa ka ho loha likhoele tse mahoashe tse mahoashe le likhoele tse ntle tsa weft, tse sebelisoang hangata bakeng sa tlhoekiso ea ultrafine)

4. Reverse Dutch Weave (E na le matla a phahameng le matla a ho jara, a loketseng ho sefa ka khatello e phahameng)

|

|

Mekhoa e Meng ea Lintho

|

1. Tshipi e sa Kgethehang (304, 316, 316L)

2. Nickel Alloy(Monel, Hastelloy、Inconel)

3. Mesh ea Titanium

ETC

|

|

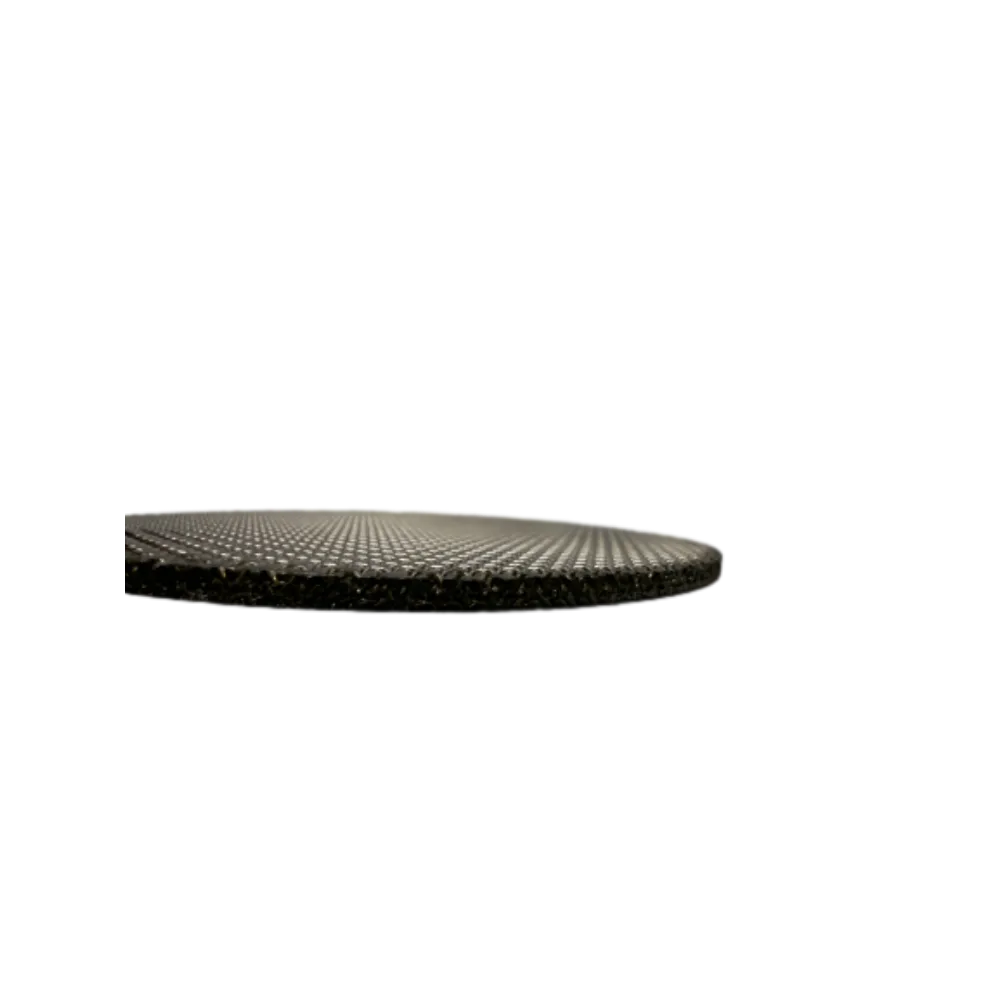

Palo ea Meralo

|

3, 5, 7 layers (kapa sebopeho sa mekhahlelo e mengata e hlophisitsoeng)

|

|

Ho Nepaha ha Sefe

|

1μm - 200μm (ka tloaelo)

|

|

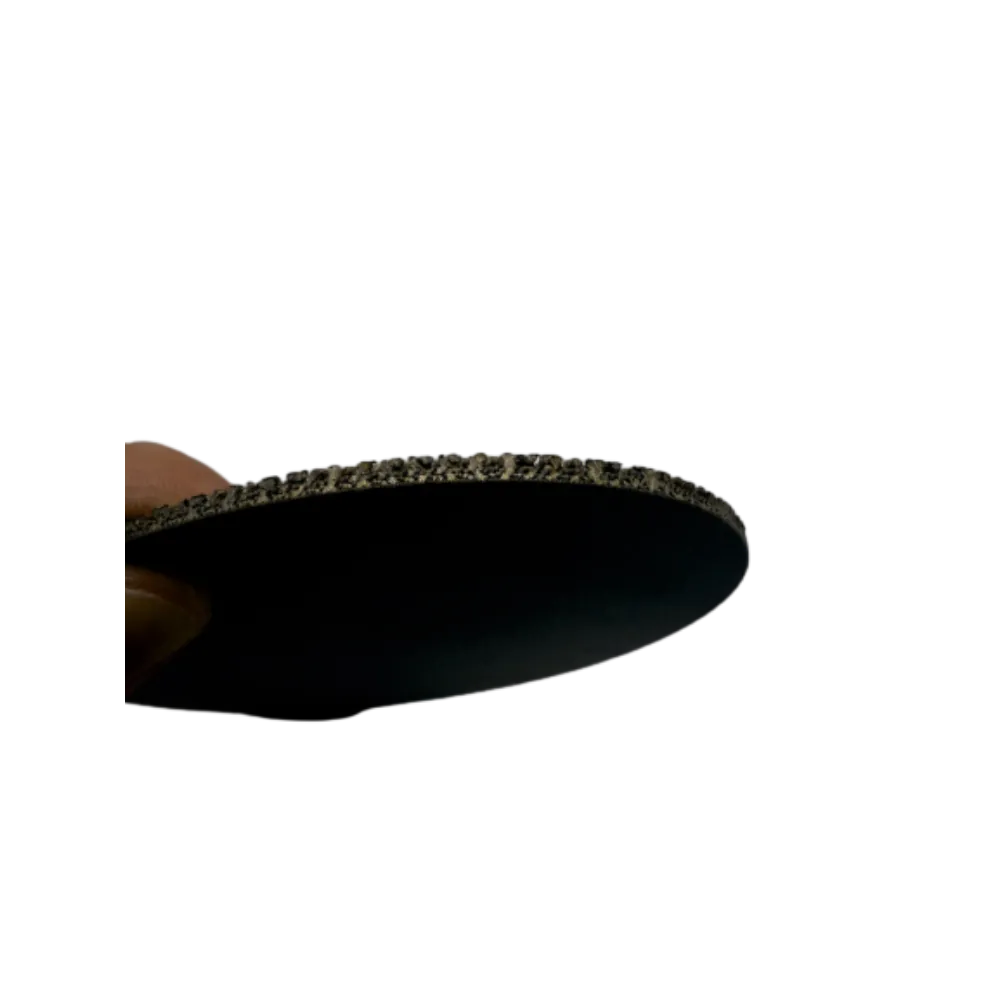

Botenya Range

|

0.5mm - 5mm (e fapana ho ea ka palo ea lihlopha)

|

|

Sekoti Kabo ea boholo

|

Moralo oa pore oa gradient bakeng sa ho sefa hantle le ho phalla ha mokelikeli

|

|

Kalafo ea Bokaholimo

|

Ho khetha asiti (tšepe e se nang tšepe / k'habone),

Electrolytic polishing(Stainless Steel)

Nickel plating(Stainless Steel/Carbon Steel)

Anodizing (Aluminium) joalo-joalo.

|

|

Mocheso oa ho sebetsa

|

-200 ℃ ho 600 ℃ (ho itšetlehile ka thepa)

|

|

Ho Hanyetsa Khatello

|

Ho fihla ho 30MPa kapa ho feta (e fapana ho ipapisitsoe le mesh le botenya)

|

|

Permeability/ Ho hanana ha Phallo

|

Ho hanyetsa ho tlaase le ho phunyeletsa ho phahameng, ho loketse ho hloekisa khase le metsi

|

|

Khanyetso ea Corrosion

|

E hanyetsana le li-acids, alkalis, salt spray, le oxidation libakeng tse thata

|

|

Mekhoa ea ho Hloekisa

|

Ho hlatsoa mokokotlo, ho hloekisa ka mokhoa oa Ultrasonic, ho baka ka mocheso o phahameng, ho hloekisa lik'hemik'hale, le ho sebelisoa hape

|

|

Mokhoa oa Tlhahiso

|

Mocheso o phahameng oa vacuum sintering, Rolling

|

|

Libopeho tse fumanehang

|

Cylindrical, Square, Sheet, Pleated, Custom dibopeho di teng

|

|

Mekhoa ea Khokahano

|

Khokahano ea Flange, Welding, Khokahano ea likhoele, Clamping

|

|

Mekelikeli e sebetsang

|

E loketse maro, likhase, oli, mouoane, joalo-joalo.

|

|

Libaka tsa Kopo

|

Petrochemical, Lijo le Seno, Meriana, Phekolo ea Metsi a Tikoloho, Aerospace, Indasteri ea Likoloi, jj.

|

|

Melemo ea Sehlahisoa

|

1. Matla a phahameng le ho hanyetsa khatello, ha ho bonolo ho holofatsa

2. Ho hloekisa khafetsa, bophelo bo bolelele

3. Ho hloekisa ka mokhoa o nepahetseng, kabo ea boholo ba pore e tšoanang

4. Mocheso o phahameng le ho hanyetsa kutu, ho ikamahanya le maemo a thata

|

![$ntho[sehlooho] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)