|

Zinthu

|

Kufotokozera

|

|

Dzina lazogulitsa

|

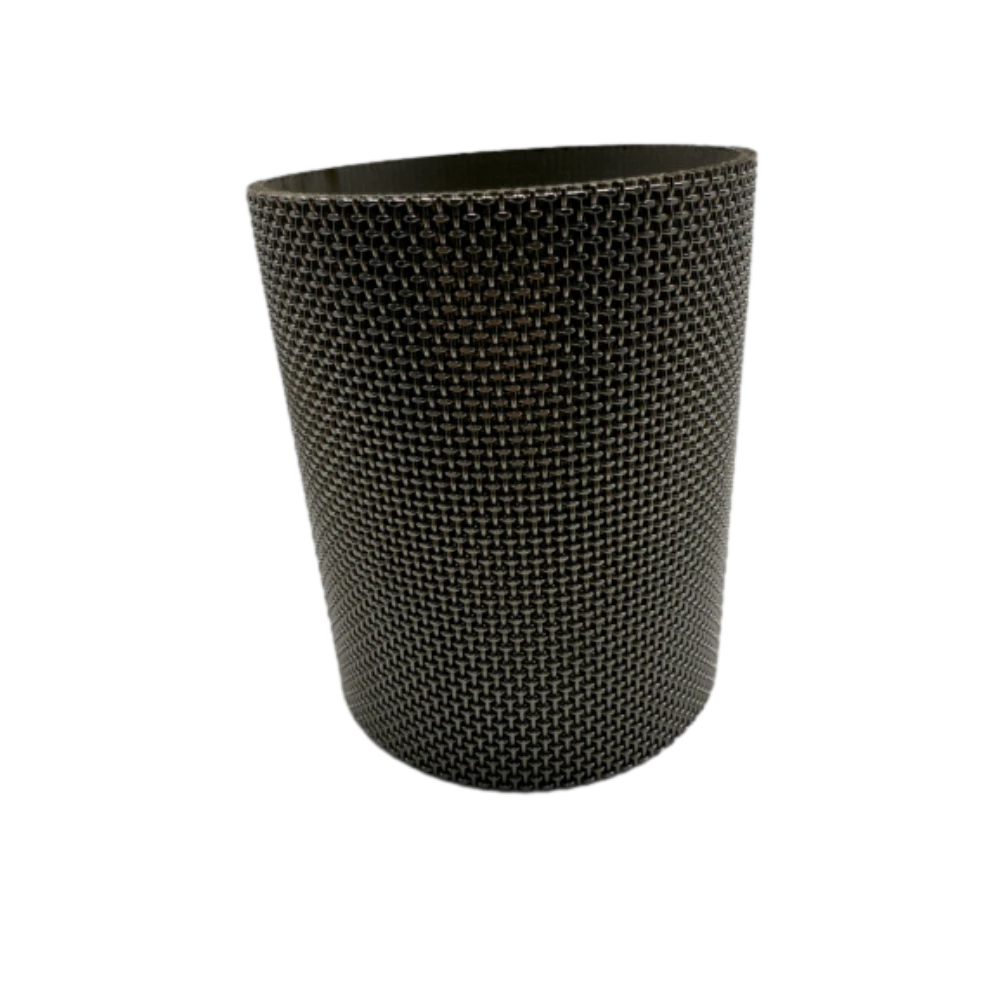

Sintered Wire Mesh Tube

|

|

Njira Yopangira

|

1. Sintering: Pa kutentha kwambiri, kufalikira kwa tinthu tachitsulo timamanga mauna achitsulo pamodzi kuti apange dongosolo logwirizana

2. Kugudubuza: Ndi kugubuduza kwakukulu, wosanjikiza aliyense wa mauna amalumikizidwa mwamphamvu kuti atsimikizire kufanana kwake

3. Kudula kwa Laser / Plasma Cutting: Dulani Sintered Wire Mesh kuti muwonetsetse kukula kwake ndi mawonekedwe ake.

|

|

Njira yoluka ya mesh ya waya

|

1. Plain Weave (Njira yodziwika kwambiri yoluka ili ndi mabowo a mauna ofanana ndipo ndiyoyenera kusefera wamba)

2. Twill Weave(Kulondola kwambiri kusefa, mawonekedwe olimba, oyenera kusefa mwatsatanetsatane)

3. Dutch Weave(Zosefera zokhala ndi kachulukidwe kwambiri zimapangidwa ndi ulusi wokhotakhota wolukana ndi ulusi wabwino kwambiri, womwe umagwiritsidwa ntchito posefera kopitilira muyeso)

4. Reverse Dutch Weave (Ili ndi mphamvu zapamwamba komanso mphamvu yonyamula katundu, yoyenera kusefa kwakukulu)

|

|

Njira Zina

|

1. Chitsulo chosapanga dzimbiri (304, 316, 316L)

2. Nickel Aloy (Monel, Hastelloy, Inconel)

3. Titaniyamu Mesh

ETC

|

|

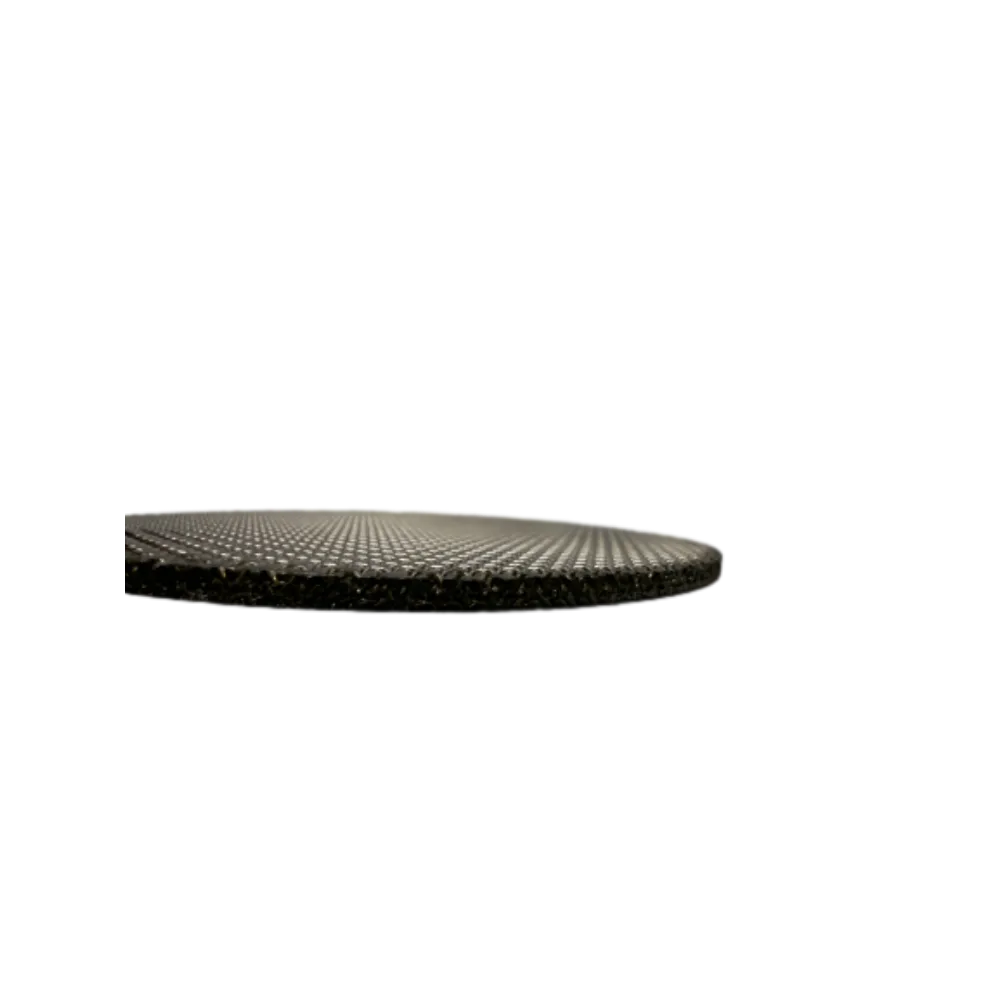

Chiwerengero cha zigawo

|

3, 5, 7 zigawo (kapena makonda angapo wosanjikiza kapangidwe)

|

|

Kulondola Kosefera

|

1μm - 200μm (zosintha mwamakonda)

|

|

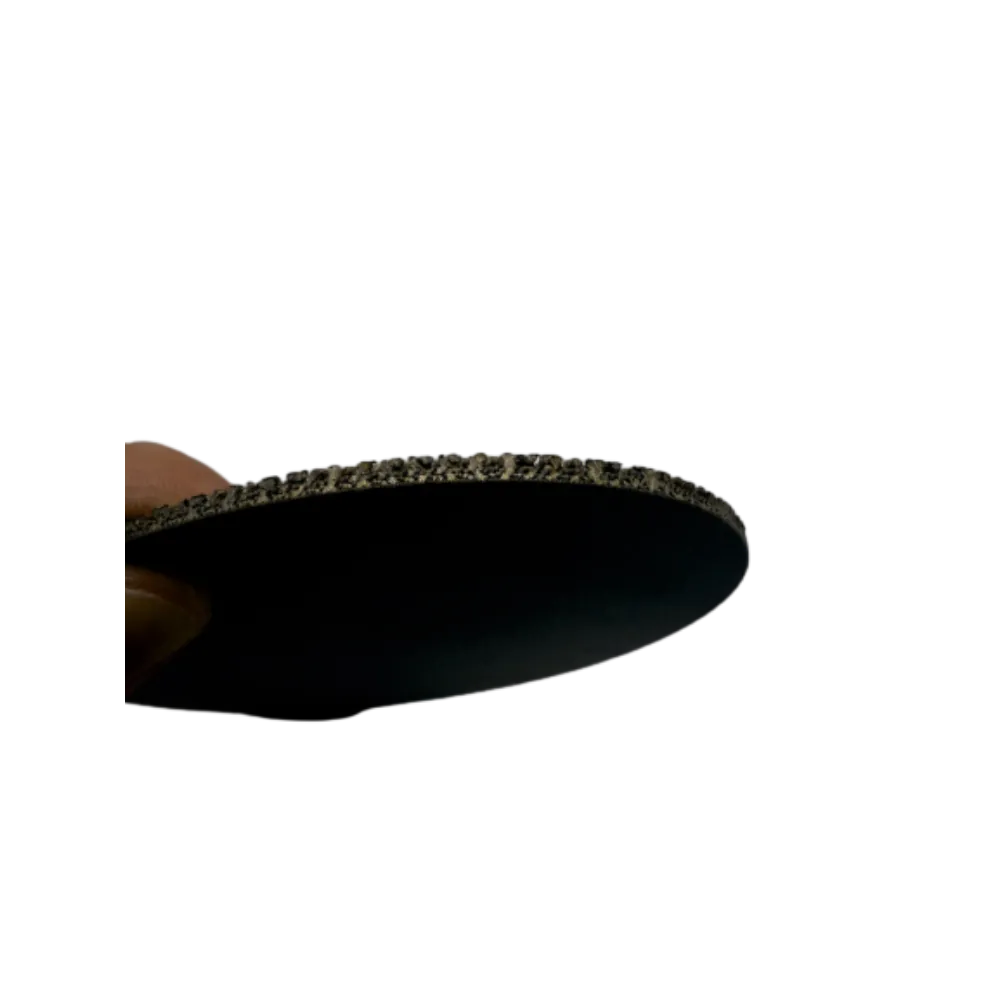

Makulidwe osiyanasiyana

|

0.5mm - 5mm (amasiyana ndi chiwerengero cha zigawo)

|

|

Bowo Kugawa Kwakukulu

|

Mapangidwe a gradient pore kuti azisefera bwino komanso kuyenda kwamadzimadzi

|

|

Chithandizo cha Pamwamba

|

Acid pickling(Stainless Steel/Carbon steel),

Electrolytic polishing(Chitsulo chosapanga dzimbiri)

Nickel plating (Chitsulo chosapanga dzimbiri/Chitsulo cha Mpweya)

Anodizing (Aluminium) etc.

|

|

Kutentha kwa Ntchito

|

-200 ℃ mpaka 600 ℃ (malingana ndi zinthu)

|

|

Kukaniza Kupanikizika

|

Kufikira 30MPa kapena kupitilira apo (amasiyanasiyana kutengera mauna ndi makulidwe)

|

|

Permeability / Flow Resistance

|

Low kukana ndi mkulu permeability, oyenera gasi ndi madzi kusefera

|

|

Kukaniza kwa Corrosion

|

Kugonjetsedwa ndi zidulo, alkalis, mchere wopopera, ndi okosijeni m'malo ovuta

|

|

Njira Zoyeretsera

|

Backwashing, Akupanga kuyeretsa, High-kutentha kuphika, Chemical kuyeretsa, ndi reusable

|

|

Njira Yopangira

|

Kutentha kwakukulu kwa vacuum sintering, Rolling

|

|

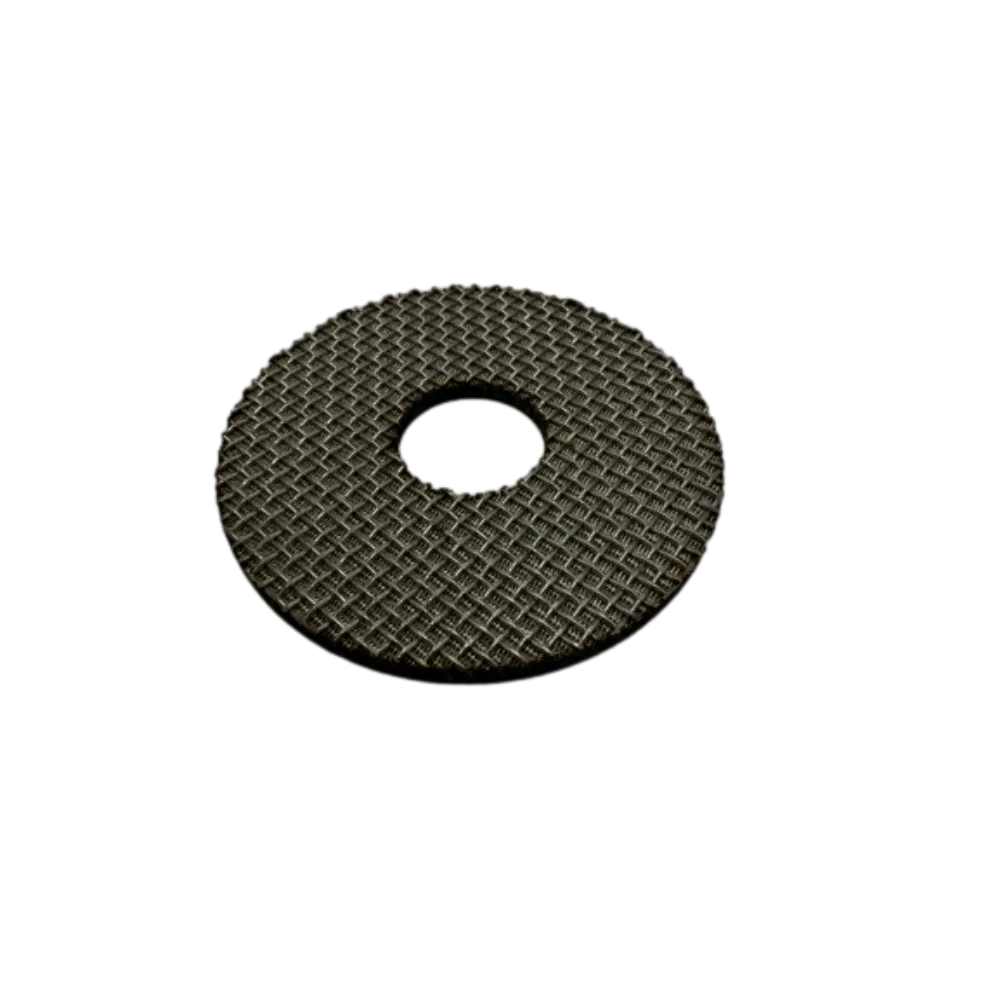

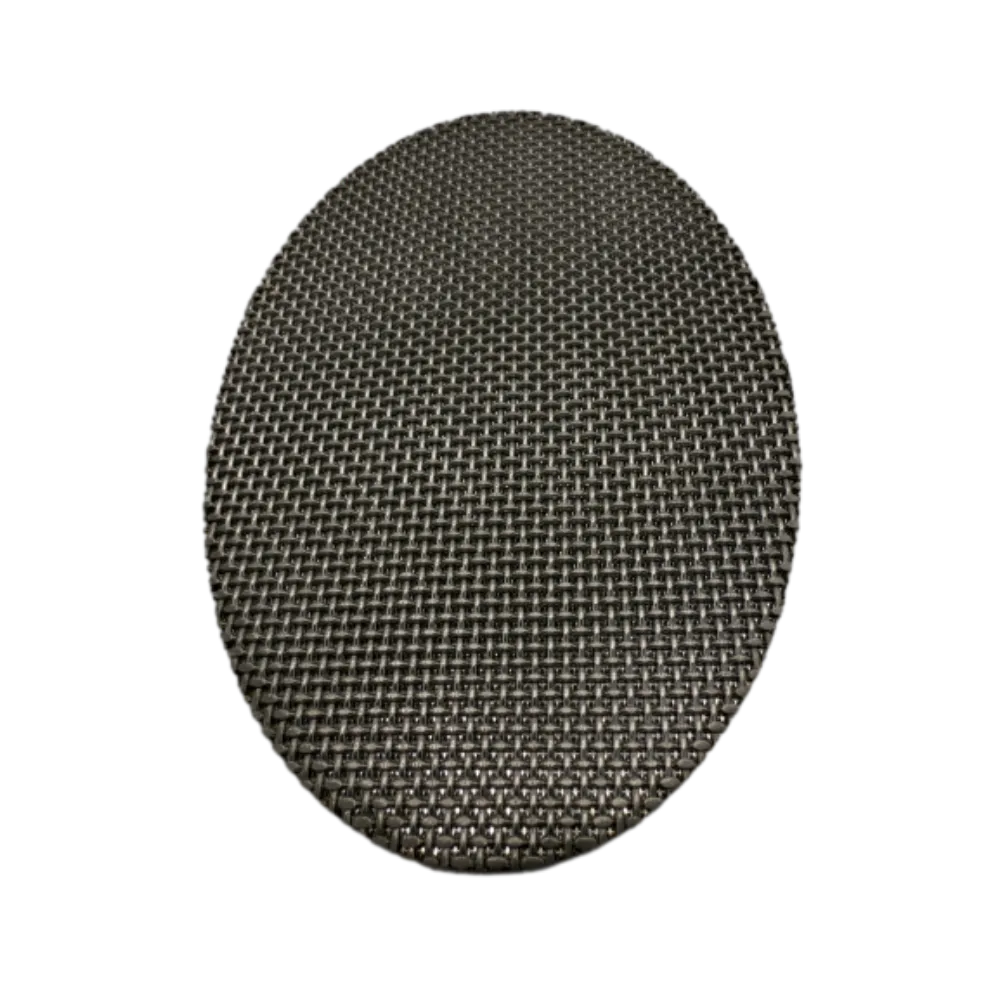

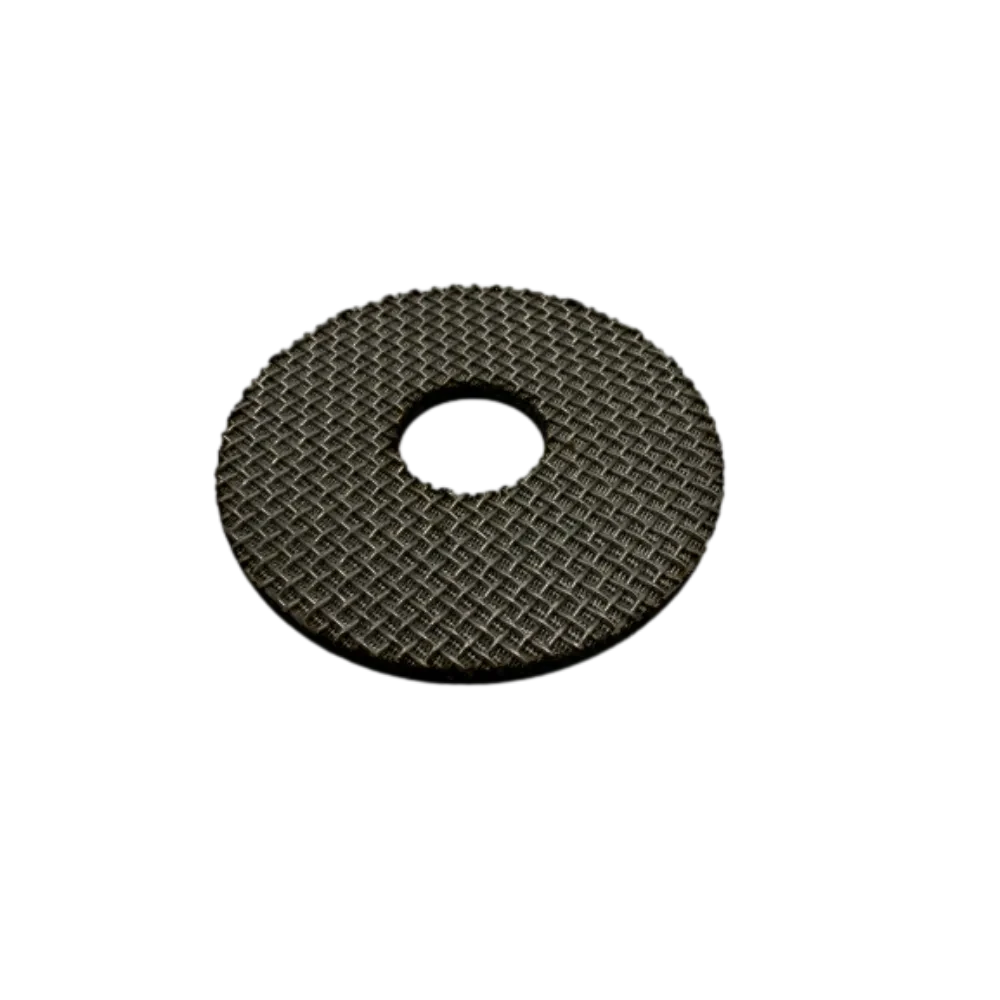

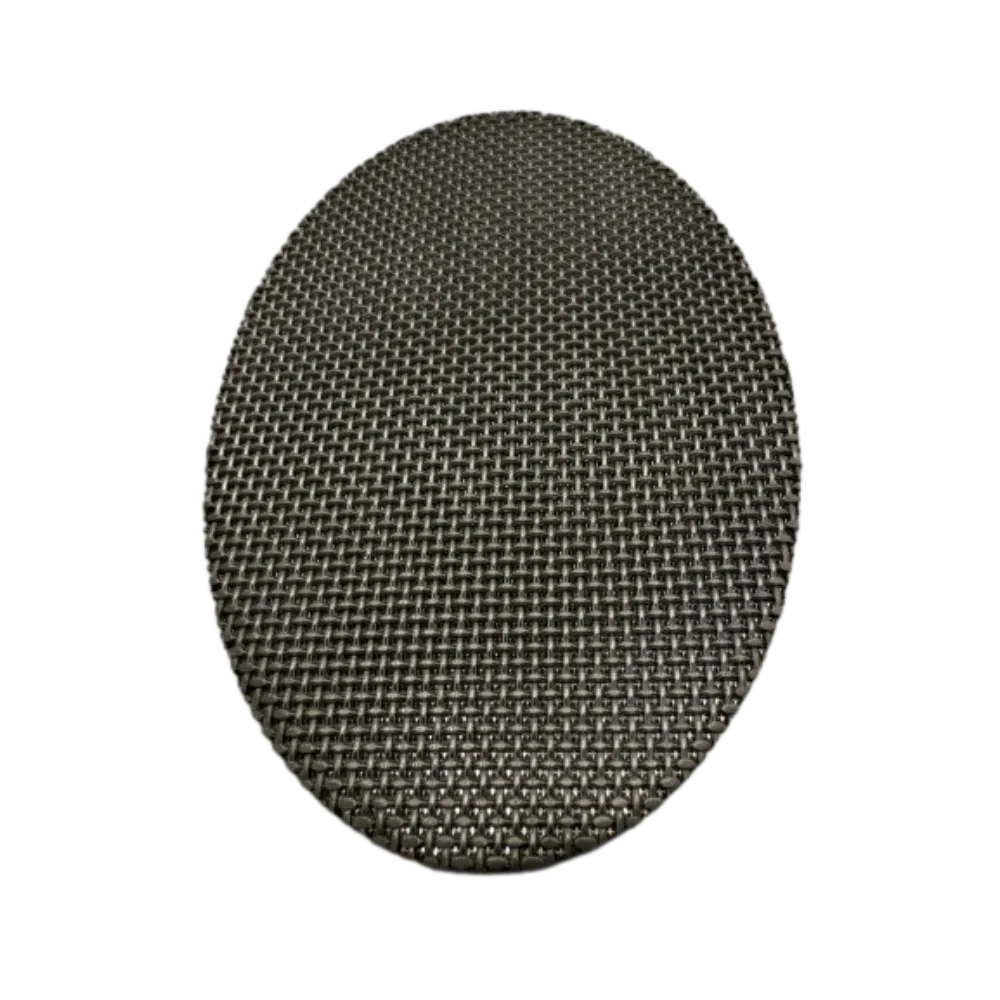

Mawonekedwe Opezeka

|

Cylindrical, Square, Mapepala, Pleated, Mawonekedwe Mwamakonda alipo

|

|

Njira Zolumikizirana

|

Kulumikizana kwa Flange, Kuwotcherera, Kulumikizana kwa Threaded, Clamping

|

|

Kugwiritsa Ntchito Madzi

|

Oyenera zakumwa, mpweya, mafuta, nthunzi, etc.

|

|

Minda Yofunsira

|

Petrochemical, Food & Beverage, Pharmaceuticals, Environmental Water Treatment, Azamlengalenga, Makampani Agalimoto, etc.

|

|

Ubwino wa Zamalonda

|

1. Mphamvu yayikulu ndi kukana kukakamiza, osati kosavuta kufooketsa

2. Kuyeretsa mobwerezabwereza, moyo wautali

3. Kusefedwa kolondola, kugawa kofanana kwa pore

4. Kutentha kwakukulu ndi kukana kwa dzimbiri, kusinthika kumadera ovuta

|

![$chinthu[mutu] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)