|

Izinto

|

Inkcazo

|

|

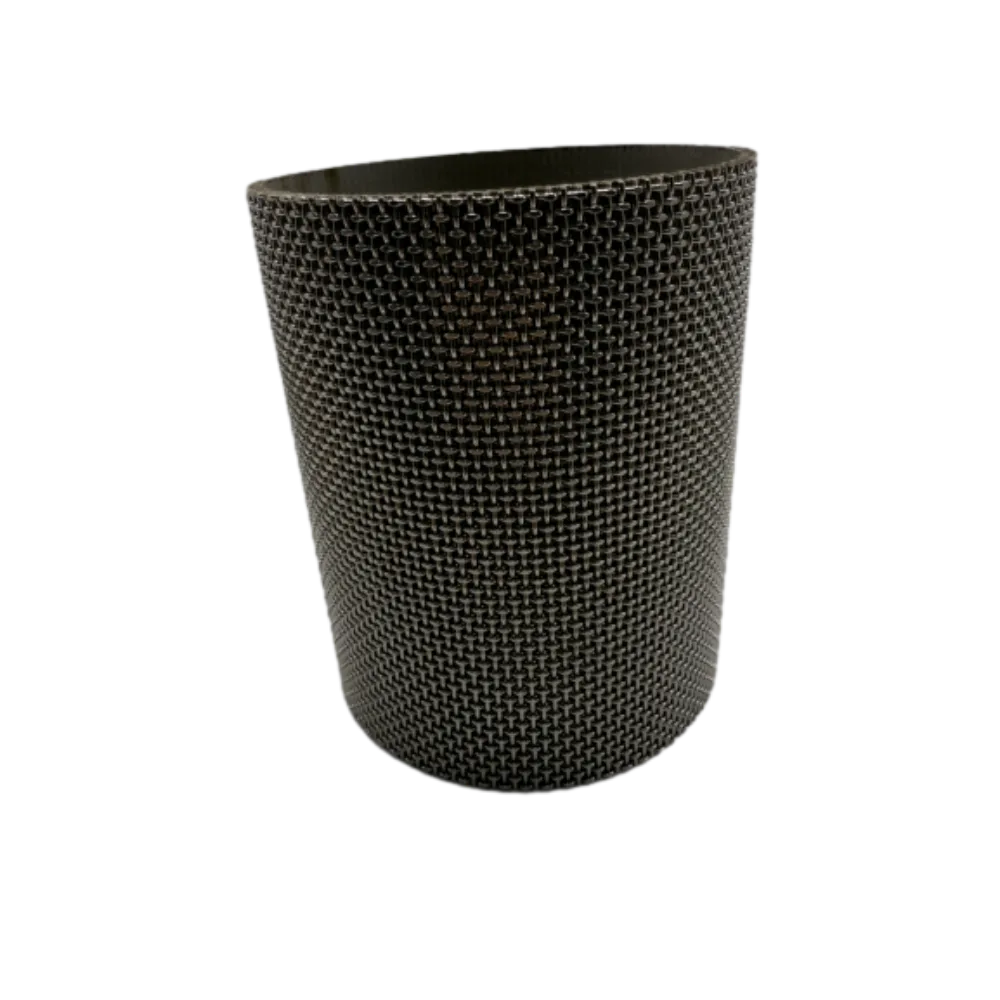

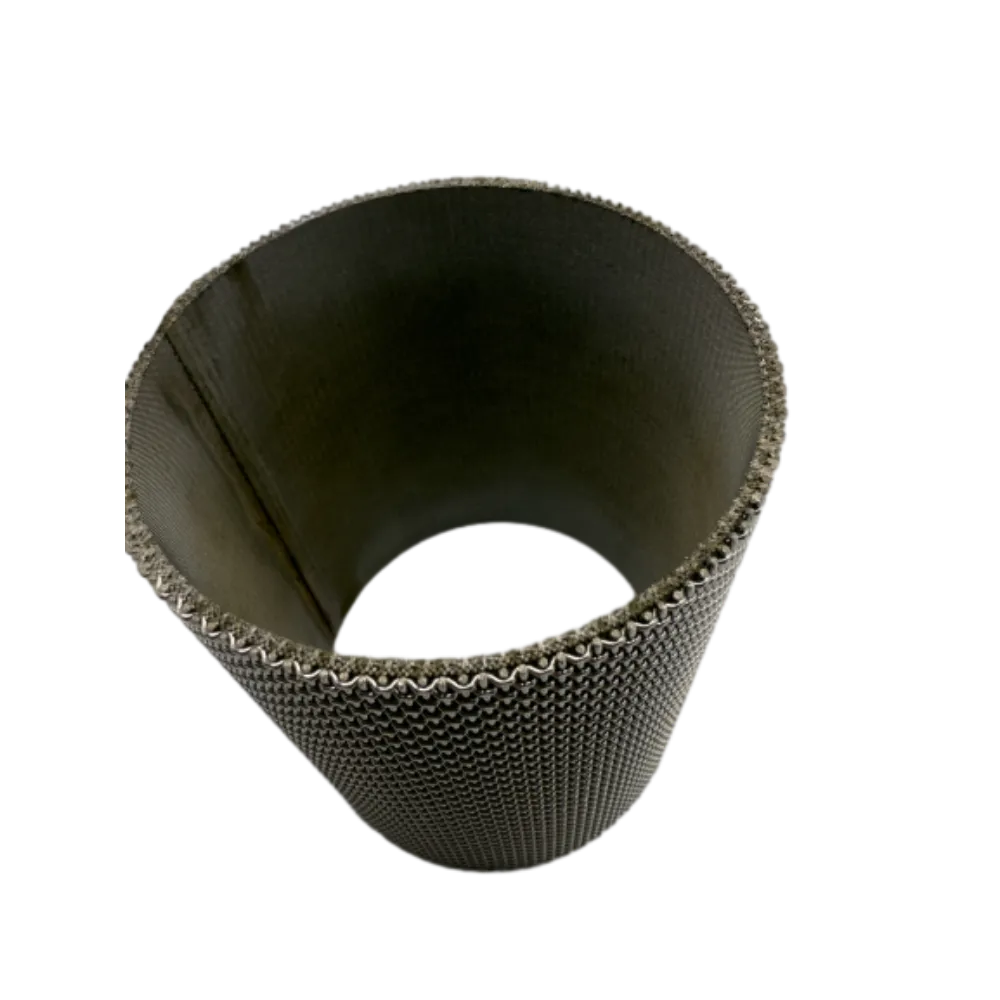

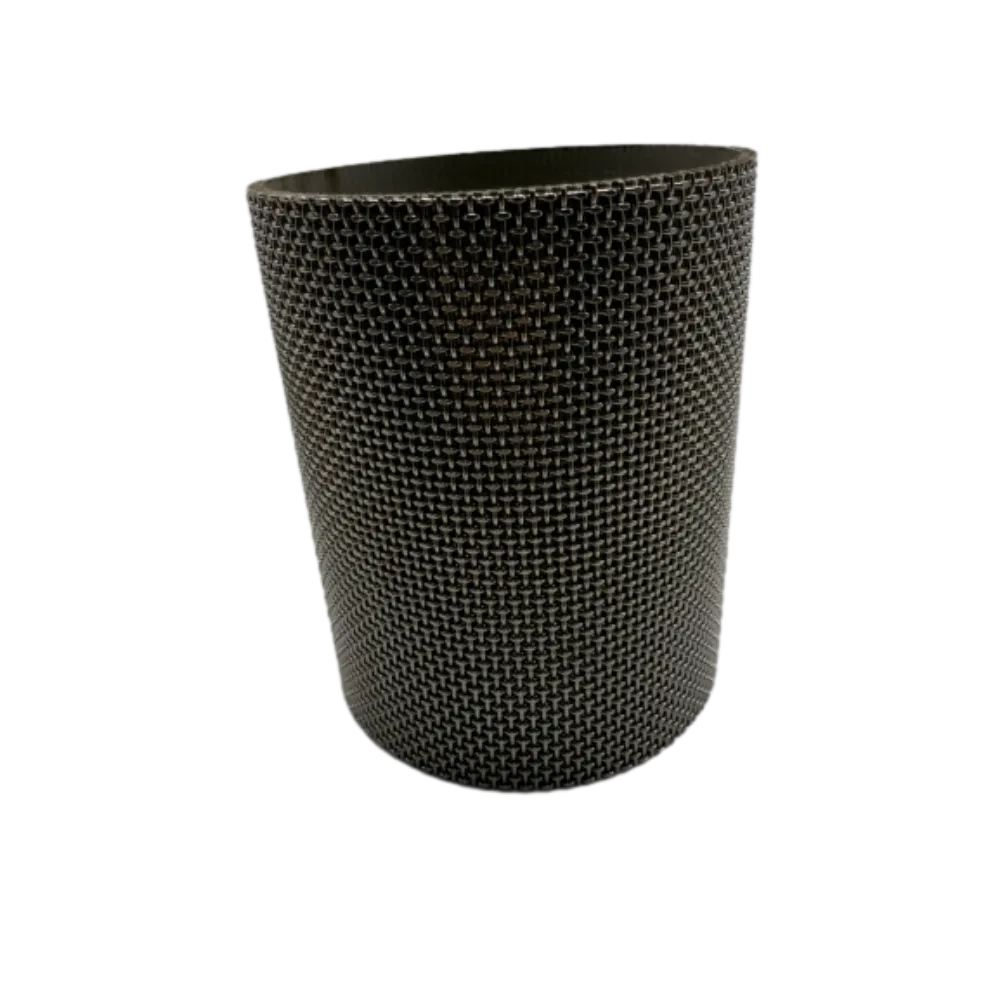

Igama lemveliso

|

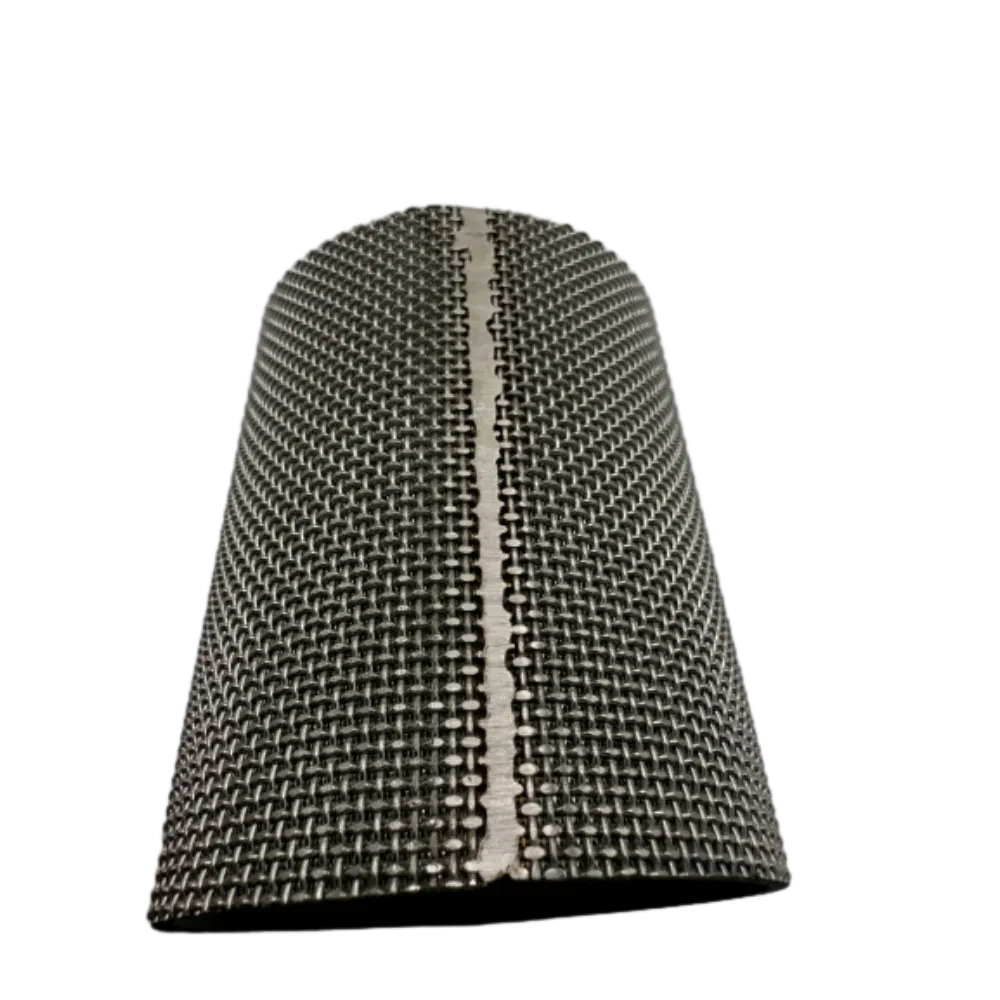

Sintered Wire Mesh Tube

|

|

Inkqubo yokuVelisa

|

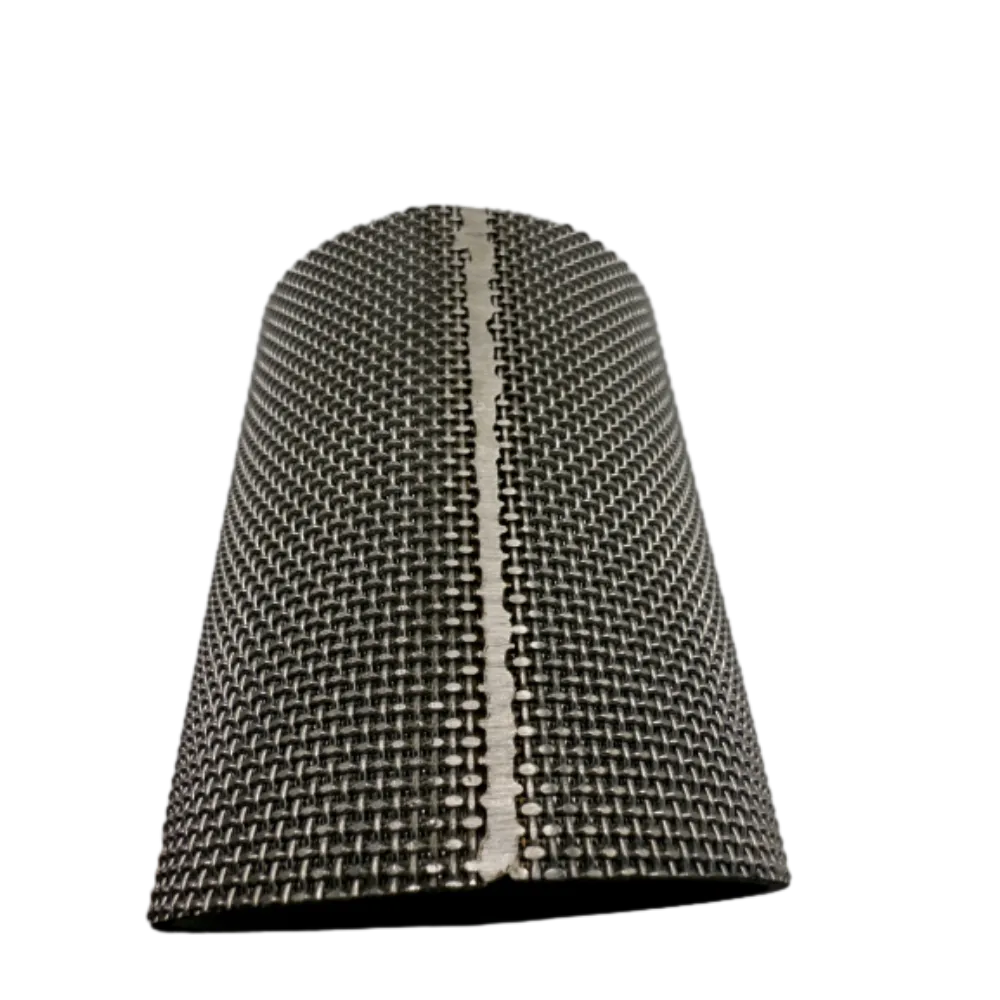

1. I-Sintering: Kubushushu obuphezulu, ukusasazwa kwamasuntswana esinyithi kubopha umnatha wesinyithi kunye ukwenza ulwakhiwo oludityanisiweyo.

2. Ukuqengqeleka: Ngokuqengqeleka koxinzelelo oluphezulu, umaleko ngamnye we-mesh uqhagamshelwe ngokuqinileyo ukuqinisekisa ukufana kobukhulu bayo.

3. Ukusika iLaser/Ukusika iPlasma:Ukusika iSintered Wire Mesh,Qinisekisa ukuba ukusika kuchanekile ngokobungakanani kunye nokumila.

4. Welding: Isetyenziselwa ukuwelda ibe imilo cylindrical

|

|

Indlela elukiweyo yomnatha wocingo olukiweyo

|

1. I-Plain Weave (Eyona ndlela yokuluka ixhaphakileyo inemingxuma efanayo yomnatha kwaye ifanele ukuhluzwa ngokubanzi)

2. I-Twill Weave(Ukuchaneka okuphezulu kokucoca, ubume obuqina ngakumbi, bulungele ukuhluza okuchanekileyo)

3. I-Dutch Weave (Isakhiwo sokuhluza esinoxinaniso oluphezulu lwenziwa ngokuluka imisonto erhabaxa ye-warp kunye nemisonto ye-weft ecolekileyo, esetyenziswa ngokuqhelekileyo kuhluzo lwe-ultrafine)

4. I-Reverse Dutch Weave (Inamandla aphezulu kunye nomthamo wokuthwala umthwalo, ilungele ukuhluzwa koxinzelelo oluphezulu)

|

|

Izinto ezizezinye ezinokusetyenziswa

|

1. iStainless Steel (304, 316, 316L)

2. I-Nickel Alloy(iMonel, Hastelloy, Inconel)

3. I-Titanium Mesh

ETC

|

|

Inani leMaleko

|

3, 5, 7 umaleko (okanye ulwakhiwo olulungelelanisiweyo lwamaleko amaninzi)

|

|

Ukuchaneka koHlulo

|

1μm - 200μm (inokwenziwa ngokwezifiso)

|

|

Ukutyeba Range

|

0.5mm - 5mm (iyahluka ngenani leeleya)

|

|

Umngxuma Ukwabiwa kobungakanani

|

Uyilo lwepore yegradient ukwenzela ukuhluzwa okusebenzayo kunye nokuhamba kwamanzi

|

|

Unyango loMphezulu

|

I-Acid pickling(Intsimbi engatyiwayo/intsimbi yeCarbon),

Electrolytic polishing(Intsimbi engatyiwayo)

I-Nickel plating(Intsimbi eNgatyiwayo/Intsimbi yeCarbon)

Anodizing(Aluminiyam) njl.

|

|

Ubushushu bokusebenza

|

-200℃ ukuya ku-600℃ (kuxhomekeke kwizinto)

|

|

Ukuxhathisa Uxinzelelo

|

Ukuya kuthi ga kwi-30MPa okanye ngaphezulu (iyahluka ngokusekwe kumaleko omnatha kunye nobukhulu)

|

|

Ukufikeleleka / ukuchasana nokuqukuqela

|

Ukuchasana okuphantsi kunye nokunyuka okuphezulu, okufanelekileyo kwigesi kunye nokucoca ulwelo

|

|

Ukunyangwa kokuMhlwa

|

Ukumelana neeasidi, iialkali, isitshizi setyuwa, kunye ne-oxidation kwindawo enzima

|

|

Iindlela zokucoca

|

Ukuhlamba umva, ukucocwa kwe-Ultrasonic, ukubhaka okuphezulu kobushushu, ukucocwa kweekhemikhali, kunye nokuphinda kusetyenziswe

|

|

Inkqubo yokuVelisa

|

Ubushushu obuphezulu bevacuum sintering, Ukuqengqeleka, ukuWelding, Stamping

|

|

Iimilo ezifumanekayo

|

Cylindrical, Square, Sheet, Pleated, Custom imilo ziyafumaneka

|

|

Iindlela zoNxibelelwano

|

Uqhagamshelo lweFlange, ukuWelding, uqhagamshelo olunemisonto, UkuQhwatha

|

|

Ulwelo olusebenzayo

|

Ilungele ulwelo, iigesi, i-oyile, umphunga, njl.

|

|

Iinkalo zeSicelo

|

I-Petrochemical, Ukutya kunye neSiselo, aMayeza, ukuNyangwa kwamanzi okusiNgqongileyo, i-Aerospace, i-Automotive Industry, njl.

|

|

Iinzuzo zeMveliso

|

1. Amandla aphezulu kunye nokumelana noxinzelelo, akukho lula ukukhubaza

2. Ukucoca okuphindaphindiweyo, ubomi obude

3. Ukuhluzwa okuchanekileyo, ukusabalalisa ubungakanani bepore efanayo

4. Ubushushu obuphezulu kunye nokumelana nokugqwala, ukulungelelaniswa neendawo ezinzima

|

![$ into[isihloko] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)