|

Awọn nkan

|

Apejuwe

|

|

Orukọ ọja

|

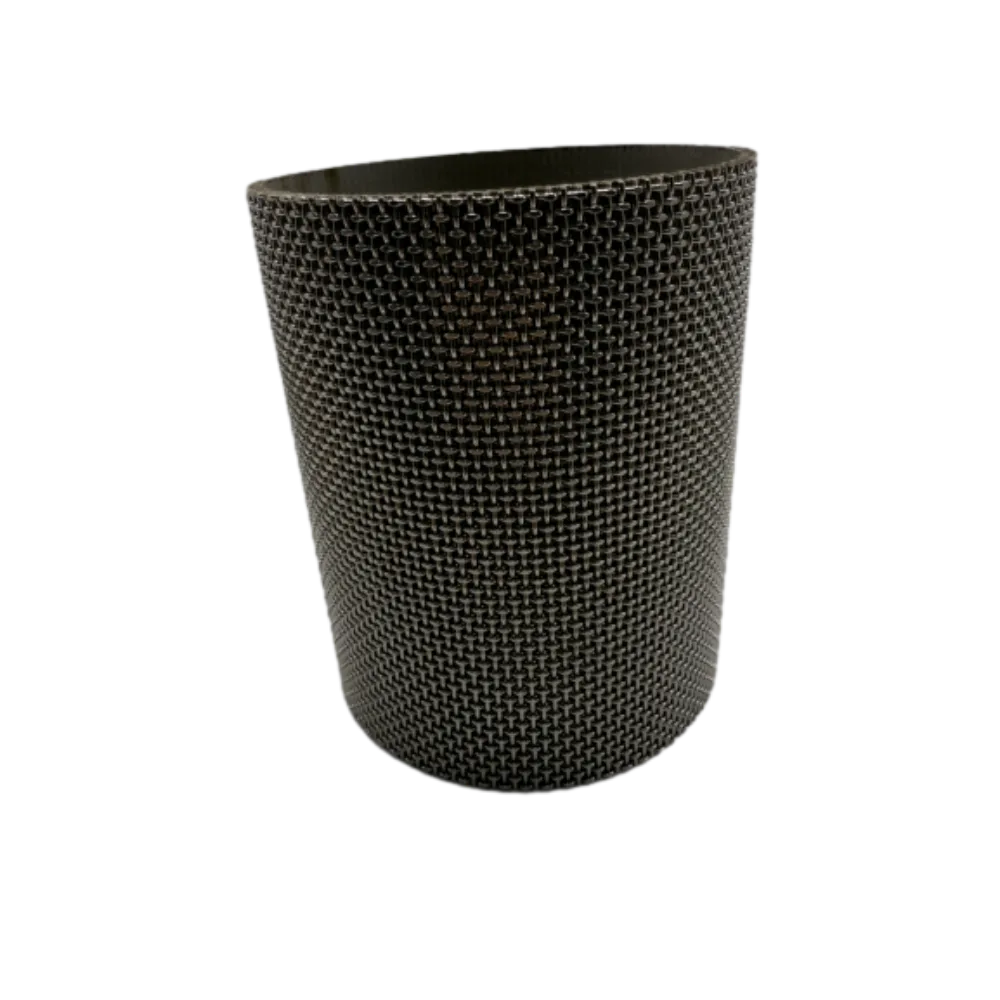

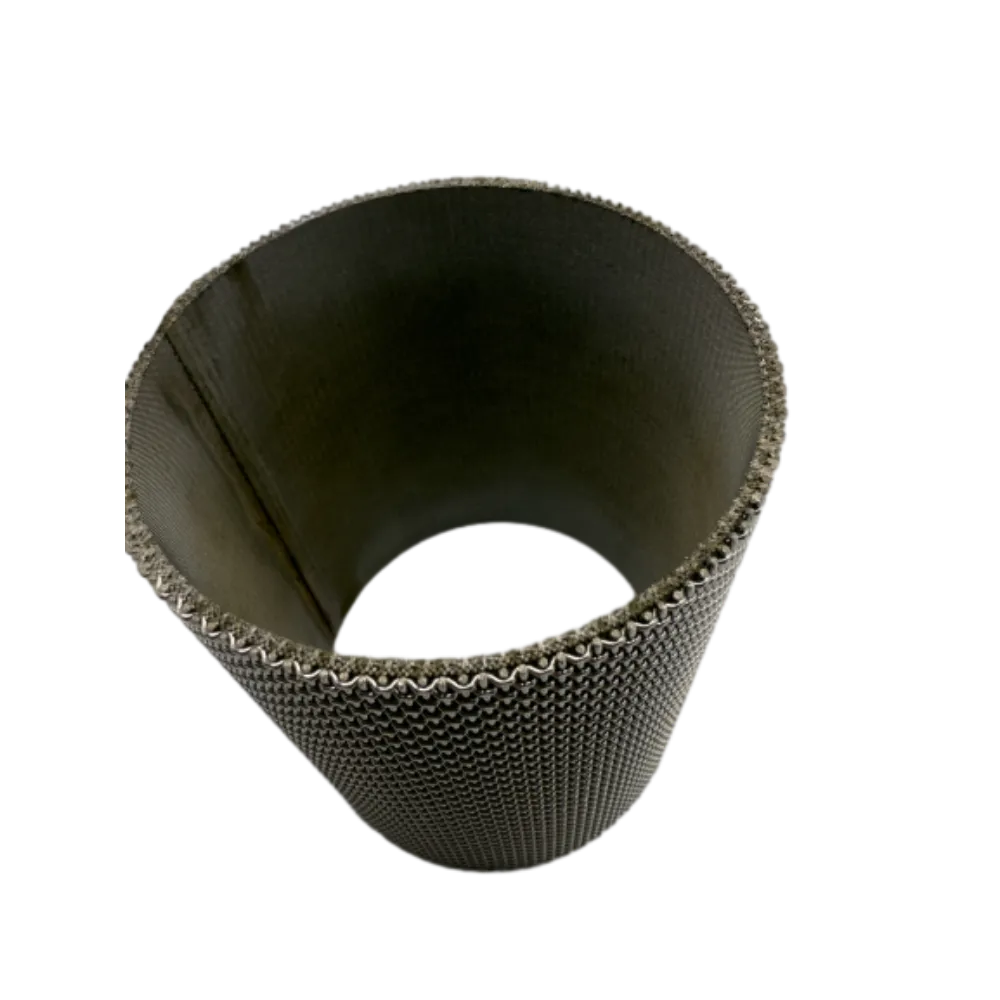

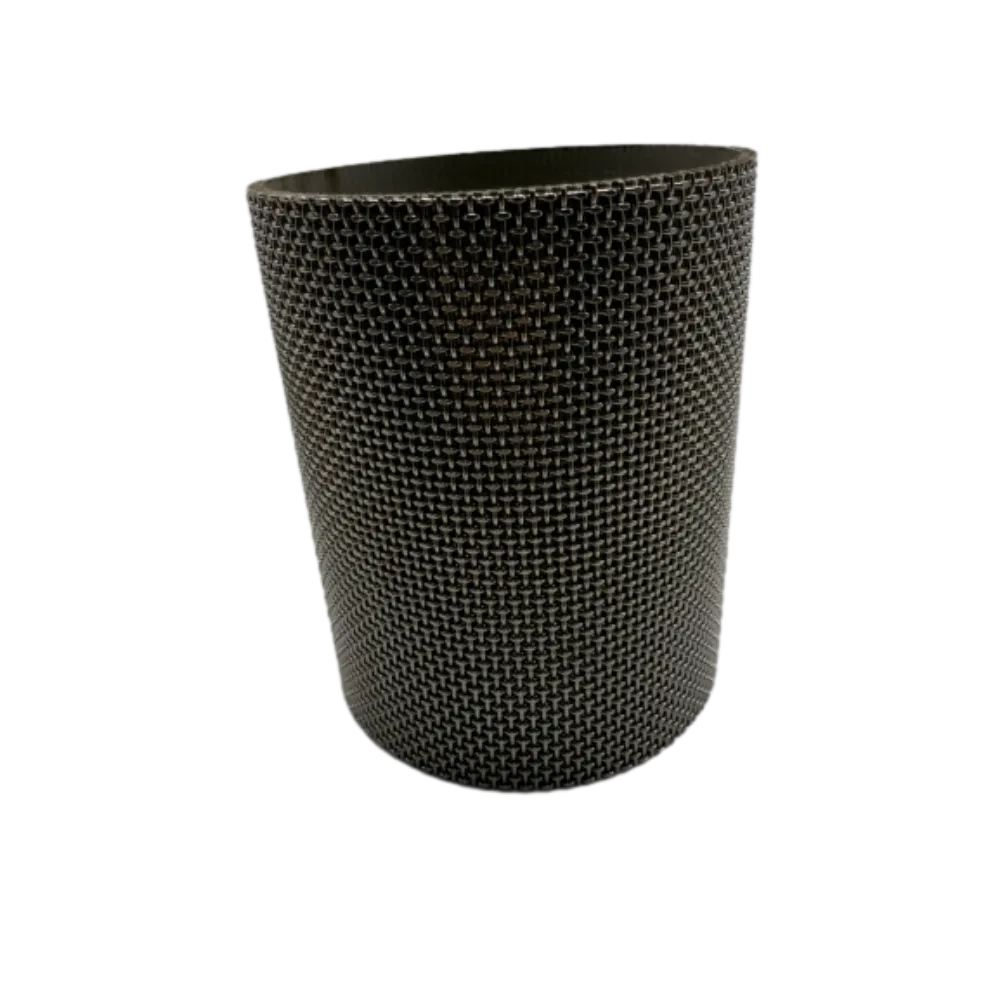

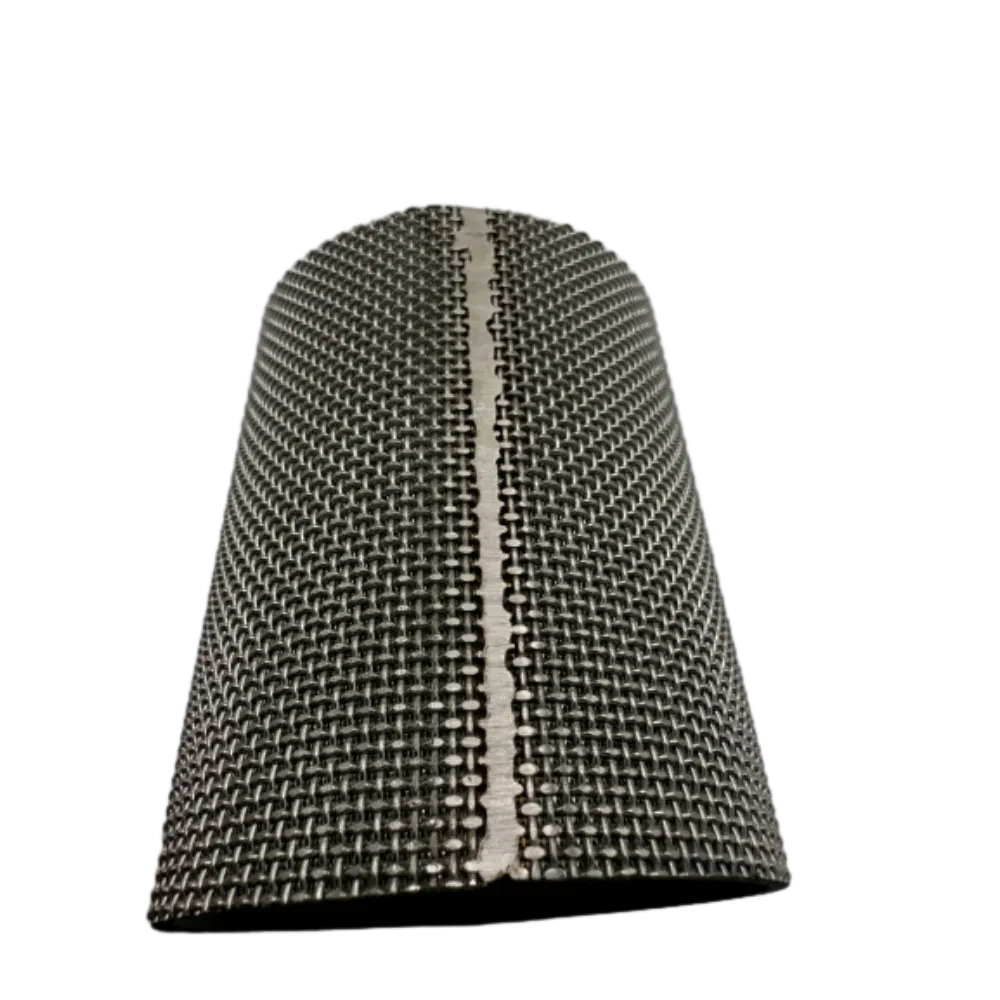

Sintered Waya Apapo Tube

|

|

Ilana iṣelọpọ

|

1. Sintering: Ni awọn iwọn otutu ti o ga julọ, itankale awọn patikulu irin ṣopọ apapo irin papọ lati ṣe eto iṣọkan kan.

2. Yiyi: Nipa sẹsẹ titẹ-giga, Layer mesh kọọkan ti ni asopọ ni wiwọ lati rii daju pe iṣọkan sisanra rẹ.

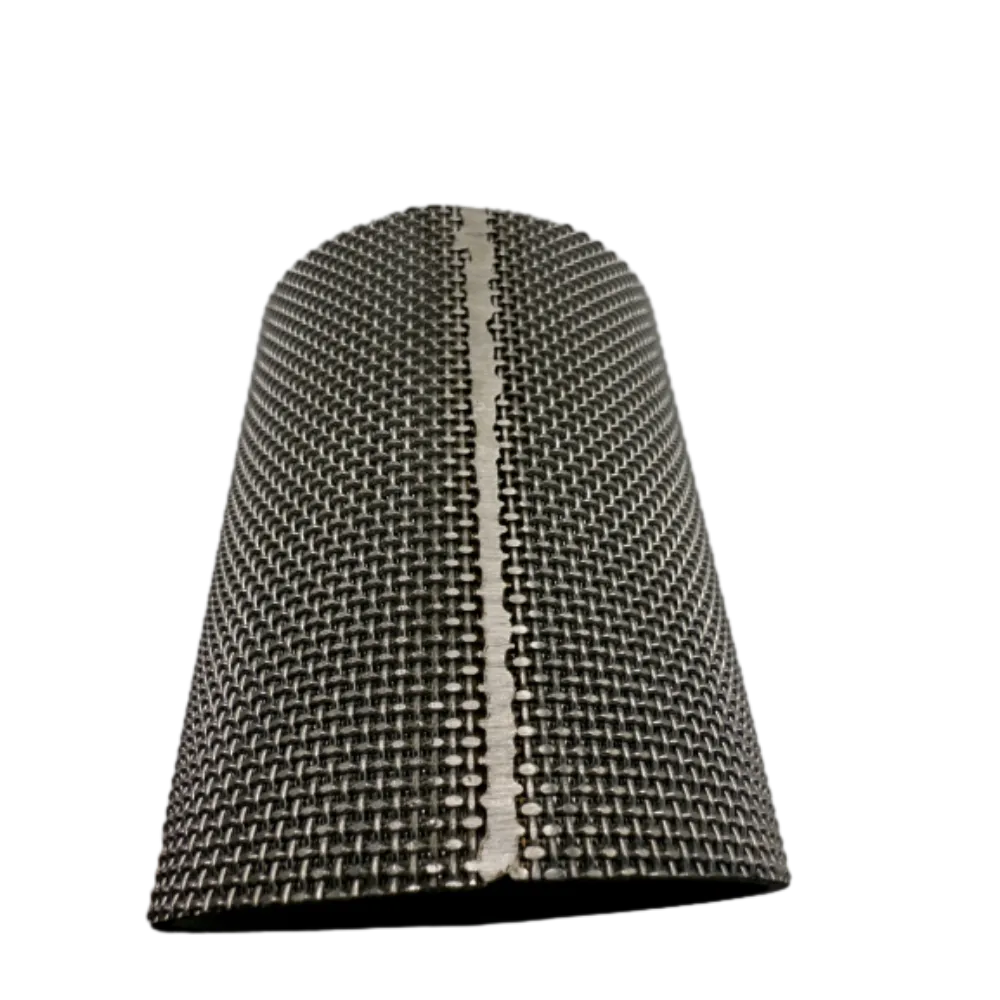

3. Ige Laser / Pilasima Ige: Gige Mesh Waya Sintered , Rii daju pe gige jẹ kongẹ ni iwọn ati apẹrẹ.

4. Alurinmorin: Lo fun alurinmorin sinu kan iyipo apẹrẹ

|

|

hun ọna ti hun waya apapo

|

1. Weave Plain (Ọna wiwu ti o wọpọ julọ ni awọn ihò apapo aṣọ ati pe o dara fun sisẹ gbogbogbo)

2. Twill Weave (ipeye sisẹ ti o ga julọ, ọna ti o ni wiwọ, o dara fun sisẹ pipe-giga)

3. Dutch Weave (Ipilẹ sisẹ iwuwo giga kan jẹ akoso nipasẹ interweaving awọn okun warp isokuso ati awọn okun weft ti o dara, ti a lo nigbagbogbo fun sisẹ ultrafine)

4. Yiyipada Dutch Weave (Ni agbara ti o ga julọ ati agbara gbigbe, o dara fun sisẹ titẹ-giga)

|

|

Ohun elo Yiyan

|

1. Irin Alagbara (304, 316, 316L)

2. Nickel Alloy (Monel, Hastelloy, Inconel)

3. Titanium Mesh

bbl

|

|

Nọmba ti Layer

|

3, 5, 7 fẹlẹfẹlẹ (tabi ti a ṣe adani ti ọpọlọpọ-Layer be)

|

|

Yiye sisẹ

|

1μm - 200μm (ṣe asefara)

|

|

Ibiti Sisanra

|

0.5mm - 5mm (yatọ nipasẹ nọmba awọn fẹlẹfẹlẹ)

|

|

Iho Pipin Iwọn

|

Apẹrẹ pore gradient fun sisẹ daradara ati ṣiṣan omi

|

|

dada Itoju

|

Yiyan acid (irin alagbara / irin erogba),

Electrolytic didan(Irin Alagbara)

Nickel plating (Irin Alagbara/ Irin Erogba)

Anodizing (Aluminiomu) ati be be lo.

|

|

Awọn iwọn otutu ti nṣiṣẹ

|

-200 ℃ si 600 ℃ (da lori ohun elo)

|

|

Titẹ Resistance

|

Titi di 30MPa tabi ga julọ (yatọ da lori awọn fẹlẹfẹlẹ apapo ati sisanra)

|

|

Permeability / sisan Resistance

|

Agbara kekere ati agbara giga, o dara fun gaasi ati sisẹ omi

|

|

Ipata Resistance

|

Sooro si acids, alkalis, iyo sokiri, ati ifoyina ni awọn agbegbe lile

|

|

Awọn ọna mimọ

|

Backwashing, Ultrasonic Cleaning, Giga-otutu yan, Kemikali ninu, ati reusable

|

|

Ilana iṣelọpọ

|

Giga-otutu igbale sintering, sẹsẹ, Welding, Stamping

|

|

Awọn apẹrẹ ti o wa

|

Cylindrical, Square, Sheet, Pleated, Aṣa ni nitobi wa

|

|

Awọn ọna asopọ

|

Flange asopọ, Welding, Asapo asopọ, Clamping

|

|

Awọn Omi to wulo

|

Dara fun awọn olomi, gaasi, epo, nya si, ati bẹbẹ lọ.

|

|

Awọn aaye Ohun elo

|

Petrochemical, Ounjẹ & Ohun mimu, Awọn oogun, Itọju Omi Ayika, Aerospace, Ile-iṣẹ adaṣe, ati bẹbẹ lọ.

|

|

Awọn anfani Ọja

|

1. Agbara giga ati resistance resistance, ko rọrun lati ṣe idibajẹ

2. Repeatable ninu, gun aye

3. Itọjade pipe, pinpin iwọn pore aṣọ

4. Iwọn otutu ti o ga ati ipata ipata, iyipada si awọn agbegbe ti o lagbara

|

![$nkan[akọle] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)