|

Barang

|

Katerangan

|

|

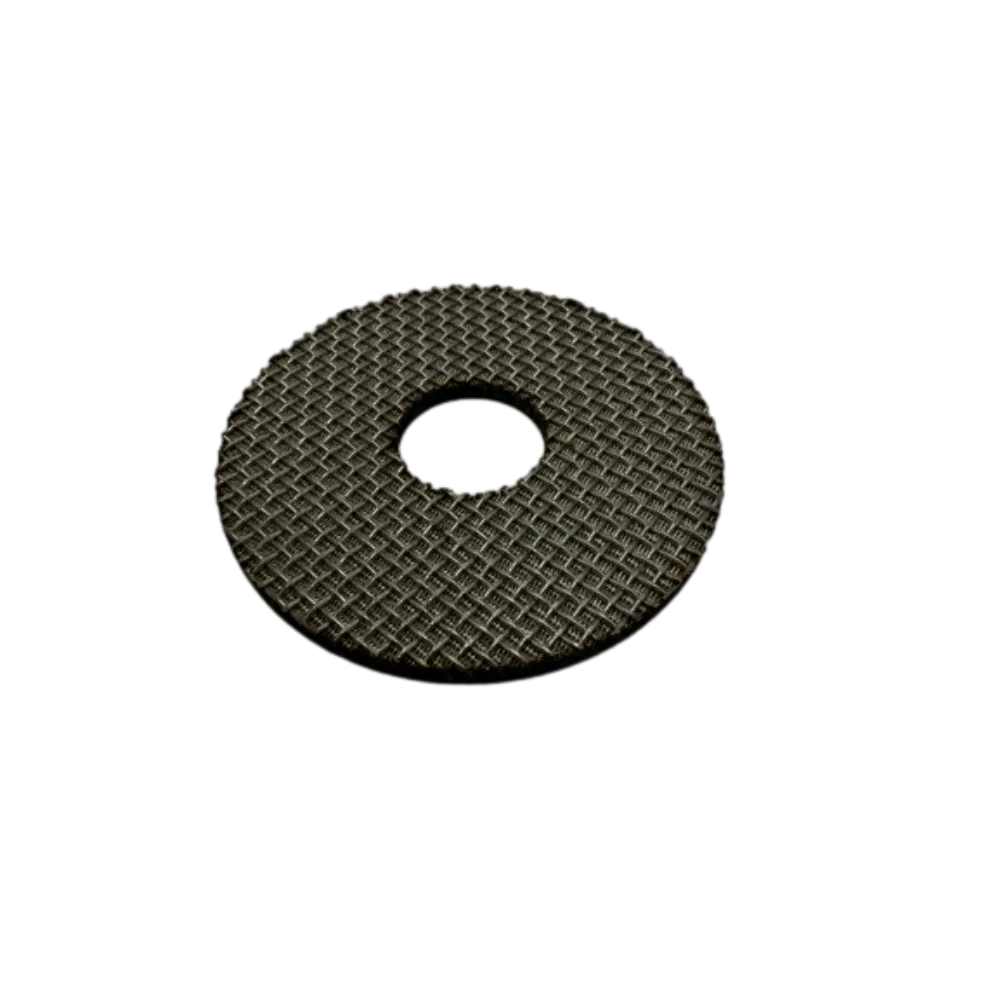

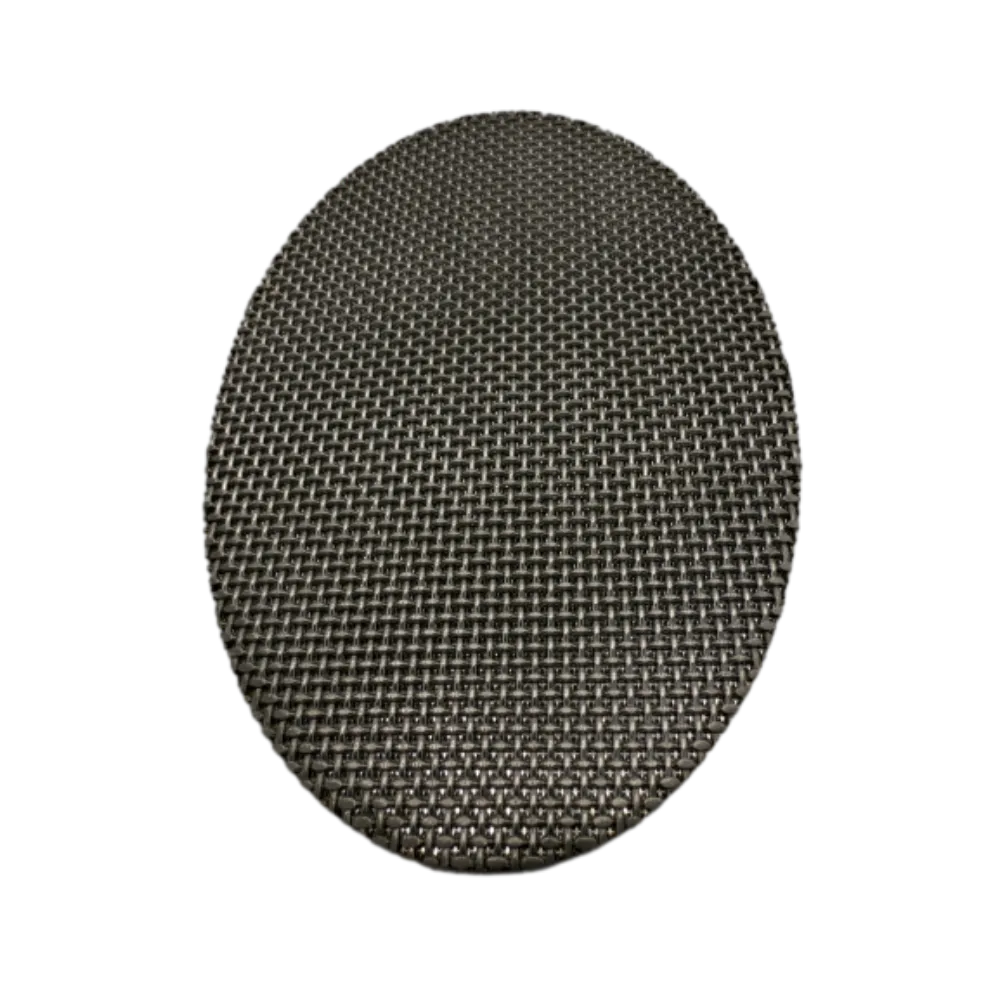

Ngaran produk

|

Sintered Wire Mesh Tube

|

|

Prosés Manufaktur

|

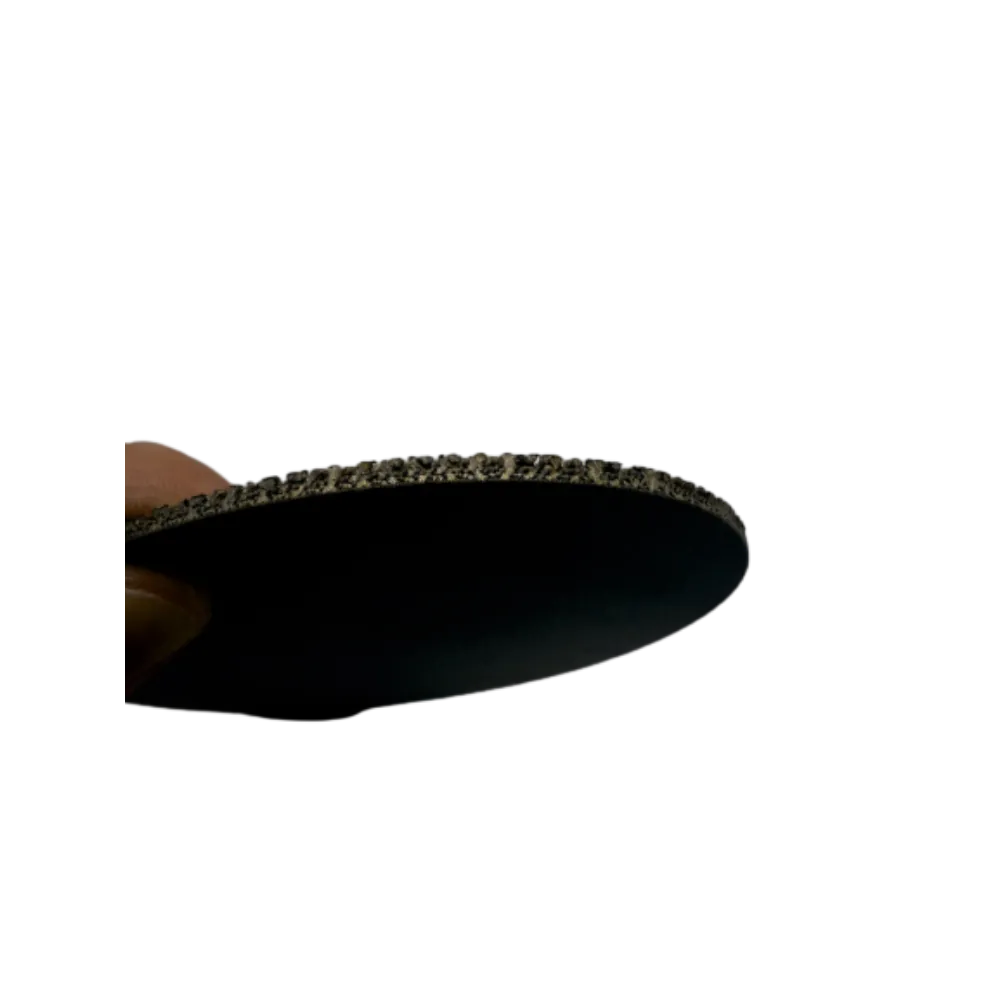

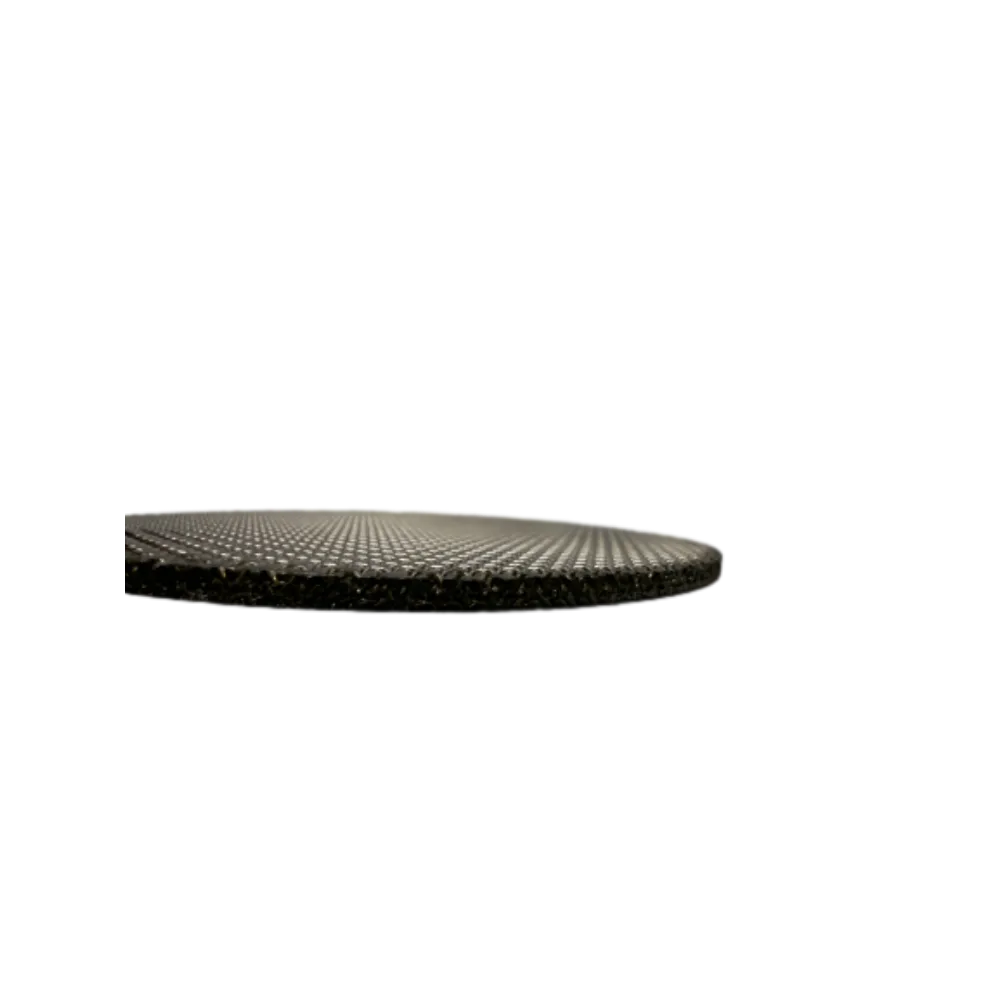

1. Sintering: Dina suhu luhur, difusi partikel logam ngiket bolong logam babarengan pikeun ngabentuk struktur cohesive.

2. Rolling: Ku-tekanan tinggi rolling, unggal lapisan bolong disambungkeun pageuh pikeun mastikeun uniformity ketebalan na

3. Laser Motong / Plasma Motong: Motong Sintered Wire Mesh pikeun mastikeun ukuran jeung bentuk tepat.

|

|

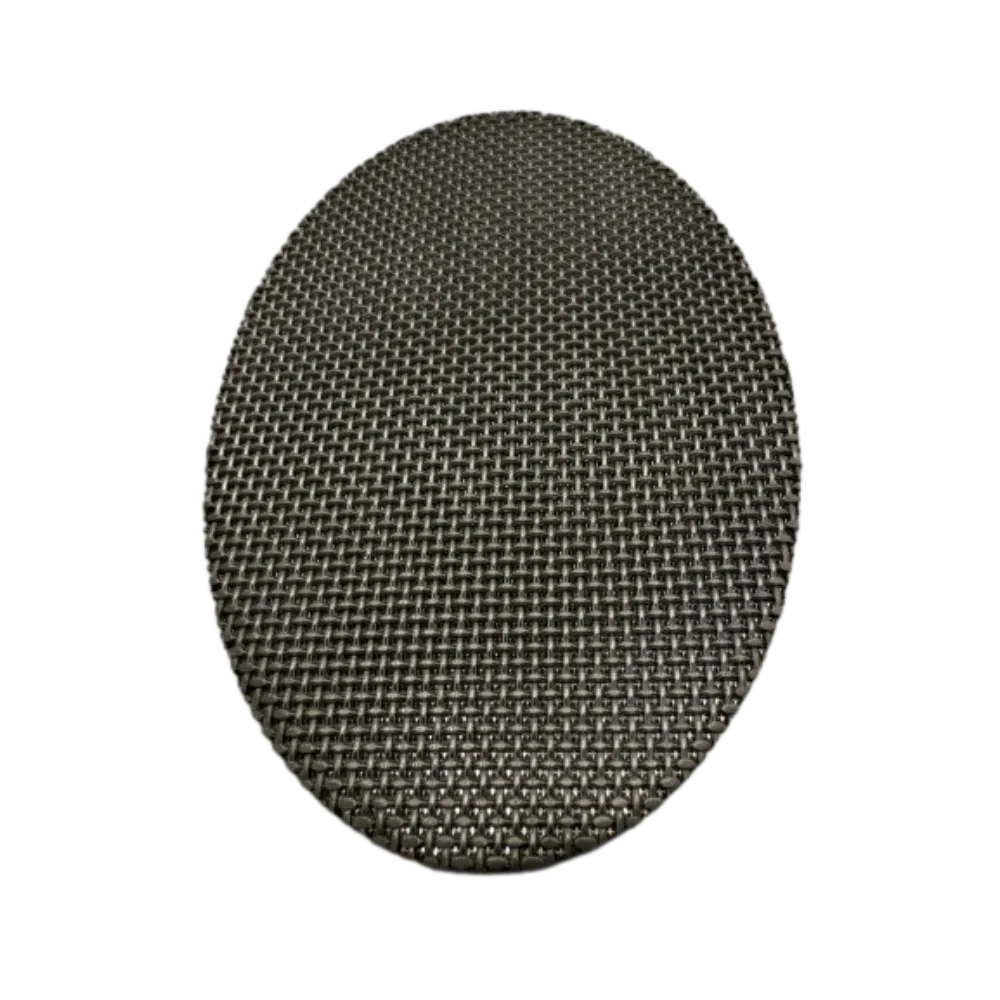

Cara anyaman tina anyaman kawat bolong

|

1. Ninun polos (Metoda anyaman anu paling umum ngagaduhan liang bolong seragam sareng cocog pikeun filtrasi umum)

2. Twill Weave (Akurasi panyaring anu langkung luhur, struktur anu langkung ketat, cocog pikeun panyaring precision tinggi)

3. Walanda Ninun (A-dénsitas tinggi struktur nyaring dibentuk ku interweaving threads Lungsi kasar jeung threads weft rupa, ilahar dipaké pikeun filtration ultrafine)

4. Ngabalikeun Walanda Ninun (Mibanda kakuatan luhur jeung kapasitas beban-bearing, cocog pikeun filtration-tekanan tinggi)

|

|

Bahan Alternatif

|

1. Stainless Steel (304, 316, 316L)

2. Nikel Alloy (Monel, Hastelloy, Inconel)

3. Titanium bolong

Jsb

|

|

Jumlah Lapisan

|

3, 5, 7 lapisan (atawa ngaropéa struktur multi-lapisan)

|

|

Akurasi Filtrasi

|

1μm - 200μm (bisa disaluyukeun)

|

|

Ketebalan Range

|

0.5mm - 5mm (variasina dumasar kana jumlah lapisan)

|

|

Liang Distribusi Ukuran

|

Desain pori gradién pikeun filtration efisien sarta aliran cairan

|

|

Perlakuan permukaan

|

Asam pickling (Stainless Steel / baja Karbon),

Polishing éléktrolit (Stainless Steel)

Nikel plating (Stainless Steel/Baja Karbon)

Anodizing (Aluminium) jsb.

|

|

Suhu Operasi

|

-200 ℃ nepi ka 600 ℃ (gumantung bahan)

|

|

Résistansi tekanan

|

Nepi ka 30MPa atanapi langkung luhur (variasina dumasar kana lapisan bolong sareng ketebalan)

|

|

Perméabilitas / Résistansi Aliran

|

Résistansi lemah sareng perméabilitas anu luhur, cocog pikeun filtrasi gas sareng cair

|

|

Résistansi korosi

|

Tahan ka asam, alkali, semprot uyah, sareng oksidasi dina lingkungan anu parah

|

|

Métode beberesih

|

Backwashing, beberesih ultrasonik, baking suhu luhur, beberesih kimiawi, sarta reusable

|

|

Prosés Manufaktur

|

Sintering vakum-suhu luhur, Rolling

|

|

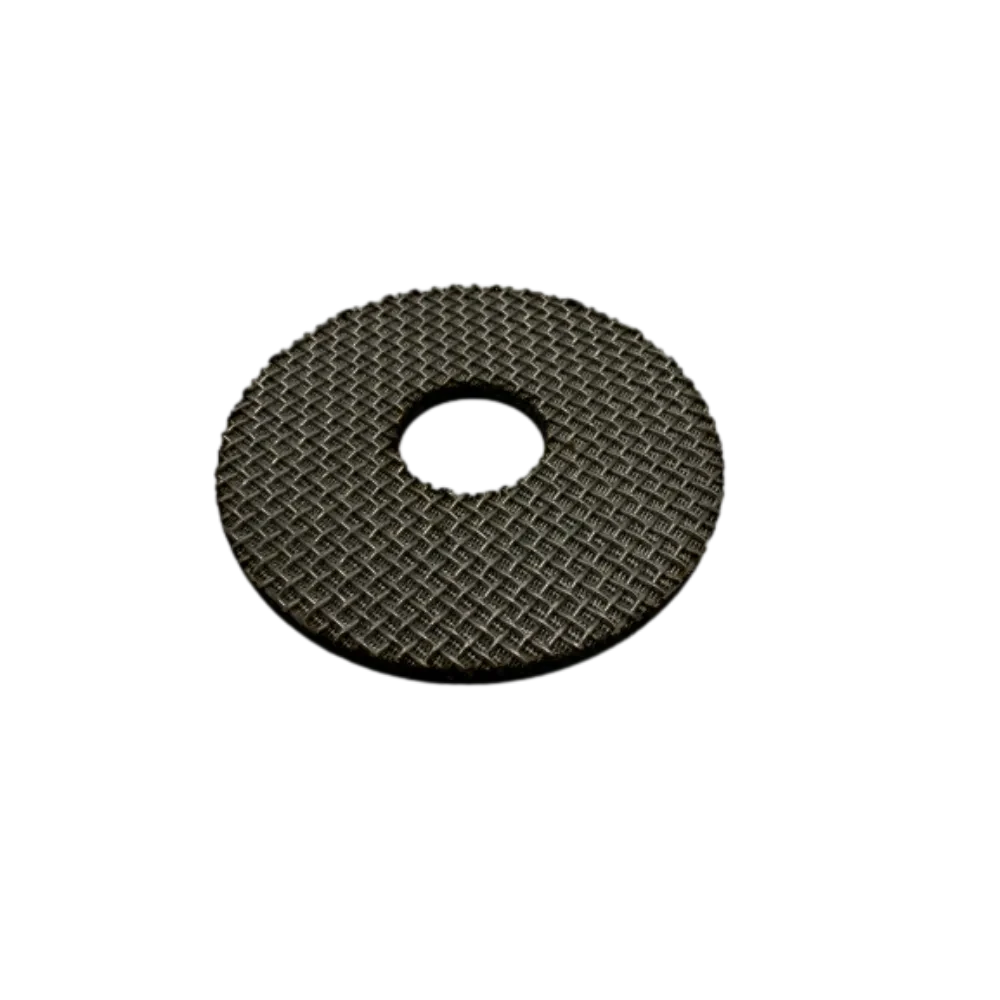

Bentuk sadia

|

Cylindrical, Square, Sheet, Pleated, Bentuk Adat sayogi

|

|

Métode sambungan

|

sambungan Flange, las, sambungan Threaded, Clamping

|

|

Cairan lumaku

|

Cocog jeung cair, gas, minyak, uap, jsb.

|

|

Widang Aplikasi

|

Pétrokimia, Pangan & Inuman, Farmasi, Perlakuan Cai Lingkungan, Aerospace, Industri Otomotif, jsb.

|

|

Kaunggulan produk

|

1. kakuatan High sarta lalawanan tekanan, teu gampang deform

2. beberesih repeatable, umur panjang

3. filtration Precision, distribusi ukuran pori seragam

4. Suhu luhur sarta lalawanan korosi, adaptable kana lingkungan kasar

|

![$item[judul] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)