|

barang

|

Katrangan

|

|

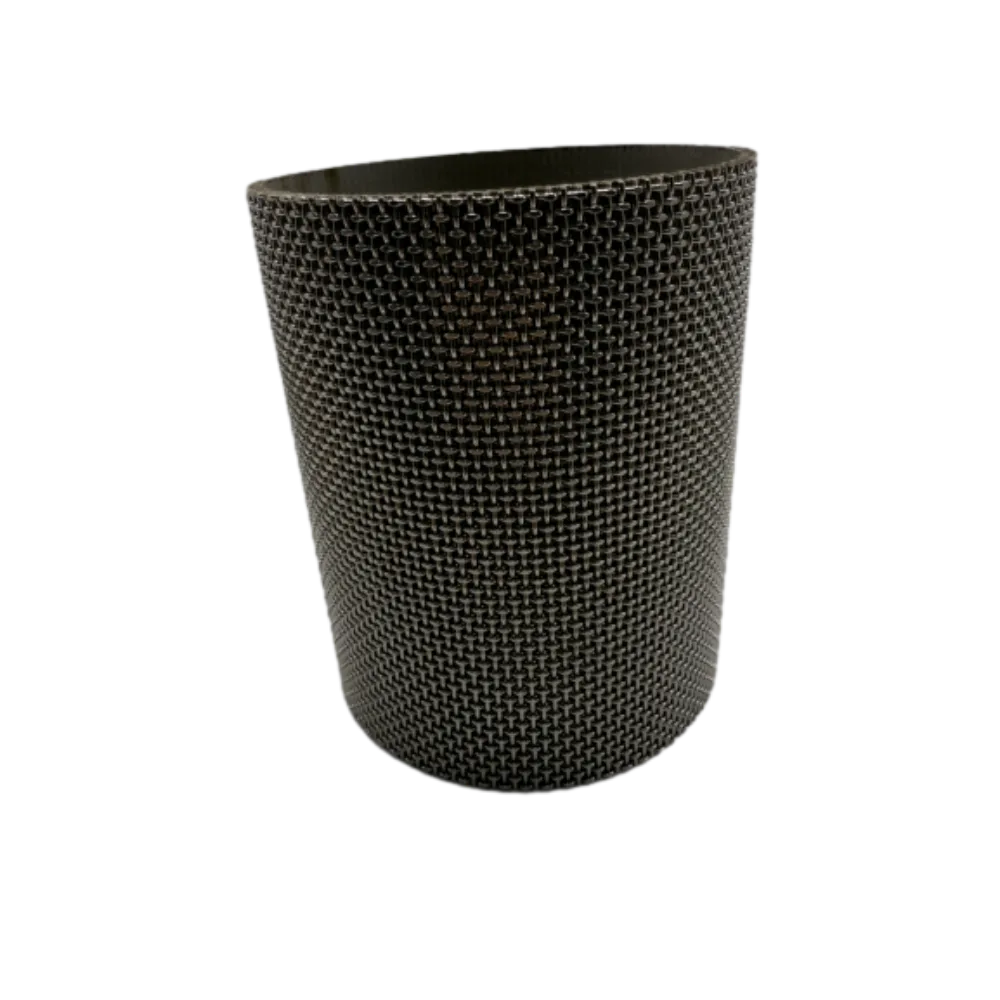

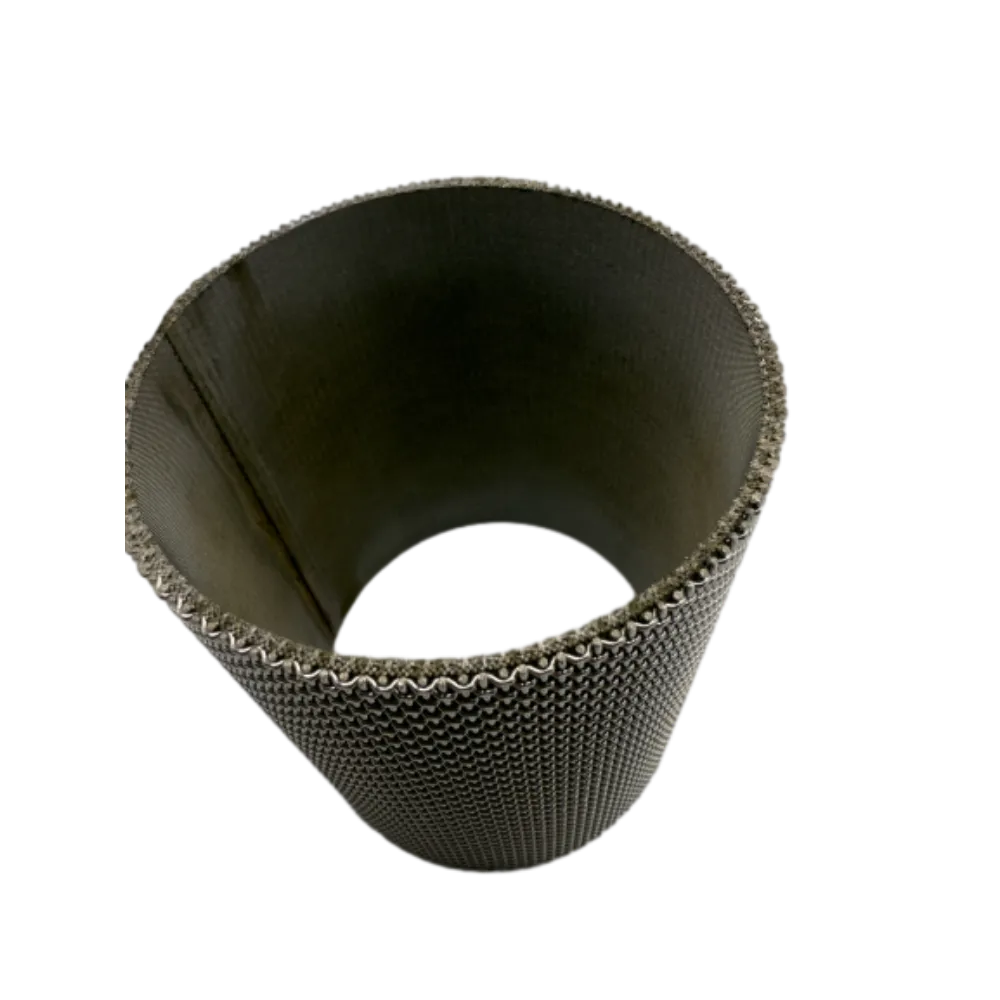

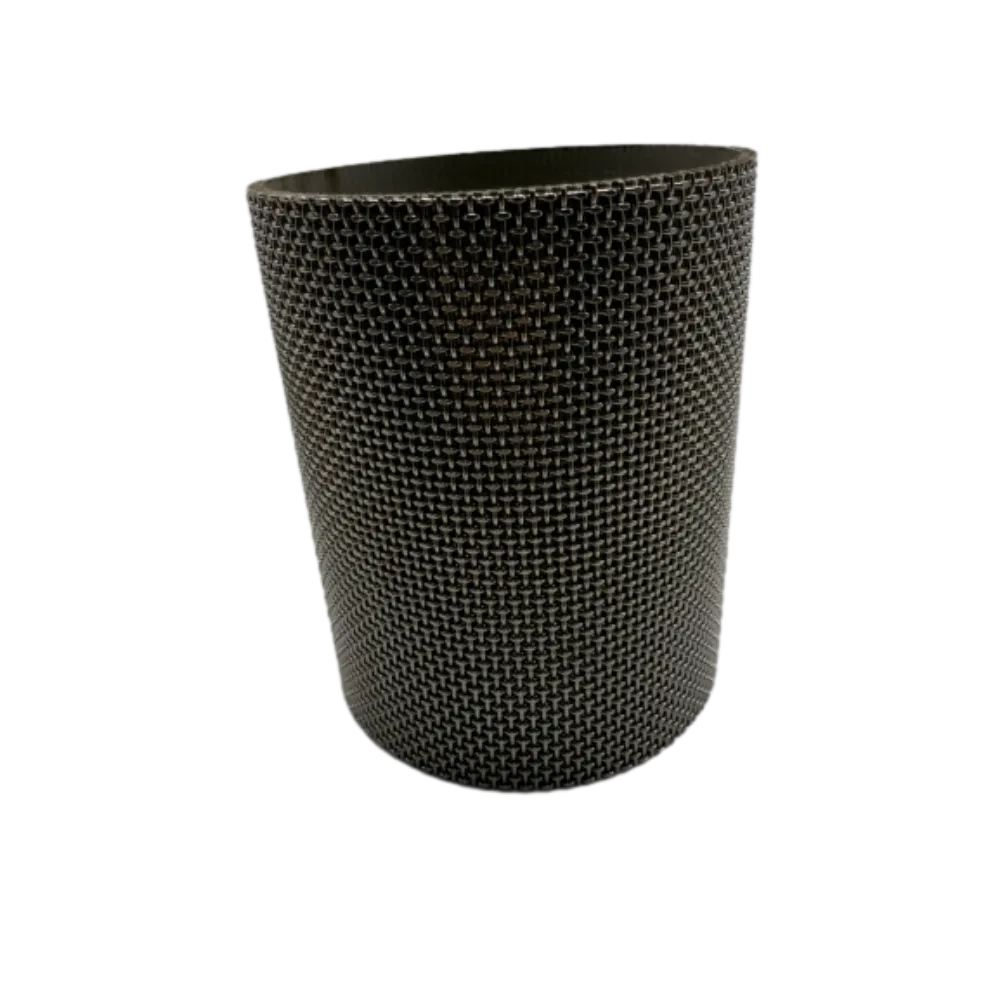

Jeneng produk

|

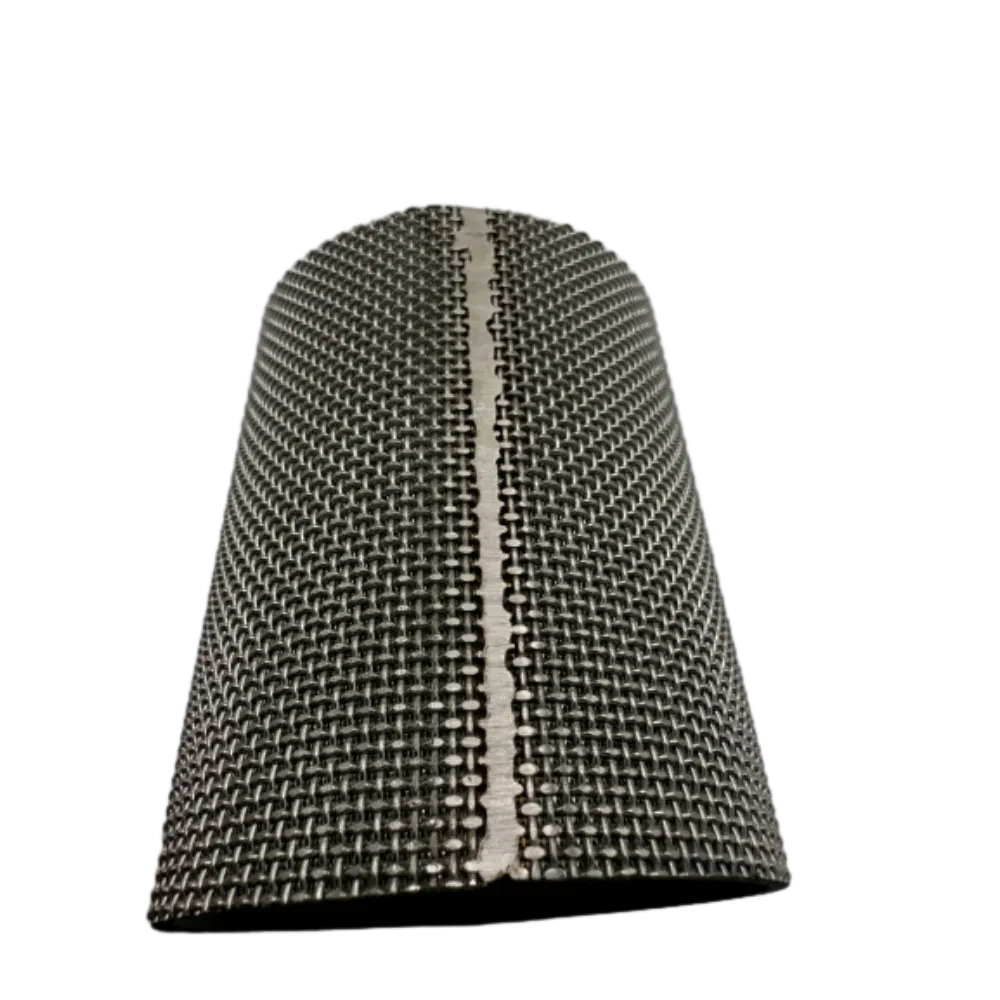

Sintered Wire Mesh Tube

|

|

Proses Manufaktur

|

1. Sintering: Ing suhu dhuwur, difusi partikel logam njiret bolong logam bebarengan kanggo mbentuk struktur cohesive

2. Rolling: Kanthi rolling tekanan dhuwur, saben lapisan bolong disambungake kanthi rapet kanggo mesthekake keseragaman ketebalan.

3. Laser Cutting/Plasma Cutting: Cutting Sintered Wire Mesh,Mesthekake yen nglereni pas ing ukuran lan wangun.

4. Welding: Digunakake kanggo welding menyang wangun silinder

|

|

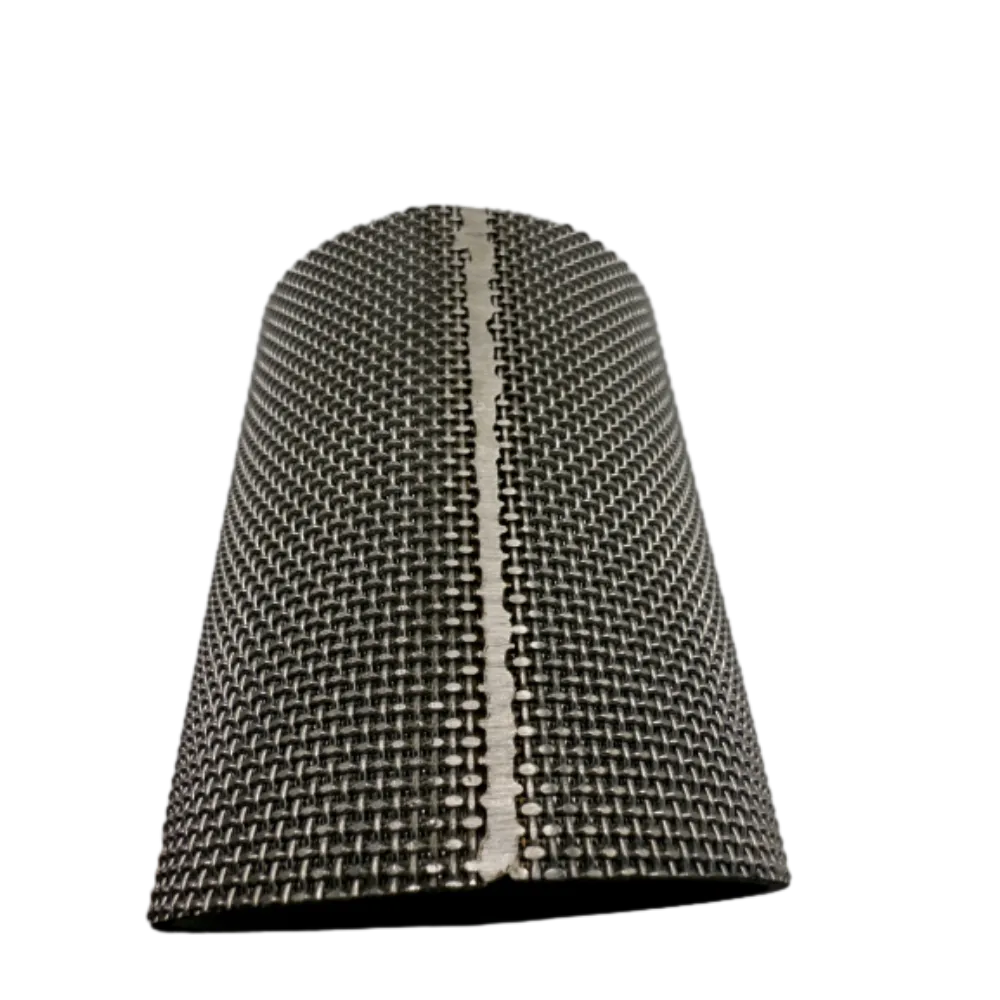

Cara anyaman saka anyaman wire mesh

|

1. Plain Weave (Cara tenun sing paling umum nduweni bolongan bolong seragam lan cocok kanggo filtrasi umum)

2. Twill Weave (Akurasi penyaringan sing luwih dhuwur, struktur sing luwih kenceng, cocok kanggo nyaring kanthi tliti dhuwur)

3. Tenun Walanda (Struktur panyaring kanthi kapadhetan dhuwur dibentuk kanthi nggabung benang warp kasar lan benang pakan sing apik, umume digunakake kanggo filtrasi ultrafine)

4. Reverse Dutch Weave (Nduwe kekuatan sing luwih dhuwur lan kapasitas beban, cocok kanggo filtrasi tekanan dhuwur)

|

|

Alternatif Material

|

1. Baja Tahan Karat (304, 316, 316L)

2. Paduan Nikel (Monel, Hastelloy, Inconel)

3. Jaring Titanium

DLL

|

|

Jumlah Lapisan

|

3, 5, 7 lapisan (utawa struktur multi-lapisan sing disesuaikan)

|

|

Akurasi filtrasi

|

1μm - 200μm (bisa disesuaikan)

|

|

Range Ketebalan

|

0.5mm - 5mm (beda-beda miturut jumlah lapisan)

|

|

bolongan Distribusi Ukuran

|

Desain pori gradien kanggo filtrasi efisien lan aliran cairan

|

|

Perawatan lumahing

|

Pengawetan asam (Stainless Steel/Baja Karbon),

Polishing Elektrolit (Stainless Steel)

Nikel plating (Stainless Steel/Baja Karbon)

Anodizing (Aluminium) etc.

|

|

Suhu operasi

|

-200 ℃ nganti 600 ℃ (gumantung saka materi)

|

|

Tekanan Resistance

|

Nganti 30MPa utawa luwih dhuwur (beda-beda adhedhasar lapisan bolong lan kekandelan)

|

|

Permeabilitas / Tahan Aliran

|

Resistance kurang lan permeabilitas dhuwur, cocok kanggo filtrasi gas lan cair

|

|

Tahan karat

|

Tahan kanggo asam, alkali, semprotan uyah, lan oksidasi ing lingkungan sing atos

|

|

Metode Reresik

|

Backwashing, Reresik ultrasonik, baking suhu dhuwur, reresik kimia, lan bisa digunakake maneh

|

|

Proses Manufaktur

|

Sintering vakum suhu dhuwur, Rolling, Welding, Stamping

|

|

Wujud sing kasedhiya

|

Cylindrical, Square, Sheet, Pleated, Bentuk khusus kasedhiya

|

|

Metode Sambungan

|

Sambungan flange, Welding, Sambungan Utas, Clamping

|

|

Cairan sing ditrapake

|

Cocog kanggo cairan, gas, lenga, uap, lsp.

|

|

Bidang Aplikasi

|

Petrokimia, Pangan & Minuman, Farmasi, Perawatan Banyu Lingkungan, Dirgantara, Industri Otomotif, lsp.

|

|

Kaluwihan produk

|

1. Kekuwatan dhuwur lan resistance meksa, ora gampang deform

2. Pembersihan sing bisa diulang, umur dawa

3. Precision filtrasi, distribusi ukuran pori seragam

4. Suhu dhuwur lan resistance karat, adaptasi kanggo lingkungan atos

|

![$item[judul] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)